Sonar slagging analysis apparatus and method based on flue sound picking

A technology of an analysis device and an analysis method, applied in the direction of manufacturing converters, etc., can solve the problem that the slag process cannot completely reach a stable state, and achieve the effects of reducing production costs, reducing metal loss, and improving furnace lining life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

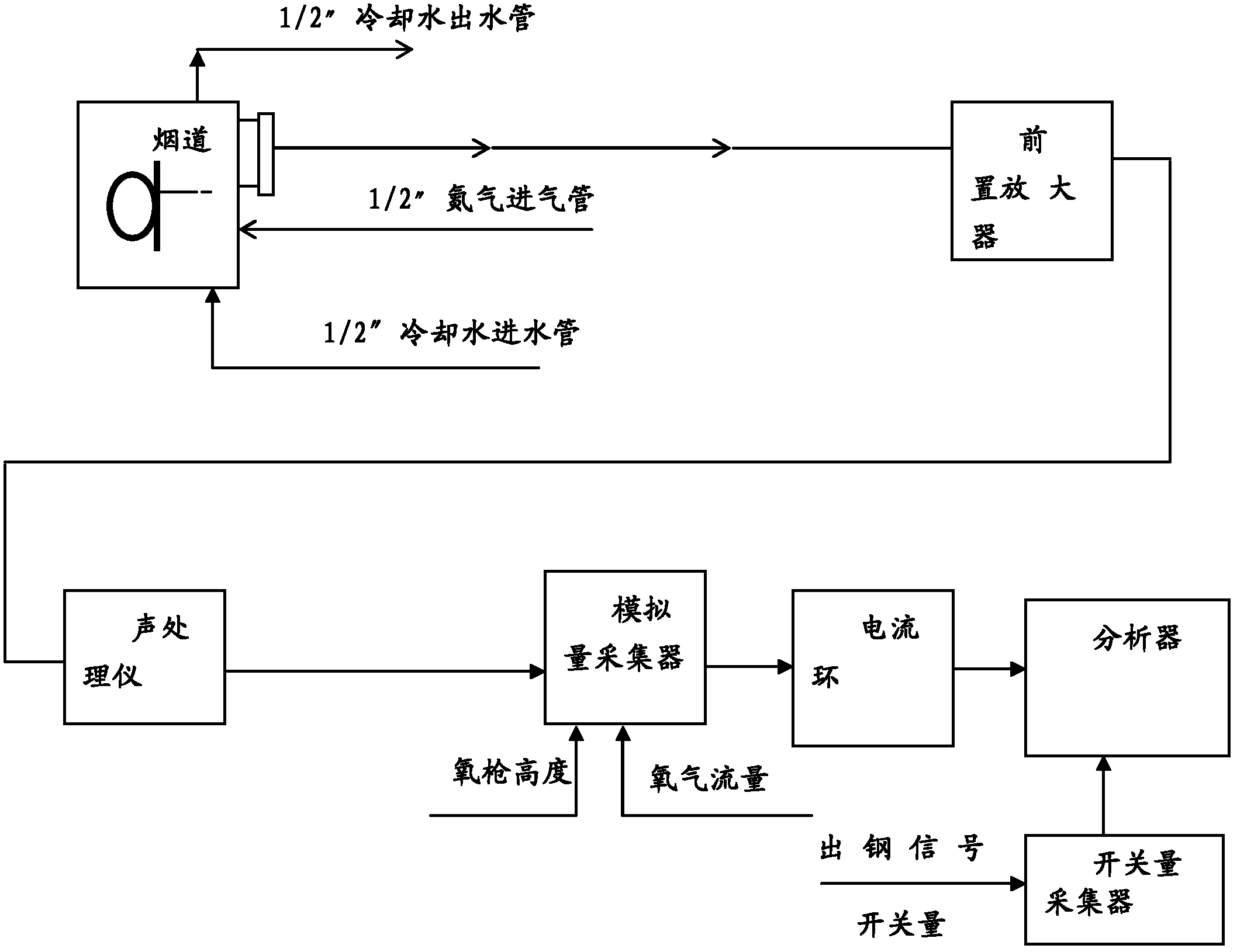

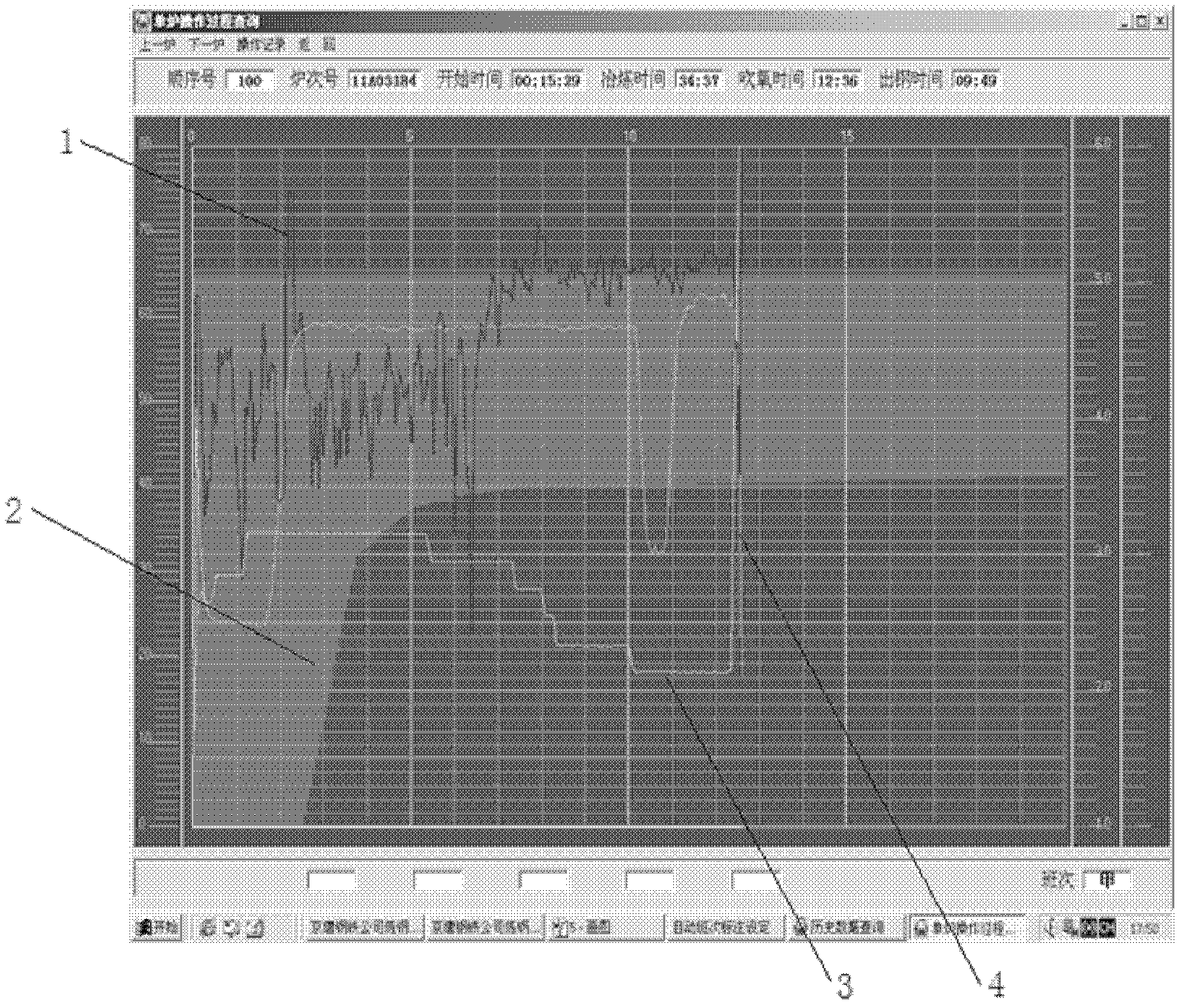

[0023] see figure 1 A sonar slag analysis device based on flue sound acquisition provided by an embodiment of the present invention includes a noise collection device, an analog quantity collector, and an analyzer. The noise collecting device is arranged at the sampling port of the platform flue, and collects noise information and transmits the noise information to the analog quantity collector. The analog quantity collector collects oxygen lance height information, oxygen flow information and receives the noise information collected by the noise acquisition device, and sends the oxygen lance height information, oxygen flow information and noise information to the analyzer; the analyzer receives The oxygen lance height information, oxygen flow information and noise information are used to analyze the slag formation. An analysis screen is generated for each furnace. The sonar slag analysis device also includes a sound processor, which is connected between the noise collection...

Embodiment 2

