Lifting mechanism for blinds

A lifting mechanism and shutter technology, applied in the field of doors and windows, can solve the problems of rope loops scratching or overlapping, the lifting mechanism is stuck, and the spacing is difficult to guarantee, and achieves the effects of tight and orderly arrangement, convenient assembly, and stable transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

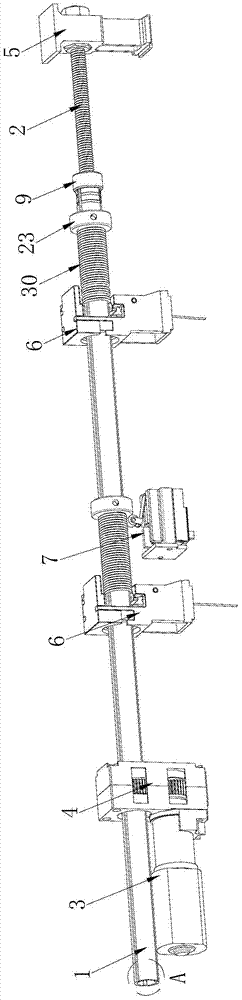

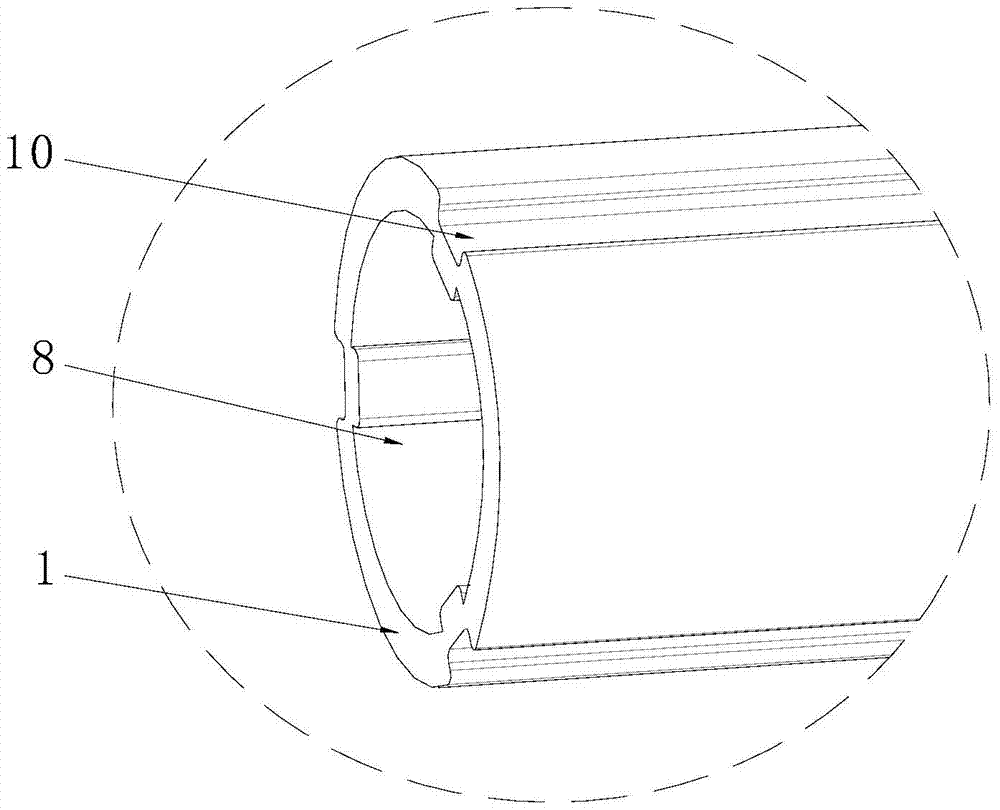

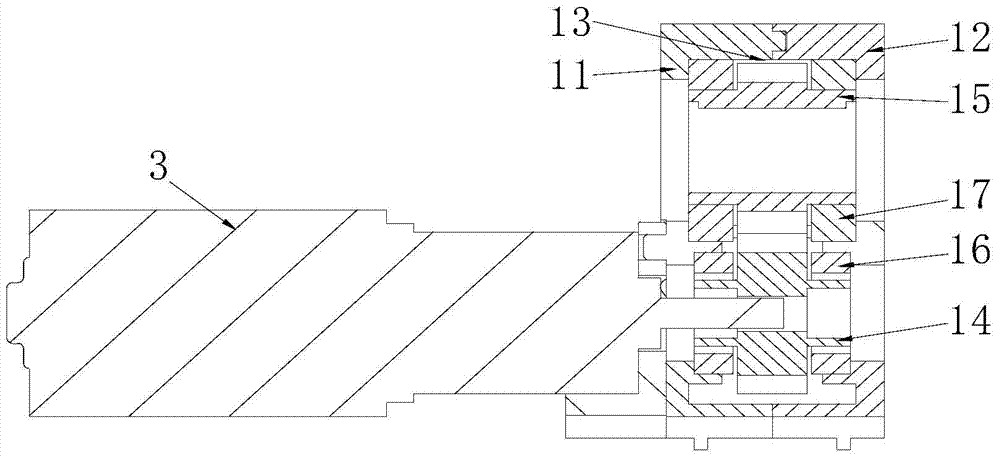

[0034] like figure 1 , 2 The lifting mechanism shown includes a transmission rod 1, a screw rod 2, a motor 3, a gear transmission block 4, a bearing seat 5, two dialing rope seats 6 and a travel switch 7. The transmission rod 1 is a hollow structure, and the transmission rod 1 is provided with transmission rod through holes 8 distributed along its longitudinal direction. The transmission rod through hole 8 runs through the entire transmission rod 1 longitudinally along the transmission rod 1, so that the screw rod 2 extends into the transmission rod 1, and at the same time reduces the weight of the transmission rod 1, so that the power mechanism drives the transmission rod 1 to rotate. One end of the transmission rod 1 is connected with the gear transmission block 4, and the gear transmission block 4 is connected with the motor 3; One end of the screw rod 2 extends into the through hole 8 of the transmission rod, and the other end is fixed on the receiving seat 5 . The tran...

Embodiment 2

[0045] The difference between this embodiment 2 and embodiment 1 is that in this embodiment 2, if Figure 9-11 As shown, a turning wheel 28 is also provided in the dialing rope seat 6, and a turning wheel fastening block 29 is provided in the turning wheel 28, and the turning wheel fastening block 29 is embedded in the fastening groove 10, so that the turning wheel 28 can follow the transmission Rod 1 turns to turn. The turning wheel 28 is provided with a turning pull cord 31 for adjusting the angle of the louver blade, and the turning pull cord 31 is connected with the louver leaf. The connection method between the overturning pull cord 31 and the louver leaf can refer to the existing louver, and will not be repeated here.

[0046] When the louver leaf needs to be turned over, the operator starts the motor 3, and the motor 3 drives the second gear 15 to rotate through the first gear 14, and then drives the transmission rod 1 to rotate a small angle, and the louver leaf can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com