Adding method of steelmaking slag charge of oxygen converter

A technology of oxygen converters and converters, applied in the manufacture of converters, etc., can solve the problems of iron ore one-time addition splash, increase the amount of slag, slag overflow, etc., to reduce process splash and smoke phenomenon, optimize process and End point control, effect of reducing smelting cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: A method for mixing and adding slag-making materials for oxygen converter steelmaking

[0020] ① Splash slag to protect the furnace before smelting the converter, and check the furnace condition. Add the first batch of slagging materials to the converter, including 603kg of limestone, 945kg of lime, 1505kg of lightly burned dolomite, 712kg of sludge balls, and 497kg of iron ore;

[0021] ② The operation of adding molten iron began, and the converter loading system adopted quantitative loading, with 90.5 tons of molten iron and 7.3 tons of scrap steel;

[0022] ③ 0-5 minutes after the start of oxygen blowing, the smelting is stable, and no other slag is added;

[0023] ④ 6 to 8 minutes after the start of oxygen blowing, 201kg of limestone, 450kg of lime, 198kg of lightly burned dolomite, 205kg of sludge balls, and 289kg of iron ore;

[0024] ⑤ 9 to 11 minutes after the start of blowing with oxygen, 355kg of lime and 211kg of iron ore.

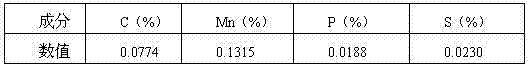

[0025] See Table ...

Embodiment 2

[0028] Embodiment 2: A kind of oxygen converter steelmaking slagging material compounding method

[0029] ① Splash slag to protect the furnace before smelting the converter, and check the furnace condition. Add the first batch of slagging materials to the converter, including 597kg of limestone, 995kg of lime, 1492kg of lightly burned dolomite, 707kg of sludge balls, and 512kg of iron ore;

[0030] ②The operation of adding molten iron began, and the converter loading system adopted quantitative loading, with 90.46 tons of molten iron and 7.98 tons of scrap steel;

[0031] ③Oxygen blowing started 0~5min, the smelting was stable, no other slag was added;

[0032] ④ 6 to 8 minutes after the start of blowing with oxygen, 224kg of limestone, 506kg of lime, 203kg of lightly burned dolomite, 213kg of sludge balls, and 306kg of iron ore;

[0033] ⑤ 9-11 minutes after the start of blowing with oxygen supply, 309kg of lime and 197kg of iron ore.

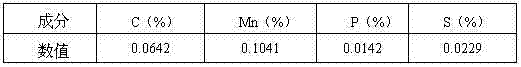

[0034] ⑥See the following table 2 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com