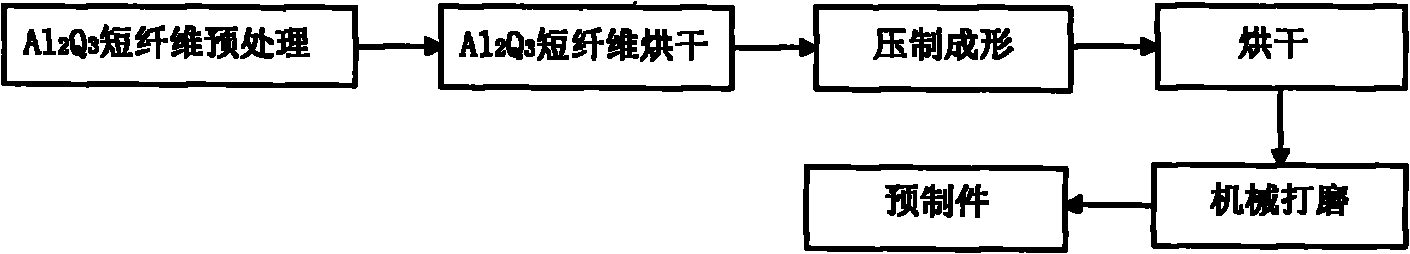

Preparation method of Al2O3 short fiber reinforced composite prefabricated part

A short fiber reinforced composite material technology is applied in the field of extrusion casting molding to prepare composite materials. Control, improve production efficiency, and reduce the amount of machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

