Patents

Literature

39results about How to "Torque controllable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

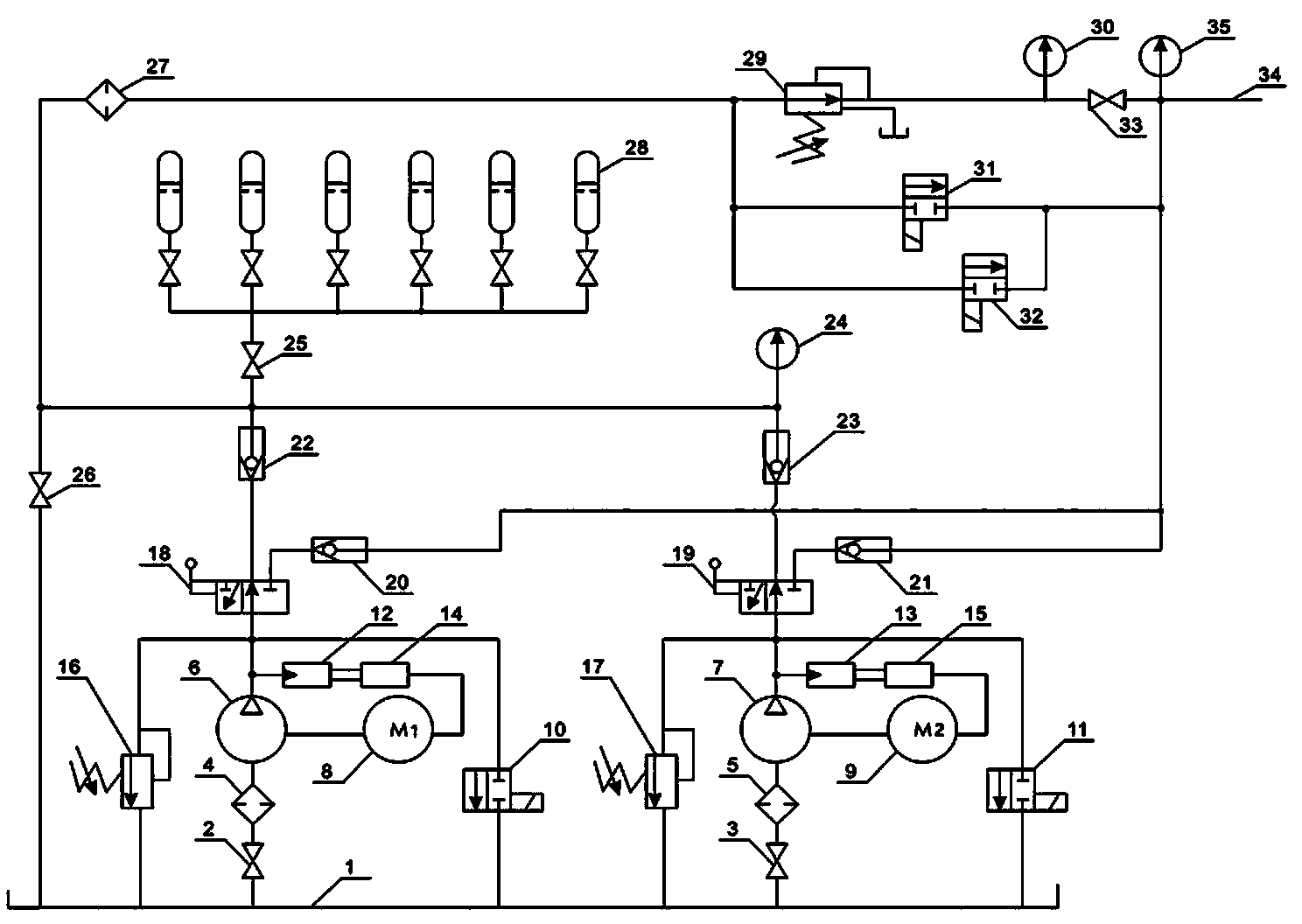

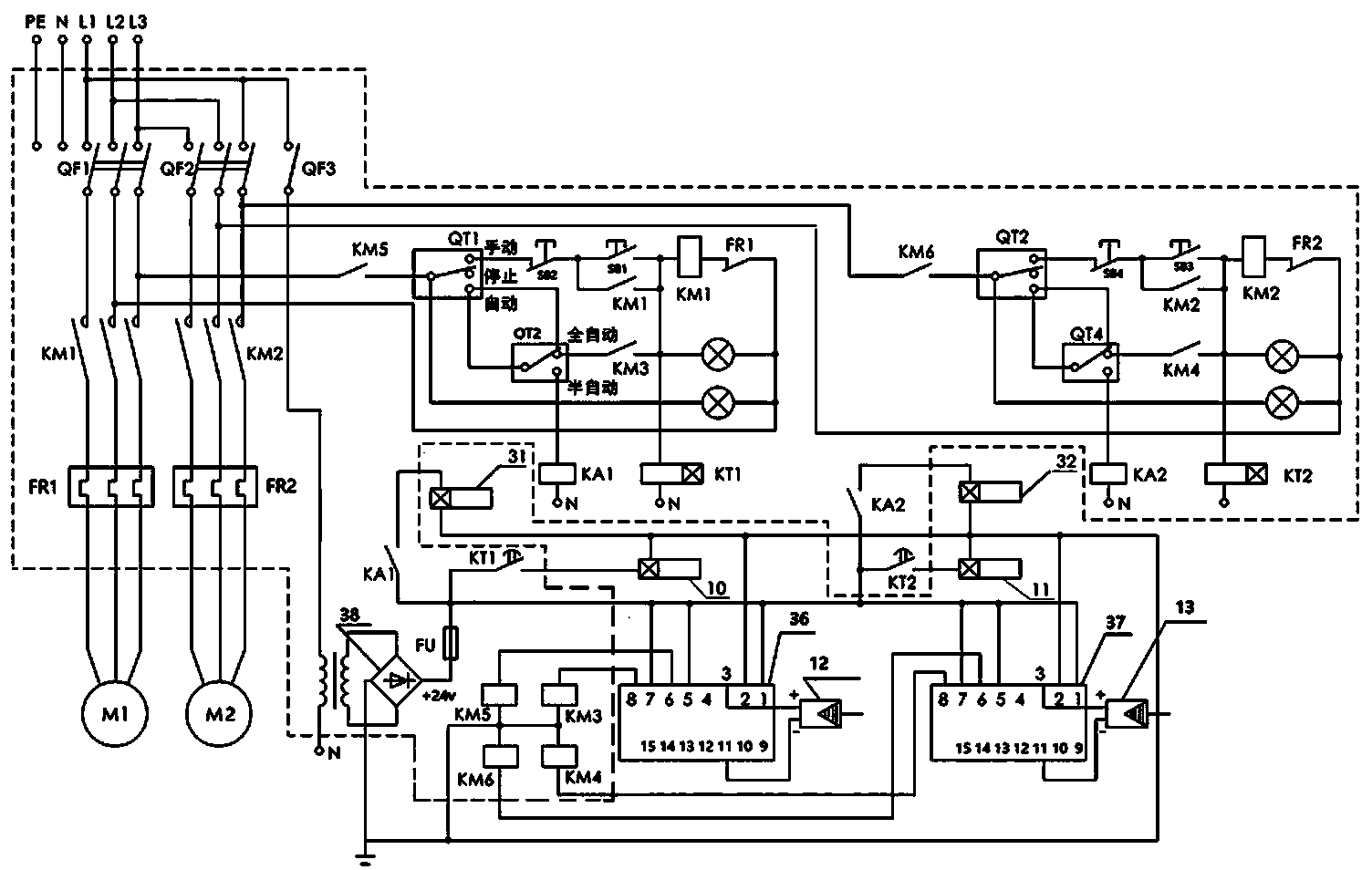

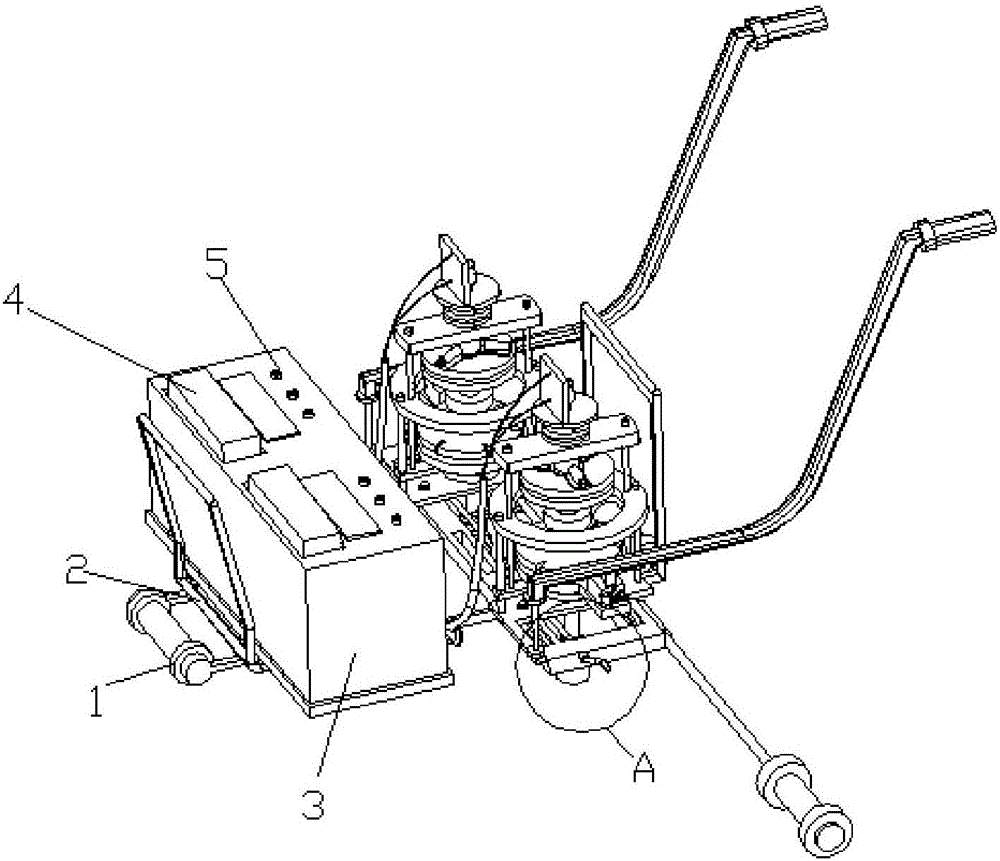

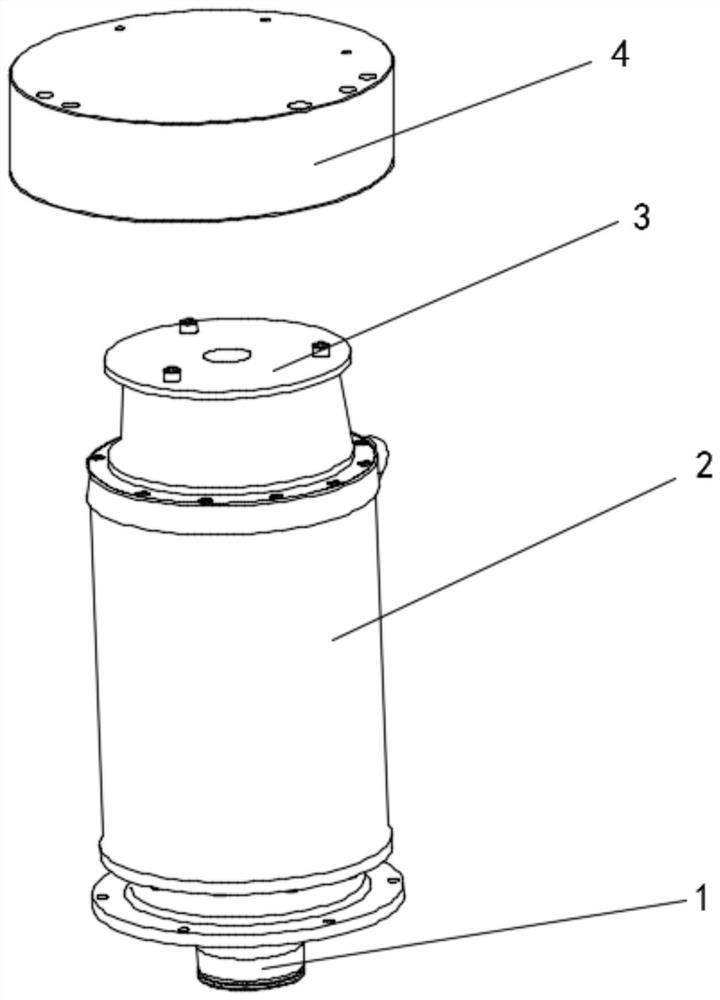

Multifunctional hydraulic power station

ActiveCN104389827ALower skill requirementsRelieve stressServomotorsEnergy industryAutomatic controlPower station

The invention relates to a multifunctional hydraulic power station, which mainly consists of two pump groups, an electric cabinet, a hand-operated direction valve, a check valve, an overflow valve, an energy accumulator, a manual pressure-reduction pressure-regulation overflow valve, a normally-closed solenoid valve, a normally-opened solenoid valve, a stop valve, a high-pressure oil output end and an automatic control device. On the basis that the hydraulic power station has an original function, the defects and the deficiencies of an original hydraulic power station are overcome, and functions, such as free regulation of oil pressure, optimal torque control, energy saving and accumulation, multifunctional changeover, no-load time delay startup and automatic control, which are provided for a load, are increased. The multifunctional hydraulic power station is simple in operating, saves electric energy by more than 50%, can provide hydraulic power for various petroleum drilling tools, is also suitable for other industries to provide hydraulic power for hydraulic tools by taking high-pressure hydraulic oil as mediums, and can achieve the effects of energy saving, energy accumulation and controllable torque.

Owner:范清云 +1

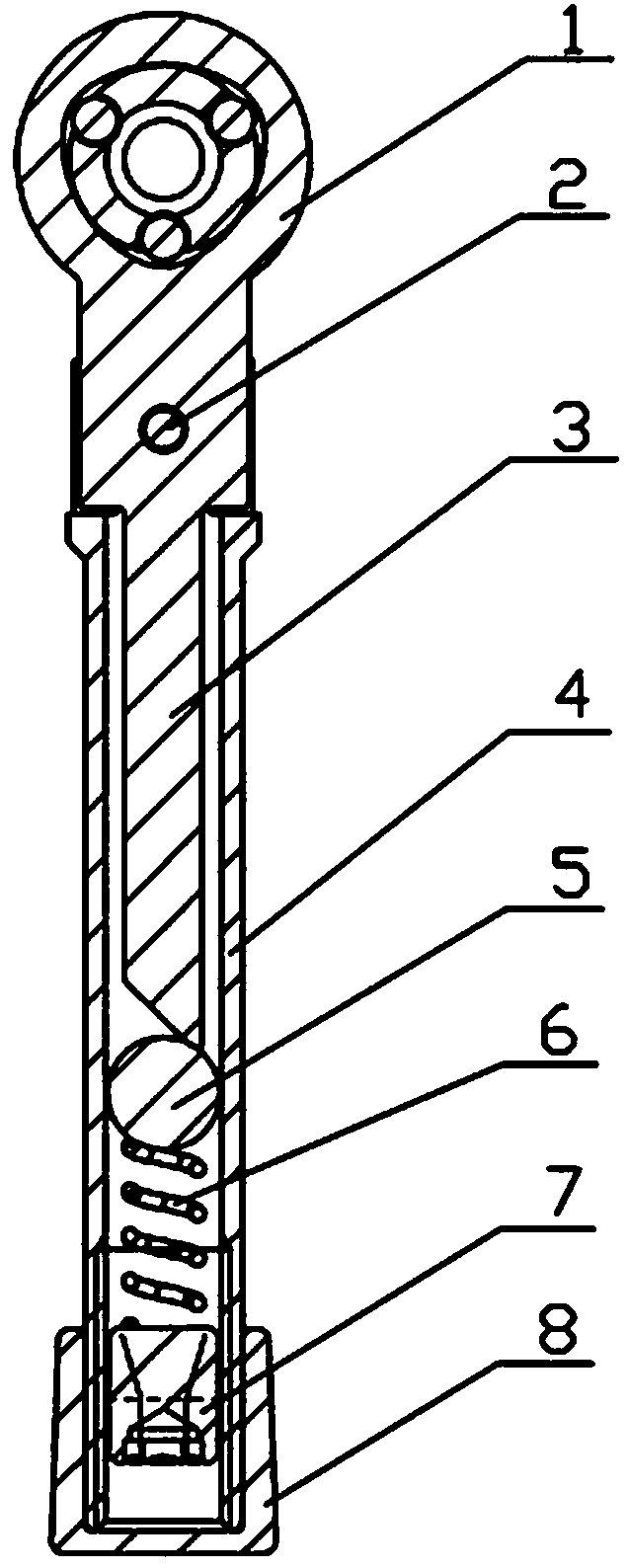

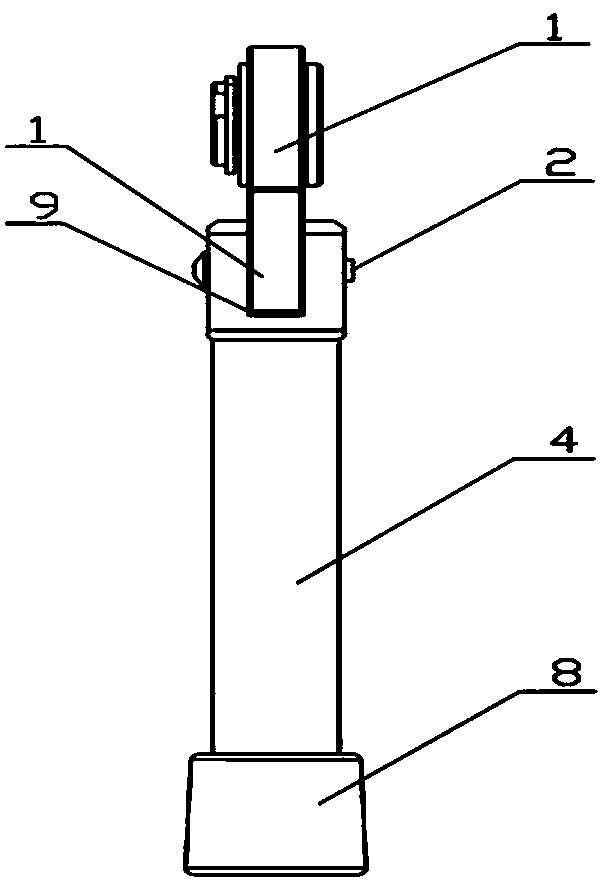

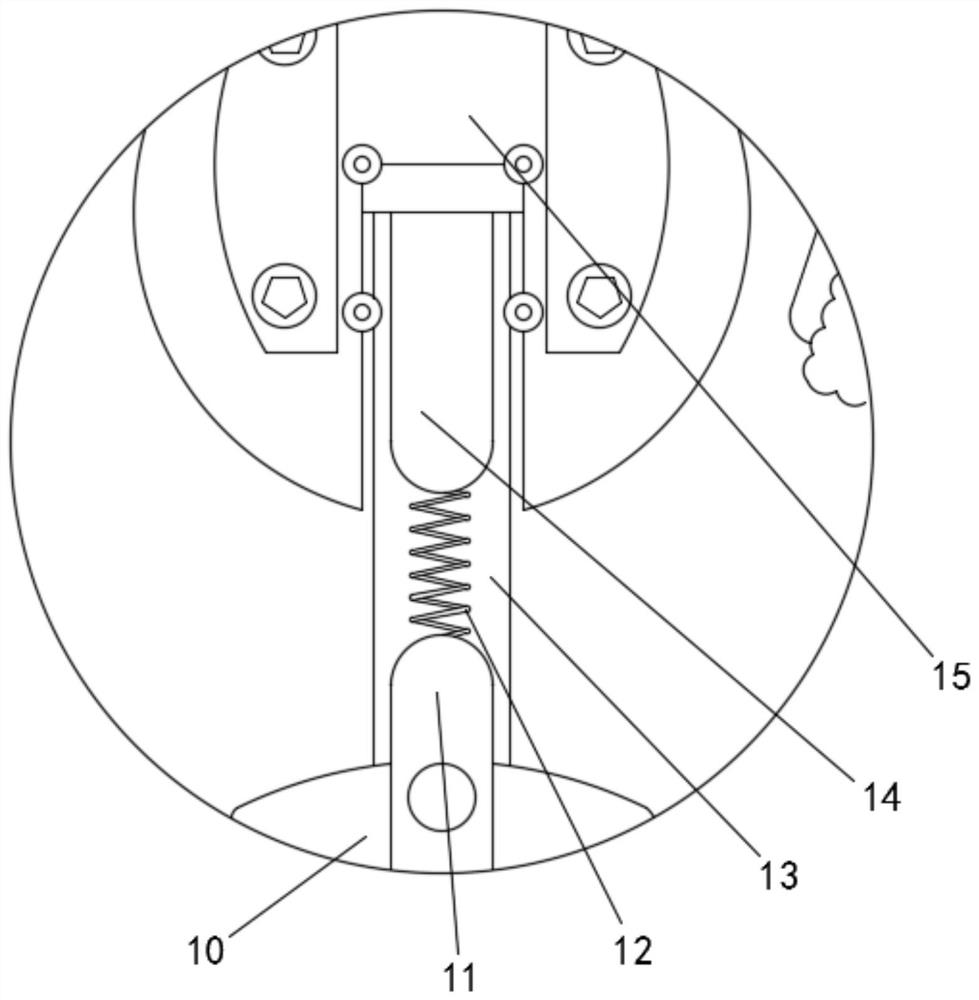

Torque spanner

Disclosed is a torque spanner. The torque spanner comprises a spanner end, a spanner bar and a stress application loop bar. The stress application loop bar refers to a hollowed shell, and a connectinggroove is formed in the upper end of the stress application loop bar. The spanner end and the spanner bar are of an integrated structure. A boss is arranged at the necking position of the lower end of the spanner end. A connecting groove of the spanner bar abuts against the boss surface of the spanner end. The spanner bar and the stress application loop bar are movably connected together througha rotating shaft. A steel ball and a spring are further arranged inside the stress application loop bar. A diagonal plane is arranged at the lower end of the spanner bar and further abuts against theouter surface of the steel ball. The lower end of the steel ball is connected with the spring, and the lower end of the spring is connected with an adjusting jackscrew. The adjusting jackscrew is in threaded connection with the inner wall of the lower end of the stress application loop bar. The torque spanner is simple in structure, a nut can stretch into a bayonet inside the spanner end in the using process, the stress application loop bar is twisted, the steel ball can touch the inner wall of the stress application loop bar and a clear alarm can be raised when a set torque value is reached,vibrations can be felt on the stress application loop bar, and locking can be stopped at the moment. Operation is convenient, time and labor are saved and the torque can be adjusted.

