Preparation device and method for diamond-containing coating

A technology of diamond coating and preparation equipment, which is applied in the direction of metal material coating technology, coating, metal processing equipment, etc., and can solve the problems of unusable coating, high surface roughness of coating, and decreased wear resistance of coating , to achieve the effect of simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

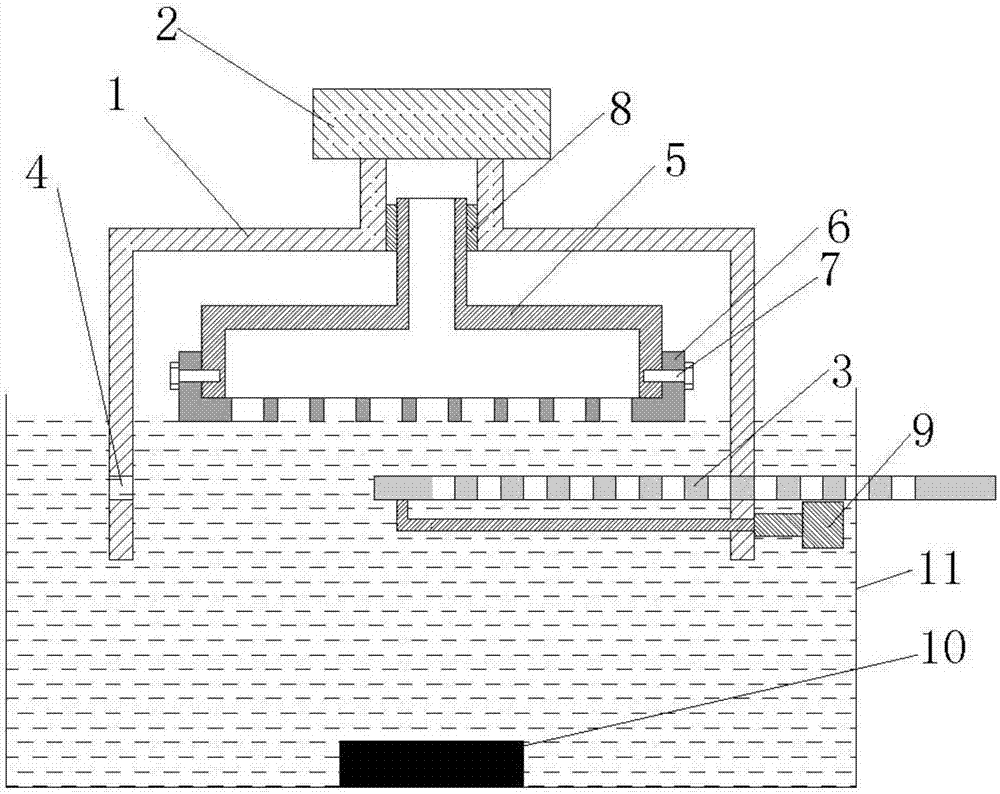

[0028] A preparation device containing a diamond coating, which is composed of an arrangement device and a container; the arrangement device includes an adsorption device and a filtrate fishing device; the adsorption device is surrounded by a cylinder liner at the upper end and an adsorption orifice plate at the lower end, and the adsorption orifice are fixed by screws; the filtrate fishing device is composed of a shell and a filtrate orifice, the upper end of the shell is connected to the first driving device, the shell and the cylinder liner are connected through the second driving device, the bottom of the shell is provided with a through groove, and the filtrate orifice Through the through groove to the bottom of the adsorption orifice, the filtrate orifice is connected to the third driving device; a container is arranged under the arrangement device, and an ultrasonic vibrator is arranged at the bottom of the container.

[0029] Further, the cylinder liner is connected wit...

Embodiment 1

[0058] The first step: select artificial single crystal diamond with a particle size of 18-20 mesh and regular shape, then put the diamond in a nitric acid solution with a concentration of 10%, wash it for 10 minutes, remove surface grease and sundries, and then use deionized water Wash until neutral, and finally dry for later use.

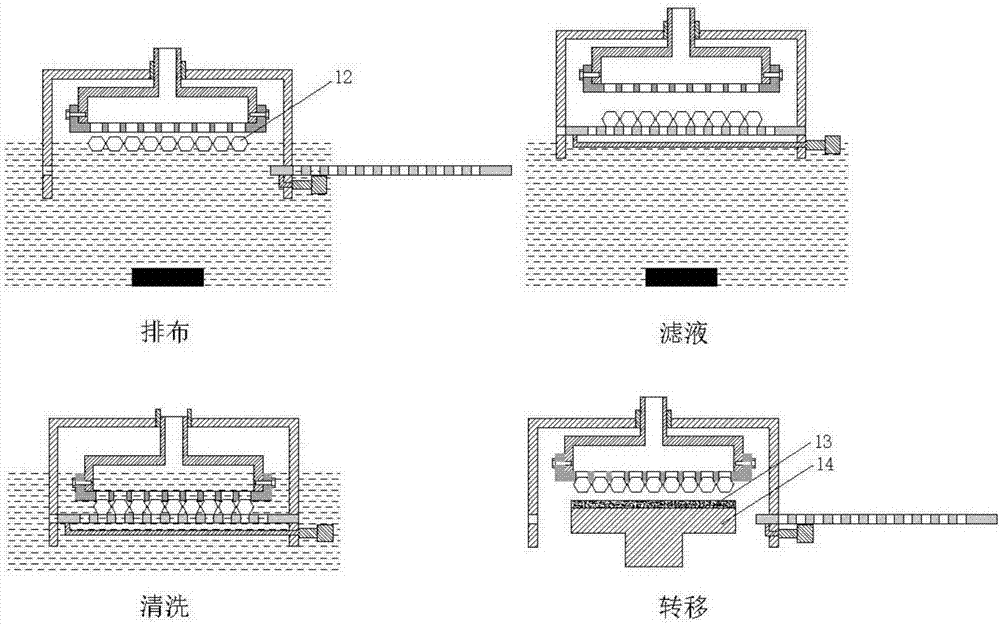

[0059] Step 2: Put 2 / 3 of 10% NaOH and 15% Na in the container 2 CO 3 solution, put the dried diamonds in the first step into the solution, and use a glass rod to stir the diamonds. The diamonds will float on the surface of the solution by using their own hydrophobicity and the tension of the solution, forming a layer of tightly arranged and orderly diamonds" pose" uniform single-layer diamond layer.

[0060] Step 3: Use an isolation orifice plate to transfer and isolate the diamond layer floating on the liquid surface to the liquid surface below the adsorption device.

[0061] Step 4: Start the ultrasonic vibrator (10) to adjust the "position"...

Embodiment 2

[0070] The first step: select artificial single crystal diamond with a particle size of 35-40 mesh and regular shape, then put the diamond in a sulfuric acid solution with a concentration of 10%, wash it for 10 minutes, remove surface grease and sundries, and then use deionized water Wash until neutral, and finally dry for later use.

[0071] The second step: Put 2 / 3 of the mixed solution containing 5% HCl and 15% NaCl in the beaker and the container, put the diamond dried in the first step into the solution, stir the diamond with a glass rod, and the diamond will use The self-hydrophobicity and the tension of the solution float up on the surface of the solution, forming a single-layer diamond layer that is closely and orderly arranged and the "position and posture" of diamonds is uniform.

[0072] Step 3: Use an isolation orifice plate to transfer and isolate the diamond layer floating on the liquid surface to the liquid surface below the adsorption device.

[0073] Step 4: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com