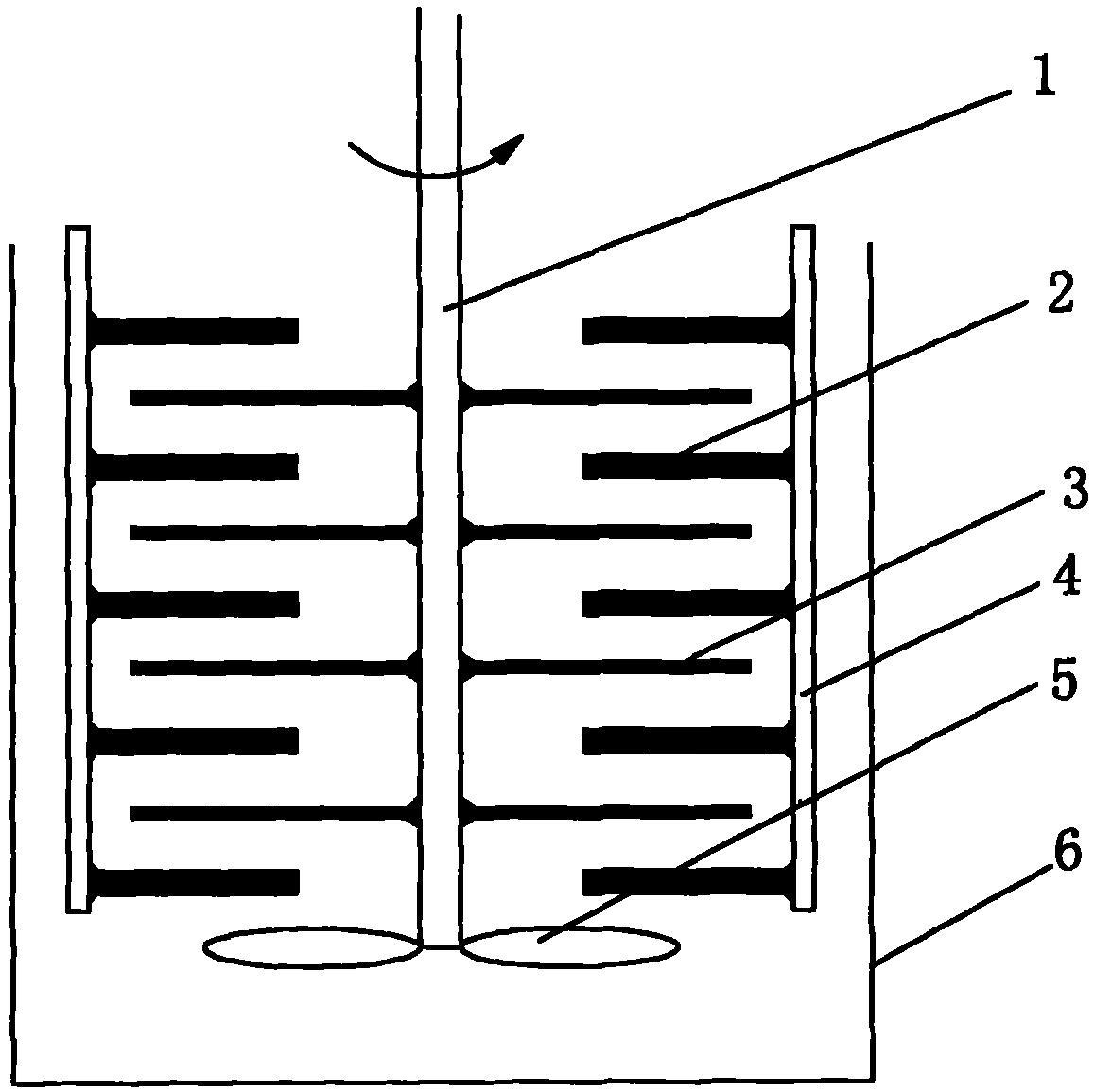

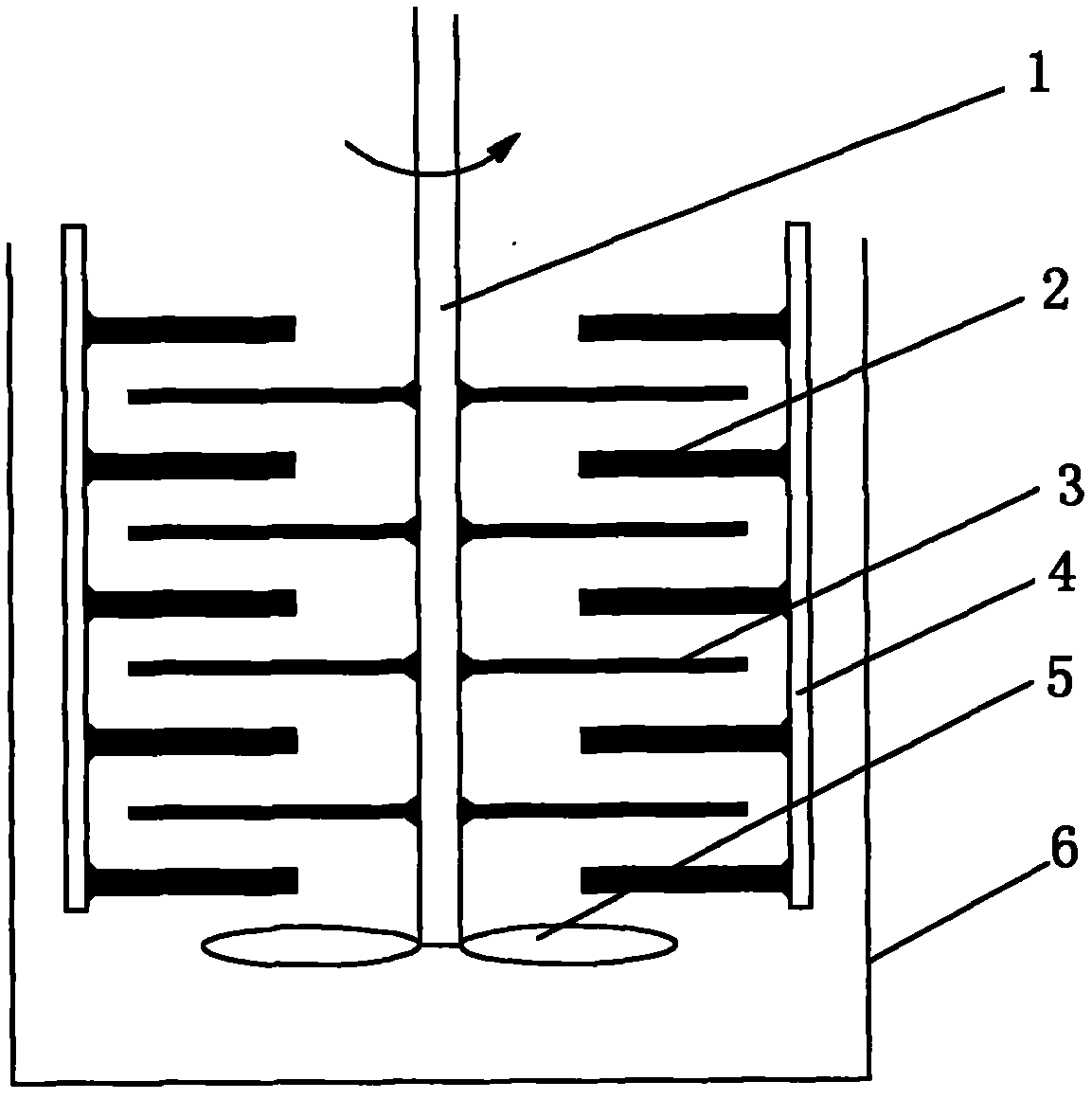

[0026] (1), Al 2 o 3 Short fiber pretreatment: Al 2 o 3 The short fibers are put into the mixing drum 6 of the mechanical liquid crushing device, and the Al 2 o 3 9 times the weight of short fiber, turn on the motor, adjust the motor speed to 80r / min, the main shaft 1 drives the main blade 5 and the auxiliary blade 3 to rotate, and the fixed shaft 4 is provided with the fixed blade 2, which is stationary, Al 2 o 3 Under the combined action of main shaft 1, main blade 5, auxiliary blade 3, fixed shaft 4, and fixed blade 2, short fibers have a 2 o 3 The short fibers were crushed, stirred for 20 minutes, left to stand for 10 minutes, drained, and then washed with tap water. Repeated twice, the Al 2 o 3 Remove short fibers and place on a clean plate.

[0027] Among them, the mechanical liquid crushing device is shown in figure 1 , which is that the main shaft 1 is provided with main blades 5 and auxiliary blades 3 from bottom to top. Correspondingly, the fixed blades 2 a...

specific Embodiment 2

[0034] (1), Al 2 o 3Short fiber pretreatment: Al 2 o 3 The short fibers are put into the mixing drum 6 of the mechanical liquid crushing device, and the Al 2 o 3 Water with 10 times the short fiber weight, turn on the motor, adjust the motor speed to 90r / min, the main shaft 1 drives the main blade 5 and the auxiliary blade 3 to rotate, and the fixed shaft 4 is provided with the fixed blade 2, which is stationary, Al 2 o 3 Under the combined action of main shaft 