Owner:山东乐乐机械有限公司

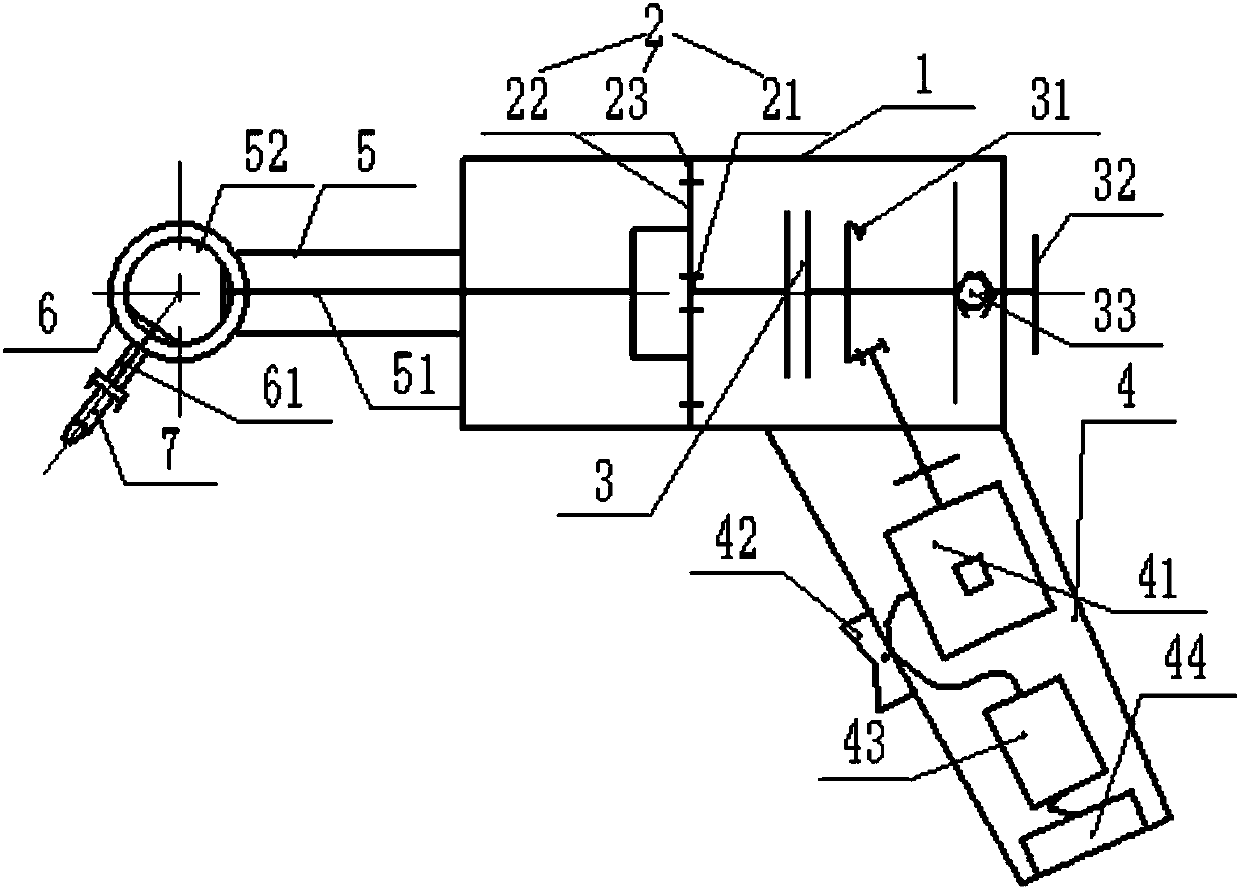

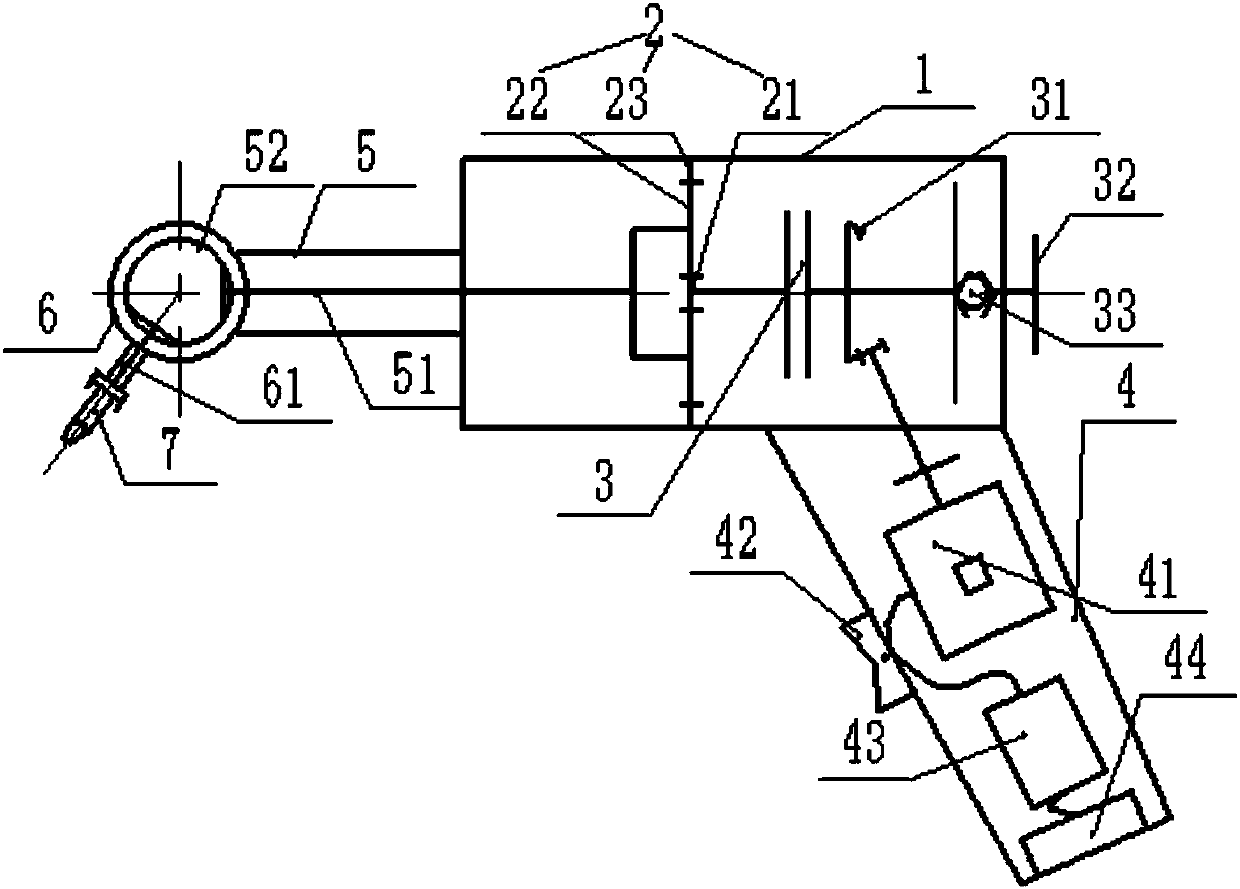

Reduction gear and control method thereof

InactiveCN101875199ALow costHigh precisionComputer controlSingle motor speed/torque controlLocation detectionCoupling

The invention relates to a reduction gear and a control method thereof. The reduction gear comprises a servo motor and a reducing mechanism connected with the servo motor, the reducing mechanism comprises a driving part and a driven part mutually matched, and the servo motor is connected with the driving part through a coupler. The driving part and the driven part are matched to input the power of the servo motor and output the power after reduction. An input shaft of the servo motor and an output shaft of the reducing mechanism are respectively provided with a first detecting device and a second detecting device, the first detecting device and the second detecting device input signals to a servo controller, the servo controller controls the servo motor to drive the reducing mechanism so as to input the power of the servo motor and output the power after reduction. The reduction gear has low cost, high control precision and quick response; the torque and the rotating speed are controllable; networked and integrated control is conveniently realized; and instructions of a main controller can be received, and the operation of a mechanical arm is controlled in a closed loop mode.

Owner:杭州中科赛思伺服电机有限公司

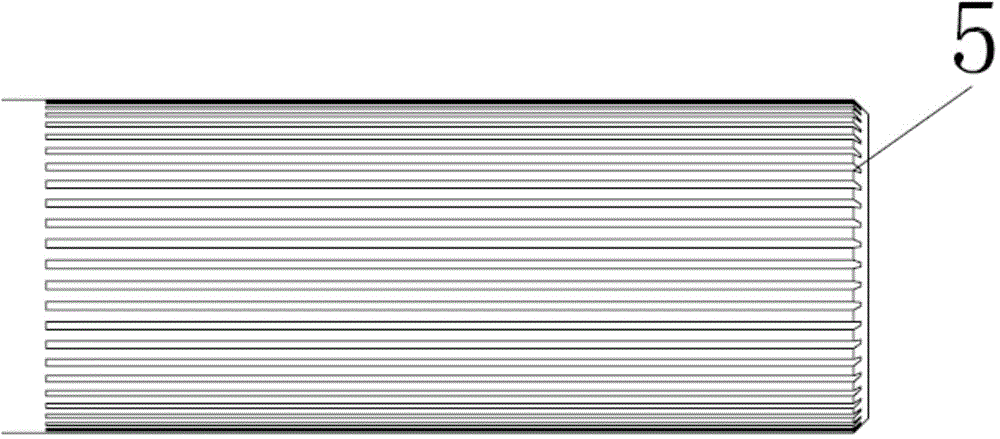

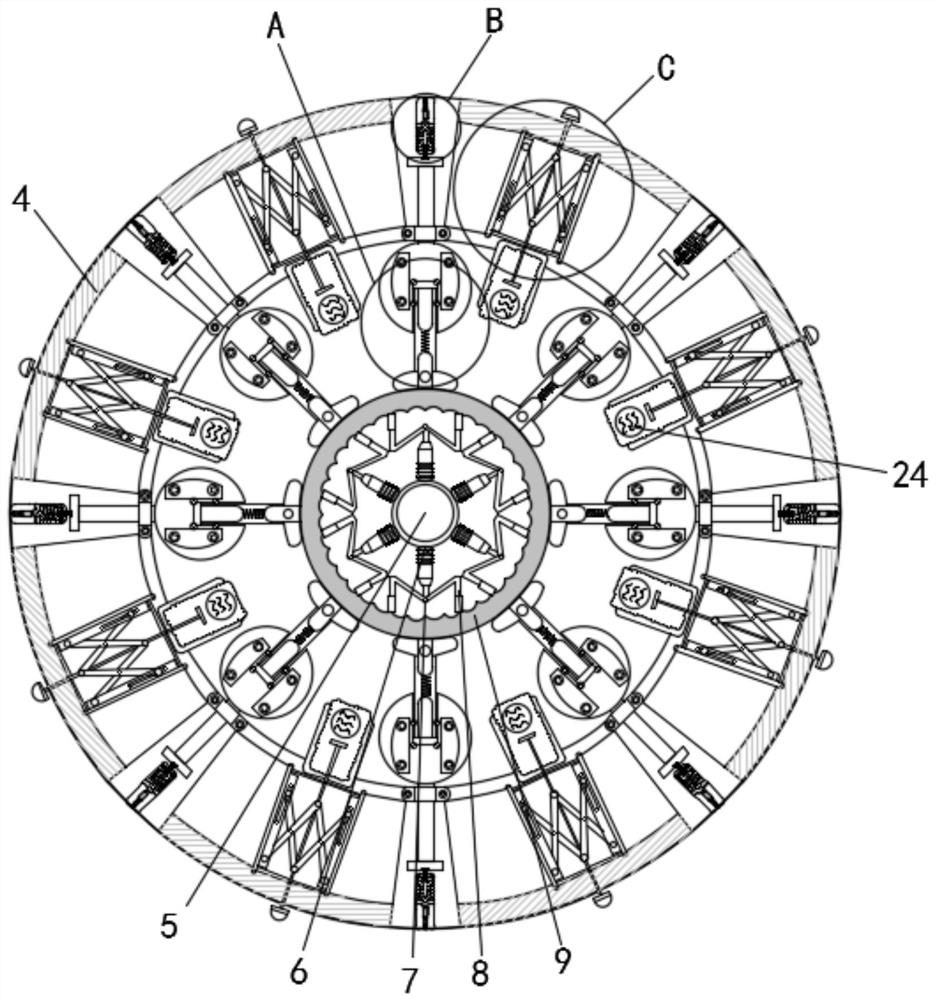

Self-centering type torque adjusting wire winding device

ActiveCN106744002ATorque controllableReasonable and effective adjustment structureFilament handlingEngineeringConductor Coil

Owner:内蒙航天动力机械测试所

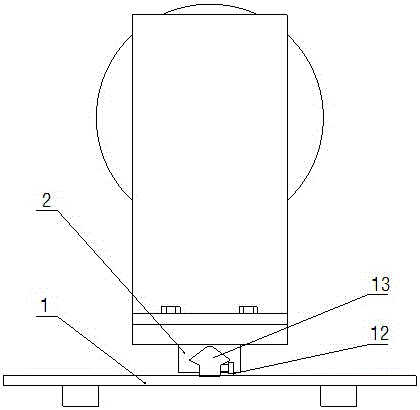

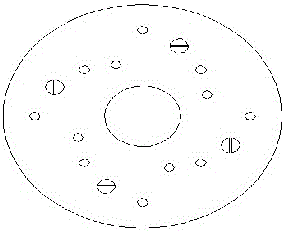

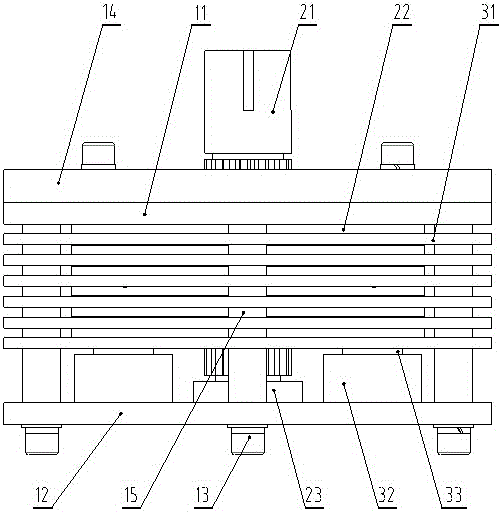

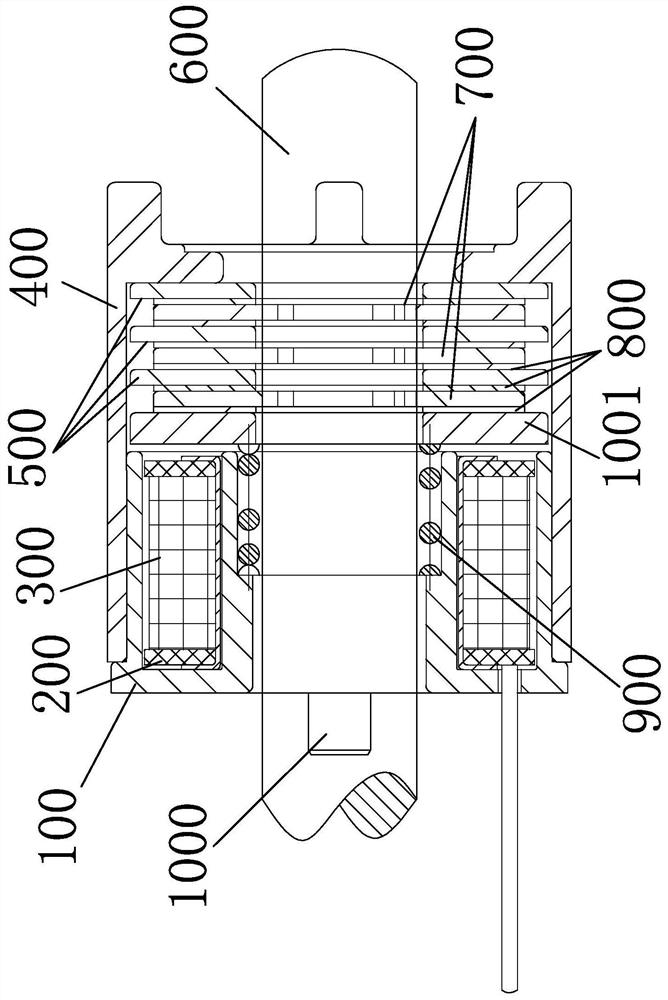

Testing apparatus for service life of load of valve execution mechanism and using method thereof

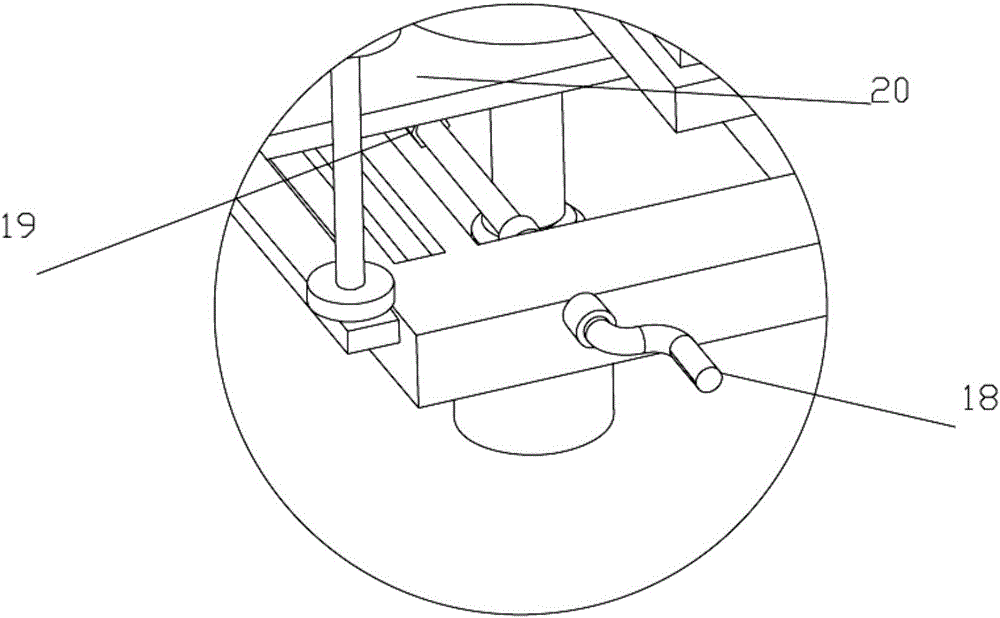

The invention provides a testing apparatus for a service life of a load of a valve execution mechanism and a using method thereof. The testing apparatus comprises a rack, a rotating mechanism and a loading mechanism. The rack is supported between a top plate and a bottom plate by support posts. A testing plate covers the top plate. Rotating shafts are installed in bearings between the top plate and the bottom plate and the upper ends of the rotating shafts pass out of the top plate and a mounting plate. More than one rotating plate is installed on the rotating shafts horizontally and rotates with the rotating shafts. The loading mechanism includes friction plates and hydraulic systems; through holes are formed in the friction plates and the friction plates sleeve the support posts through the through holes. One friction plate is arranged below each rotating plate; and the friction plates are separated by sleeving rings arranged on the support posts. The hydraulic systems are installed on the bottom plate and mandrils of the hydraulic systems support the bottom friction plates; under pushing of the mandrils, upward contact with the rotating plates is realized and the last friction plate is pushed upwardly by the sleeving ring and is in contact with the rotating plate arranged on the friction plate; and the rotating plates and the friction plates in close contact with the rotating plates respectively generate friction and the friction forces are transformed into torques by the rotating shafts, thereby realizing testing of the service life of the load of the valve execution mechanism.

Owner:TEFULONG SHANGHAI TECH CO LTD

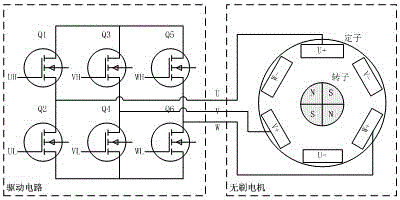

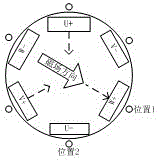

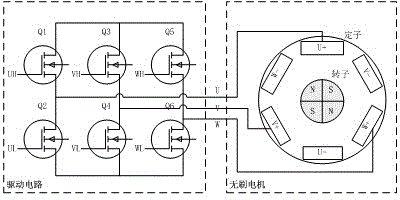

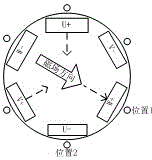

Brushless direct-current motor for single-step motion of automobile gear selector

InactiveCN104660125AHigh precisionHigh control precisionDC motor speed/torque controlBrushless motorsElectric machine

The invention relates to a brushless direct-current motor for single-step motion of an automobile gear selector. The brushless direct-current motor comprises a driving circuit and a brushless motor, and is characterized in that the brushless motor consists of a stator and a rotor, the stator is a coil winding, the U, V and W phases of the stator are fixedly connected with the shell of the motor to form a circuit, and the rotor consists of a permanent magnet; a magnetic field is formed in the motor by supplying power for the U, V and W phases, the direction of the magnetic field constantly changes, and the rotor can rotate under the effect of the magnetic field; the position of the magnet is detected and the voltages of the U, V and W phases of the motor are controlled through the Hall sensor so as to control single-step rotation of the motor; the motor rotates in a single step, and works in a three-phase self-locking mode or a two-phase self-locking mode. The brushless direct-current motor has the advantages of high precision, adjustable torque and convenience in control.

