High-toughness corrosion-resistant steel and manufacturing method thereof

A corrosion-resistant steel and high-toughness technology, applied in the field of high-strength, high-toughness corrosion-resistant steel and its manufacturing, can solve the problems of unstable impact, unsatisfactory impact toughness, and high alloy cost, and achieve strong manufacturability and sufficient margin. Effect

Active Publication Date: 2012-12-26

BAOSHAN IRON & STEEL CO LTD +1

View PDF9 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

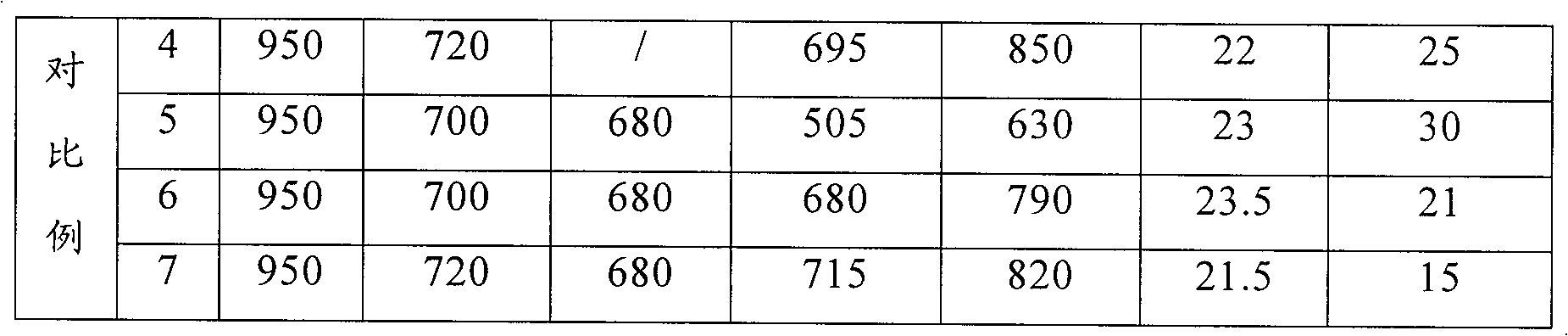

Use UNS42400 (C≤0.06%, Si: 0.3-0.6%, Mn: 0.5-1.00%, P≤0.03%, S≤0.03%, Cr: 12-14%, Ni: 3.5-4.5%, Mo: 0.3- 0.7%) material can better solve the problem of impact instability, but because more expensive alloy elements such as Ni and Mo are added to the material, the cost of the alloy is too high

[0004] CN101096744A discloses a high steel grade and high resistance to carbon dioxide and chloride ion corrosion oil casing steel and its manufacturing method, C: 0.15-0.25%, Si: 0.2-1.0%, Mn: 0.2-1.0%, Cr: 12/14% , Ni: 0.5-1.5%

