Torque spanner

A torque wrench and wrench head technology, applied in the field of torque wrenches, can solve the problems of violent destruction of nuts, low cost performance and high production cost, and achieve the effects of time-saving, labor-saving torque, strong practicability and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical solution of the present invention is further illustrated below through specific examples.

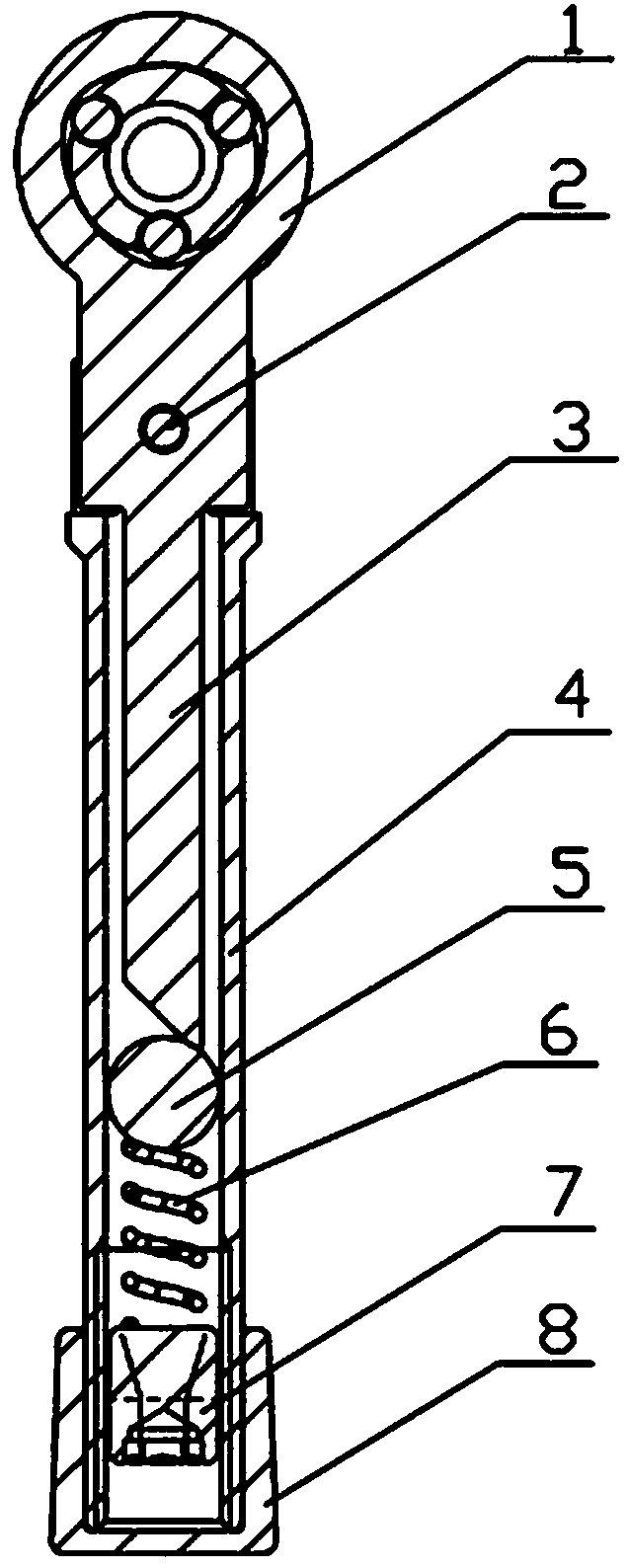

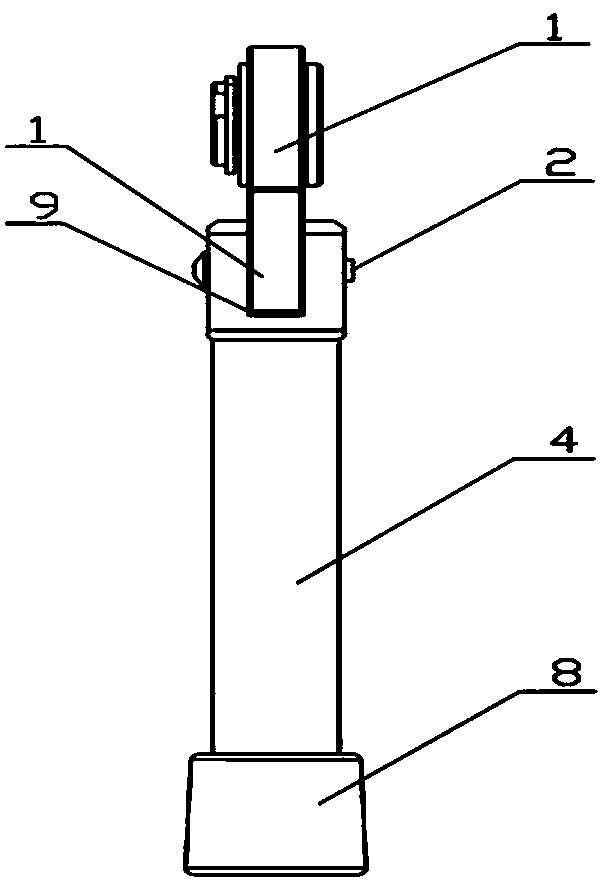

[0011] Such as Figure 1-2 Shown: a torque wrench, including a wrench head 1, a wrench rod 3 and a booster sleeve rod 4, the booster sleeve rod 4 is a hollow shell, the upper end is provided with a connecting groove 9, the wrench head 1 and the wrench rod 3 is the overall structure, the lower end of the wrench head 1 is provided with a boss, the connecting groove 9 of the wrench rod 3 is in contact with the convex table surface of the wrench head 1, the wrench rod 3 and the booster sleeve rod 4 are plug-in structures, And connected together through the rotating shaft 2. The steel ball 5 and the compression spring 6 are also arranged in the reinforcing sleeve rod 4. The lower end of the wrench rod 3 is provided with a beveled surface, and the beveled surface is in contact with the outer surface of the steel ball 5. The lower end of the steel ball 5 A compression spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com