Owner:SHANXI GUOLI INFORMATION TECH

Mechanical torque-adjustable screwdriver

InactiveCN104162866ATo achieve the purpose of fastening screwsTorque controllableSpannersWrenchesEngineeringMechanical engineering

The invention relates to the field of auxiliary tools, in particular to a mechanical torque-adjustable screwdriver. The mechanical torque-adjustable screwdriver comprises a U-shaped hollow handle and a screwdriver rod sleeve, the screwdriver rod sleeve is connected to a screwdriver rod in a sleeved mode, the screwdriver rod penetrates through an adjusting nut and an adjusting screw rod and is connected with a lower ratchet wheel, an upper ratchet wheel matched with the lower ratchet wheel is connected with the handle through a planar roller bearing, and a spring is arranged between the adjusting screw rod and the lower ratchet wheel. According to the mechanical torque-adjustable screwdriver, torque is applied to the lower ratchet wheel through the handle, the helicoidal surface of the lower ratchet wheel and the helicoidal surface of the upper ratchet wheel are meshed to drive the upper ratchet wheel, the upper ratchet wheel is in rigid connection with the screwdriver rod through a rectangular hole, so that the screwdriver rod is driven by the upper ratchet wheel to rotate, the purpose of fastening screws is achieved, and the torque is adjustable.

Owner:SHAANXI ALLIANCE LOGISTICS

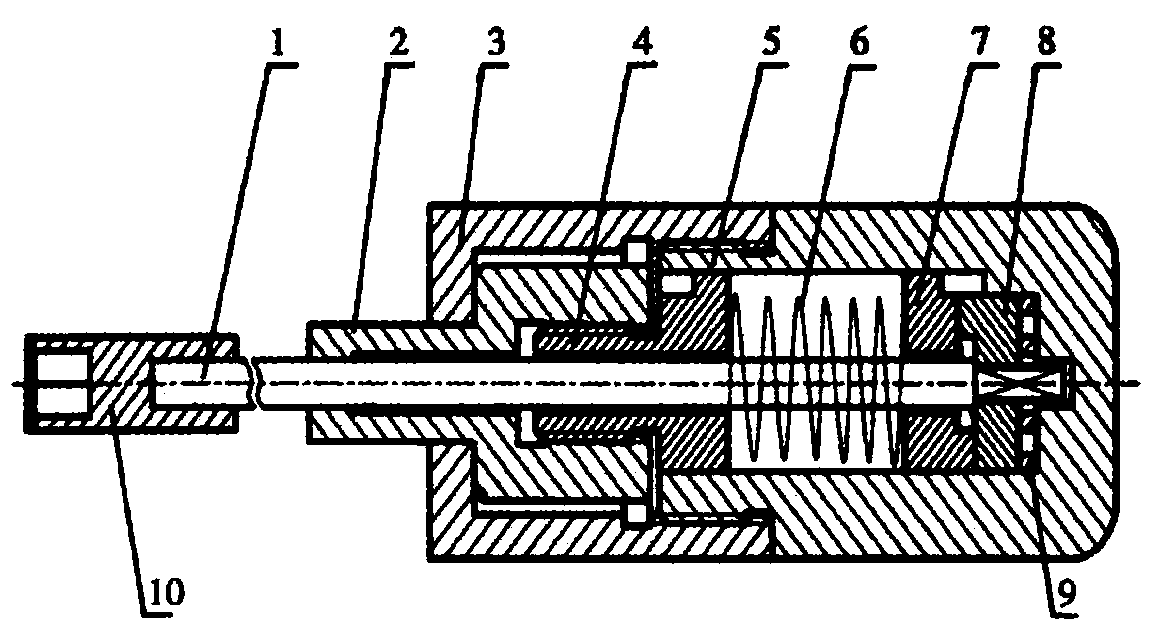

Embedded hinge for automobile headrest and armrest and manufacturing method thereof

ActiveCN104527477APrevent outflowSimple structureArm restsPivotal connectionsEmbedded systemPoint contact

The invention relates to an embedded hinge for an automobile headrest and an armrest and a manufacturing method of the embedded hinge. The embedded hinge is that the middle part of a main shaft (3) is smooth; a plurality of frictional plates (4) which are closely arranged in parallel sleeve the outer side of the smooth part; the main shaft (3) transversely passes through a housing (1); the frictional plates (4) are positioned in the housing (1) and connected with the inner sidewall of the housing (1), wherein the frictional plates (4) are in point contact connection with the main shaft (3) and rotate opposite to the main shaft (3); the housing (1) is full of lubricating oil, and end covers (3) are mounted at two ends of the housing (1) by a sealing manner. The embedded hinge has the characteristics of being simple in structure, convenient to manufacture, low in production cost, high in fatigue resisting intensity, and adjustable in torque.

Owner:NINGBO JIFENG AUTO PARTS

Ultra-low speed dynamometer based on ultrasonic antifriction principle

InactiveCN109029807ASolve the peristalsisFix stability issuesWork measurementTorque measurementMotor speedLow speed

The invention discloses an ultra-low speed dynamometer based on an ultrasonic antifriction principle. The ultra-low speed dynamometer includes two parts of a motor speed torque measurement and controlmachine and a torque generator, and the torque generator is fixed on a base of the motor speed torque measurement and control machine. According to the ultra-low speed dynamometer based on the ultrasonic antifriction principle, sinusoidal waves of different frequencies can be applied to a single phase according to an ultrasonic antifriction phenomenon of a traveling wave type ultrasonic motor, and adjustable torque can be obtained by measuring a motor; and the defects of creep performance, load instability and inaccurate measurement data generated by dynamometers in market when the motor speed is lower than a certain value are overcame so that stable and adjustable torque can be obtained in the motor low speed operation process.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

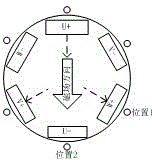

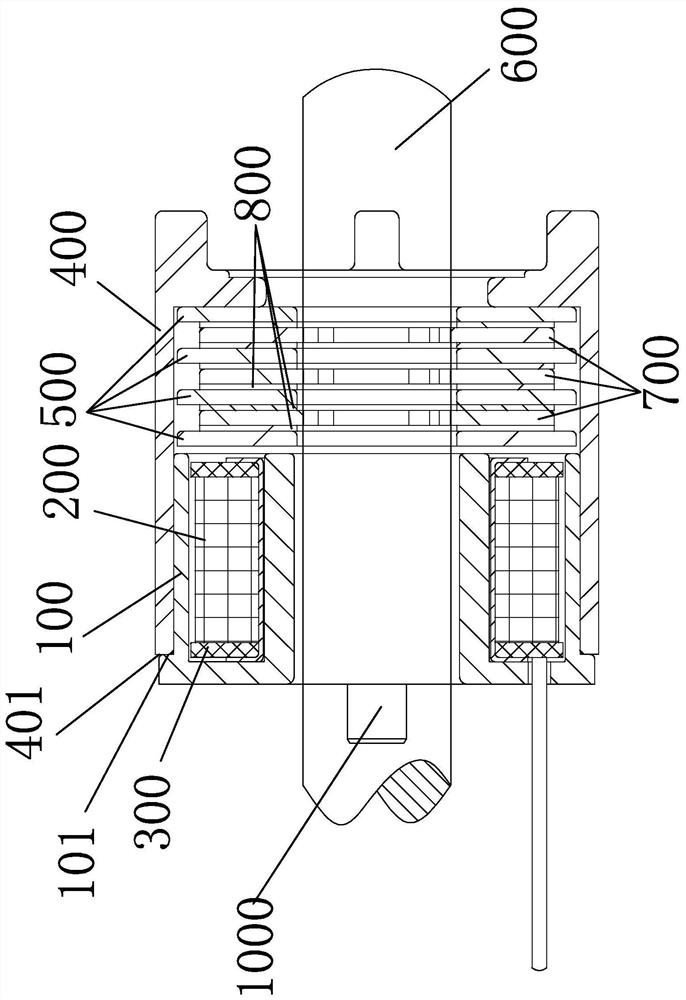

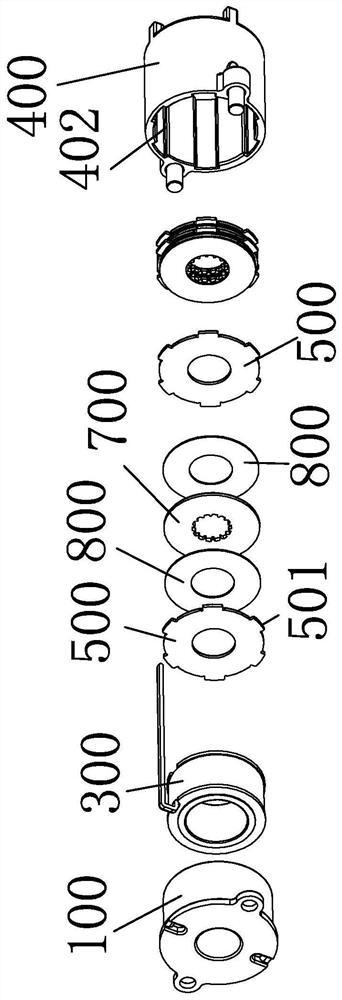

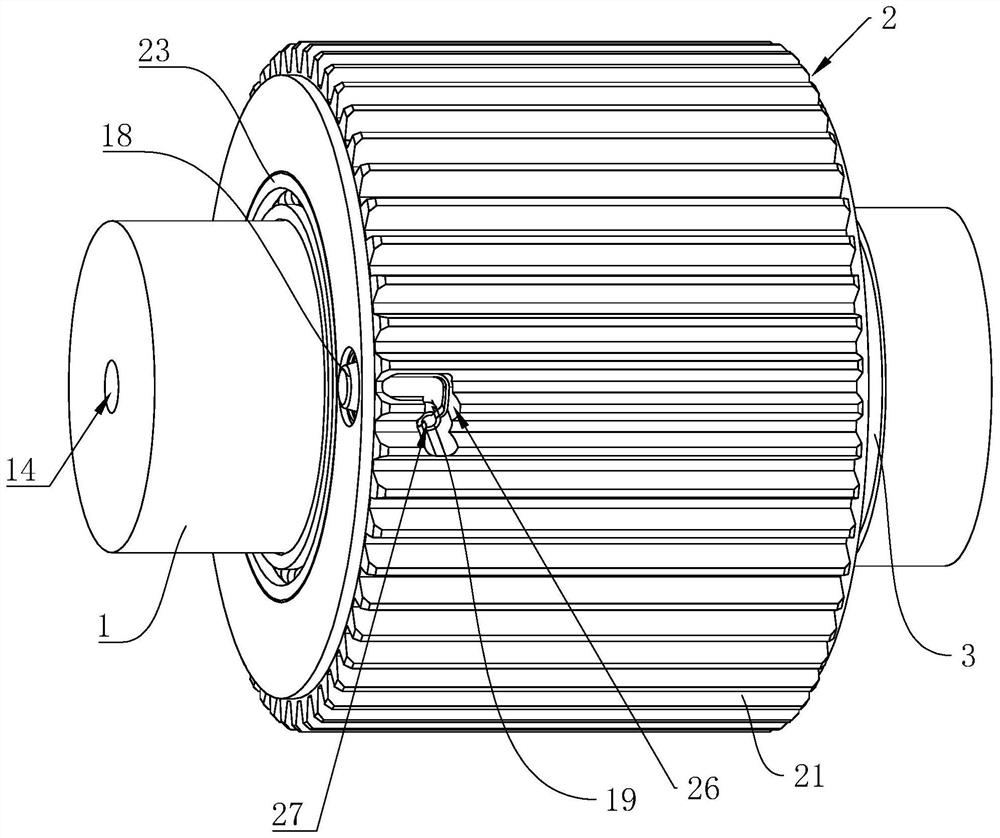

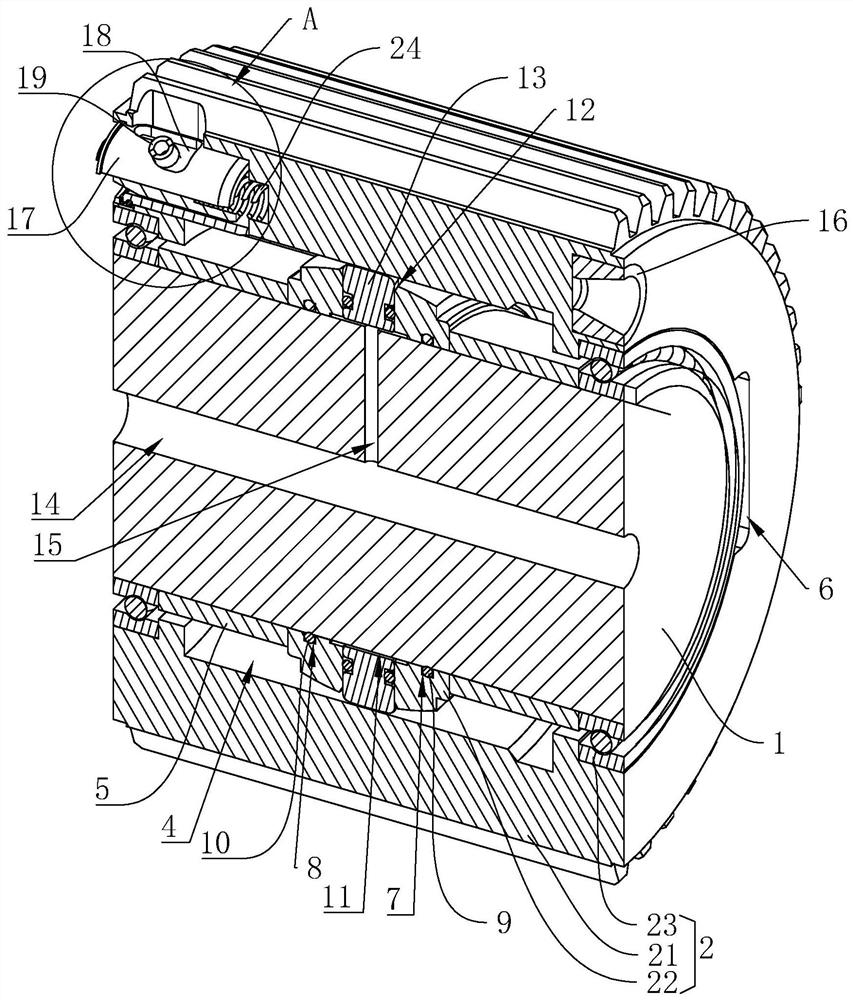

Electric supporting rod electromagnetic brake

PendingCN113187833ASmall form factorTorque controllableMechanically actuated brakesPower-operated mechanismBrake torqueInternal resistance

The invention belongs to the technical field of electric supporting rods, and provides an electric supporting rod electromagnetic brake. The electric supporting rod electromagnetic brake comprises a stator, a coil, a coil frame, a shell, an armature pressing sheet, a friction assembly and a spline shaft, wherein the coil is wound on the coil frame to form a coil assembly and assembled in the stator, the armature pressing sheet and the friction assembly are assembled in the shell and located on the right part of the stator, and the spline shaft transversely penetrates through the stator, the armature pressing sheet and the friction assembly and is connected with the friction assembly through a spline. The electric supporting rod electromagnetic brake has the advantages that the brake torque can be adjusted according to different working conditions and different voltages output by an ECU; it is ensured that the internal resistance in an electric supporting rod / a driving mechanism is adjustable, and the functions of electric / manual opening and closing, hovering and the like of a vehicle door under the various working conditions are met when the electric supporting rod / driving mechanism is assembled on the whole vehicle; when the brake works, the brake adjustment is rapid, the response is fast, and the noise is low during operation; the mechanism is small in boundary dimension, small in occupied space and capable of meeting the assembly requirements of different occasions.

Owner:NINGBO XINTAI MACHINERY

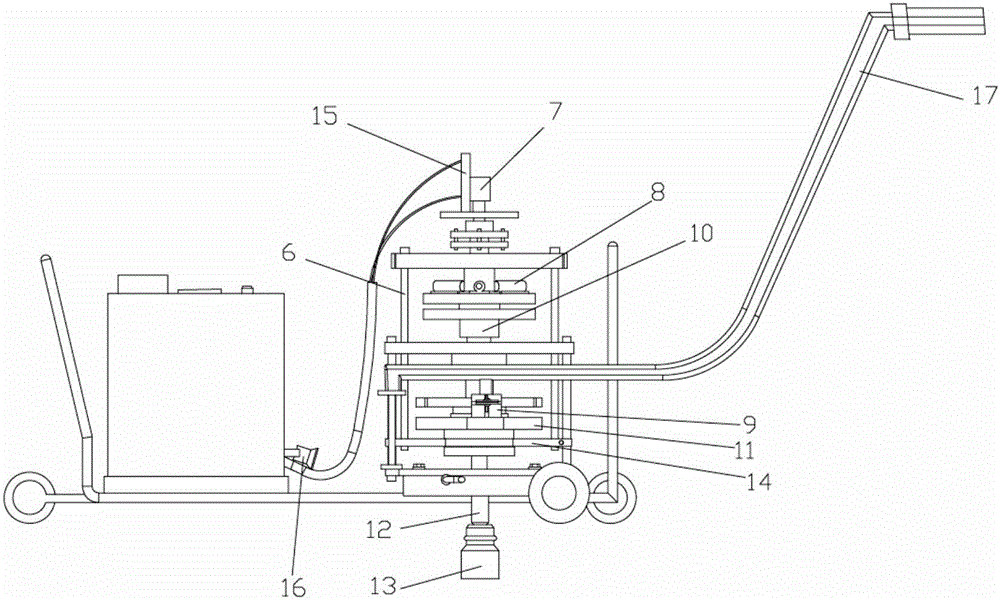

Numerical control constant torque vertical bolt wrench

InactiveCN106801367ATorque controllableEasy to operate on siteRailway track constructionNumerical controlDrive shaft

The invention provides a numerical control constant torque vertical bolt wrench which comprises travel wheels, a travel frame, a power supply device, a driving frame and two wrench bodies. The travel wheels are mounted at two ends of the travel frame, the power supply device and the driving frame are respectively mounted on the travel frame, and the two wrench bodies are respectively mounted on the movable driving frame and comprise support frames, motors, clutches, torque switches, drivers, torque sensors, transmission shafts and working sleeves. Torque is easily controlled, on-site operation is convenient, too low torque or too high torque is avoided, the double sleeves independently work, a single sleeve of the double sleeve can work as required, and the numerical control constant torque vertical bolt wrench is adaptable to tightening and loosening operation of various vertical bolts of railway fasteners and turnout junctions.

