Preparation method of Al*O* short fiber reinforced composite prefabricated part

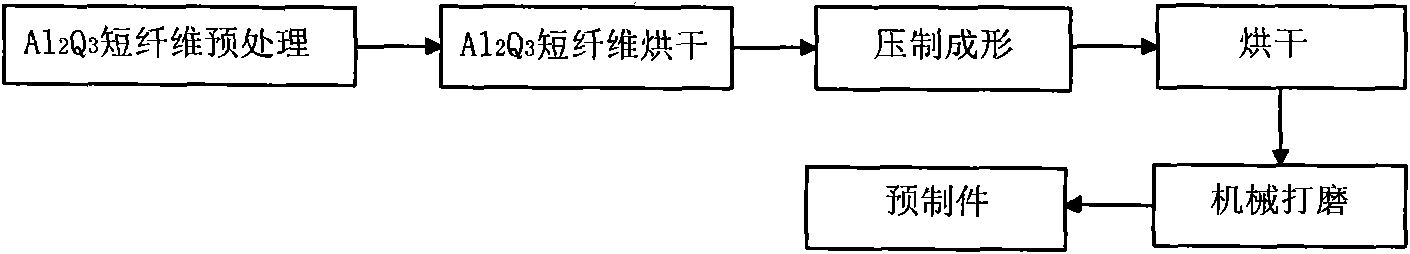

A short fiber reinforced, composite material technology is applied in the field of extrusion casting molding method to prepare composite materials, which can solve the problems of long manufacturing cycle of short fiber preforms, difficult to meet mass production, irregular shapes, etc., and achieve outline size and void ratio. Easy to control, improve production efficiency, the effect of regular shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

