Method for producing goblet by using glass tube

A technology for glass tubes and glass cups, which is applied in the field of making goblet glasses with glass tubes. It can solve the problems of complex processing technology, easy breakage at the interface, poor brightness, etc., and achieve simple production technology, convenient operation, and good brightness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

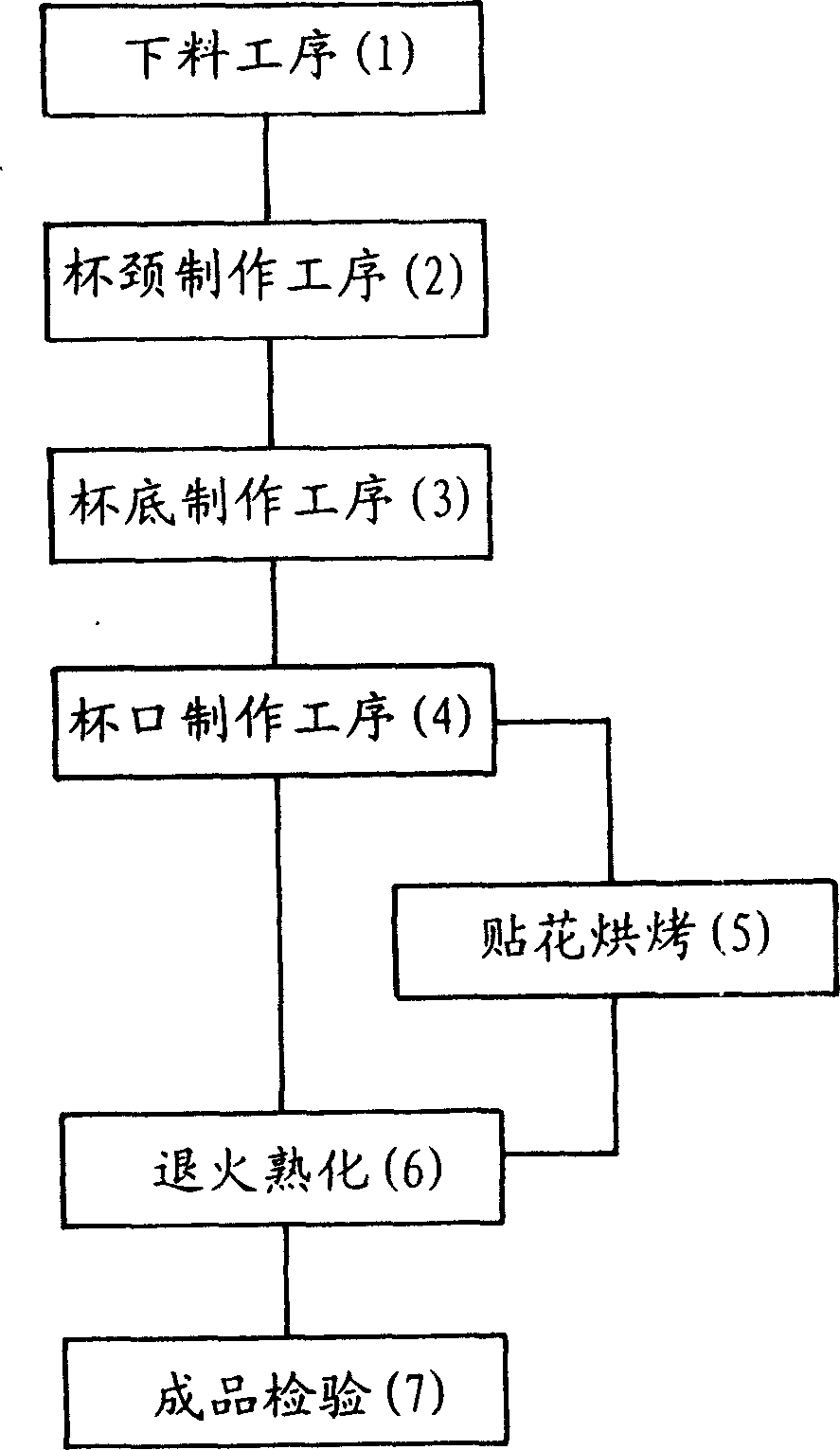

[0011] figure 1 Shown, be a kind of concrete embodiment of the method for making goblet with glass tube of the present invention, it may further comprise the steps:

[0012] A. Cutting process 1: Cut the glass tube into a glass tube section corresponding to the goblet glass. The size of the glass depends on the size of the glass tube;

[0013] B. Cup neck production process 2: First, position the glass tube section on the special firing equipment, and rotate the glass tube section; then aim at the cup neck and gradually blow air to heat to 1000°C-1400°C to soften the glass tube; The neck of the cup is press-molded on the neck of the cup to make the glass tube shrink and deform inward until the diameter of the tube hole is less than 1 cm; separate the die from the neck of the cup, continue to blow air and heat it to 1400°C-1600°C to melt the glass, so that the glass tube is melted into Solid column, the bottom of the cup is naturally concave toward the neck of the cup; and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com