Bainite steel frog and manufacture method thereof by three-stage cooling after rolling

A technology of bainitic steel and three-stage cooling, which is applied in the manufacture of tools, switches, rails, etc., can solve the problems of low material plasticity, poor welding performance, and unstable performance, and achieve high performance, low cost, and low cost. Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

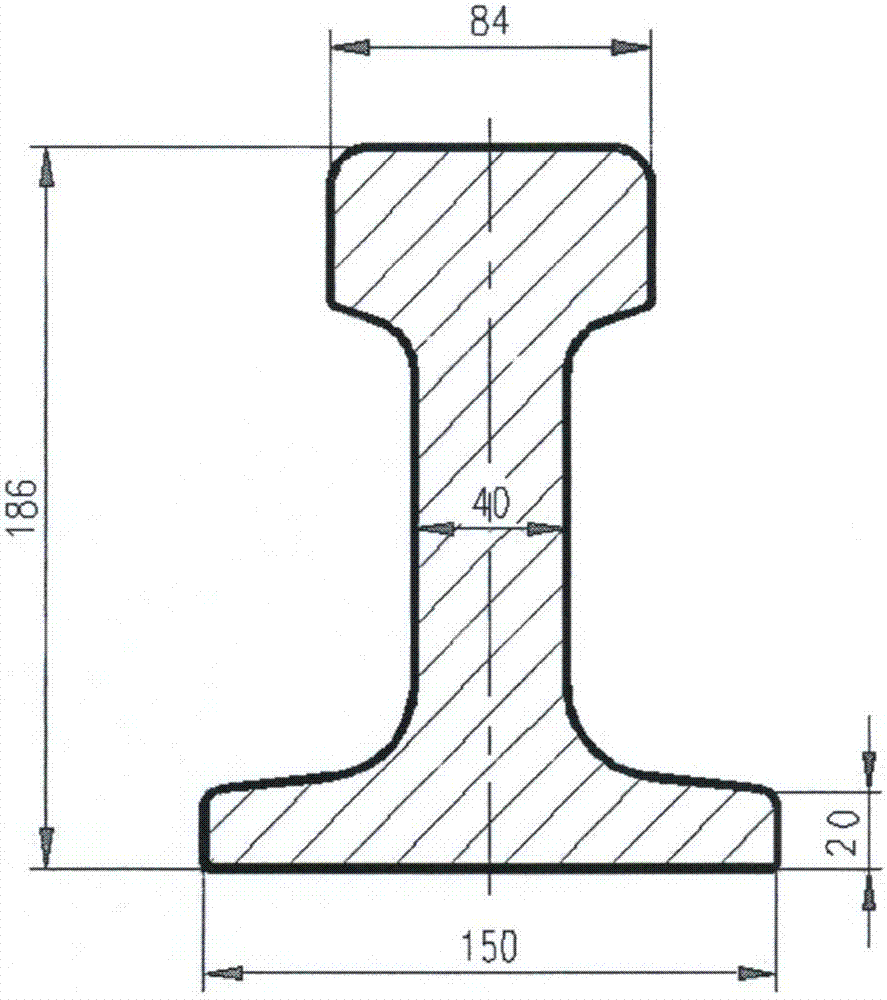

Embodiment 1

[0025] Firstly put relevant raw materials such as industrial pure iron, ferronickel, ferrochrome, ferromanganese, and industrial pure aluminum into molten steel, then use the LF furnace to refine the molten steel outside the furnace, and use the RH method to conduct vacuum degassing treatment on the molten steel . Continuous casting of molten steel at 1550°C into steel slabs, the chemical composition (wt%) of the steel slabs is: C 0.20, Mn 1.10, Al 0.50, Ni 0.62, Cr 1.92, Si 1.50, Ti 0.008, B 0.0003, H 0.00008, V 0.0011, Nb 0.008, O 0.0012, S 0.006, P 0.003, and the rest were Fe. Then, the above-mentioned continuous casting billet is subjected to hot rolling, the rolling ratio is 13, the rolling temperature is 1140°C, and the final rolling temperature is 920°C, and it is rolled into a frog material with a cross-sectional shape similar to that of a rail. Such as figure 1 shown. The rolled frog rolling is subjected to three-stage cooling treatment. The cooling rate is 50 °C / m...

Embodiment 2

[0027]Firstly put relevant raw materials such as industrial pure iron, ferronickel, ferrochrome, ferromanganese, and industrial pure aluminum into molten steel, then use the LF furnace to refine the molten steel outside the furnace, and use the RH method to conduct vacuum degassing treatment on the molten steel . The molten steel is continuously cast at 1600°C into billets. The chemical composition (wt%) of the continuously cast billets is: C 0.19, Mn 1.86, Al 0.68, Ni 0.75, Cr 1.48, Si1.15, Ti 0.009, B 0.0001, H0. 00009, V 0.009, Nb 0.005, O 0.0010, S 0.008, P 0.009, and the rest is Fe. Then, the continuous casting steel billet is hot-rolled, the rolling ratio is 14, the rolling temperature is 1130°C, and the final rolling temperature is 900°C, and it is rolled into a frog material with a cross-sectional shape similar to that of a rail, such as figure 1 shown. The rolled frog rolling is subjected to three-stage cooling treatment. The cooling rate is 65 °C / min at a temperatu...

Embodiment 3

[0029] Firstly put relevant raw materials such as industrial pure iron, ferronickel, ferrochrome, ferromanganese, and industrial pure aluminum into molten steel, then use the LF furnace to refine the molten steel outside the furnace, and use the RH method to conduct vacuum degassing treatment on the molten steel . Continuous casting of molten steel at 1580°C into steel slabs, the chemical composition (wt%) of the continuous casting slabs is: C 0.22, Mn 1.65, Al 0.52, Ni 0.92, Cr 1.67, Si1.31, Ti 0.006, B 0.0003, H 0.00007, V 0.0013, O 0.0011, S 0.009, P 0.008, Nb 0.003, and the rest were Fe. Then, the above-mentioned continuous casting billet is subjected to hot rolling, the rolling ratio is 11, the rolling temperature is 1100°C, and the final rolling temperature is 860°C, and it is rolled into a cross-sectional frog material with a cross-sectional shape similar to that of a rail, such as figure 1 shown. After rolling, the frog rolling is subjected to three-stage cooling tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Σ0.2 | aaaaa | aaaaa |

| Σ0.2 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com