Pressure-flow-type magnesium alloy smelting heat insulating furnace

A magnesium alloy, pressurized flow technology, applied in the field of magnesium alloy smelting equipment, pressurized magnesium alloy smelting and holding furnace, can solve the problems of large conveying flow, easy blockage, slow floating or sinking of metal pumps, etc., to prevent sealing sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

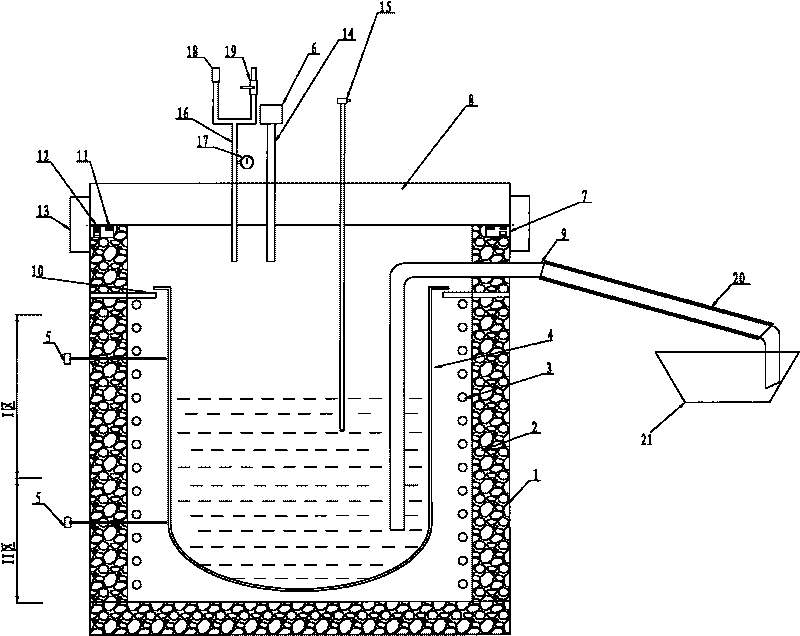

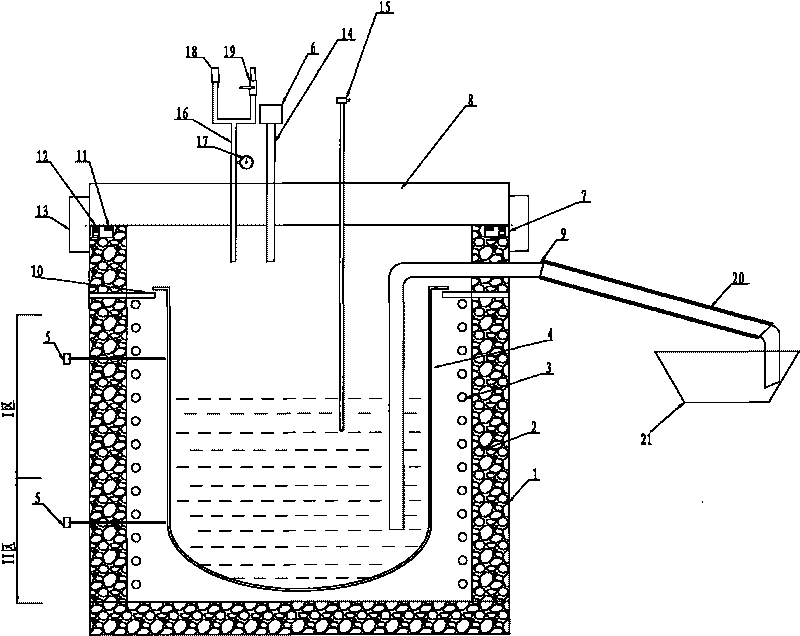

[0025] The invention provides a new pressurized flow type magnesium alloy smelting and holding furnace, which integrates smelting, heat preservation and melt transportation in the magnesium alloy smelting process, accurately controls the flow of magnesium alloy melt, and realizes continuous delivery of constant flow.

[0026] Such as figure 1 As shown, the pressure flow type magnesium alloy smelting and holding furnace includes a furnace body with an insulating layer, a crucible 4 placed in the furnace, a heating element 3, a temperature measuring device 5 and a furnace cover 8, and the furnace body includes a furnace shell 1 and a furnace lining 2. The upper part of the furnace body and the furnace cover are provided with a water-cooled flange 7. The water-cooled flange 7 is provided with a high-temperature resistant refractory filling material 11 and a silicone rubber sealing ring 12. The high-temperature resistant filling material 11 and the silicone rubber sealing ring 12 r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com