Cu-contained and Cr-controlled seamless steel tube for nuclear power station and production method for Cu-contained and Cr-controlled seamless steel tube

A technology of seamless steel pipe and production method, which is applied in the field of metallurgical materials, can solve the problems such as no problems, and achieve the effects of high production efficiency, saving wall thickness and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

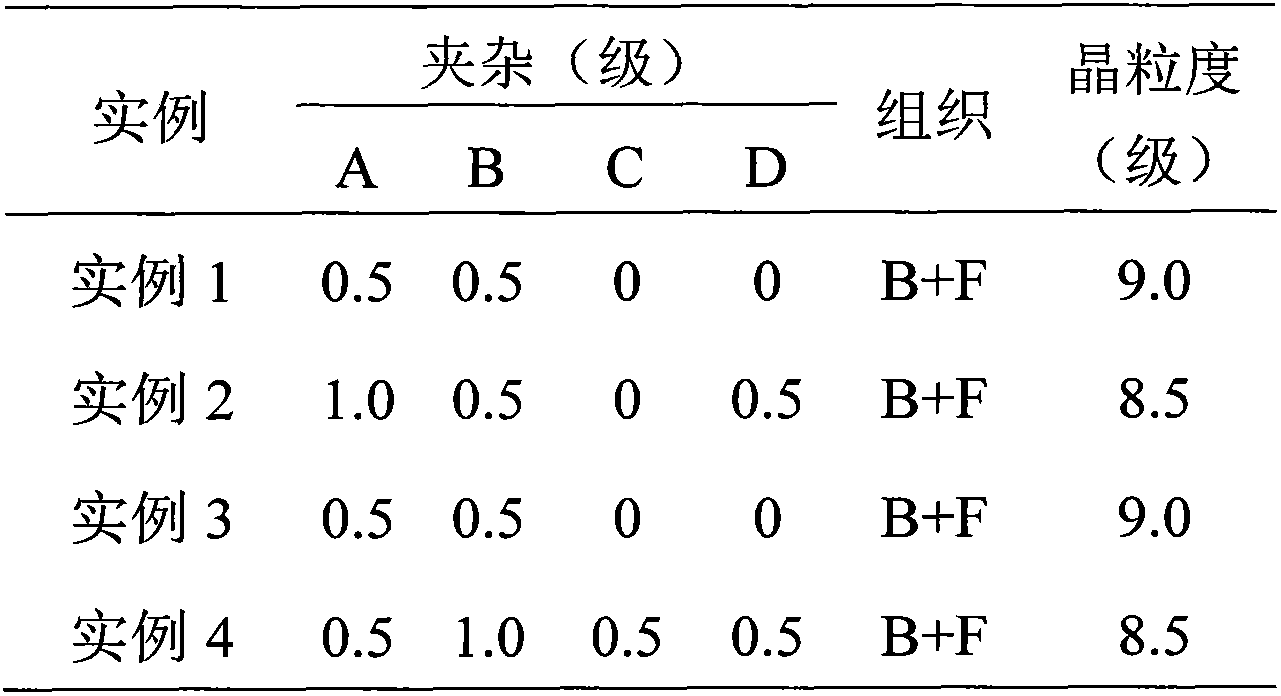

[0019] The specification of the tube produced in Example 1 is Φ127×10mm, the required round billet is Φ210mm, the heating temperature of the ring furnace is 1250°C, and the heating time is 240min; the specifications of the tubes produced in Example 2, Example 3, and Example 4 are Φ457×50mm and Φ325 ×18mm, Φ406×22mm, the required round billet is Φ350mm, the heating temperature of the ring furnace is 1250°C, and the heating time is 390min.