Owner:宁波永航铁路机电科技有限公司

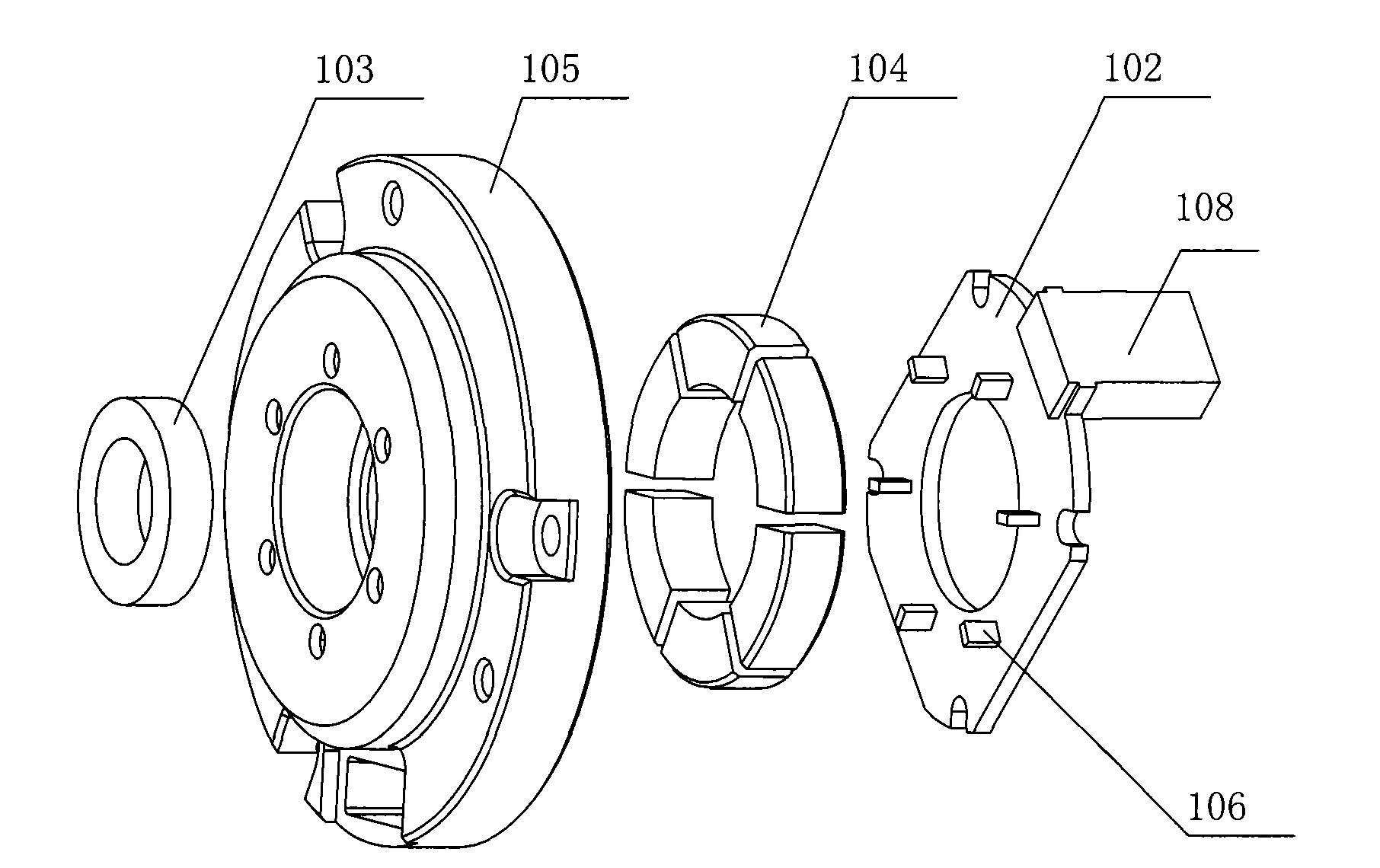

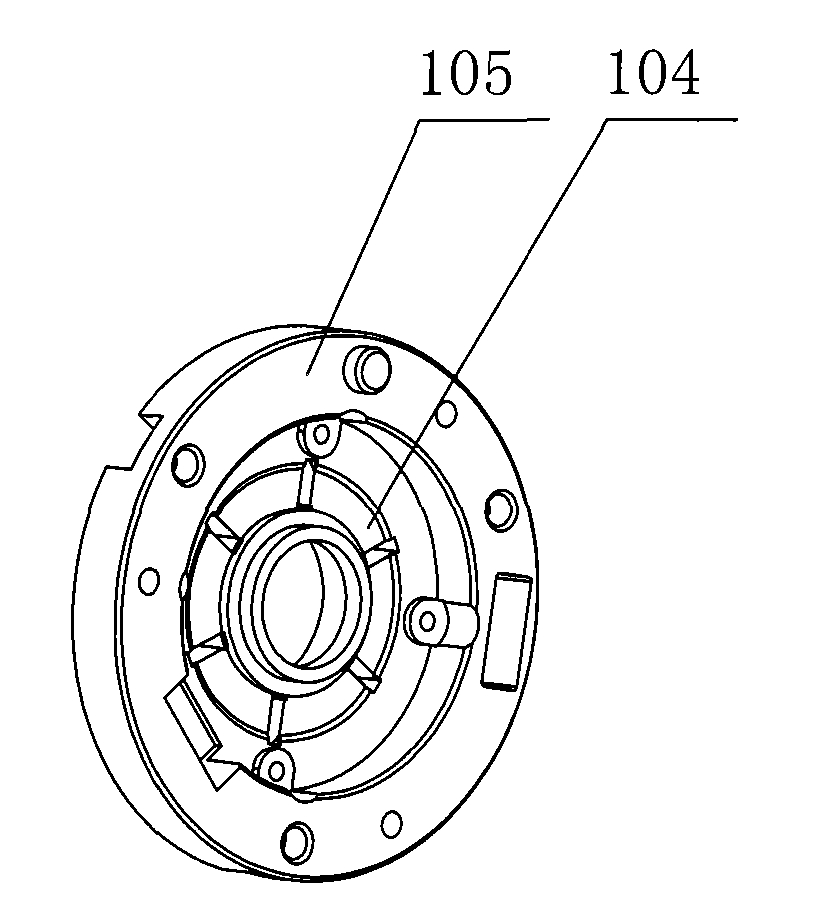

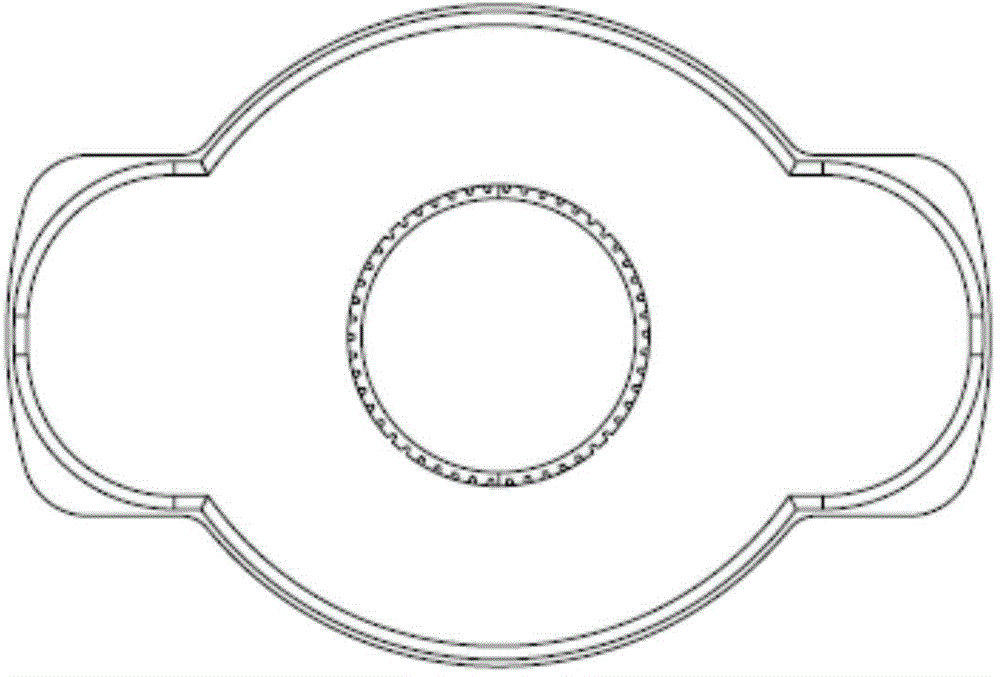

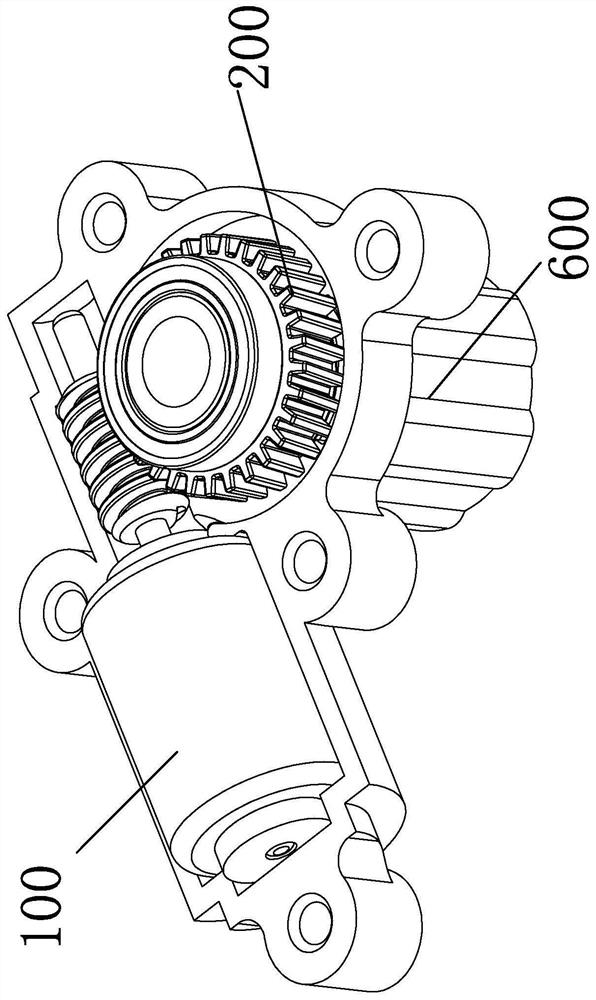

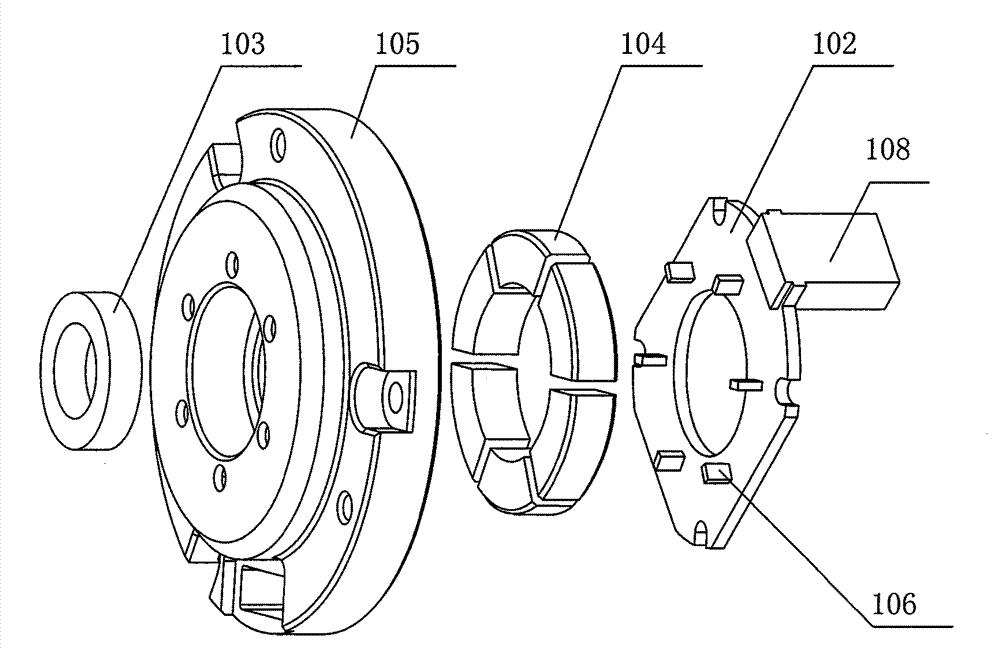

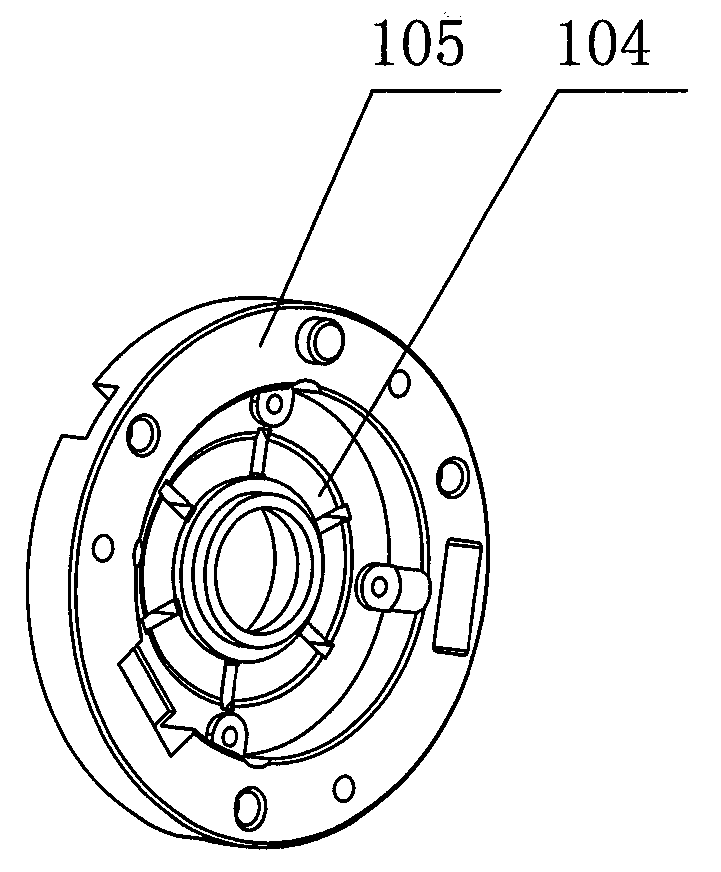

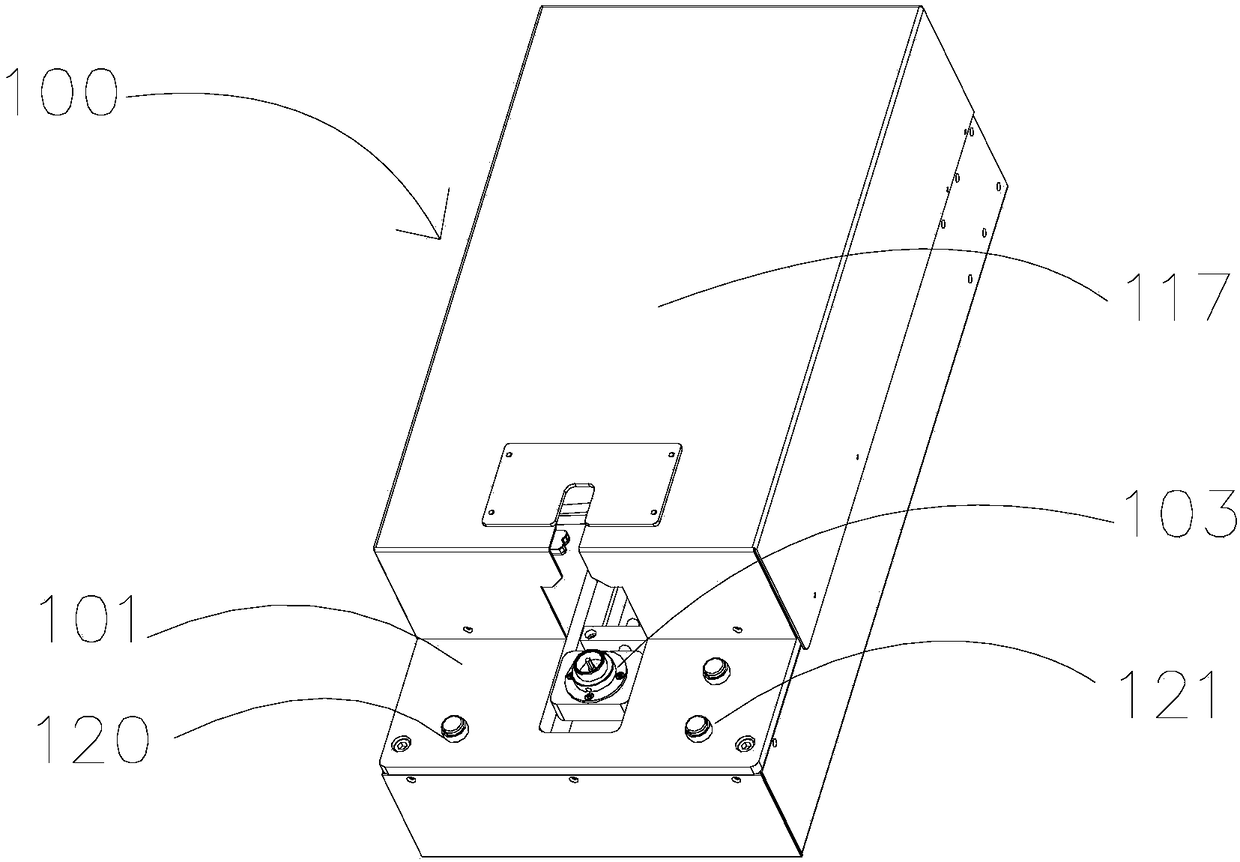

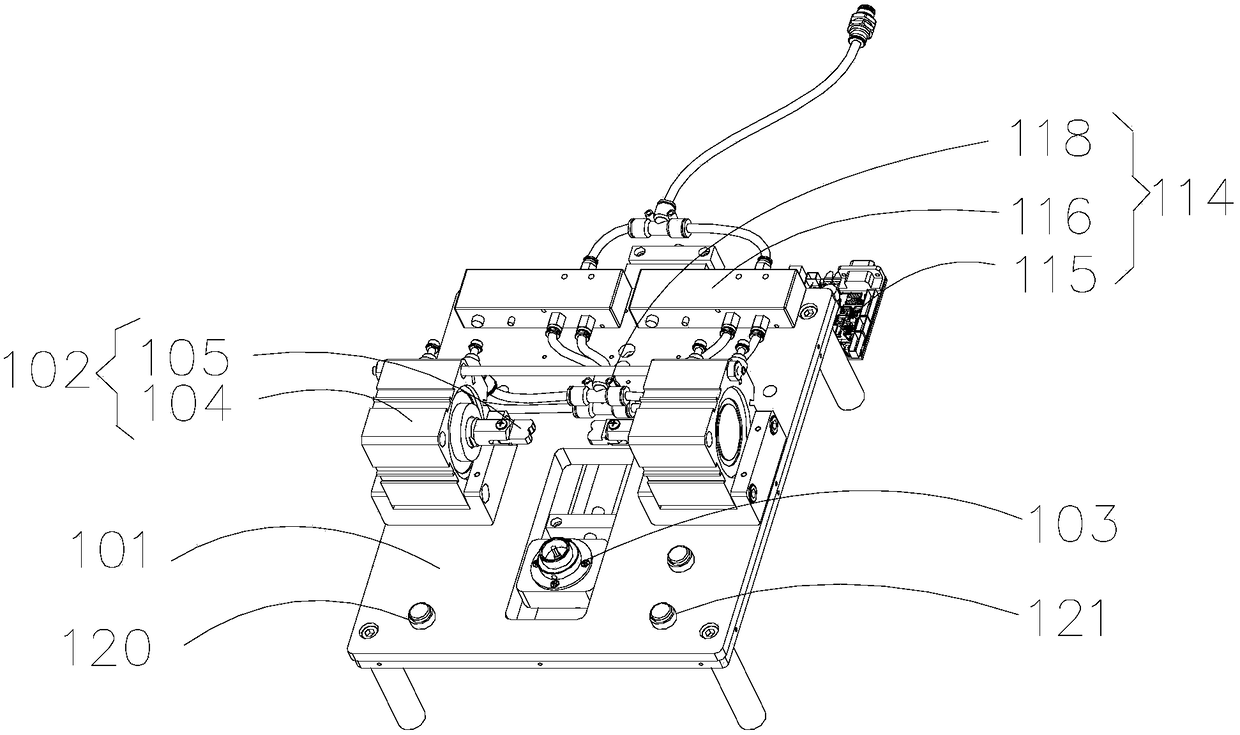

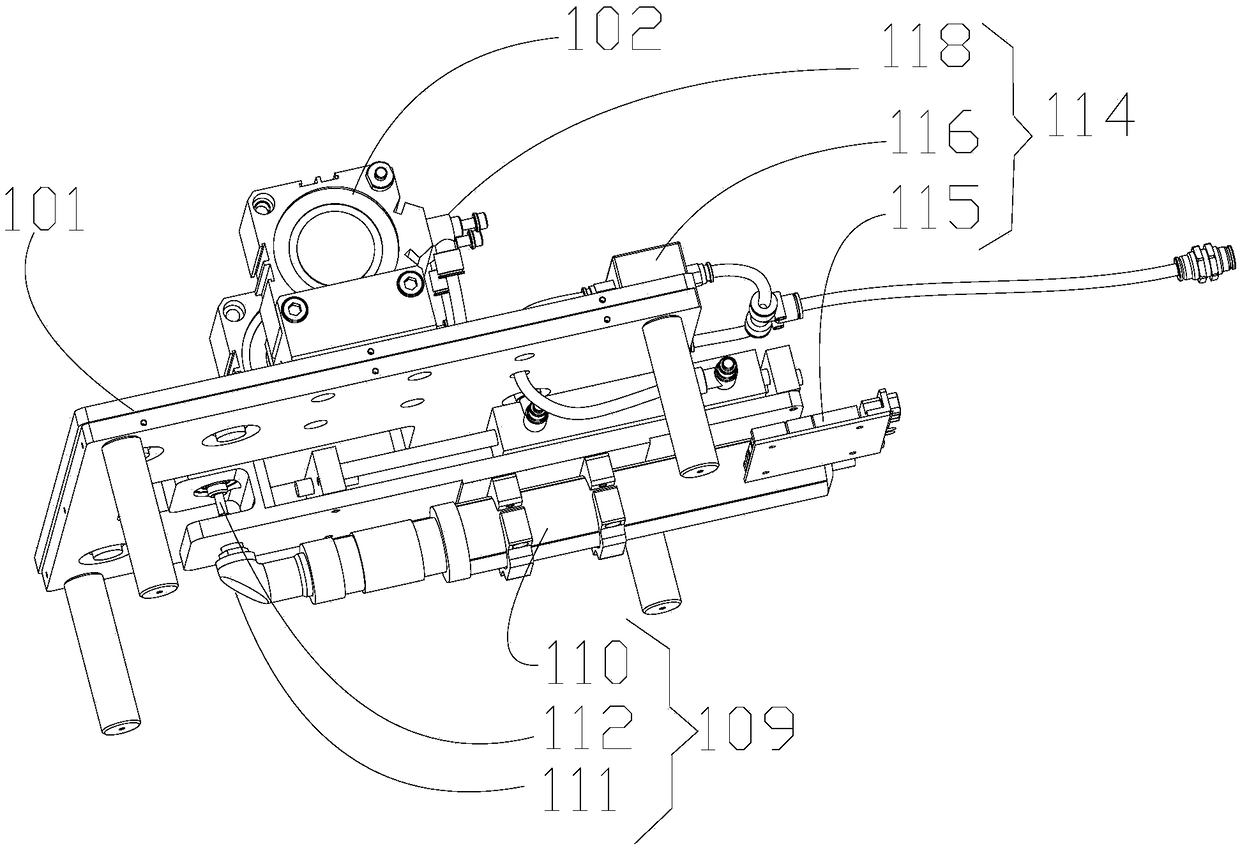

Assembly device for rotational connection

ActiveCN105965243AReduce labor intensityTorque controllableMetal working apparatusEngineeringAutomation