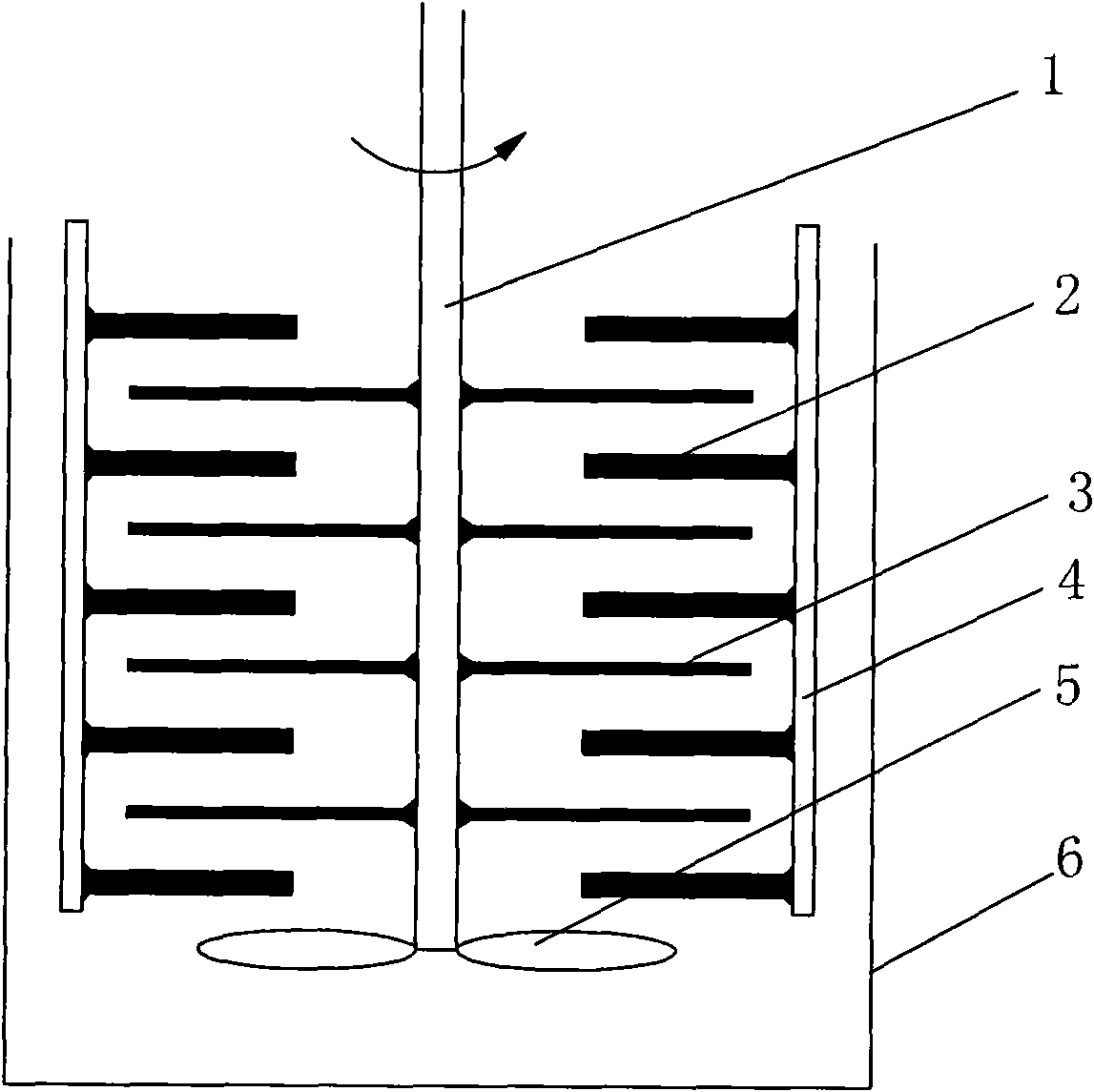

[0026] (1), Al 2 O 3 Short fiber pretreatment: Al 2 O 3 The short fiber is put into the mixing cylinder 6 of the mechanical liquid crushing device, and Al is added 2 O 3 Water with 9 times the weight of the short fiber, turn on the motor, adjust the motor speed to 80r / min, the main shaft 1 drives the main blade 5 and the auxiliary blade 3 to rotate, the fixed shaft 4 is set with the fixed blade 2, static, Al 2 O 3 Under the joint action of the main shaft 1, the main blade 5, the auxiliary blade 3, the fixed shaft 4, and the fixed blade 2, the short fiber will affect the Al 2 O 3 The short fiber is pulverized, stirred for 20 minutes, allowed to stand for 10 minutes, drained of water, and then washed with tap water. Repeat twice to remove the Al 2 O 3 Remove the short fibers and place them in a clean dish.

[0027] Among them, see the mechanical liquid crushing device figure 1 , Which is that the main shaft 1 is provided with main blades 5 and auxiliary blades 3 from bottom to top....

specific Embodiment 2

[0034] (1), Al 2 O3 Short fiber pretreatment: Al 2 O 3 The short fiber is put into the mixing cylinder 6 of the mechanical liquid crushing device, and Al is added 2 O 3 Water with 10 times the weight of the short fiber, turn on the motor, adjust the motor speed to 90r / min, the main shaft 1 drives the main blade 5 and the auxiliary blade 3 to rotate, the fixed shaft 4 is set with the fixed blade 2, static, Al 2 O 3 Under the joint action of the main shaft 1, the main blade 5, the auxiliary blade 3, the fixed shaft 4, and the fixed blade 2, the short fiber will affect the Al 2 O 3 The short fiber is pulverized, stirred for 30 minutes, allowed to stand for 15 minutes, drained of water, and then washed with tap water. Repeat twice to remove the Al 2 O 3 Remove the short fibers and place them in a clean dish.

[0035] (2)Al 2 O 3 Drying treatment of short fiber: the Al after pretreatment 2 O 3 The short fibers are baked in an oven at a temperature of 180 degrees Celsius for 18 hours;

...

specific Embodiment 3

[0041] (1), Al 2 O 3 Short fiber pretreatment: Al 2 O 3 The short fiber is put into the mixing cylinder 6 of the mechanical liquid crushing device, and Al is added 2 O 3 Water with 11 times the weight of the short fiber, turn on the motor, and adjust the motor speed to 100r / min. The main shaft 1 drives the main blade 5 and the auxiliary blade 3 to rotate, and the fixed shaft 4 is equipped with a fixed blade 2, which is stationary, Al 2 O 3 Under the joint action of the main shaft 1, the main blade 5, the auxiliary blade 3, the fixed shaft 4, and the fixed blade 2, the short fiber will affect the Al 2 O 3 The short fiber is pulverized, stirred for 40 minutes, allowed to stand for 15 minutes, drained of water, and then washed with tap water. After repeating three times, the Al 2 O 3 Remove the short fibers and place them in a clean dish.

[0042] (2)Al 2 O 3 Drying treatment of short fiber: the Al after pretreatment 2 O 3 The short fibers are baked in an oven at a temperature of 200...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com