Embedded hinge for automobile headrest and armrest and manufacturing method thereof

An automobile headrest and manufacturing method technology, which are applied to armrests, special positions of vehicles, vehicle seats, etc., can solve the problems of high price, time-consuming production and assembly, unfavorable dripping of lubricating oil, etc., and achieve low production cost, high resistance to The effect of strong fatigue resistance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

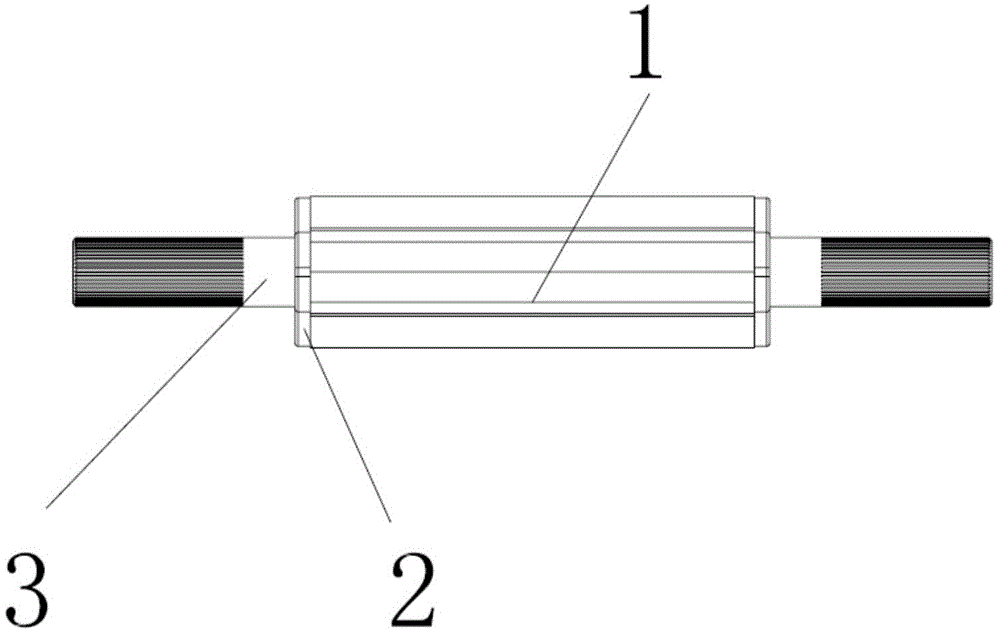

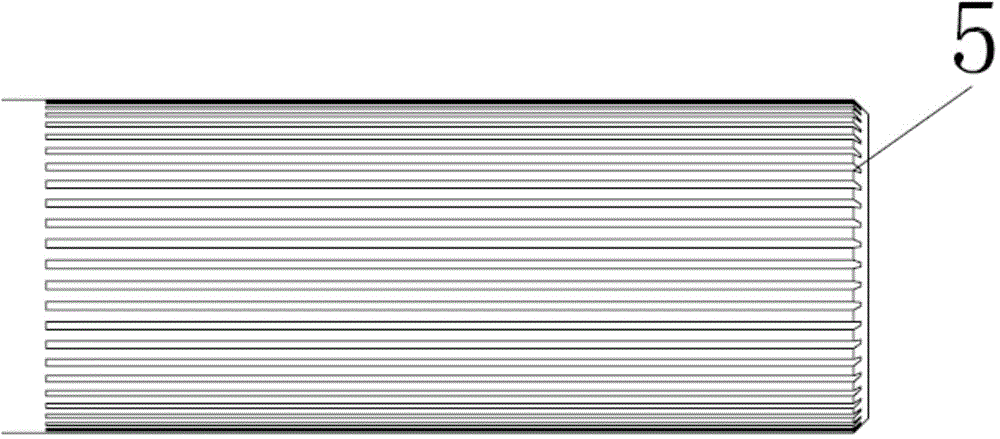

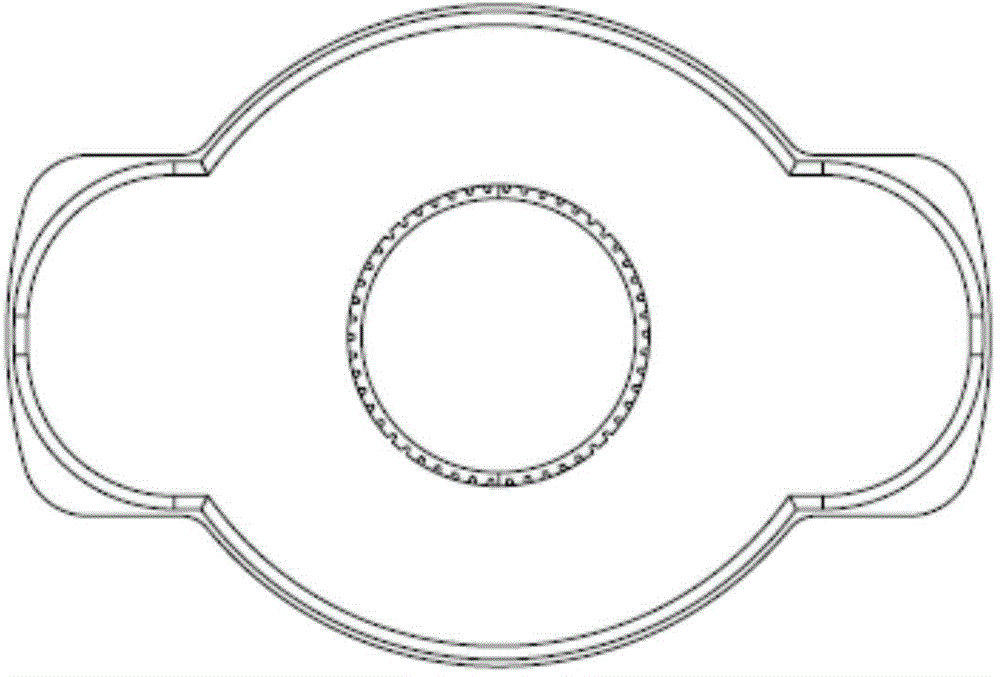

[0026] According to the torque required by the hinge, first stack and install the friction plate 4 on the smooth position in the middle of the main shaft 2, then install the main shaft 2 in the housing 1, then set the pressure of the press according to the required torque, and press it through the press The shell 1 deforms the shell 1 and generates pressure, which causes the internal friction plate 4 to deform, so that the friction force between the friction plate 4 and the main shaft 3 is generated through point contact, so that the torque of the hinge changes, and then through the shell The arc-shaped grooves 7 at both ends are injected with high and low temperature resistant lubricating oil, and finally sealed by the end cover 2 to prevent dust from entering and preventing the lubricating oil from leaking out.

Embodiment 2

[0028] When the hinge needs to be installed inside the headrest, the hinge is placed into the mold, the shell 1 of the hinge is installed on the fixed part of the headrest, and the end of the main shaft 2 corresponds to the connection position of the rotating part of the headrest, and then through injection molding Machine injection molding forms the headrest skeleton, and the entire headrest skeleton is integrally formed, wherein the connection position of the headrest rotating part wraps the transverse groove 5 on the end of the main shaft 2, which is not easy to fall off.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com