Vanadium-titanium-boron steel material for high-strength bolt and preparation method of vanadium-titanium-boron steel material

A technology of high-strength bolts and steel materials, applied in the manufacture of converters and other directions, can solve the problems of long cycle, high energy consumption, difficult to achieve, etc., to improve metal yield and quality of cast slabs, good workability and hardenability properties, and the effect of improving strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

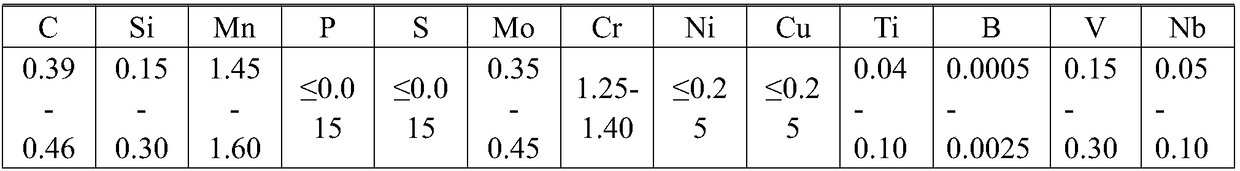

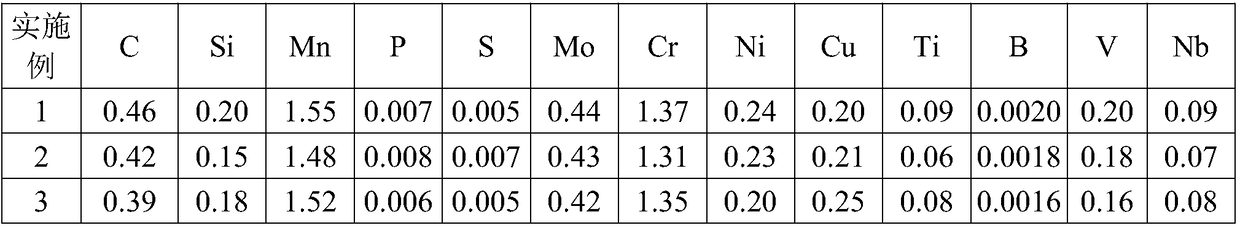

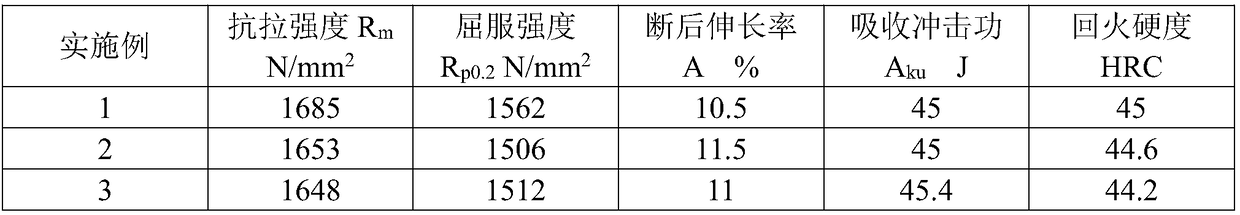

[0034] A vanadium-titanium-boron iron and steel material used for high-strength bolts of the present invention, the chemical element composition and mass percentages thereof include: 0.46% carbon, 0.20% silicon, 1.55% manganese, 0.007% phosphorus, 0.005% sulfur, molybdenum 0.44%, chromium 1.37%, nickel 0.24%, copper 0.20%, titanium 0.09%, boron 0.0020%, vanadium 0.20%, niobium 0.09%, and the balance is iron.

[0035] Its preparation method comprises the following steps:

[0036] (1) Steel is smelted in an oxygen top-blown converter. Carbon, nickel, copper, phosphorus, sulfur and iron are all derived from steel. Ferrosilicon is added for strong deoxidation before tapping, and ferrovanadium, ferromanganese and ferrotitanium are added. The smelting continues to deoxidize, and then ferroboron is added to achieve partial alloying, and the steel is tapped after the smelting is completed; the temperature of the converter smelting is controlled at 1600 ° C ~ 1660 ° C, and the temperat...

Embodiment 2

[0042] A vanadium-titanium-boron iron and steel material for high-strength bolts of the present invention, the chemical element composition and mass percentages thereof include: 0.42% carbon, 0.15% silicon, 1.48% manganese, 0.008% phosphorus, 0.007% sulfur, molybdenum 0.43%, chromium 1.31%, nickel 0.23%, copper 0.21%, titanium 0.06%, boron 0.0018%, vanadium 0.18%, niobium 0.07%, and the balance is iron.

[0043] Its preparation method comprises the following steps:

[0044] (1) Steel is smelted in an oxygen top-blown converter. Carbon, nickel, copper, phosphorus, sulfur and iron are all derived from steel. Ferrosilicon is added for strong deoxidation before tapping, and ferrovanadium, ferromanganese and ferrotitanium are added. The smelting continues to deoxidize, and then ferroboron is added to achieve partial alloying, and the steel is tapped after the smelting is completed; the temperature of the converter smelting is controlled at 1600 ° C ~ 1660 ° C, and the temperature o...

Embodiment 3

[0050] A vanadium-titanium-boron iron and steel material for high-strength bolts of the present invention, the chemical element composition and mass percentages thereof include: 0.39% carbon, 0.18% silicon, 1.52% manganese, 0.006% phosphorus, 0.005% sulfur, molybdenum 0.42%, chromium 1.35%, nickel 0.20%, copper 0.25%, titanium 0.08%, boron 0.0016%, vanadium 0.16%, niobium 0.08%, and the balance is iron.

[0051] Its preparation method comprises the following steps:

[0052] (1) Steel is smelted in an oxygen top-blown converter. Carbon, nickel, copper, phosphorus, sulfur and iron are all derived from steel. Ferrosilicon is added for strong deoxidation before tapping, and ferrovanadium, ferromanganese and ferrotitanium are added. The smelting continues to deoxidize, and then ferroboron is added to achieve partial alloying, and the steel is tapped after the smelting is completed; the temperature of the converter smelting is controlled at 1600 ° C ~ 1660 ° C, and the temperature o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com