Manganese-molybdenum-vanadium steel material for high-strength bolt and preparation method of manganese-molybdenum-vanadium steel material

A technology of high-strength bolts and steel materials, applied in the field of high-strength fasteners, can solve the problems that plasticity cannot be adapted to cold drawing and cold heading processing, is difficult to achieve, and has a long cycle, so as to improve metal yield, increase strength and toughness , Improving the effect of billet quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

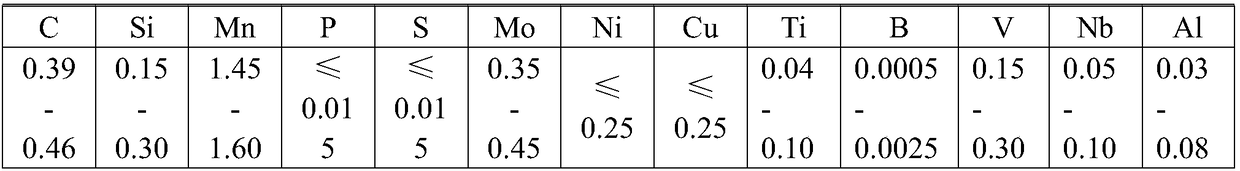

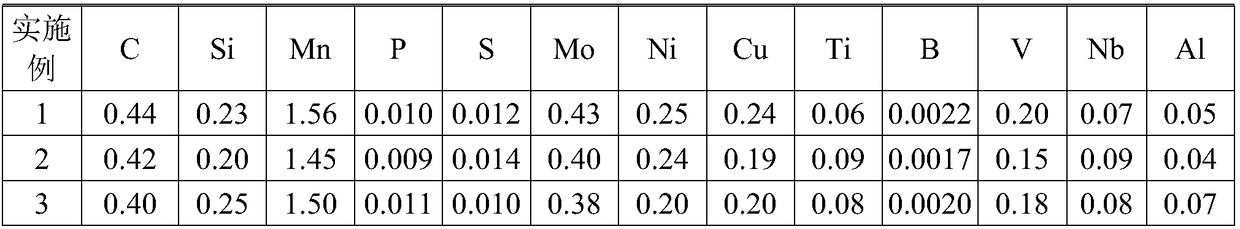

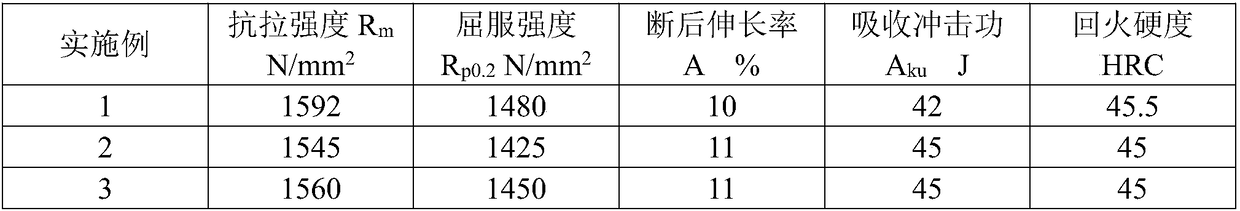

[0033] A steel material for high-strength bolts of the present invention contains chemical element components and their mass percentages: carbon 0.44%, silicon 0.23%, manganese 1.56%, phosphorus 0.010%, sulfur 0.012%, molybdenum 0.43%, Nickel 0.25%, copper 0.24%, titanium 0.06%, boron 0.0022%, vanadium 0.20%, niobium 0.07%, aluminum 0.05%, and the balance is iron.

[0034] The preparation method includes the following steps:

[0035] (1) Add iron and steel to an oxygen top-blown converter for smelting. The carbon, nickel, copper, phosphorus, sulfur and iron elements are all derived from iron and steel. Before tapping, add ferro-aluminum and ferrosilicon to strongly deoxidize, and then add ferro-vanadium and ferromanganese. Continue to deoxidize with ferro-titanium smelting, then add ferro-boron to achieve partial alloying, and tap steel after smelting; the temperature of converter smelting is controlled at 1600℃~1660℃, and the temperature of tapping is controlled at 1580℃~1600℃;

[...

Embodiment 2

[0041] A steel material for high-strength bolts of the present invention contains chemical element components and their mass percentages: carbon 0.42%, silicon 0.20%, manganese 1.45%, phosphorus 0.009%, sulfur 0.014%, molybdenum 0.40%, Nickel 0.24%, copper 0.19%, titanium 0.09%, boron 0.0017%, vanadium 0.15%, niobium 0.09%, aluminum 0.04%, and the balance is iron.

[0042] The preparation method includes the following steps:

[0043] (1) Add iron and steel to the oxygen top-blown converter for smelting. The carbon, nickel, copper, phosphorus, sulfur and iron elements are all derived from iron and steel. Before tapping, add ferro-aluminum and ferrosilicon to strongly deoxidize, and then add ferro-vanadium and ferromanganese. Continue to deoxidize with ferro-titanium smelting, then add ferro-boron to achieve partial alloying, and tap steel after smelting; the temperature of converter smelting is controlled at 1600℃~1660℃, and the temperature of tapping is controlled at 1580℃~1600℃;

...

Embodiment 3

[0049] A steel material for high-strength bolts of the present invention contains chemical element components and their mass percentages: carbon 0.40%, silicon 0.25%, manganese 1.50%, phosphorus 0.011%, sulfur 0.010%, molybdenum 0.38%, Nickel 0.20%, copper 0.20%, titanium 0.08%, boron 0.0020%, vanadium 0.18%, niobium 0.08%, aluminum 0.07%, and the balance is iron.

[0050] The preparation method includes the following steps:

[0051] (1) Add iron and steel to the oxygen top-blown converter for smelting. The carbon, nickel, copper, phosphorus, sulfur and iron elements are all derived from iron and steel. Before tapping, add ferro-aluminum and ferrosilicon to strongly deoxidize, and then add ferro-vanadium and ferromanganese. Continue to deoxidize with ferro-titanium smelting, then add ferro-boron to achieve partial alloying, and tap steel after smelting; the temperature of converter smelting is controlled at 1600℃~1660℃, and the temperature of tapping is controlled at 1580℃~1600℃;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com