[0026] see figure 1 In addition to the device described in Embodiment 1, a sonar slag analysis device based on flue sound acquisition provided by the embodiment of the present invention also includes a preamplifier, a current loop and a switch value collector. The pre-amplifier is set between the noise collection device and the sound processor, and is used to amplify the noise information, reduce the impedance for remote transmission, and remove other interference and stray noise signals on site to improve signal quality. The current loop is connected between the analog quantity collector and the analyzer, and is used for converting the noise signal into a digital signal. The switch value collector is connected with the analyzer, and controls the analyzer to end the current slag analysis after collecting the tapping signal.

Embodiment 3

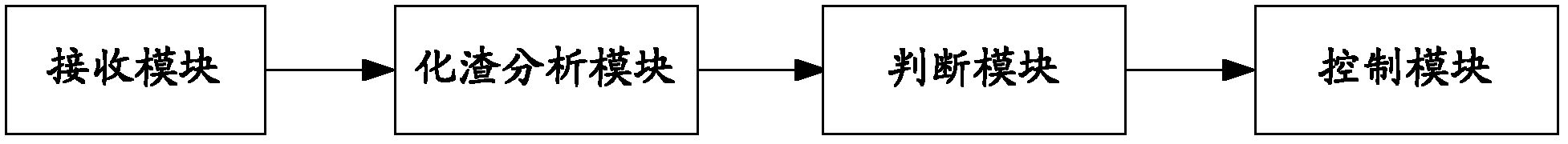

[0028] An embodiment of the present invention provides a sonar slag analysis method based on flue sound acquisition, including:

[0029] Step 10, collecting the noise information of the flue sampling port of the platform.

[0030] Step 20, collect oxygen lance height information and oxygen flow information.

[0031] Step 30, analyzing the slagging situation according to the noise information, the oxygen lance height information and the oxygen flow information.

[0032] Step 40, making a judgment according to the slag analysis result, and adjusting the height of the oxygen lance and the oxygen flow rate according to the judgment result.

[0033] The above steps can be realized by the sonar slag analysis device based on flue sound acquisition provided in Embodiments 1 and 2, and will not be repeated here.

[0034] The sonar slag analysis device and method based on flue sound acquisition provided by the present invention can detect and process the noise of the slagging process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com