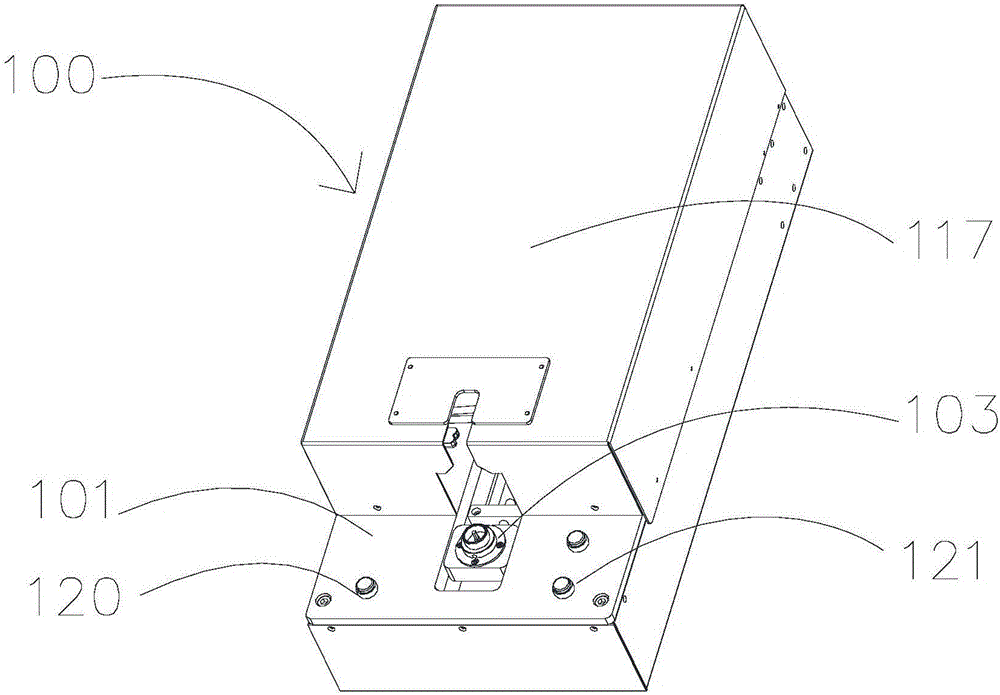

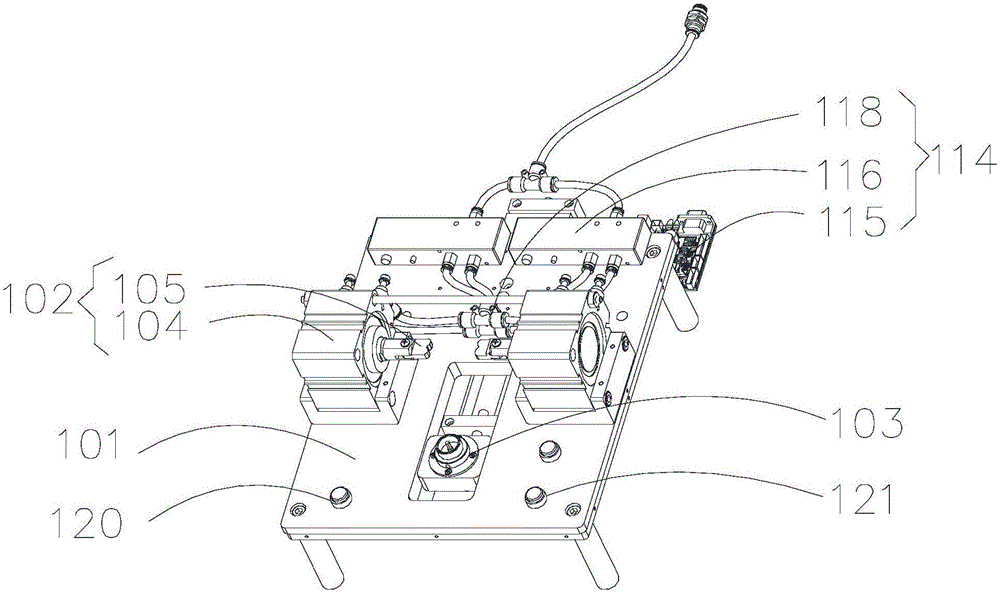

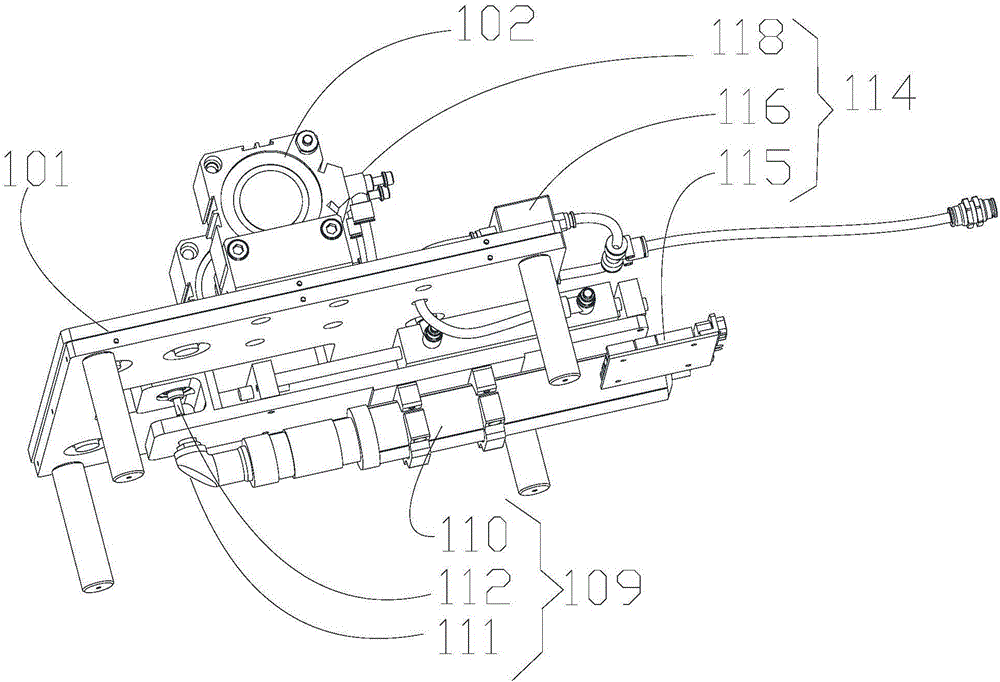

The invention discloses an assembly device (100) for rotational connection. The assembly device for rotational connection is used for realizing rotational connection for a first component and a second component, and comprises a base (101), a clamping component (102) arranged on the base (101) and used for clamping the first component, and a rotating component (103) arranged on the base (101) and used for longitudinally aligning the second component with the first component and tightening the second component on the first component in a rotating manner. The assembly device (100) disclosed by the invention has the characteristics of controllable rotating torque, good product assembly consistency, high automation degree, and high production efficiency.

Owner:COMBA TELECOM TECH (GUANGZHOU) CO LTD

Barrel bottom flange automatic screw fixing equipment

InactiveCN109514244AHigh degree of automationImprove accuracyMetal working apparatusEngineeringFlange

The invention discloses barrel bottom flange automatic screw fixing equipment which comprises an automatic tightening unit, a rotary positioning tool and an automatic screw feeding unit. The automaticscrew feeding unit is composed of a stock bin, a screw screening mechanism, a screw separation mechanism and a screw blowing mechanism. The screw screening mechanism pushes screws in the stock bin toa screw temporary storage track through lifting, multiple sets of air cylinders of the screw separation mechanism are combined with sensor signals to distribute the screws to screw feeding pipelines,the screw blowing mechanism senses screw side blowing to blow the screws to a spray head, the automatic tightening unit is composed of a servo system, a lifting mechanism and tightening mechanism, apressing mechanism drives the tightening mechanism to descend to the preset height, a screwdriver drivers the screws to descend to a given position, and the servo system drives the screwdriver to tighten the screws. The automation degree is high, automatic screw conveying and tightening can be achieved, an air cylinder pushes a screw feeding mechanism to feed screws, operation is economic and simple, the accuracy rate is high, torque is controllable, and compatibility is high.

Owner:徐晃

Method for reinforcing reinforced concrete structure by using prestressed hose clamp

The invention relates to a method for reinforcing a reinforced concrete structure by using a prestressed hose clamp. The method comprises the following specific steps of: 1) arranging prestressed hoseclamps at equal intervals outside the reinforced concrete structure, and pre-tightening hose clamp screws by using a universal hose clamp batch or a straight line; 2) fastening the pre-stressed hoseclamp by using a torque wrench, and setting a fastening torque value as a preset value; 3) considering the deformation of the reinforced concrete structure and the moment attenuation during the installation of the prestressed hose clamp, secondarily fastening the prestressed hose clamp; 4) after fastening is completed, marking with a black marking stroke line; and 5) checking whether the prestressed hose clamp has a thread slipping and loosening phenomenon, and if so, replacing the thread slipping and loosening phenomenon. The adjustable and controllable prestress hose clamp reinforcing method is used in cooperation with the torque wrench, prestress can be accurately applied, prestress loss caused by later-stage steel loosening can be prevented, the overall deformation capacity and the bearing capacity of the reinforced concrete structure are effectively improved, and development of concrete cracks is restrained.

Owner:GUANGXI UNIV

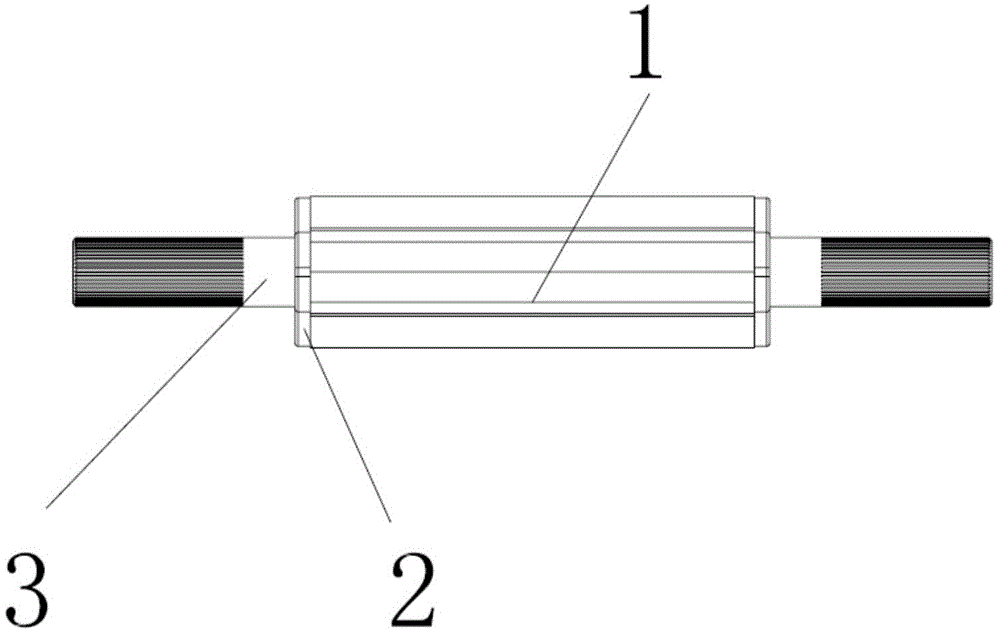

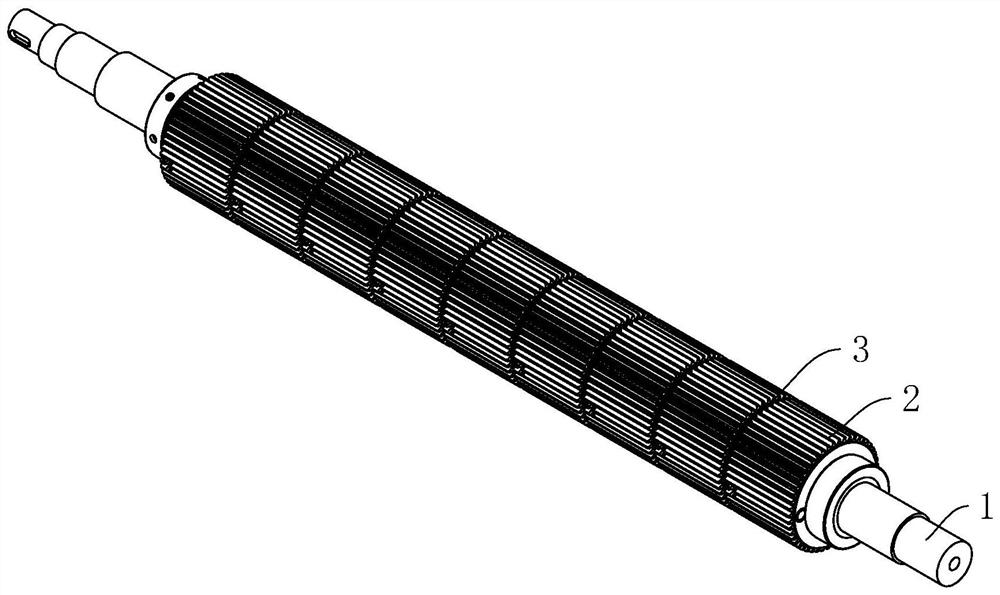

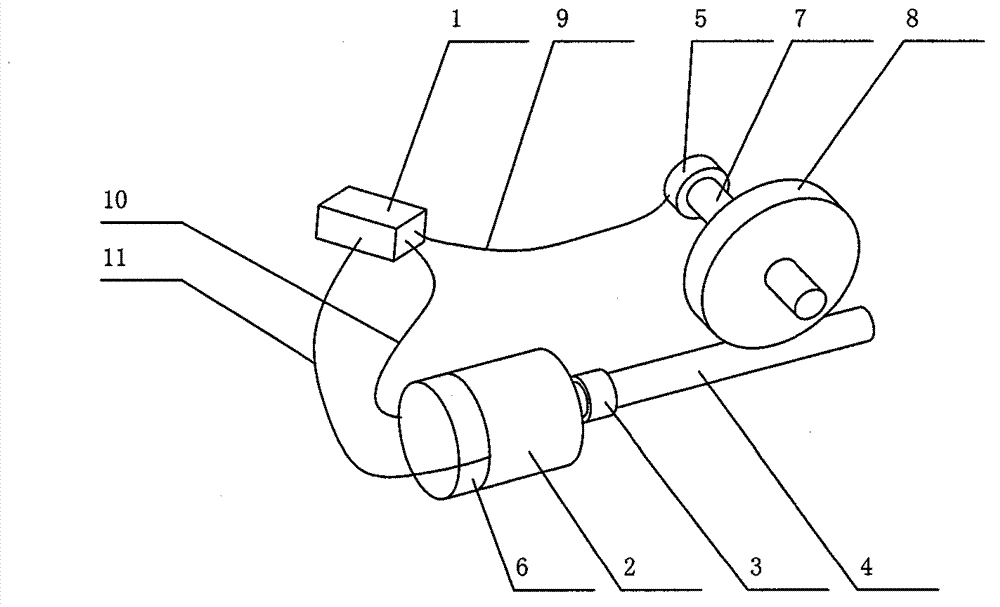

Tension-adjustable slip shaft

The invention relates to a tension-adjustable slip shaft, and relates to the technical field of slip shafts. The slip shaft comprises an air shaft main body and a plurality of slip rings mounted on the air shaft main body, each slip ring comprises a gear ring, a tension ring body and an end face bearing, both the tension ring bodies and the end face bearings sleeve the air shaft main body, the gear rings sleeve the end face bearings, air inlet ring grooves are formed in the inner walls of the tension ring bodies, piston holes are formed in the groove bottoms of the air inlet ring grooves, piston bodies are installed in the piston holes, an intake header pipe is arranged on the air shaft main body, an intake branch pipe is arranged on the side wall of the intake header pipe, a plug-in cylinder body is installed at one end of each gear ring, a fixed sleeve is installed at the other end of each gear ring, plug-in posts are slidably installed in the fixed sleeves, deflector rods are fixedly arranged on the side walls of the plug-in posts, a sliding groove and a limit part are arranged on the side wall of each fixed sleeve, springs are installed in the fixed sleeves, adjustment groovesare formed in the side walls of the gear rings, and the deflector rods are located in the adjustment grooves. The slip shaft has the characteristics of adjustable tension, wide application range and non-replacement.

Owner:上海承秉机械有限公司

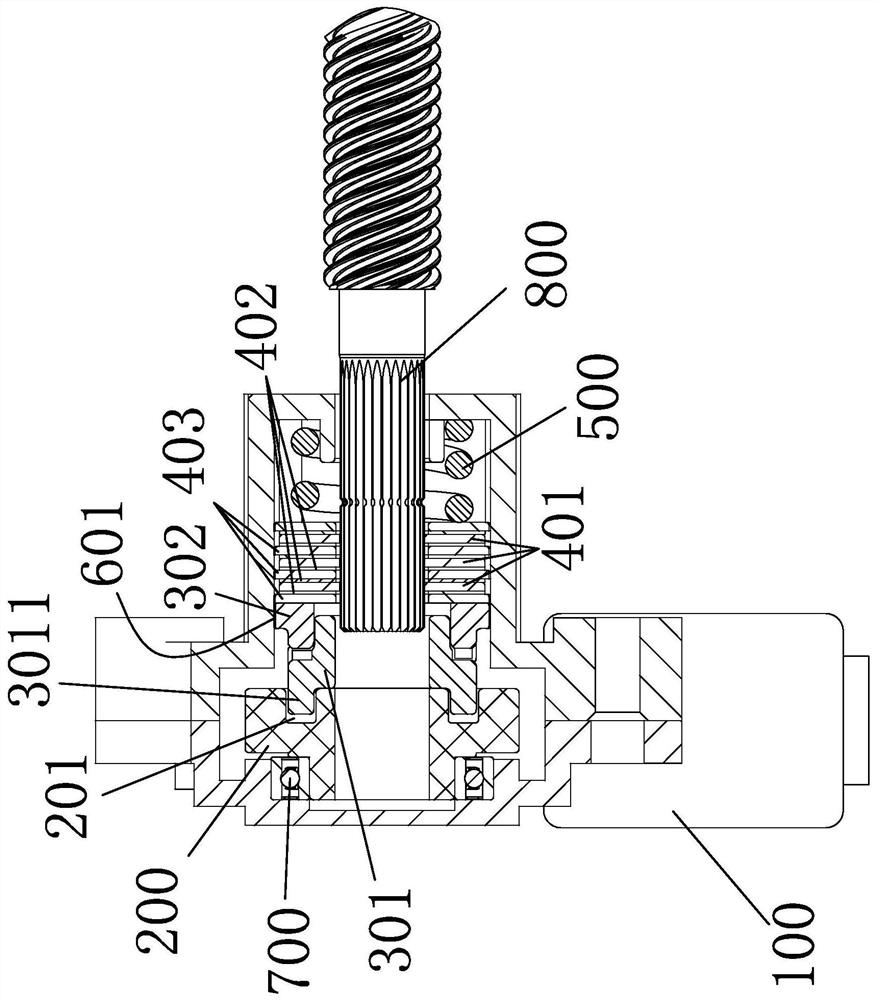

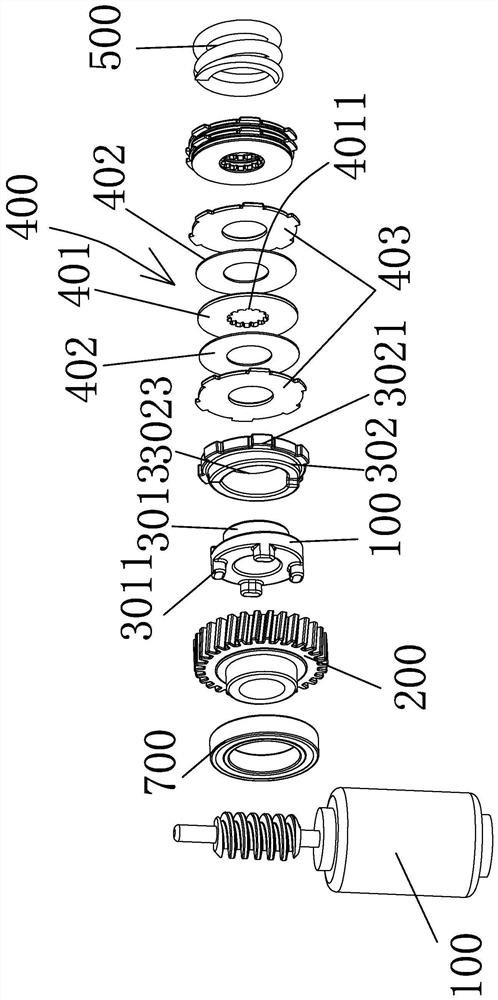

Worm gear and worm brake

PendingCN113217562ASmall form factorSmall footprintMechanically actuated brakesBrake actuating mechanismsElectric machineryControl theory

The invention belongs to the technical field of electric supporting rods, and provides a worm gear and worm brake. The worm gear and worm brake comprises a motor worm assembly, a worm gear, a brake pushing assembly, a friction assembly, a spring and a shell, the motor worm assembly is connected with the worm gear in a self-locking mode, the worm gear is connected with the brake pushing assembly, the friction assembly is arranged between the brake pushing assembly and the spring, one end of the spring is connected with the shell, and the other end of the spring is connected with the friction assembly. The worm gear and worm brake has the advantages that the torque of the brake can be adjusted by controlling a motor worm gear and worm mechanism through an ECU according to different working conditions; according to the worm gear and worm self-locking principle, after the ECU adjusts the torque of the brake, the torque value can be maintained under the power-off condition; the internal resistance in the electric supporting rod / driving mechanism is adjustable, and when the worm gear and worm brake is assembled on the whole vehicle, the functions of electric / manual opening and closing, hovering and the like of a vehicle door under various working conditions are met; and when the brake works, the brake adjustment is rapid, the response is fast, and the noise is low during operation.

