Anti-overload electric screw driver

An electric screwdriver and anti-overload technology, which is applied to screwdrivers, motor tools, wrench, etc., can solve the problems of screw thread jumping off, low efficiency, and non-adjustable torque, and achieves convenient screw disassembly, compact structure, and adjustable torque. tune effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

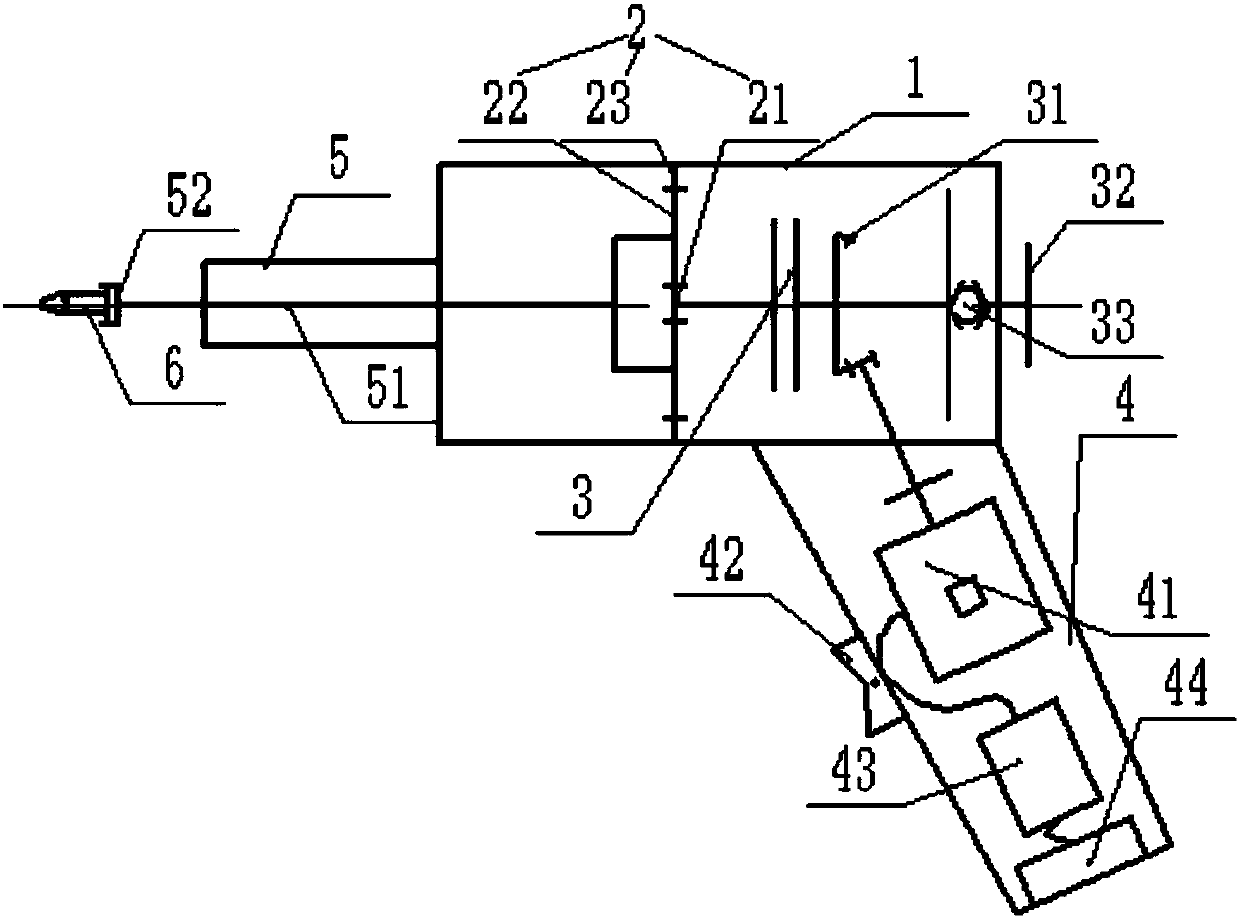

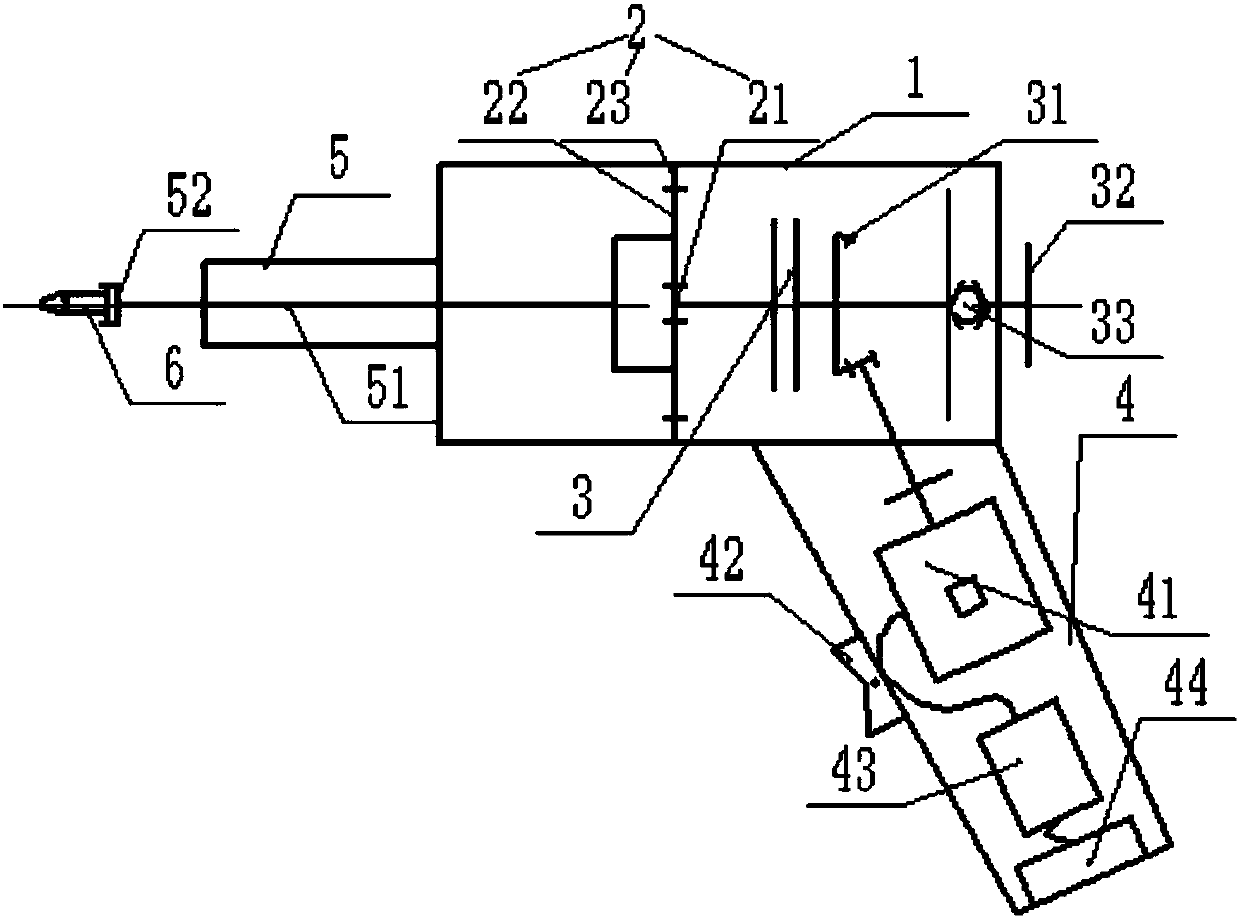

[0011] like figure 1 As shown, the specific structure of the present invention is: an anti-overload electric screwdriver, including a housing 1, a reducer 2 is arranged in the housing 1, the input end of the reducer 2 is connected with a clutch 3, and the clutch 3 The input shaft is provided with an input gear plate 31 and an adjustment handle 32; the lower end of the housing 1 is provided with a handle 4, and the inside is provided with a motor 41, a switch 42, a power supply 43, and a charging head 44, and the input shaft of the motor 41 is connected to the The input gear plate 31 meshes, the motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com