Assembly device for rotational connection

An assembly device and rotary connection technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problem of uncontrollable tightening torque of assembly parts, achieve high degree of automation, reduce labor intensity, and good assembly consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

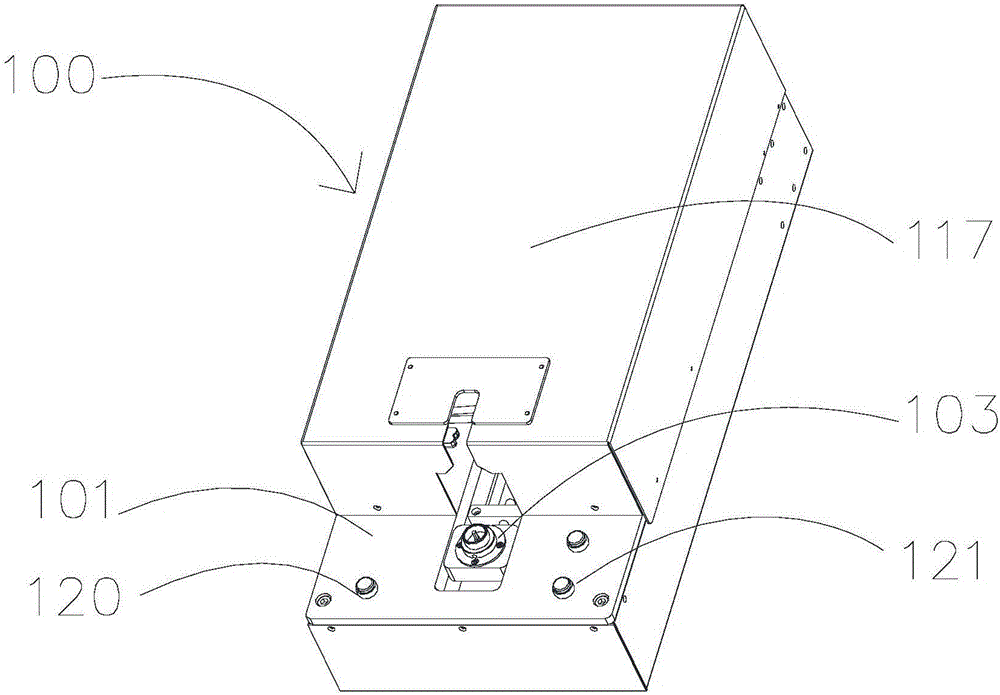

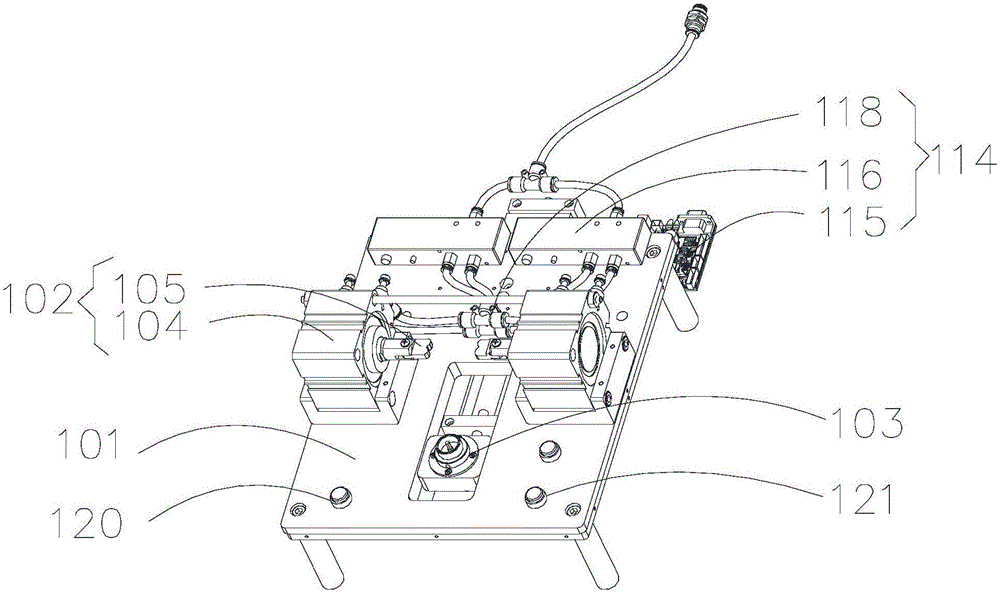

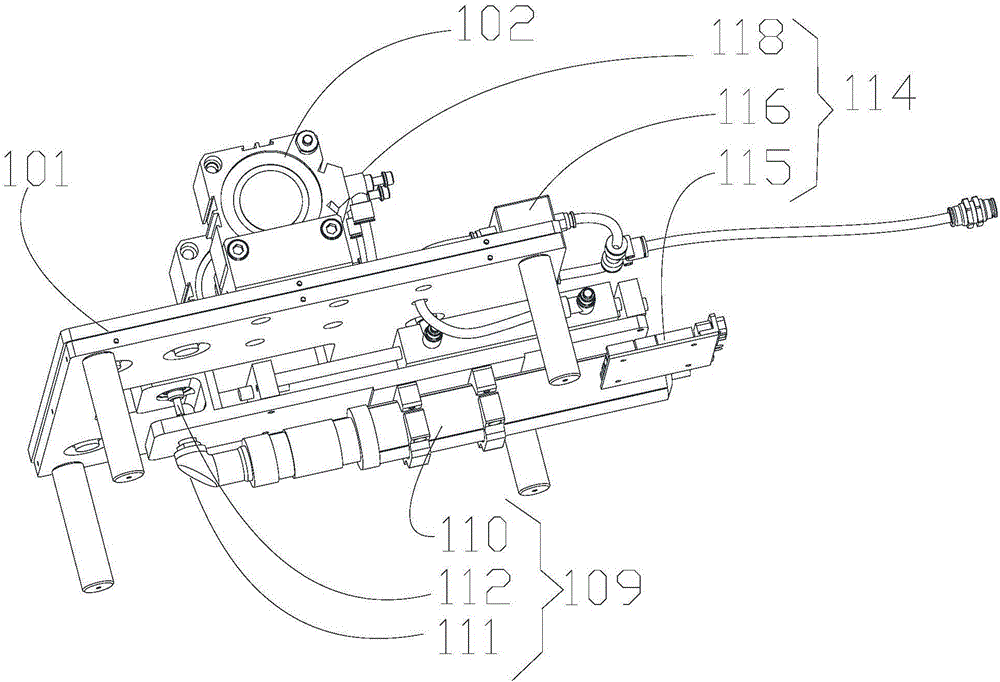

[0025] Figure 1 to Figure 6 Commonly shows the assembly device 100 (hereinafter referred to as "assembly device") of the rotary connection of the present invention, which is used to realize the assembly between two components, especially the threaded connection of two cylindrical components, so that the torque during the connection process Controllable, good product combination consistency, high production efficiency. Hereinafter, the assembly device 100 of the present invention will be described by taking the threaded connection of the coupling rod 500 (ie, the "first component") and the radio frequency connector 501 (ie, the "second component") as an example.

[0026] especially refer to image 3 , the assembly device 100 includes a base 101 and a clamping assembly 102 and a rotating assembly 103 respectively arranged on the upper and lower sides of the base 101 . The clamping assembly 102 is used to longitudinally clamp the coupling rod 500 above the rotating assembly 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com