Method for smelting low-aluminium moulded steel

A smelting method and technology for casting steel, applied in the direction of manufacturing converters, etc., can solve the problem of entering molten steel, etc., and achieve the effect of avoiding the change of composition to steel and the composition of stable composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

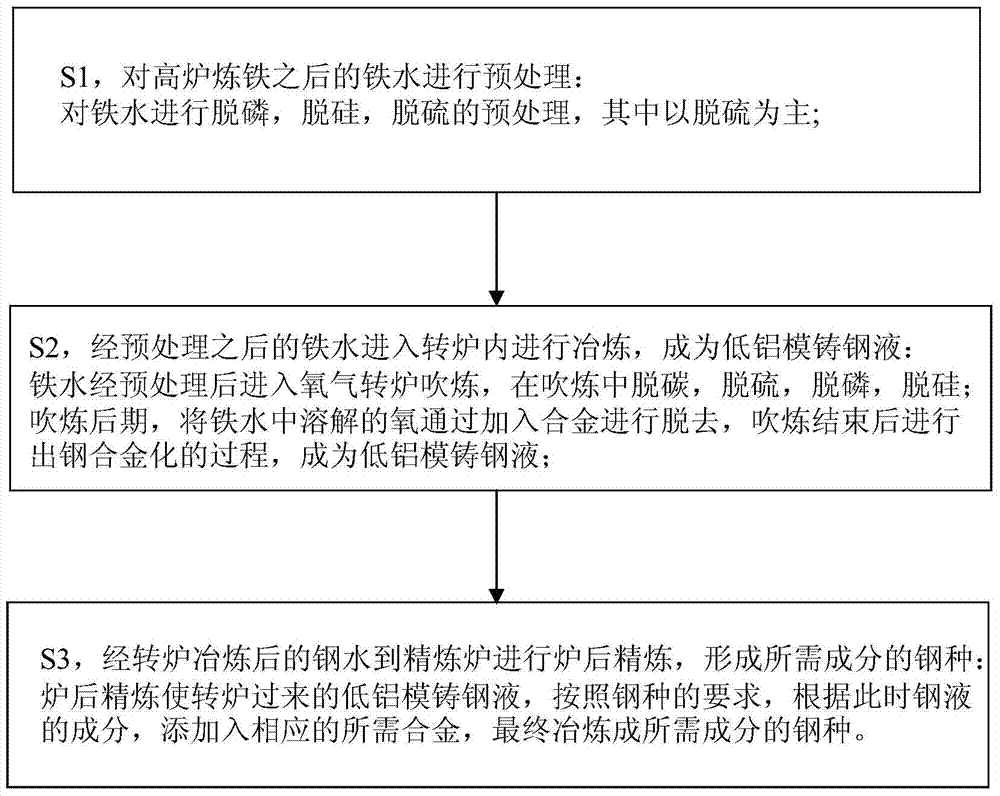

Method used

Image

Examples

Embodiment

[0106] To produce a furnace of low-aluminum die-casting steel that prohibits OB, its target composition is shown in Table 2 below. It can be seen that the composition of Al element is between 0.010% and 0.025%, and the upper limit of Al element is 0.025%, which is relatively high. low level. Therefore, according to the above-mentioned technical scheme and according to the conditions of molten iron supplied by the blast furnace to the steelmaking plant, the above three steps from S1 to S3 are carried out to complete the production plan of low-aluminum die-cast steel in Table 2 below.

[0107] Table 2 (the content unit of each element is 0.01% by weight, and the balance is Fe)

[0108] C

[0109] For the above step S1, according to the conditions of the molten iron, the composition of the molten iron before smelting is as shown in Table 3 below. As a raw material for converter steelmaking, the composition of the molten iron is mainly Fe, and the composition of the molt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com