Method for regenerating metal furnace cinder composite mushroom and shimming permeable furnace bottom

A mushroom head, breathable technology, used in the manufacture of converters and other directions

Active Publication Date: 2009-07-22

CENT IRON & STEEL RES INST

View PDF0 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Bottom-blowing gas with proper flow rate is used to cool the mol

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

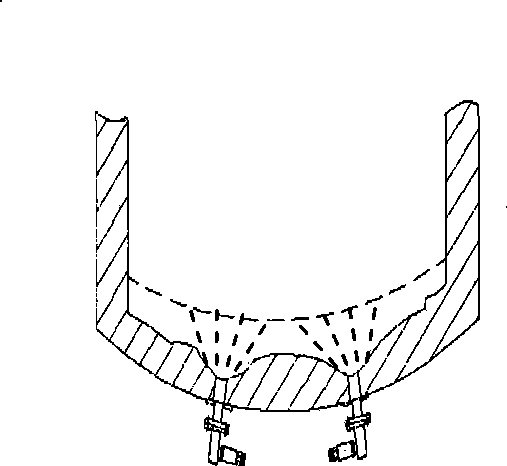

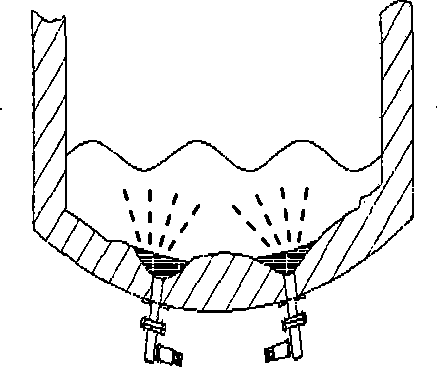

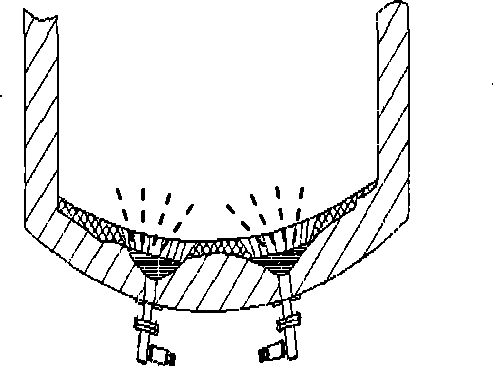

A method for the regeneration of a metal slag syntactic mushroom head and shimming a hearth with ventilation property belongs to the technique field of oxygen converter steelmaking. In the case that melting loss of hearth is caused by using a converter for smelting mild steel and the melting loss occurs correspondingly at the metal slag syntactic mushroom head, the metal slag syntactic mushroom head is regenerated and the shimming hearth with ventilation property is ensured. In the whole furnace campaign period, the sunken amount is seriously controlled to be less than or equal to 200mm according to the hearth thickness. The operation of hearth shimming comprises the following three stages: hearth cleaning, metal mushroom head regeneration and sintering hearth shimming. The invention provides a technique method for the regeneration of metal slag syntactic mushroom head and shimming the hearth with ventilation property in the case that the hearth is eroded when using a top and bottom combined blowing converter, and the technique method is used for protecting bottom blowing elements and raising the campaign of the top and bottom combined blowing converter. The sintered layer on hearth with good ventilation property is formed and finally the metal slag syntactic mushroom head with good ventilation property is reformed through adjusting the granularity ratio of repairing mass and adopting reasonable sintering technology.

Description

technical field [0001] The invention patent belongs to the technical field of oxygen converter steelmaking. In particular, it provides a method for regeneration of metal slag composite mushroom heads and padding the gas-permeable furnace bottom, which is used for the regeneration of metal slag composite mushroom heads and padding of the gas-permeable furnace when the furnace bottom of the composite blowing converter is corroded. Bottom, in order to protect the bottom blowing gas supply components, improve the service life of reblowing furnace. Background technique [0002] Converter compound blowing is an advanced converter steelmaking process technology. For many years, due to the short life of bottom blowing gas supply components, the compound blowing converter is far lower than the top blowing converter using slag splashing furnace protection technology. The process technology of using metal slag composite mushroom head to protect the bottom blowing gas supply element ca...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C21C5/30C21C5/48

Inventor 刘浏佟溥翘郑丛杰杨利彬李春龙王毅赵舸刘艳

Owner CENT IRON & STEEL RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com