Brushless direct-current motor for single-step motion of automobile gear selector

A brushed DC motor, brushless motor technology, applied in the direction of DC motor speed/torque control, electrical components, control systems, etc., can solve problems such as difficult adaptation, external interference, nonlinear time-varying, etc. Control precision, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

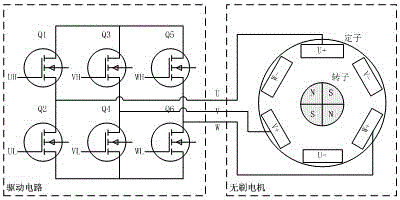

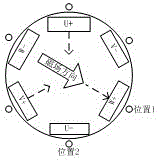

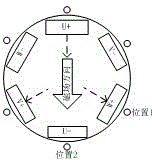

[0016] Such as figure 1 As shown, the brushless DC motor is used for the single-step movement of automobile gear selection, including the drive circuit and the brushless motor. The brushless motor is connected to the housing, and the output shaft of the DC brushless motor is connected to the gear reduction device; the magnet is embedded At the shaft end of the sensing shaft, the linear Hall sensor is used to detect the position of the gear selection fork, and the linear Hall sensor is set at the position corresponding to the magnet; the output shaft of the gear reduction device is connected to the car gear selection mechanism, and the characteristics are: no Brush motor: The motor is composed of a stator and a rotor. The stator is a coil winding that is fixedly connected to the motor casing to form a three-phase circuit of U, V, and W. The rotor is composed of a permanent magnet; a magnetic field is formed in the motor by supplying power to U, V, and W. Change the direction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com