1, main blade 5, auxiliary blade 3, fixed shaft 4, and fixed blade 2, short fibers have a 2 o 3 The short fibers were crushed, stirred for 30 minutes, left to stand for 15 minutes, drained, and then washed with tap water. Repeated twice, the Al 2 o 3 Remove short fibers and place on a clean plate.

[0035] (2)Al 2 o 3 Drying treatment of short fibers: the pretreated Al 2 o 3 The short fibers are baked in an oven at a temperature of 180 degrees Celsius for 18 hours;

[0036] (3)Al 2 o 3 Manufacture of sho...

specific Embodiment 3

[0041] (1), Al 2 o 3 Short fiber pretreatment: Al 2 o 3 The short fibers are put into the mixing drum 6 of the mechanical liquid crushing device, and the Al 2 o 3 Water with 11 times the short fiber weight, turn on the motor, adjust the motor speed to 100r / min, the main shaft 1 drives the main blade 5 and the auxiliary blade 3 to rotate, the fixed shaft 4 is provided with the fixed blade 2, and remains still, Al 2 o 3 Under the combined action of main shaft 1, main blade 5, auxiliary blade 3, fixed shaft 4, and fixed blade 2, short fibers have a 2 o 3 The short fibers were crushed, stirred for 40 minutes, left to stand for 15 minutes, drained, and then washed with tap water. After repeating three times, the Al 2 o 3 Remove short fibers and place on a clean plate.

[0042] (2)Al 2 o 3 Drying treatment of short fibers: the pretreated Al 2 o 3 The short fibers are baked in an oven at a temperature of 200 degrees Celsius for 20 hours;

[0043] (3)Al 2 o 3 Manufactu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com