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

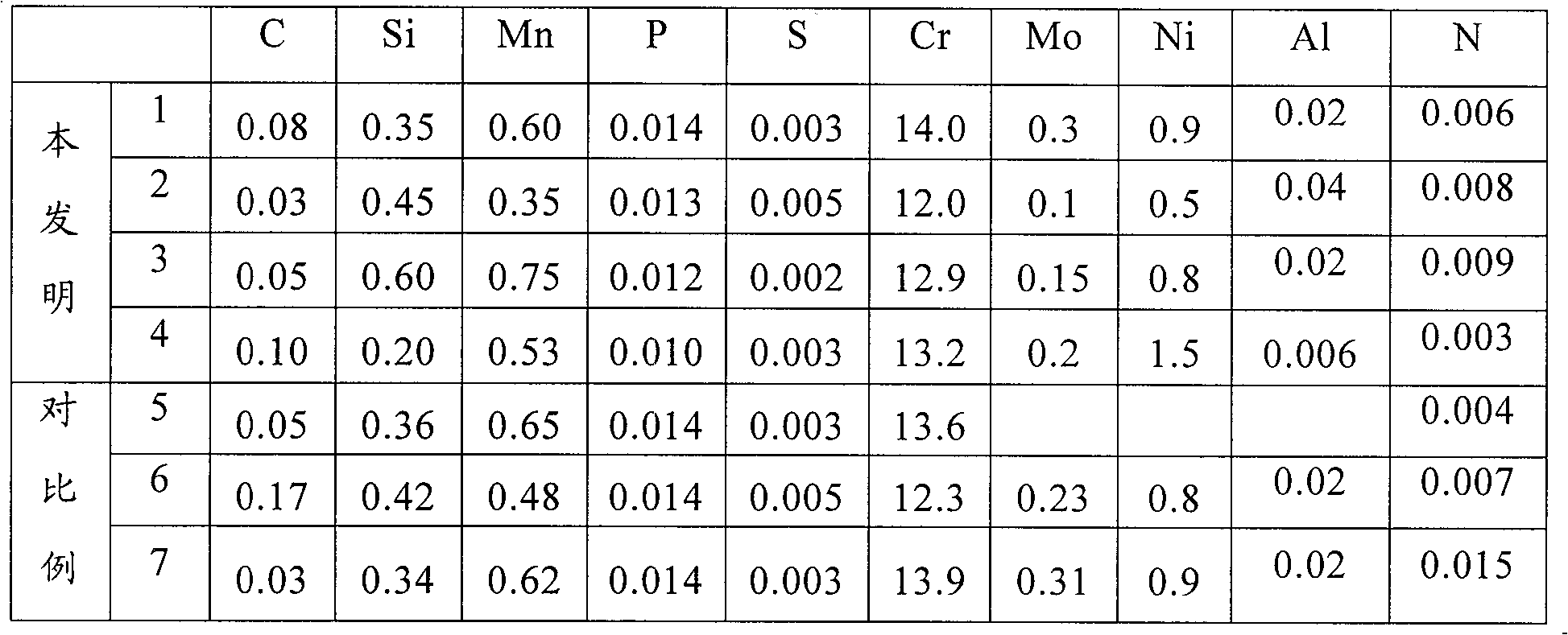

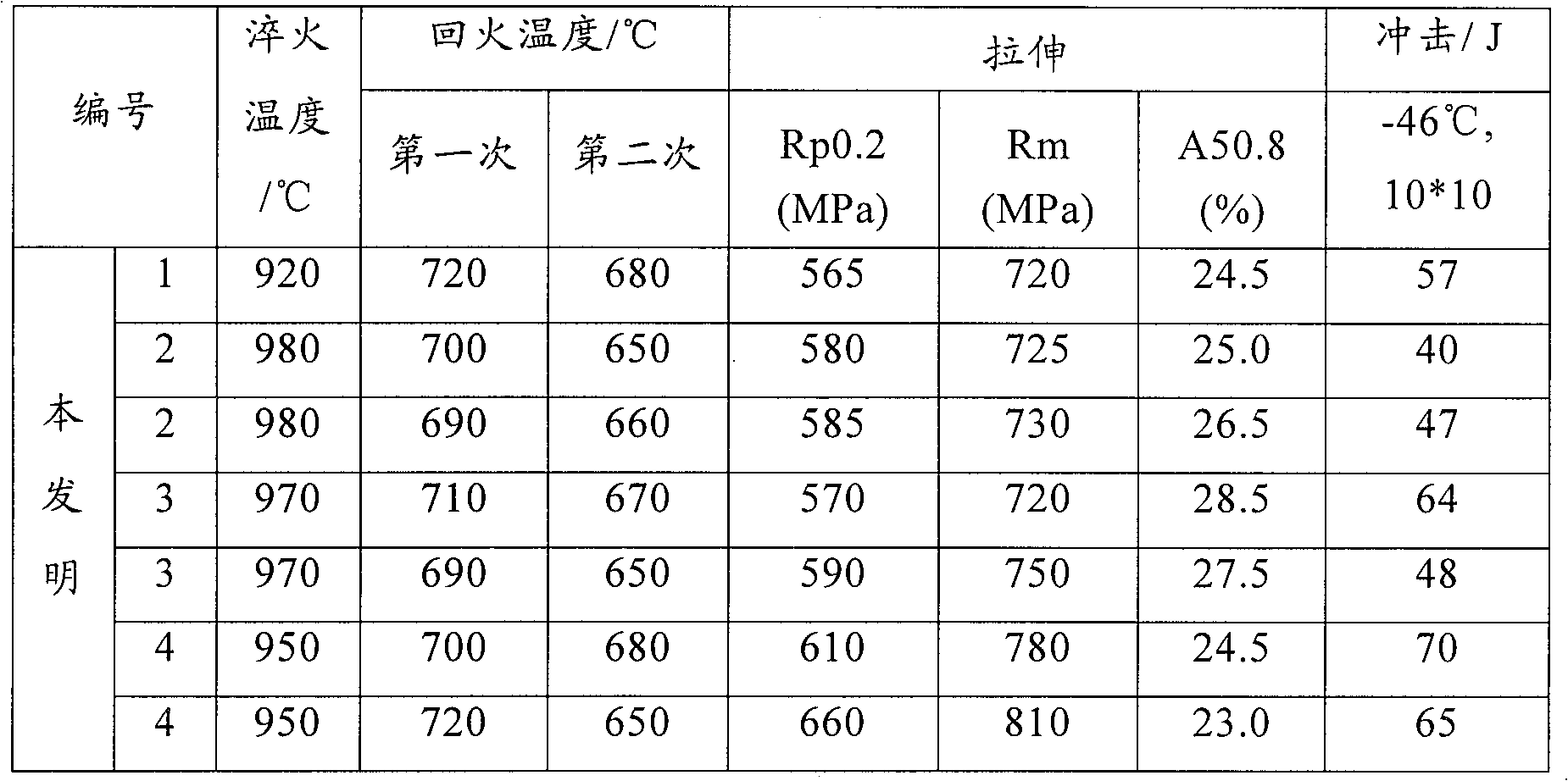

The invention relates to high-toughness corrosion-resistant steel. The high-toughness corrosion-resistant steel comprises the following chemical components in percentage by weight: 0.03 to 0.10 percent of C, 0.2 to 0.6 percent of Si, 0.35 to 0.75 percent of Mn, 12 to 14 percent of Cr, 0.5 to 1.5 percent of Ni, 0.01 to 0.04 percent of Al, 0.1 to 0.3 percent of Mo, less than or equal to 0.015 percent of P, less than or equal to 0.006 percent of S and less than or equal to 0.01 percent of N, wherein the Al/N is greater than 2, and the balance is Fe and unavoidable impurities. The manufacturing method of the high-toughness corrosion-resistant steel comprises the following steps of: smelting the chemical components by refining in and out of an electric arc furnace and performing vacuum refining treatment, or refining in and out of an oxygen converter and performing vacuum refining treatment or adopting an electroslag remelting method, and casting into ingots; making hot ingots enter the furnace before forging, wherein the surface temperature of ingots entering the furnace is less than 600 DEG C, the forging heating temperature is 1,200 to 1,250 DEG C, the finish forging temperature is greater than 1,000 DEG C, the forging ratio is greater than 6, and the grain fineness number at 1/2 of the thickness of the wall of a forged piece is not less than level 6. The high-toughness corrosion-resistant steel obtained by the method has the yield strength of greater than 517 MPa, and the ballistic work at -46 DEG C is greater than 27 J; and the high-toughness corrosion-resistant steel is suitable for FF-grade 105 MPa production tree body in oil and gas industry.

Description

technical field [0001] The invention relates to a high-toughness corrosion-resistant steel for low-temperature use in the oil and gas industry, in particular to a high-strength, high-toughness corrosion-resistant steel with a service temperature of -46°C and a manufacturing method thereof. Background technique [0002] The Christmas tree is an oil and gas well head device that provides access to the production tubing string and is an assembly of valves and fittings for fluid control. The Christmas tree hangs the tubing string running into the well, seals the annular space of the oil casing, controls and regulates the production of the oil well, ensures operation, construction, records oil and casing pressure data, tests and removes wax and other daily production management. [0003] According to different functions, the Christmas tree is divided into oil recovery (self-injection, artificial lift), gas recovery (natural gas and various acid gases), water injection, thermal re...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/44C21D1/18

Inventor 田青超熊文兵董晓明

Owner BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com