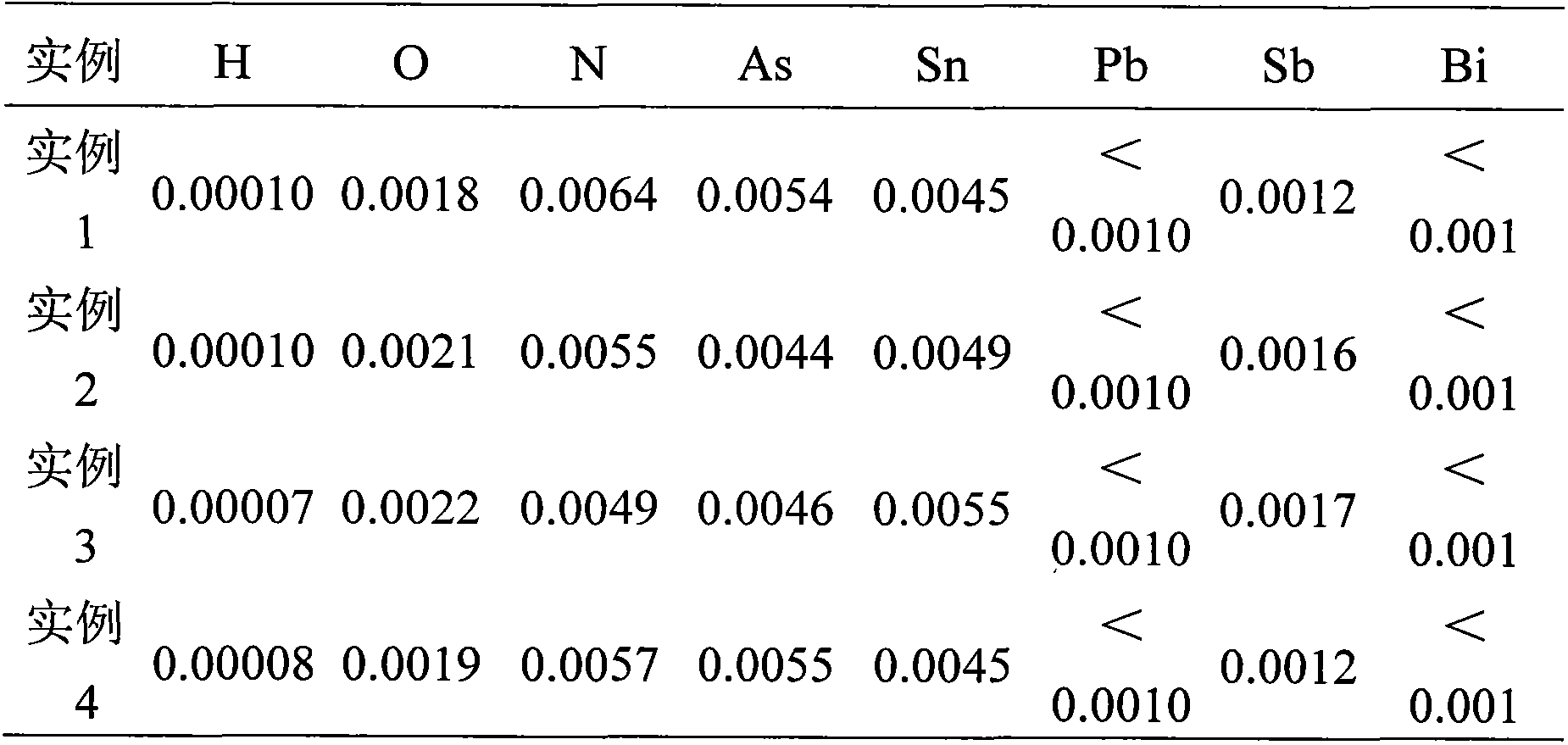

[0020] The normalizing temperature of example 1, example 2, example 3, example 4 is 940 ℃, and the normalizing holding time is respectively 35min, 100min, 45min, 50min; Tempering temperature is 640 ℃, and the tempering holding time is respectively 70min, 180min, 100min, 120min. The inclusions and metallographic structure of each example are shown in Table 3, the tensile properties are shown in Table 4, and the Charpy V-notch impact absorption energy is shown in Table 5.

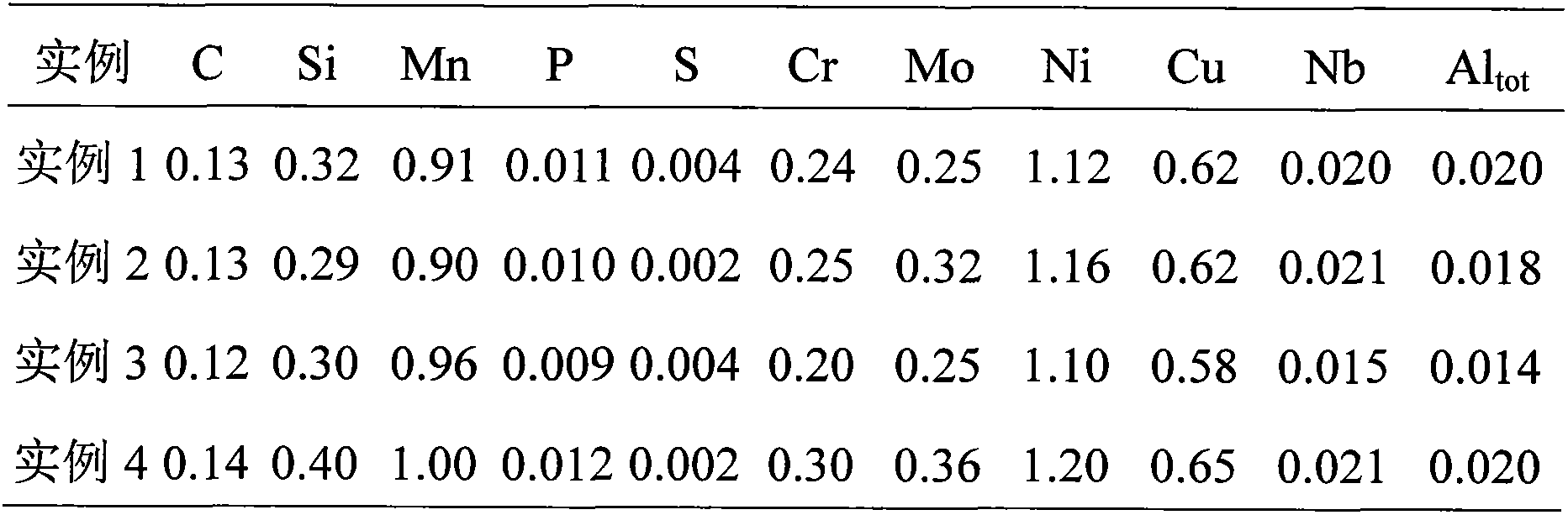

[0021] Table 3 Inclusions and metallographic structure of each exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com