Owner:NINGBO XINTAI MACHINERY

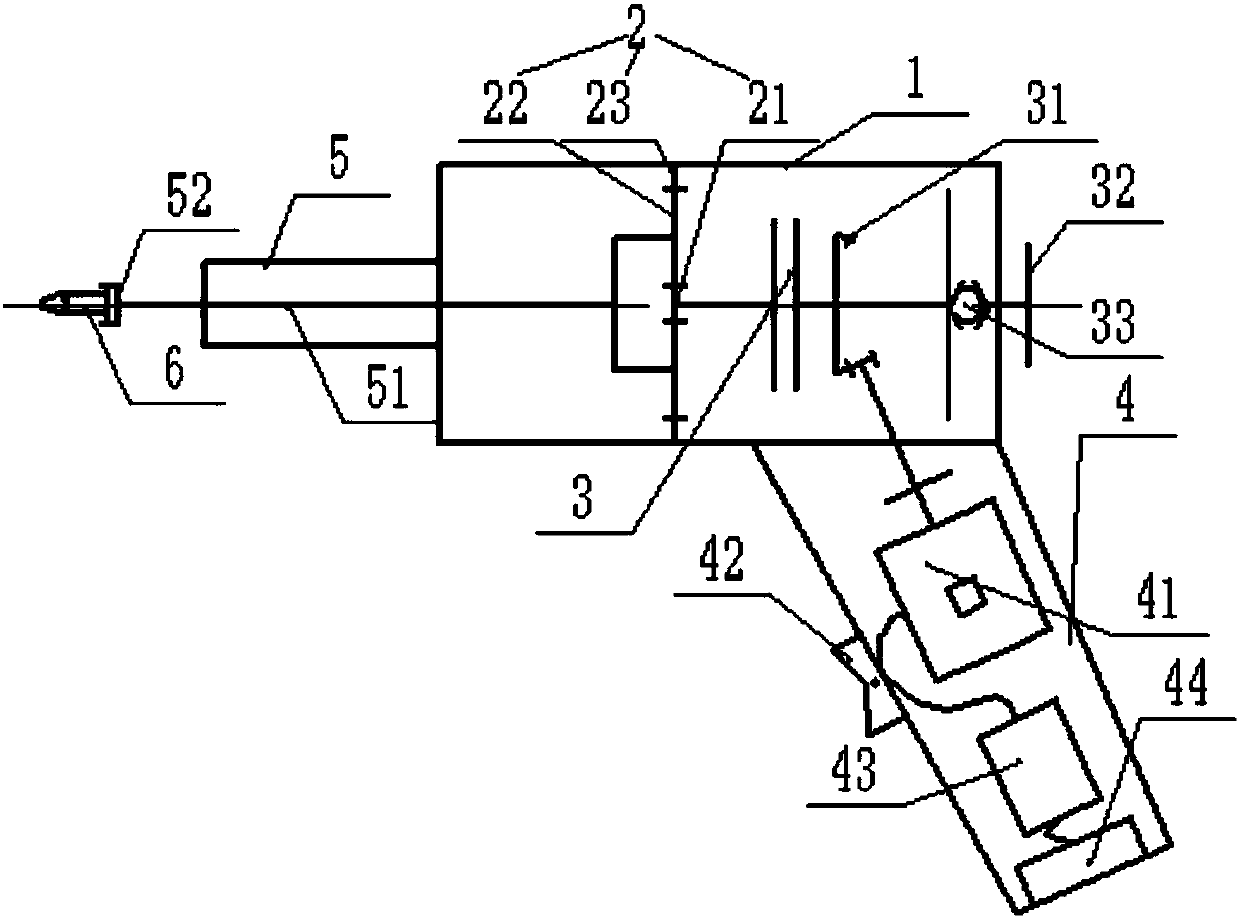

Anti-overload electric screw driver

InactiveCN109909932AAchieve steeringEasy to assemble and disassembleSpannersWrenchesElectricityReduction drive

The invention discloses an anti-overload electric screw driver. The anti-overload electric screw driver comprises a shell, a speed reducer is arranged in the shell, the input end of the speed reduceris connected with a clutch, and an input shaft of the clutch is provided with an input gear disc and an adjusting hand shank; a handle is arranged at the lower end of the shell, a motor, a switch, a power supply and a charging connector are arranged in the handle, an input shaft of the motor meshes with the input gear disc, and the motor, the switch and the charging connector are electrically connected with a power supply; and a fixing rod is arranged at the front end of the shell, a transmission rod is arranged in the fixing rod, one end of the transmission rod is connected with the output end of the speed reducer, the other end of the transmission rod is provided with an adapter, and a screw drivers bit is arranged in the adapter. According to the anti-overload electric screw driver, adjustment of the screw driver screwing torque can be achieved, the driver bit can be randomly replaced, the requirements of multiple occasions can be met, screw disassembling and assembling are convenient, and the structure is compact.

Owner:湘潭顺航环保科技有限公司

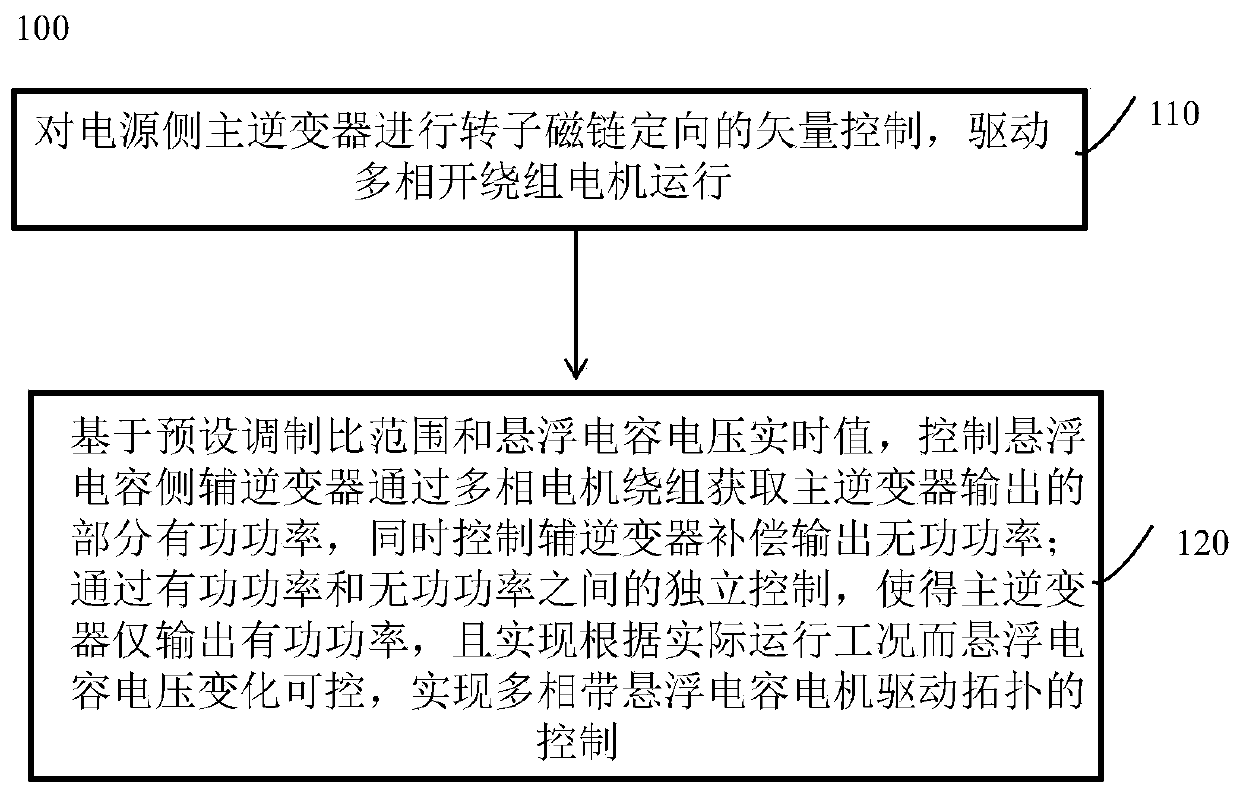

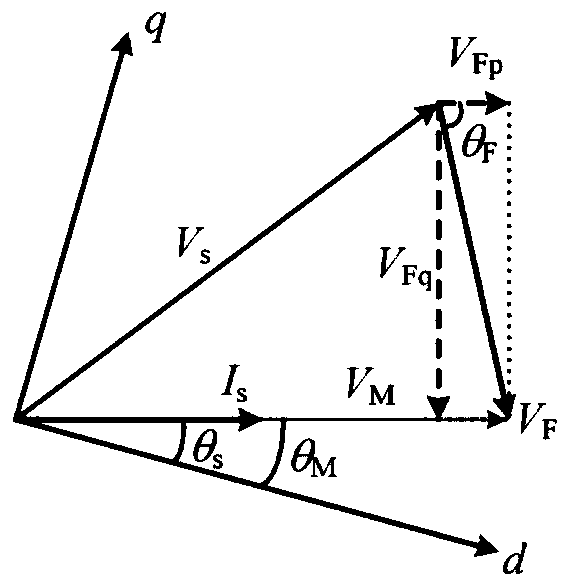

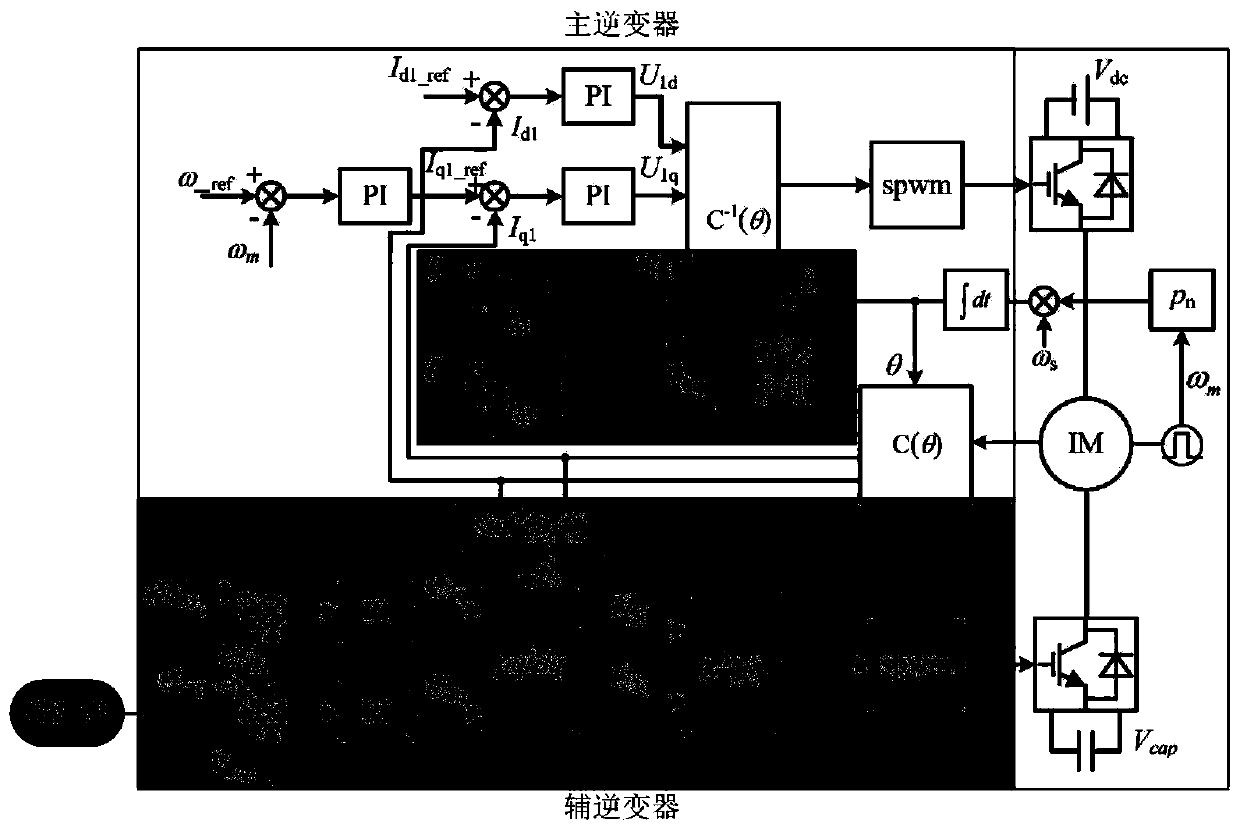

Control method of multiphase motor driving topology with suspension capacitor

InactiveCN110707975AReduce switching lossesReduce lossElectronic commutation motor controlAC motor controlCapacitancePower compensation

The invention discloses a control method of a multiphase motor driving topology with a suspension capacitor. The method comprises the following steps of performing vector control of rotor flux linkageorientation on a power supply side main inverter to drive a multiphase open winding motor to operate; based on a preset modulation ratio range and a voltage real-time value of the suspension capacitor, independently controlling a suspension capacitor side auxiliary inverter to obtain part of active power outputted by the main inverter through a multi-phase motor winding, and independently controlling the auxiliary inverter to compensate the output reactive power, so that the main inverter only outputs the active power, and the voltage change of the suspension capacitor is controllable according to the actual operation condition. According to the invention, by combining the characteristics of a power supply side and two control cores (capacitor voltage controllability and reactive power compensation) of a capacitor side, and adopting the hybrid mode of main inverter torque flux linkage decoupling and auxiliary inverter active and reactive decoupling, it is guaranteed that the working state of the capacitor side auxiliary inverter is stable, the advantage of reactive compensation of the capacitor side auxiliary inverter is brought into play to the maximum extent, the switching lossof the suspended capacitor side inverter is effectively reduced, and the system efficiency is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Variable-torque driven shaft

The invention discloses a variable-torque driven shaft, which comprises a central shaft body, supporting bearings, an electromagnetic coil, a fixed base and a torque controller, wherein the central shaft body penetrates through the central position of the electromagnetic coil; the inner diameter of each supporting bearing is the same with the diameter of the outer circle of the central shaft body; the number of the supporting bearings is two; the two support bearings are separately arranged at the two lateral sides of the electromagnetic coil; the outer circle of the electromagnetic coil is connected with the fixed base; the torque controller and the electromagnetic coil are in linear connection. By adopting the manner, during rotating, the variable-torque driven shaft utilizes the constant resistance given by the electromagnetic coil to the central shaft body, the torque is adjustable and the rotating speed is smoother under the driving of a rolling machine, so that the rolled matters have certain tension and stability.

