Material traction machine

A tractor and material technology, applied in the direction of the spring mechanism, hoisting device, portable lifting device, etc., to achieve the effect of strong adaptability, easy observation, and easy state of the rope retracting mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

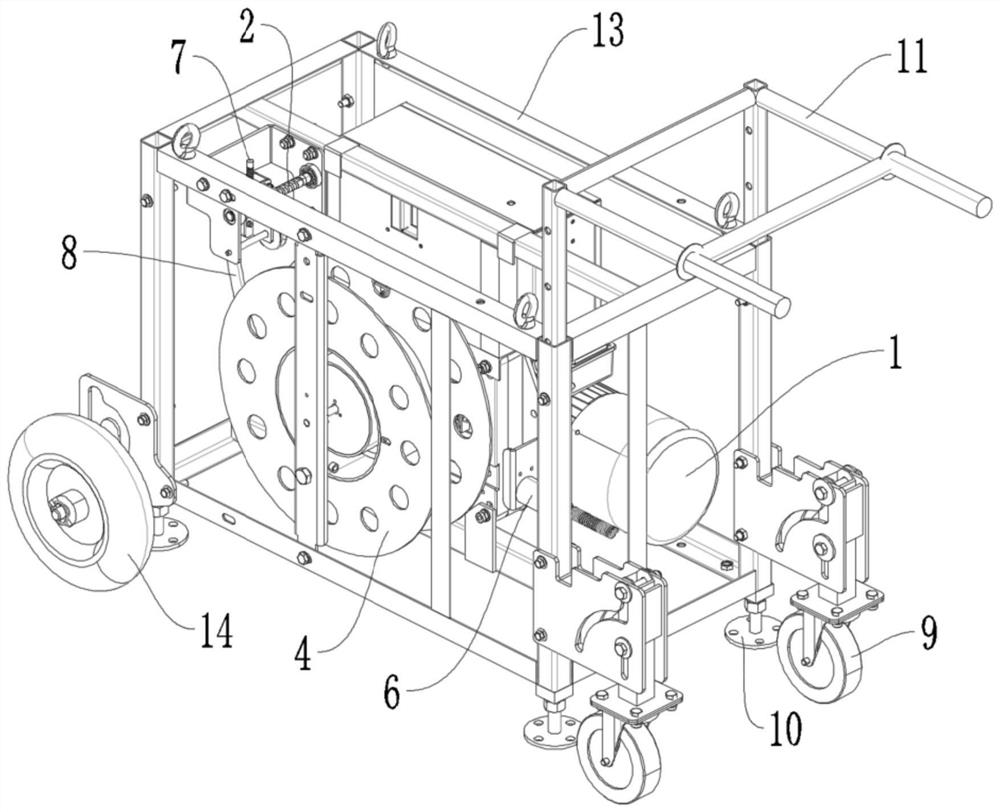

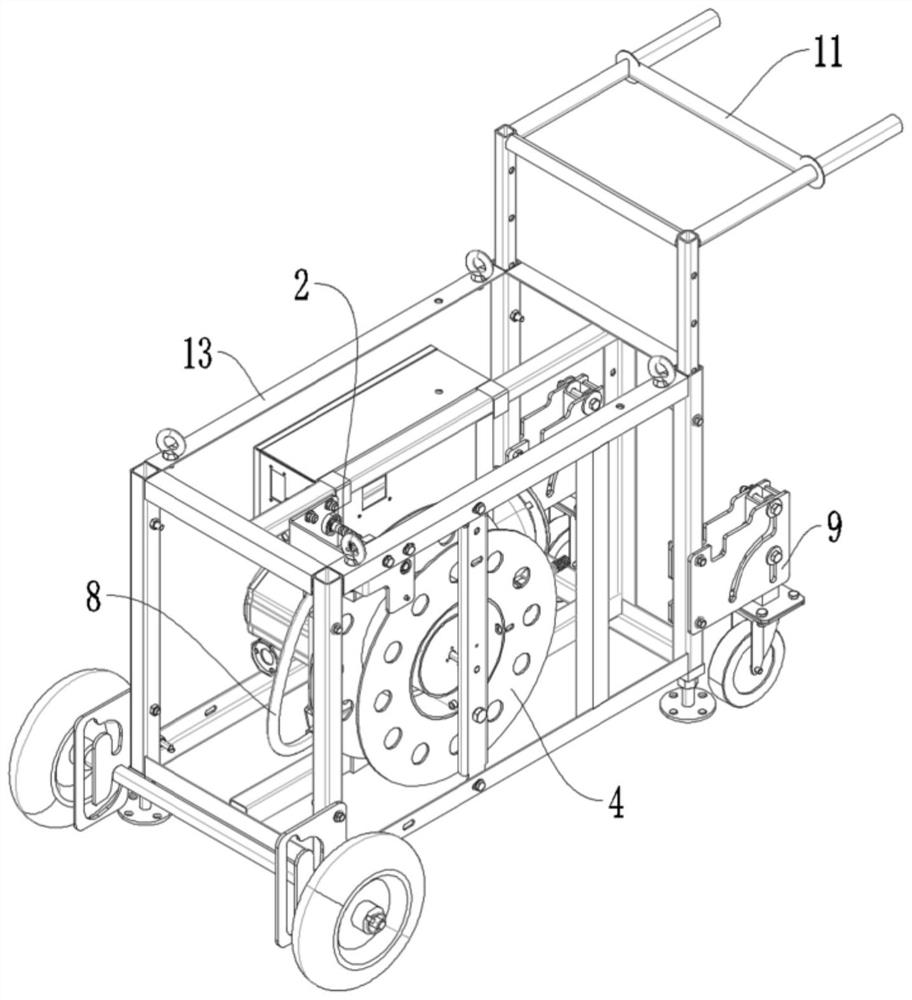

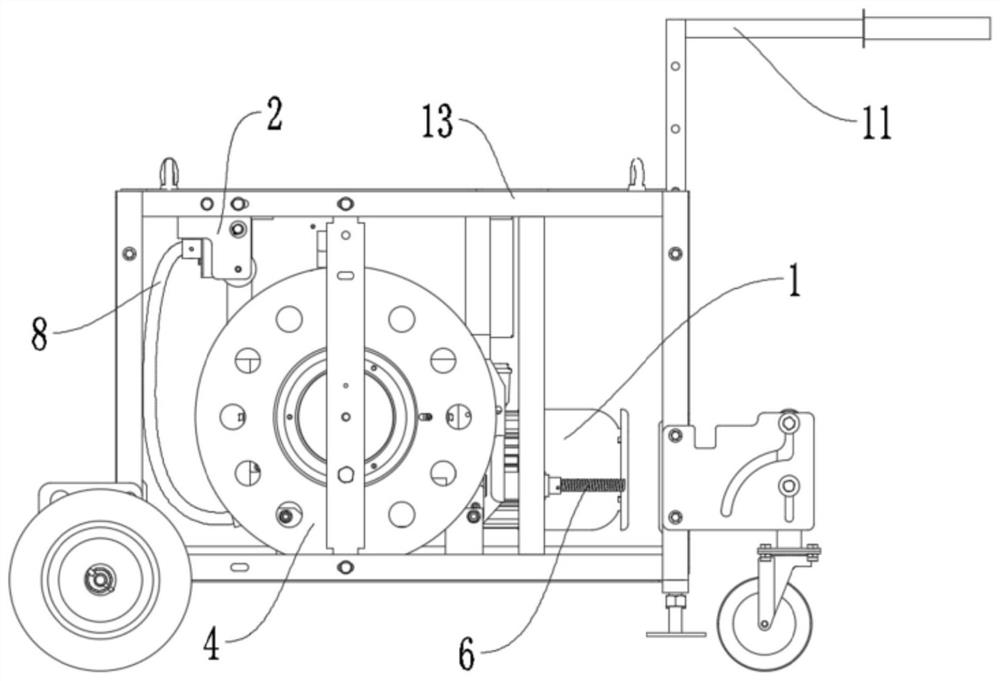

[0044] A material tractor, such as Figure 1-5 As shown, it includes a hoist 1, a rope arrangement mechanism 2, a transmission mechanism 3, a rope retracting mechanism 4, a damping mechanism 5, a rope feeding protection mechanism 6, a cordless protection mechanism 7, a telescopic directional caster assembly 8, a telescopic universal caster assembly 9, Support foot weld 10, handle assembly 11, cover plate 12, and frame 13 for integrating these components. Further, the hoist 1 is battery driven.

[0045] The hoist 1 is connected to the frame 13; the rope take-up mechanism 4 is connected to the hoist 1, and the rope take-up mechanism 4 is configured to receive power from the hoist 1 and rotate; the rope take-up mechanism 4 rotates The transmission mechanism 3 drives the rope-arranging mechanism 2 to perform linear reciprocating motion; wherein, the rope-receiving mechanism 4 rotates so that the wire rope passing through the rope-arranging mechanism 2 is wound on the rope-receivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com