Control method for improving gas recovery of new OG (Oxygen Converter Gas Recovery) converter

A converter gas and control method technology, applied in the manufacture of converters, etc., can solve problems such as difficult stable states

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to make the object, technical solution and advantages of the present invention clearer, preferred embodiments of the present invention are described in detail below.

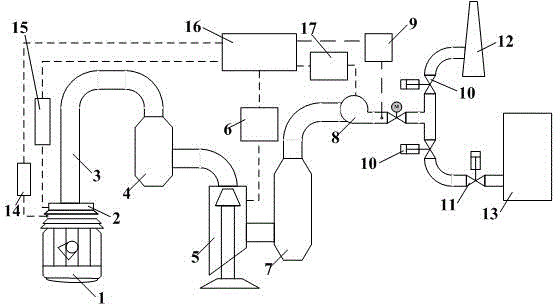

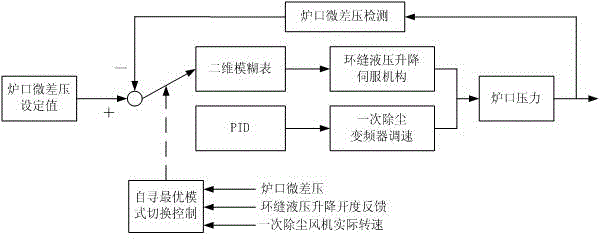

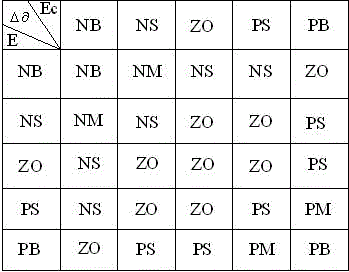

[0051] Such as figure 1 Shown is a schematic diagram of furnace gas recovery structure in a control method for improving new OG converter gas recovery of the present invention; figure 2 Shown is a kind of control block diagram of converter gas recovery in the control method that improves new OG converter gas recovery of the present invention; image 3 Shown is a kind of gas recovery flowchart in the control method that improves new OG converter gas recovery of the present invention; A kind of control method that improves new OG converter gas recovery of the present invention, its steps are as follows:

[0052]1) Before smelting, the detected pressure signal of the differential pressure at the furnace mouth of converter 1, the position signal of the ring seam washing tower 5 and the speed of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com