A special robot for projectile handling and picking

A technology of robot and robot body, applied in the field of robots, can solve the problems of difficult operation in large-span space, limited working space, limited working radius, etc., and achieve the effect of large range of activities, solving insecurity, and increasing working range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The following is a detailed introduction to the structure and working principle of the projectile handling, picking and placing special robot provided by the present invention in conjunction with the accompanying drawings:

[0059] basic structure

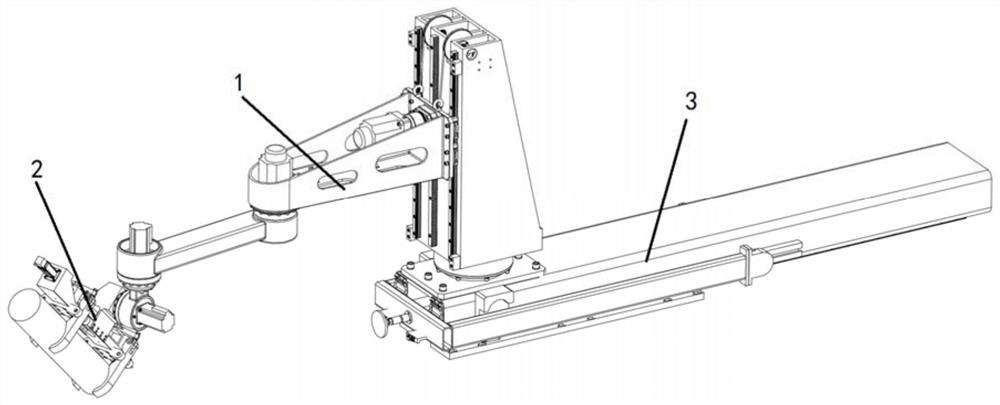

[0060] Such as figure 1 As shown, it mainly includes robot body 1, fixture 2 and telescopic platform 3. The robot body 1 is installed on the telescopic platform 3, and the robot body 1 reciprocates under the drive of the telescopic platform 3;

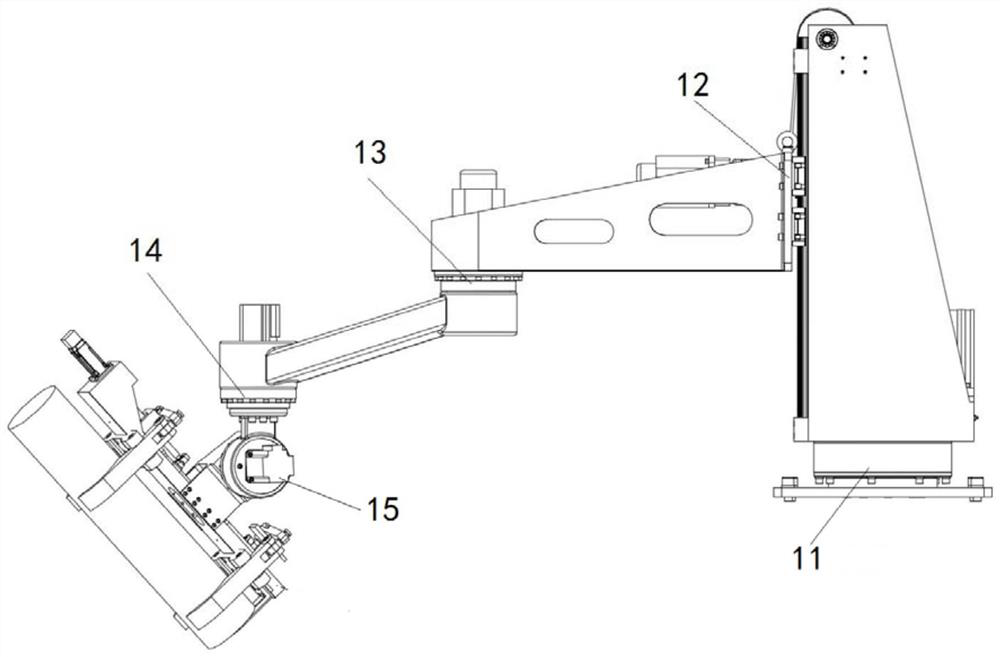

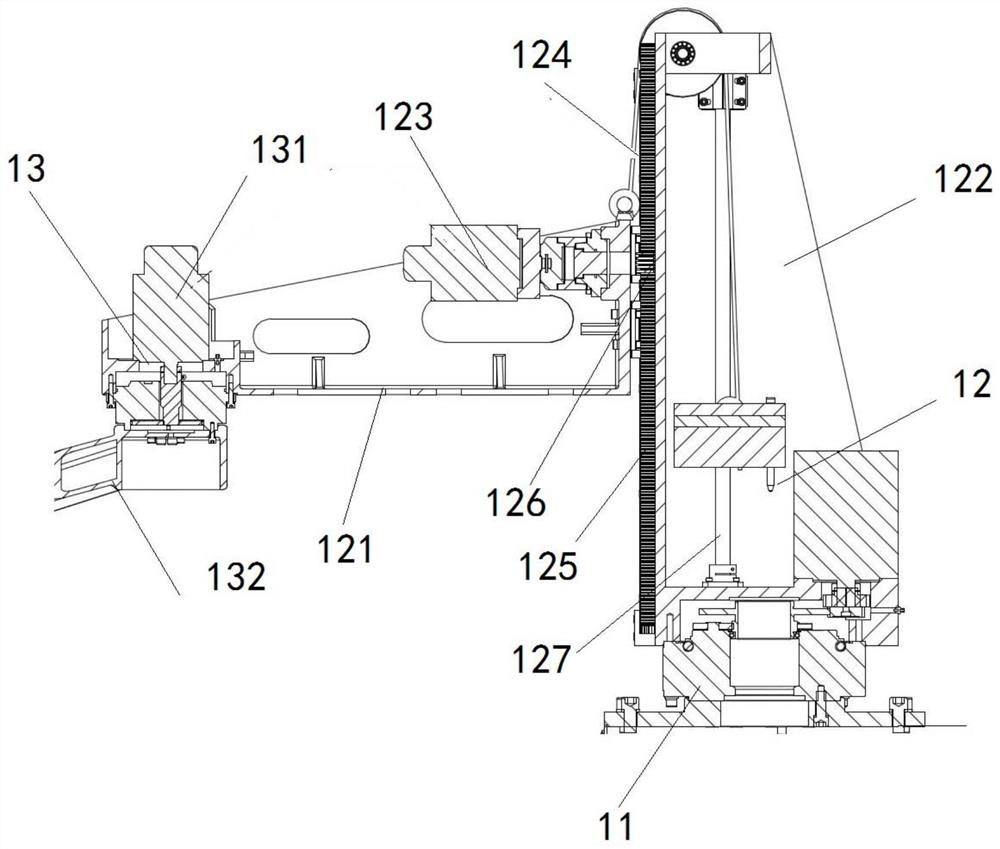

[0061] Such as figure 2 , the robot body 1 includes a first joint 11, a second joint 12, a third joint 13, a fourth joint 14, and a fifth joint 15 arranged in series; wherein, the first joint 11, the third joint 13, and the fourth joint 14 And the fifth joint 15 is for rotating motion, and the second joint 12 is for lifting motion;

[0062] The end of the fifth joint 15 is equipped with a gripper 2 for picking up ammunition. This structural design is convenient for long-distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com