Working face tailgate crushed coal grouting reinforcing method

A technology for grouting reinforcement and working face, applied in chemical instruments and methods, earthwork drilling, wellbore lining, etc., can solve the problems of low support resistance, poor roadway maintenance effect and high cost, and achieve higher bearing capacity and better maintenance. Condition, the effect of strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to enable those skilled in the art to better understand the present invention, the present invention will be further clearly and completely described below in conjunction with reference to the accompanying drawings and in conjunction with embodiments. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

[0015] A grouting reinforcement method for broken coal in return air level roadway of working face, comprising:

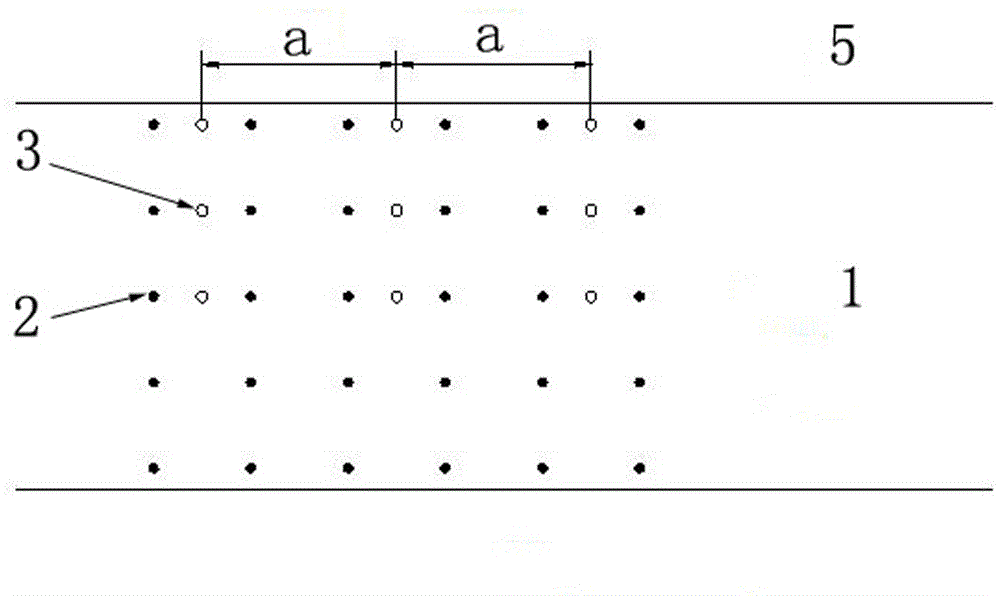

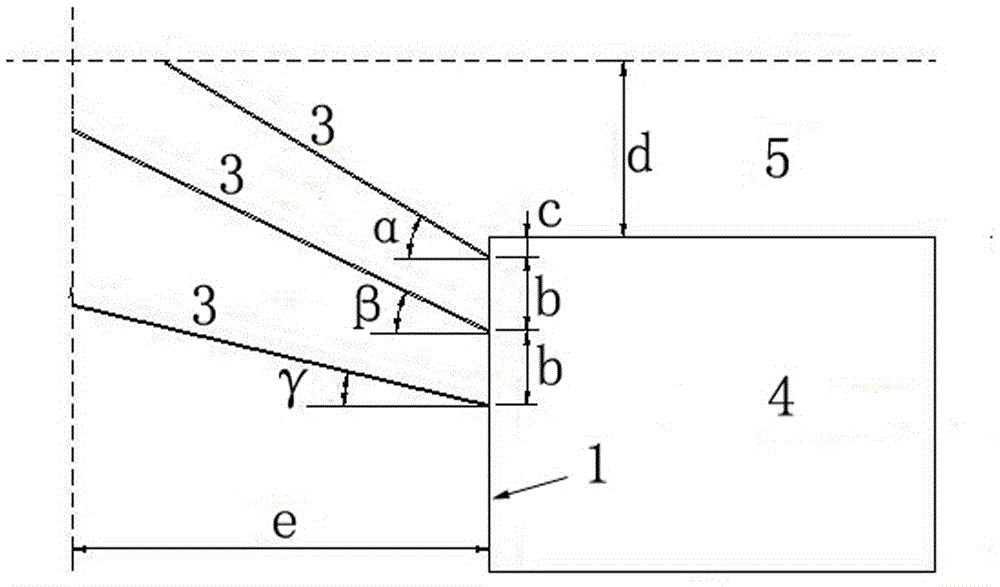

[0016] Several rows of grouting holes with a row distance a of 1.8m are arranged on the cut coal side of the return air level roadway. c is 0.2m;

[0017] In each row of grouting holes, the hole elevation angle α of the uppermost grouting hole is 30°, and the vertical projection length d of the grouting hole is 1.9m; the hole elevation angle β of the middle grouting hole is 25° , and the horizontal projection length e of the grouting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com