Reduction gear and control method thereof

A technology of reduction gear and reduction mechanism, applied in control system, single motor speed/torque control, computer control, etc., can solve the problems of inconvenient use, high cost, low reliability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

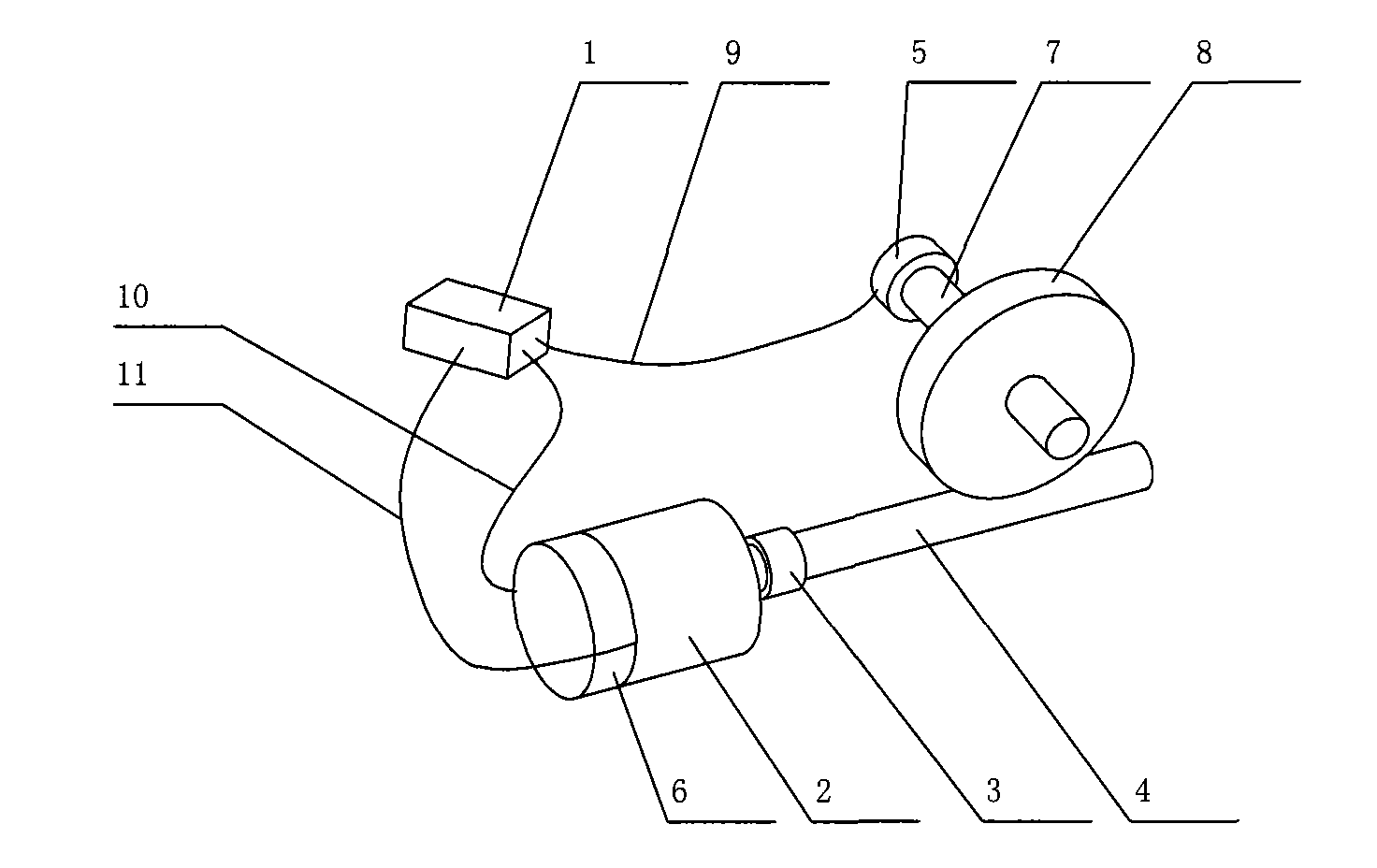

[0106] figure 1 It is a structural schematic diagram of the reduction gear transmission according to Embodiment 1 of the present invention. Such as figure 1 As shown, the deceleration device includes a servo controller 1, a servo motor 2 and a deceleration mechanism connected thereto. The deceleration mechanism is composed of a driving part and a driven part that cooperate with each other. In this embodiment, the driving part refers to the worm 4, and the driven part is The worm gear 8, the servo motor is connected with the worm 4 through the coupling 3, and the worm 4 cooperates with the worm gear 8 to input the power of the servo motor 2 and output it after deceleration. The input shaft of the servo motor 2 and the output shaft of the reduction mechanism are the worm shaft 7 A first position detection device 5 and a second position detection device 6 are respectively provided, and the first position detection device 5 and the second position detection device 6 input signals...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com