Owner:吴中区甪直渡岘工艺品厂

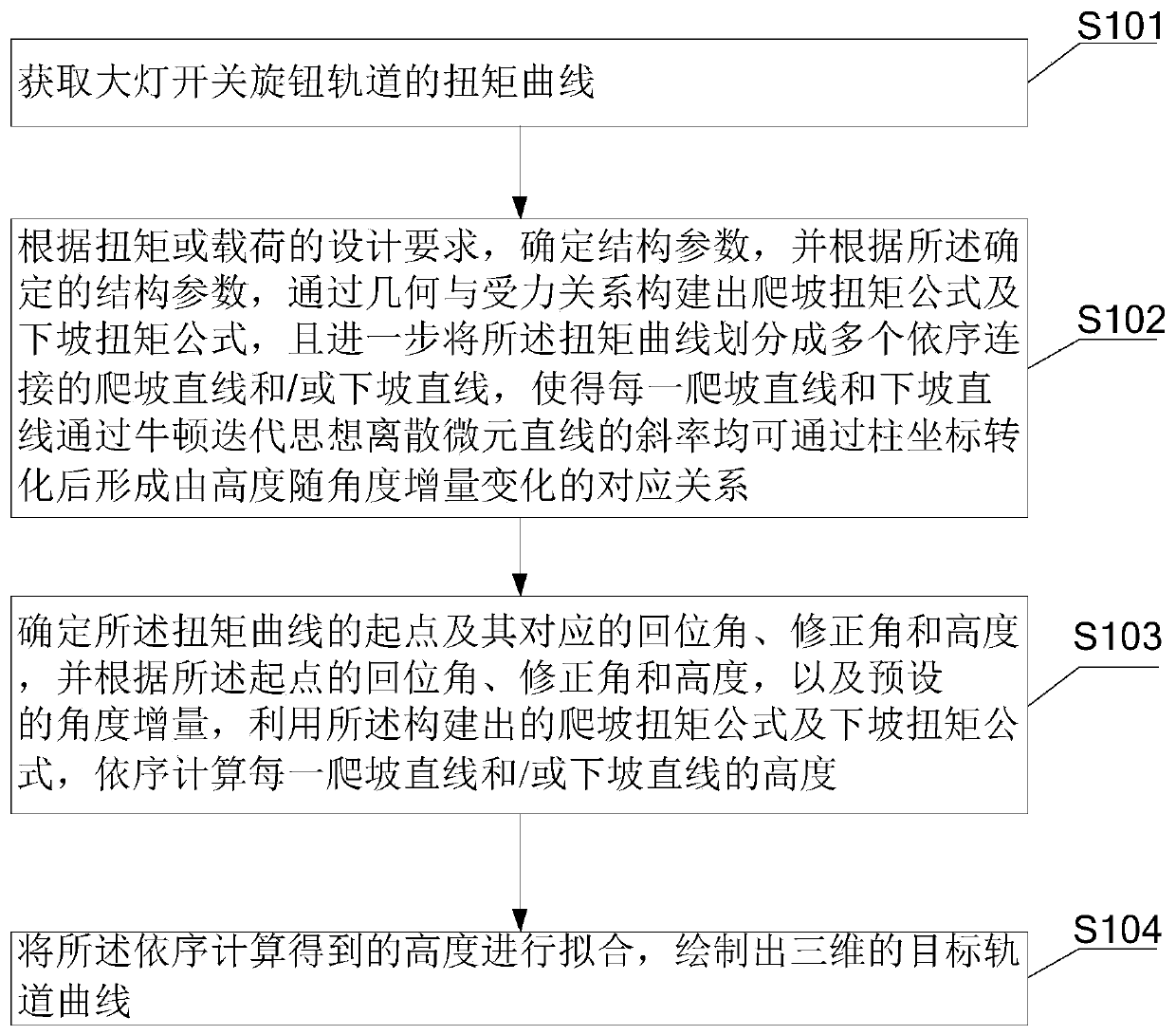

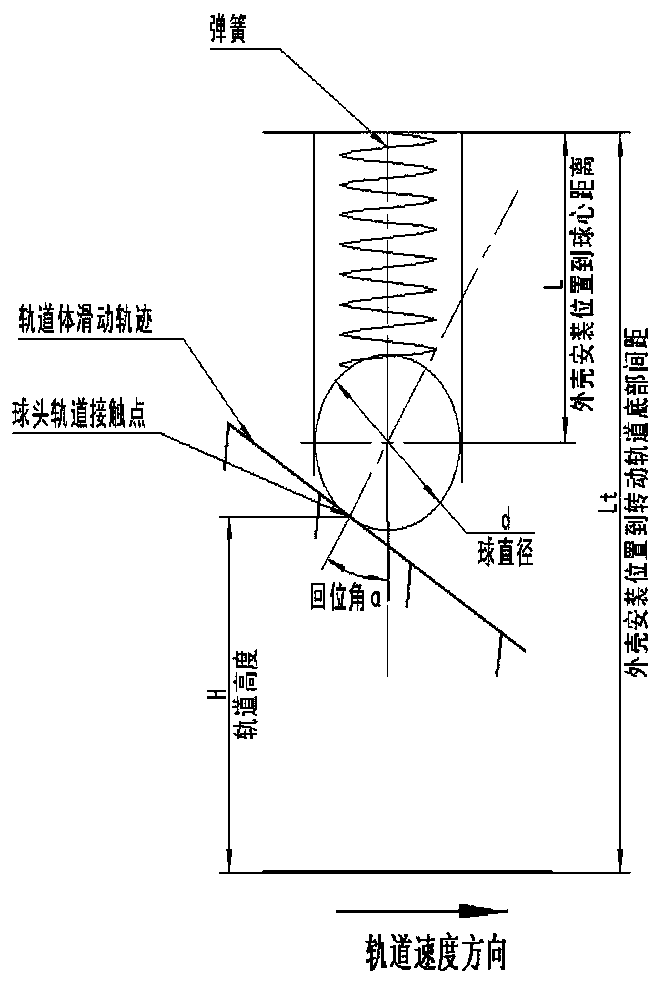

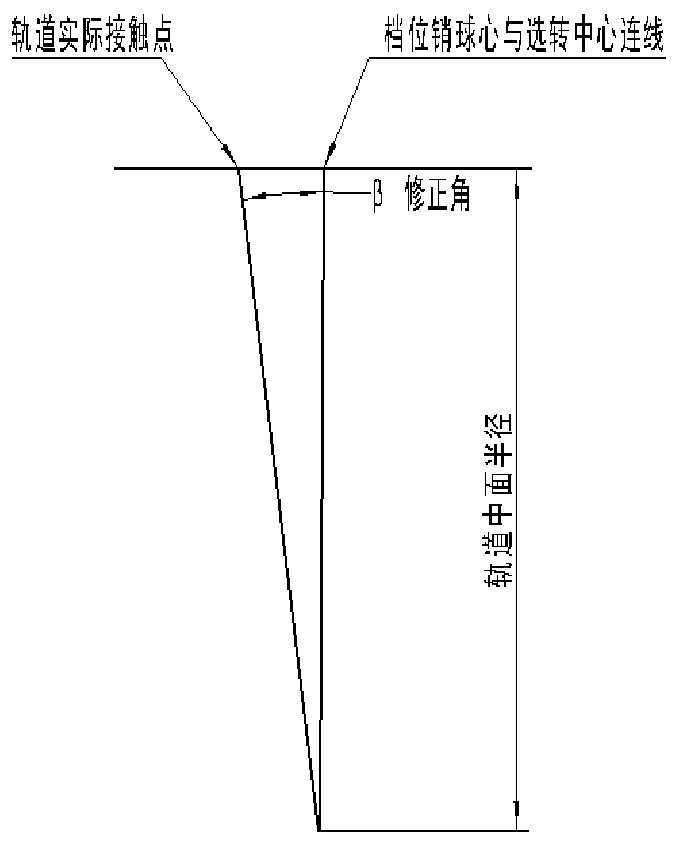

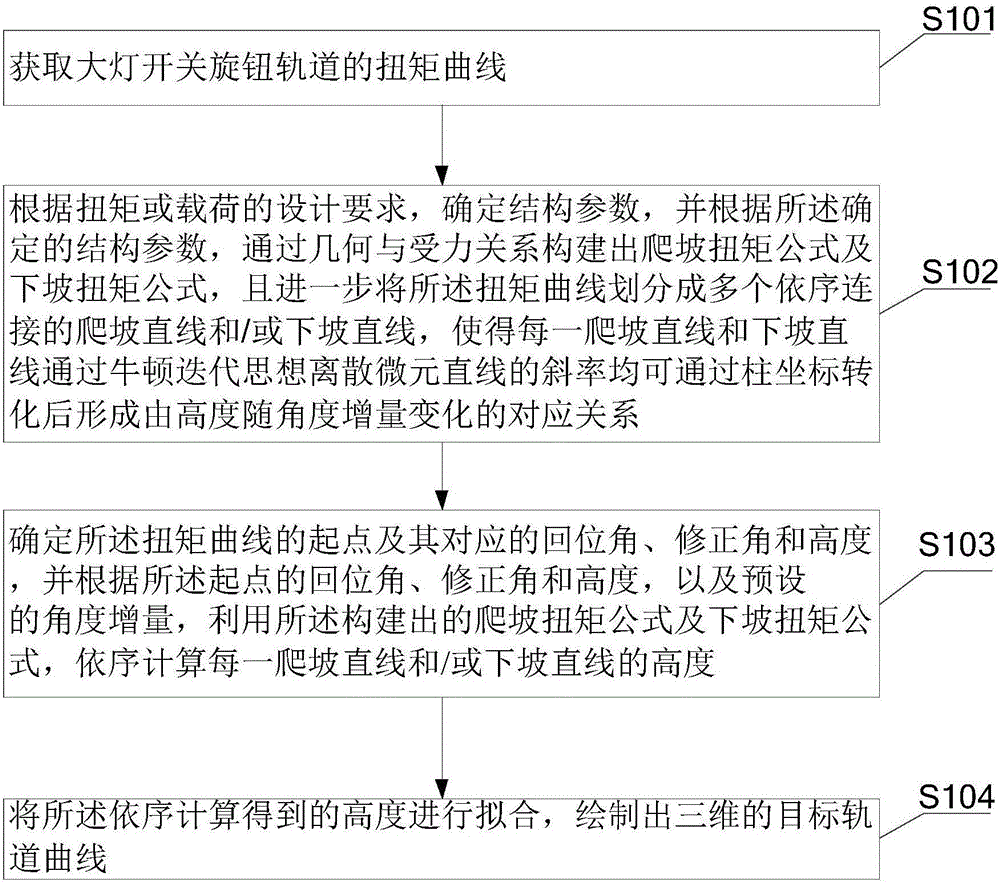

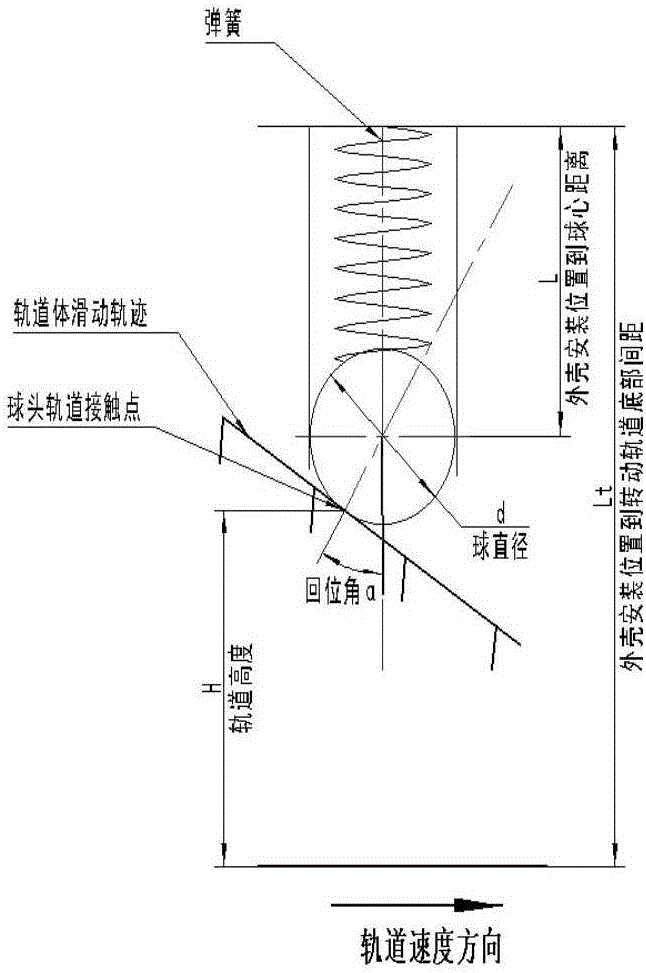

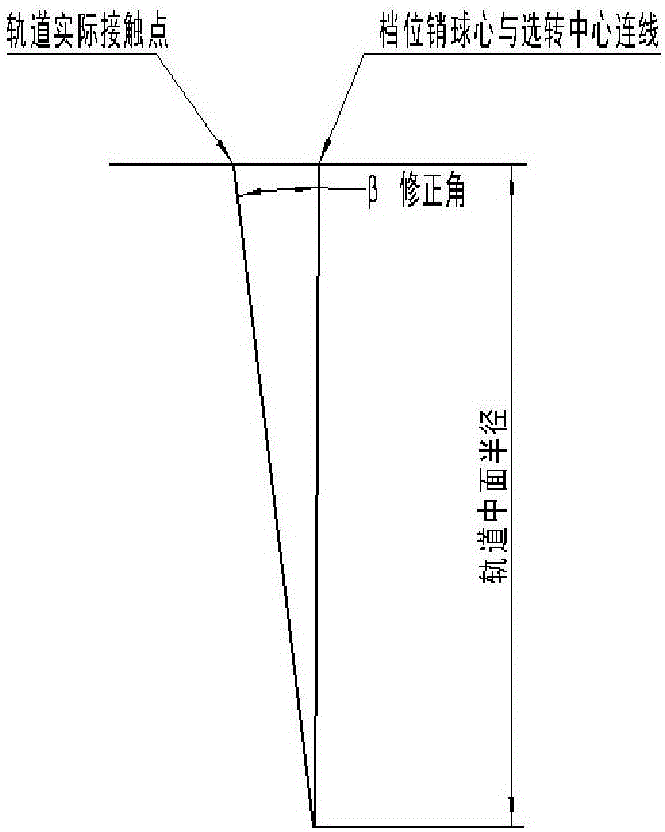

A data modeling method for headlight switch knob track

ActiveCN106294947BFast and precise buildReduce workloadGeometric CADSpecial data processing applicationsData modelingAngular degrees

The invention provides a headlight switch knob track data modeling method, which includes obtaining the torque curve of the headlight switch knob track; determining the structural parameters according to the design requirements of the torque or load, and constructing it through the relationship between geometry and force according to the structural parameters The climbing torque formula and the downhill torque formula are obtained, and the torque curve is further divided into a plurality of climbing straight lines and / or downhill straight lines connected in sequence, so that the slopes of the climbing straight line and the downhill straight line can be converted by cylindrical coordinates The corresponding relationship between the height and the angle increment is formed; determine the starting point and its corresponding return angle, correction angle and height, and according to the preset angle increment, use the climbing and downhill torque formula to calculate each The height of the climbing straight line and / or the downhill straight line; fitting the heights calculated in sequence to draw a three-dimensional target track curve and draw the curve. The implementation of the present invention solves the problem of low efficiency in the track modeling of the headlight switch knob in the prior art.

Owner:WENZHOU CHANGJIANG AUTOMOBILE ELECTRONICS SYST

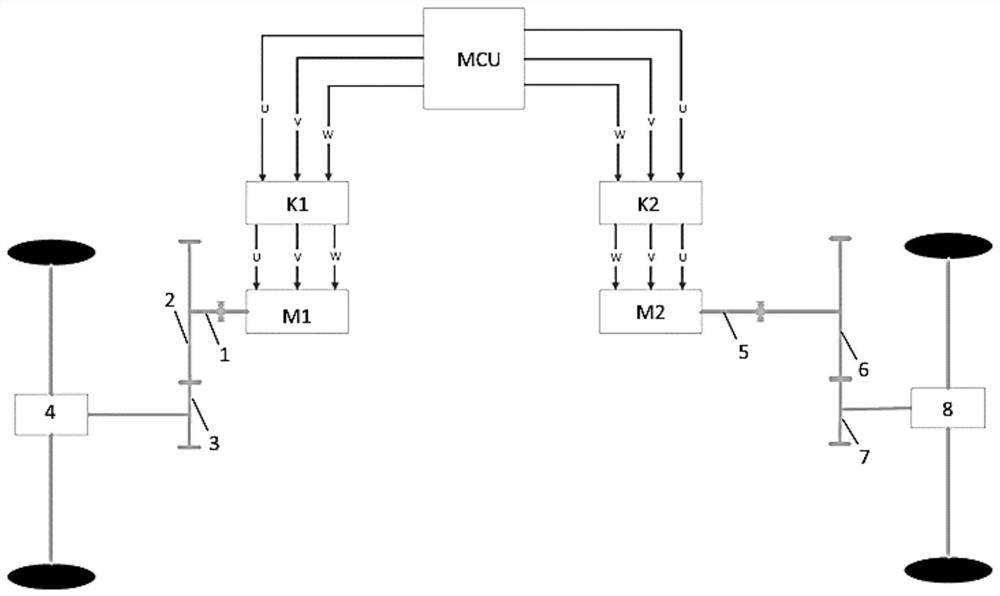

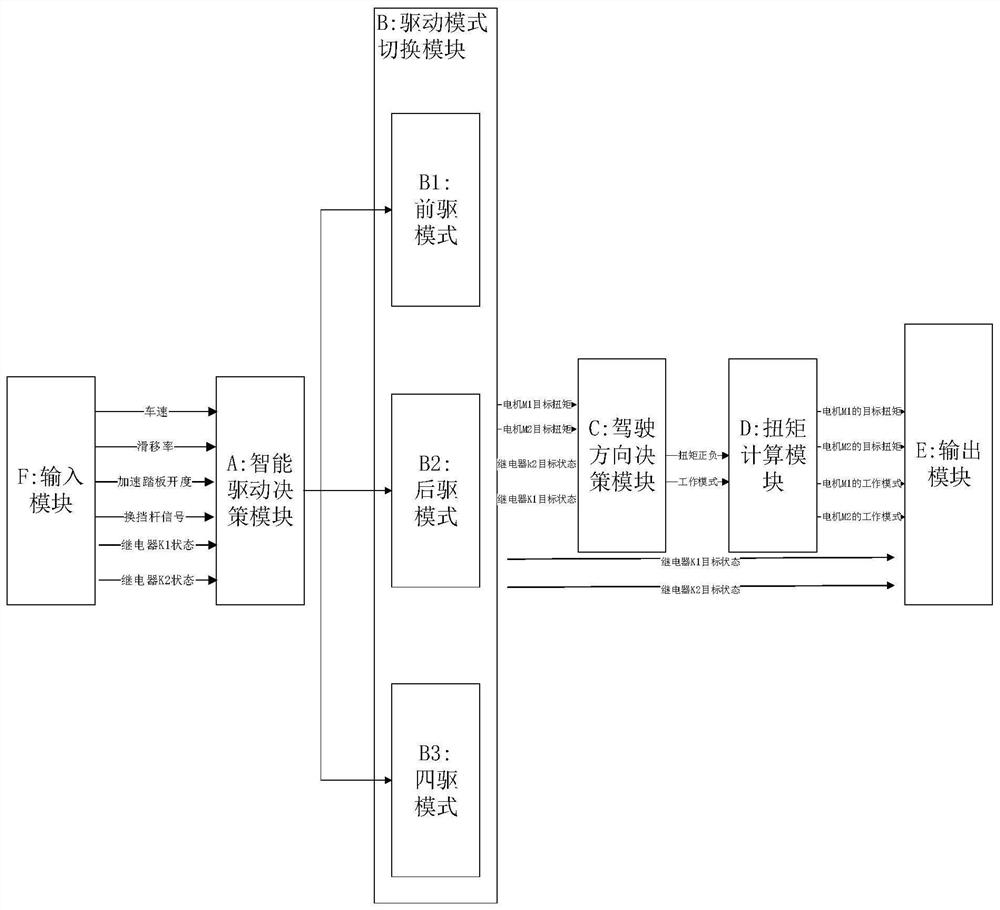

Control method based on EV front-rear drive intelligent coordination drive system

ActiveCN112009261AImprove passabilityEasy to climbSpeed controllerElectric devicesElectric machineryControl theory

The invention discloses a control method based on an EV front-rear drive intelligent coordination drive system. Corresponding instructions are outputted to relays in a front drive device and a rear drive device through an MCU connected with the front drive device and the rear drive device so as to control a motor to achieve intelligent coordination of front drive running, rear drive running, four-wheel drive running, reverse gear running and brake control. The drivability and the smoothness of the front drive can be realized, the dynamic property of the rear drive can also be realized, meanwhile, four-wheel drive can also be realized, and the drivability and the safety of the whole vehicle are ensured.

Owner:SHANGHAI AUTOMOBILE GEAR WORKS

Whole machine overlarge torque avoiding assembly for intelligent shirt manufacturing buttonholing machine

The invention relates to the technical field of buttonholing machines, and discloses a whole machine overlarge torque avoiding assembly for an intelligent shirt manufacturing buttonholing machine. The whole machine overlarge torque avoiding assembly comprises a buttonholing shaft; the top of the buttonholing shaft is provided with a buttonholing sleeve; and the top of the buttonholing sleeve is fixedly connected with a mounting top disc. According to the whole machine overlarge torque avoiding assembly for the intelligent shirt manufacturing buttonholing machine, through contact of an upper control contact and a lower control contact, an electric field wire in a control ball is powered on, then the electric field wire transmits surface current to the interior of an electrorheological body, the electrorheological body is hardened, and therefore under the action of the electrorheological body, the electrorheological body pushes an electric control plug to move towards the outer side, then under the cooperation of a movable net rack and a fixed net rack, the motion state of the electric control plug is transmitted to a limiting positioning head, then the limiting positioning head extends outwards to make contact with the inner wall of the buttonholing machine, and then the large torque state of cloth feeding wheel of the buttonholing machine is limited; and therefore, the torque of the cloth feeding wheel of the buttonholing machine is controllable.

Owner:徐州力达缝纫设备制造有限公司

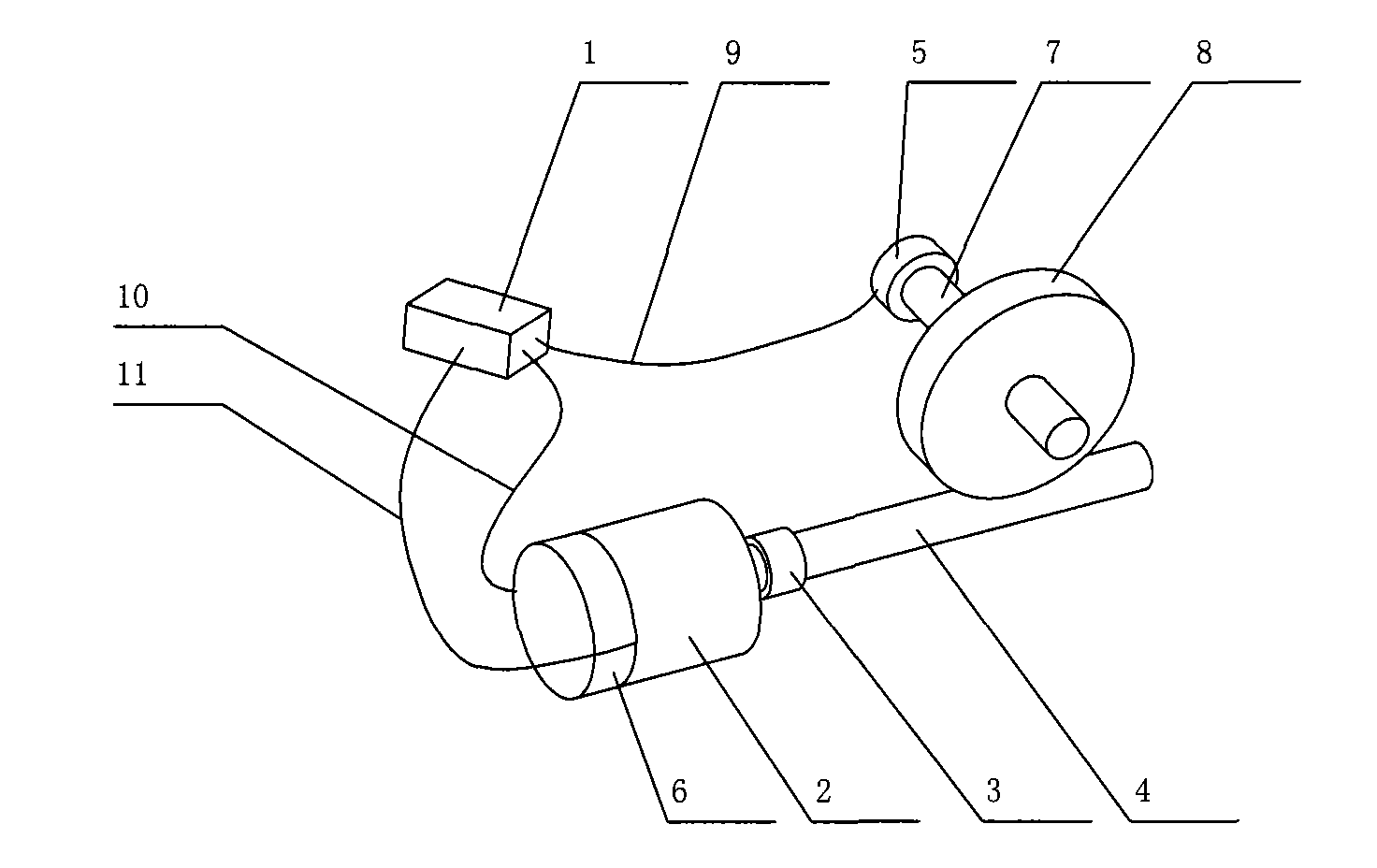

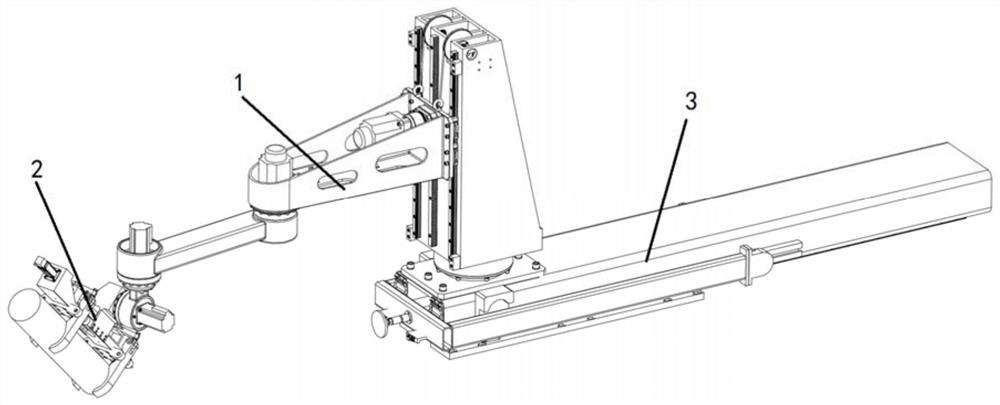

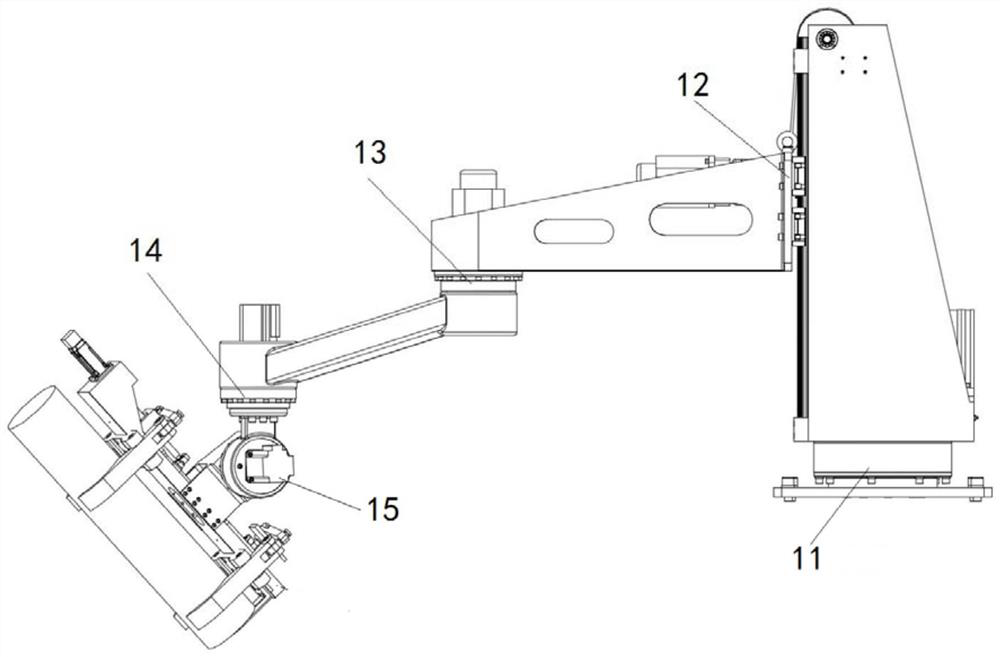

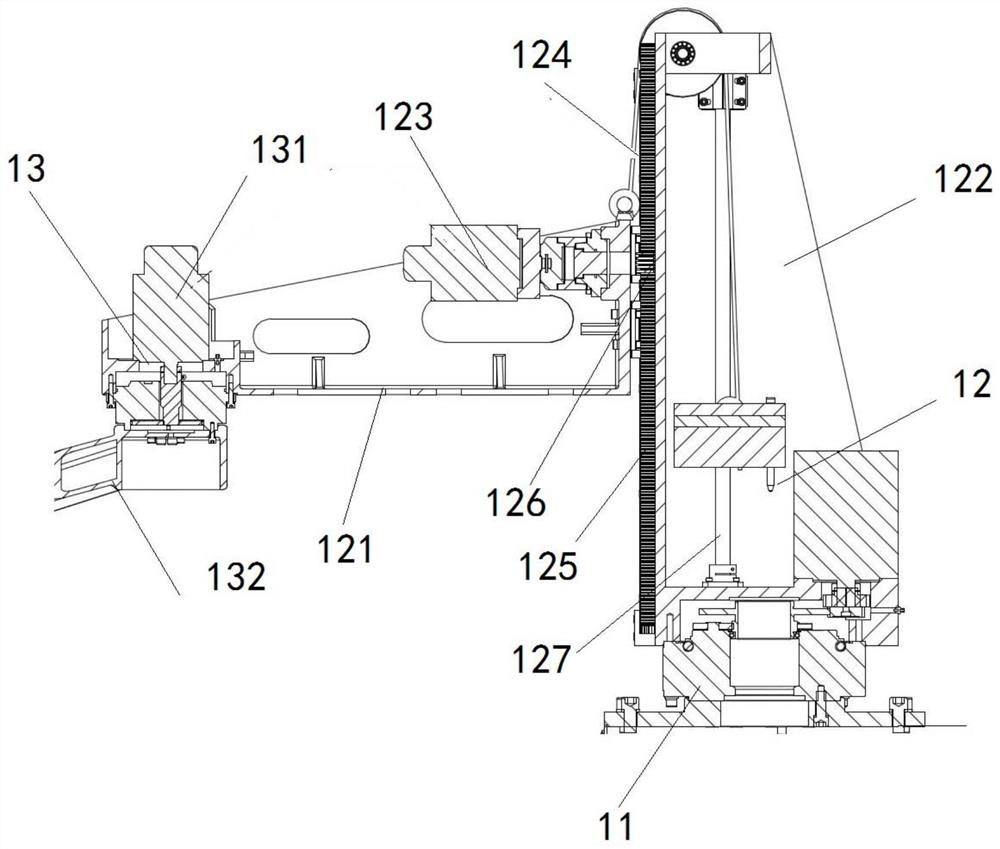

A special robot for projectile handling and picking

ActiveCN109775345BImprove flexibilityExpand the scope of activitiesAmmunition loadingConveyor partsReciprocating motionClassical mechanics

