Laser-enhanced underwater GMAW droplet transfer control method

A droplet transfer and control method technology, applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of underwater welding process stability and weld quality to be improved, so as to improve stability and weld quality , Uniform droplet size and stable arc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] An embodiment of the present invention provides a laser-enhanced underwater GMAW droplet transfer control method, the method mainly includes the following steps:

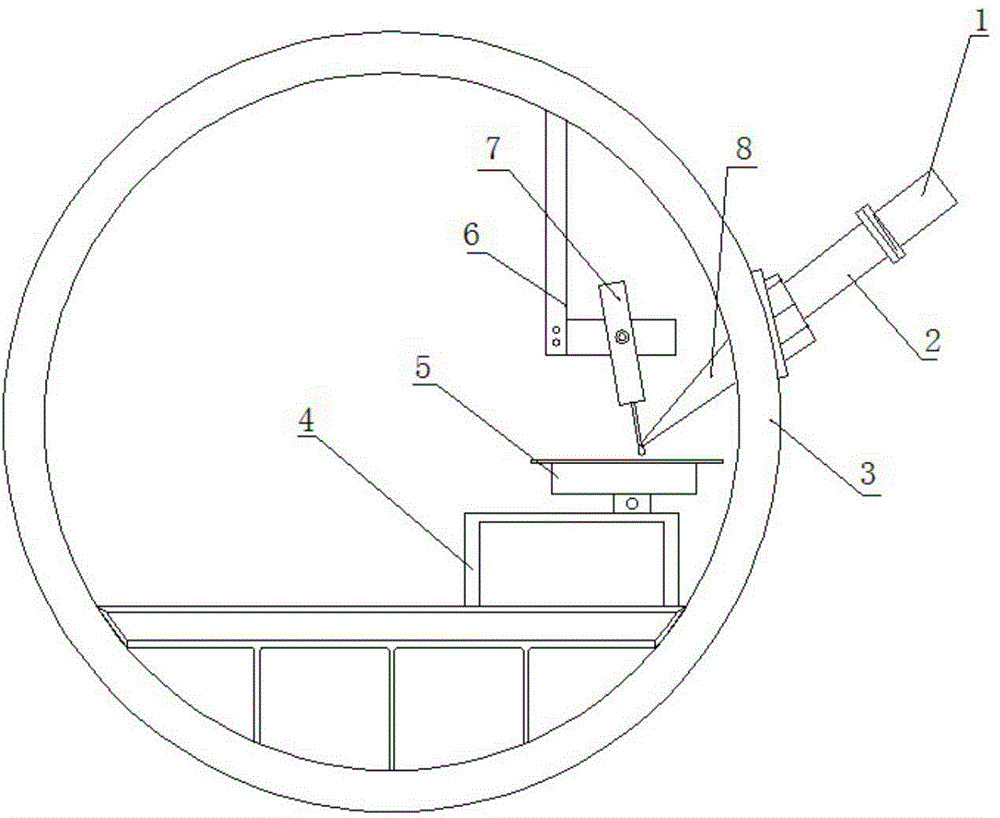

[0023] Put the melting electrode welding torch inside the underwater welding device, and the laser is placed outside or inside the underwater welding device;

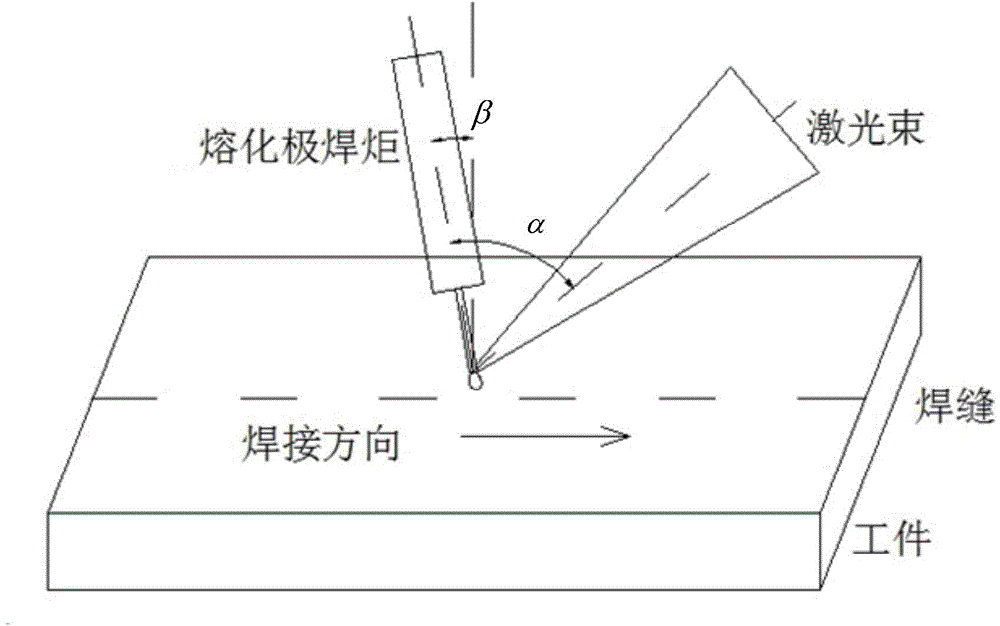

[0024] The laser beam emitted by the laser is introduced into the GMAW welding droplet transition constriction inside the underwater welding device, and the laser beam forms a certain angle with the melting electrode welding torch and is arranged in a straight line along the welding direction.

[0025] During the welding process, the recoil force generated by the laser beam weakens the adverse effect of the surrounding pressure environment on the droplet transfer, promotes the formation of the droplet transfer, and can pass the incident angle of the laser beam, laser power, pulse frequency, and defocus The adjustment of parameters such as the spot diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com