Aluminum-based titanium surface brake disc for high-speed heavy haul train and molding method thereof

A heavy-duty train, brake disc technology, applied in the direction of brake disc, brake type, brake components, etc., can solve the problems of wear resistance, poor high temperature resistance, etc., to improve wear resistance and high temperature resistance, Ensuring driving safety and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

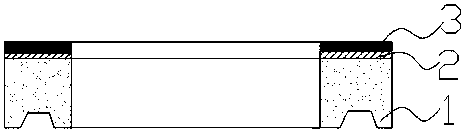

[0035] Such as figure 1As shown, the present embodiment provides an aluminum-based titanium surface brake disc for high-speed heavy-duty trains, including a brake disc base 1, the brake disc base of the present invention is an aluminum alloy brake disc base, and the aluminum alloy brake disc base A layer of wear-resistant layer 3 is also compounded on it. In this embodiment, the thickness of wear-resistant layer 3 can be 4-10mm, and the thickness of this embodiment is preferably 6mm; the wear-resistant layer 3 of this embodiment is made of titanium alloy material. In this embodiment Among them, the titanium alloy material is composed of the following alloy components in mass percentage: Al: 6%, V: 4%, ceramic particles: 5%, Ti balance, the sum of all the above alloy components is 100%; the ceramic particles are preferably WC, Its particle size is 80 mesh. The preparation method of the above-mentioned titanium alloy material is as follows: add raw materials other than ceramic ...

Embodiment 2

[0042] This embodiment provides an aluminum-based titanium surface brake disc for high-speed heavy-duty trains. Its structure is the same as that of Embodiment 1. The difference from Embodiment 1 is that the titanium alloy material used for the wear-resistant layer 3 is made of the following mass: Percentage alloy composition: Al: 2%, V: 5%, ceramic particles: 3%, Ti balance, the sum of all the above alloy components is 100%; the ceramic particles are preferably SiC, and their particle size is 50 mesh.

[0043] For the forming method of the above-mentioned aluminum-based titanium surface brake disc for high-speed and heavy-duty trains, refer to the steps in Example 1.

Embodiment 3

[0045] This embodiment provides an aluminum-based titanium surface brake disc for high-speed heavy-duty trains. Its structure is the same as that of Embodiment 1. The difference from Embodiment 1 is that the titanium alloy material used for the wear-resistant layer 3 is made of the following mass: Percentage alloy composition: Al: 5%, V: 3%, ceramic particles: 1%, Ti balance, the sum of all the above alloy components is 100%; the ceramic particles are preferably Al 2 o 3 , and its particle size is 150 mesh.

[0046] For the forming method of the above-mentioned aluminum-based titanium surface brake disc for high-speed and heavy-duty trains, refer to the steps in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com