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

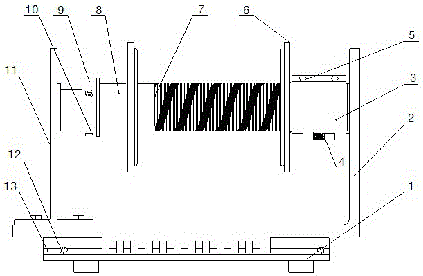

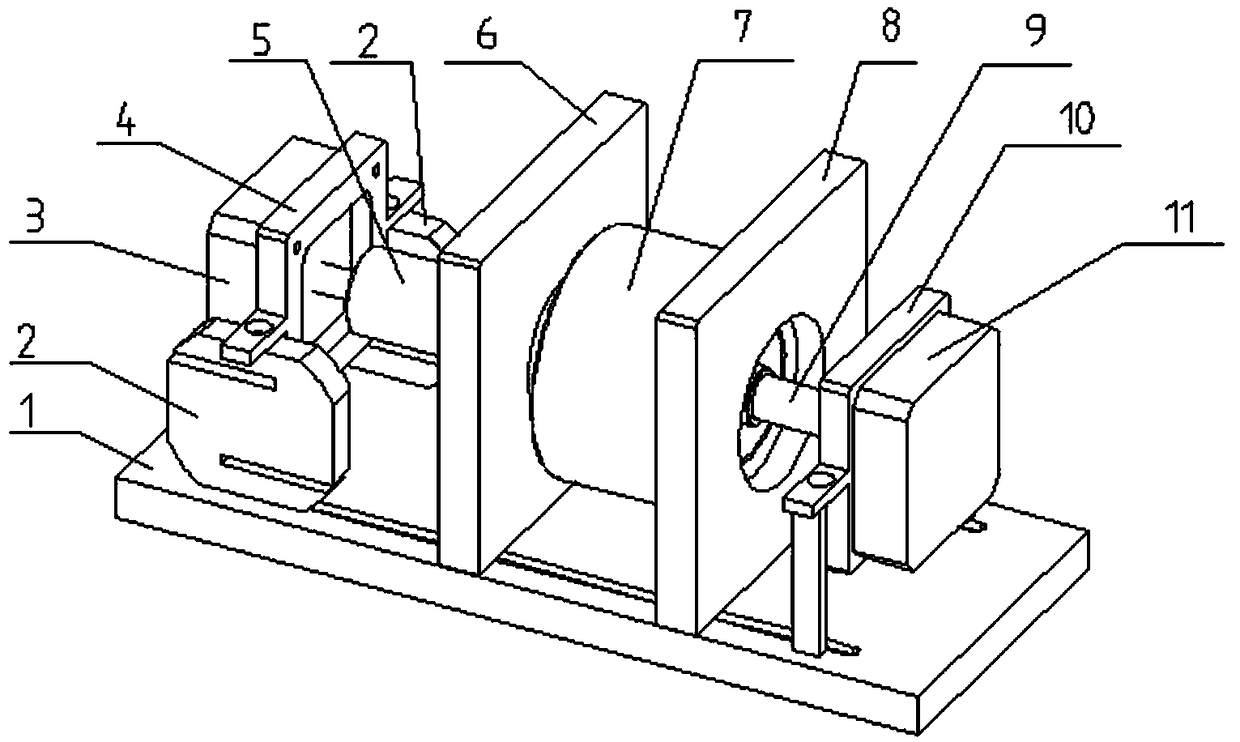

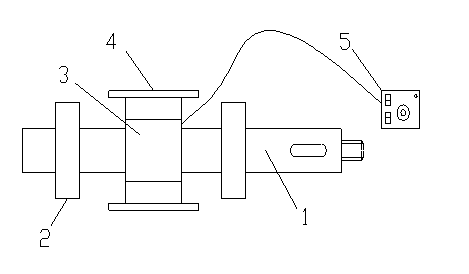

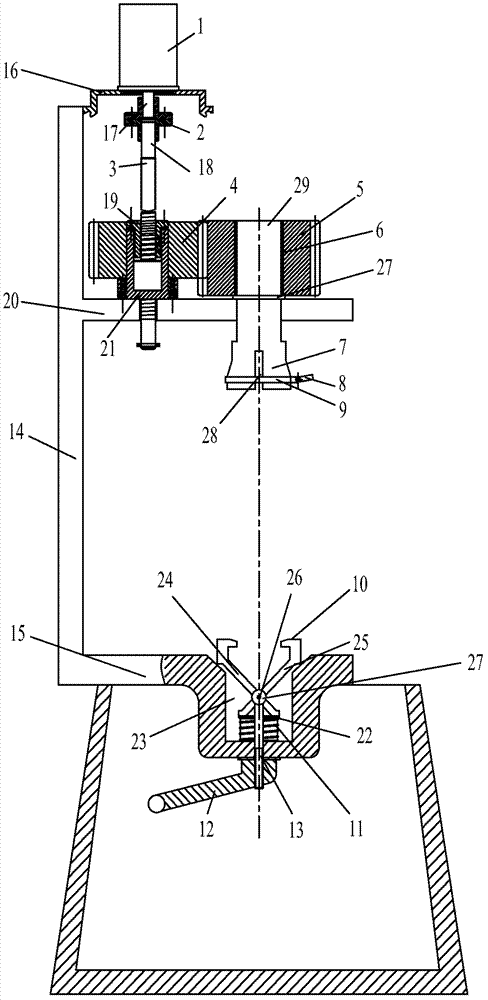

Straw torque measurement device

InactiveCN102435511BTorque controllableEasy to control the lengthStrength propertiesMeasurement deviceCoupling

The invention discloses a straw torque measurement device which is mainly used for detecting the mechanical property of a straw material. The straw torque measurement device comprises a rack, an upper clamping device and a lower clamping device; the rack is sequentially provided with a top platform frame, an upper platform frame and a lower platform frame from the top down; the top platform frameis provided with a universal testing machine, and a lead screw nut device is arranged under the universal testing machine; the lead screw nut device comprises a lead screw and a lead screw nut; the lead screw is fixedly connected with a transmission shaft of the universal testing machine through a coupling shaft; the upper platform frame is provided with an upper clamping device and a transverse transmission device; the lead screw nut is fixedly connected with one end of the transverse transmission device, and the upper clamping device is fixedly connected with the other end of the transversetransmission device and exposed at the lower end of the upper platform frame after passing through the upper platform frame; the lower platform frame is provided with a lower clamping device; and thelower clamping device is arranged under the upper clamping device.

Owner:ZHEJIANG UNIV

Reduction gear and control method thereof

InactiveCN101875199BLow costHigh precisionComputer controlSingle motor speed/torque controlCouplingRobotic arm

A speed reduction device and its control method are provided. The speed reduction device includes a servo motor and a speed reducing mechanism connected with the servo motor. The speed reducing mechanism consists of a driving part and a driven part matched with each other. The servo motor is connected to the driving part by a coupling. The driving part matches with the driven part, and introduces the power from the servo motor and outputs it after speed reducing. The input shaft of said servo motor and the output shaft of the speed reducing mechanism are respectively equipped with a first and a second position detecting device. Said position detecting devices input signals to a servo controller by signal line, and the servo controller outputs a voltage to the servo motor. The servo motor drives the speed reducing mechanism to run, which outputs the power input of the servo motor after speed reducing. Said speed reduction device has low cost, high control accuracy, fast response, controllable torque and controllable rotational speed. Said speed reduction device facilitates the networking and integration of control, and can receive commands from a general controller to control the operation of manipulator with full closed loop control.

Owner:杭州中科赛思伺服电机有限公司

Torque-adjustable screwdriver

InactiveCN109909940AAchieve steeringEasy to assemble and disassembleSpannersWrenchesEngineeringClutch

The invention discloses a torque-adjustable screwdriver. The torque-adjustable screwdriver comprises a shell, wherein a speed reducer is arranged in the shell, the input end of the speed reducer is connected to a clutch, and an input gear disc and an adjusting handle are arranged on an input shaft of the clutch; a handle is arranged at the lower end of the shell, a motor, a switch, a power supplyand a charging head are arranged in the shell, an input shaft of the motor is meshed with the input gear disc, and the motor, the switch and the charging head are electrically connected to the power supply; a fixing disc is arranged at the front end of the shell, a transmission rod A and a gear disc are arranged in the fixing disc, one end of the transmission rod A is connected to the output end of the speed reducer, and the other end of the transmission rod A is meshed with the gear disc; and one end of the fixing disc is provided with a steering disc, the steering disc is provided with a transmission rod B with one end meshed with the gear disc, and the other end of the transmission rod B is provided with a screwdriver head. According to the torque-adjustable screwdriver, the steering ofthe screwdriver head can be realized, screws can be conveniently disassembled and assembled, the torque is adjustable, and the structure is compact.

Owner:湘潭顺航环保科技有限公司

Headlight switching knob track data modeling method

ActiveCN106294947ASolve the problem of torque uncertaintySimple designGeometric CADSpecial data processing applicationsTrackwayModelling methods

The invention provides a headlight switching knob track data modeling method. The headlight switching knob track data modeling method comprises the steps that a torque curve of a headlight switching knob track is obtained; structural parameters are determined according to the design requirements of torque or load, a climbing torque formula or a downhill torque formula are established according to the structural parameters and the geometry and stress relation, the torque curve is divided into multiple sequentially connected climbing straight lines and / or downhill straight lines so that the slopes of the climbing straight lines and the downhill straight lines can be converted into the corresponding relation that height changes with angle increment through column coordinates; a starting point and the return angle, correction angle and height corresponding to the starting point are determined, the heights of the climbing straight lines and / or the downhill straight lines are calculated in sequence by utilizing the climbing torque formula and the downhill torque formula according to preset angle increment; the sequentially calculated heights are fit, a three-dimensional target track curve is drawn, and the curve is drawn. By implementing the headlight switching knob track data modeling method, the problem of low headlight switching knob track data modeling efficiency in the prior art is solved.

Owner:浙江长江汽车电子有限公司

A kind of rotating connection assembly device

ActiveCN105965243BReduce labor intensityTorque controllableMetal working apparatusEngineeringAutomation

The invention discloses an assembly device (100) for rotational connection. The assembly device for rotational connection is used for realizing rotational connection for a first component and a second component, and comprises a base (101), a clamping component (102) arranged on the base (101) and used for clamping the first component, and a rotating component (103) arranged on the base (101) and used for longitudinally aligning the second component with the first component and tightening the second component on the first component in a rotating manner. The assembly device (100) disclosed by the invention has the characteristics of controllable rotating torque, good product assembly consistency, high automation degree, and high production efficiency.

Owner:COMBA TELECOM TECH (GUANGZHOU) CO LTD

Brushless direct-current motor for single-step motion of automobile throttle valve

InactiveCN104660122AHigh precisionHigh control precisionField or armature current controlMechanical energy handlingBrushless motorsCurrent meter

The invention relates to a brushless direct-current motor for single-step motion of an automobile throttle valve. The brushless direct-current motor is characterized by comprising a driving circuit and a brushless motor, wherein the brushless motor is connected onto a shell, and the output shaft of the direct-current brushless motor is connected with a gear speed reducer; a magnet is embedded at the shaft end of a sensing shaft, a linear Hall sensor is used for detecting the position of the throttle valve, and the linear Hall sensor is arranged at the position corresponding to the magnet; the output shaft of the gear speed reducer is connected to the automobile throttle valve mechanism. The flow path comprises the following steps: 1, powering on; 2, detecting the command of an upper computer; 3, returning to the step 2 if the command is not received, and entering the next step if the command is received; 4, determining a control strategy according to the content of the command, and configuring relevant parameters to control the motor; 5, reading the value of the linear Hall sensor of the speed reducing mechanism; 6, uploading the current position information to the upper computer; 7, entering the next step if the position required by the command is reached, or returning to the step 4 to continuously control the command of the motor to be completed, controlling the motor to stop and returning to the step 2.

Owner:SHANXI GUOLI INFORMATION TECH

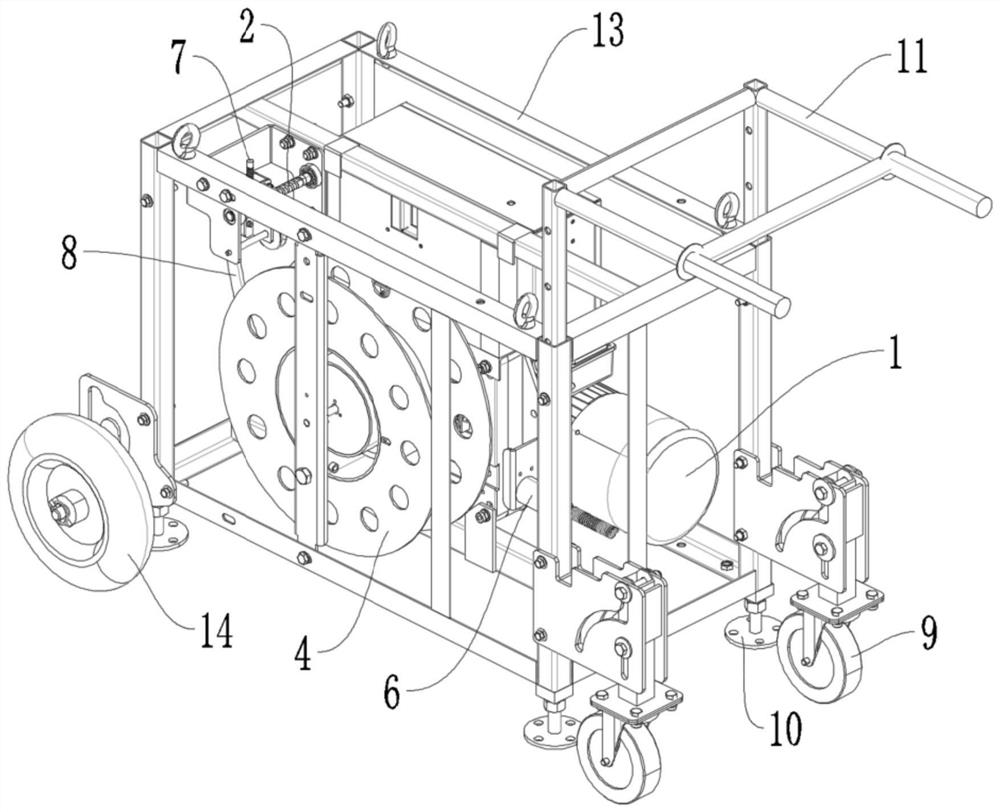

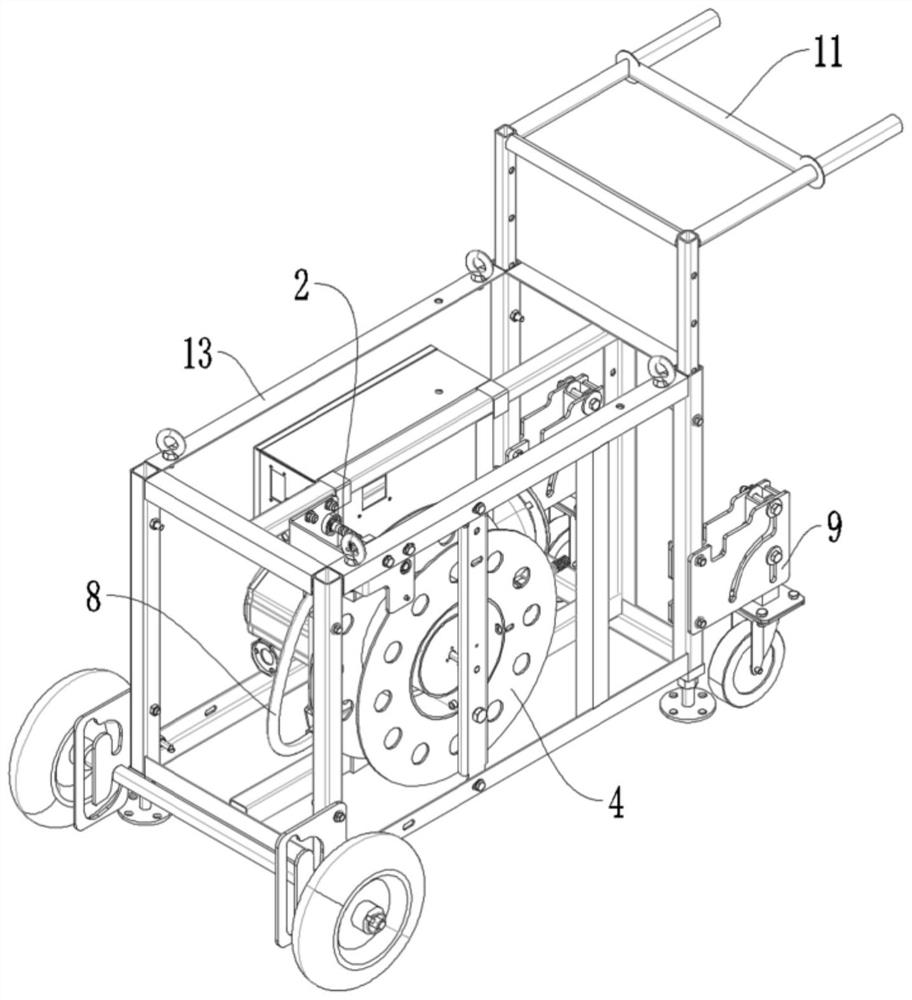

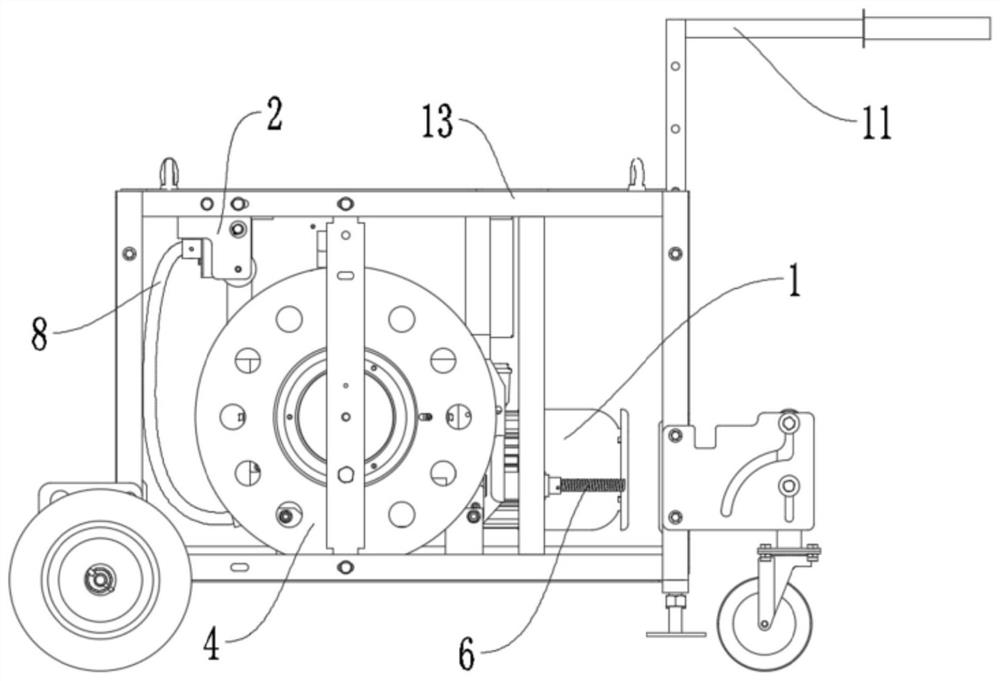

Material traction machine

PendingCN114803921AArranged tightly and orderlyNot prone to messy ropesPortable liftingWinding mechanismsReciprocating motionEngineering

The invention discloses a material traction machine, and belongs to the technical field of mechanical equipment. The material traction machine comprises a frame; the lifting machine is connected with the frame; the rope winding mechanism is connected with the hoister, and the rope winding mechanism is configured to receive power from the hoister and rotate; a transmission mechanism; the rope winding mechanism rotates and drives the rope arranging mechanism to do linear reciprocating motion through the transmission mechanism; wherein the rope winding mechanism rotates, so that the steel wire rope penetrating through the rope arranging mechanism is wound on the rope winding mechanism, and the steel wire rope penetrating through the rope arranging mechanism does linear reciprocating motion along with the rope arranging mechanism, so that the steel wire rope is wound on the rope winding mechanism in sequence. The rope arrangement is tight and orderly, the safety is high, and the adaptability of the frame is high; the sealing visible sealing plate is additionally arranged to prevent an operator from touching the rope collecting mechanism to cause danger, the state of the rope collecting mechanism can be observed more conveniently, and the rope collecting device is safe and can cope with severe environments.

Owner:WUXI RIGID MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com