A kind of go/nha/collagen composite bone repair material and preparation method thereof

A technology for bone repair and collagen, which is applied in the field of biomedical composite materials, can solve problems such as cell membrane damage, and achieve the effects of simple operation, dense and orderly arrangement of collagen fibers, and excellent cross-linking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

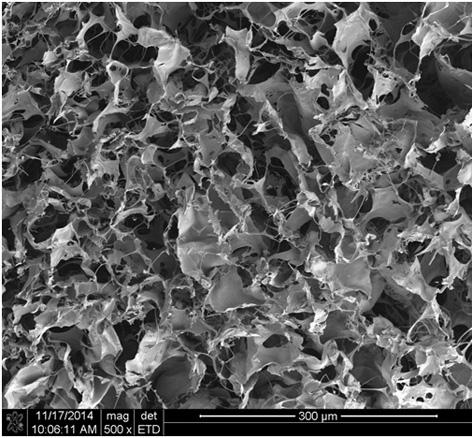

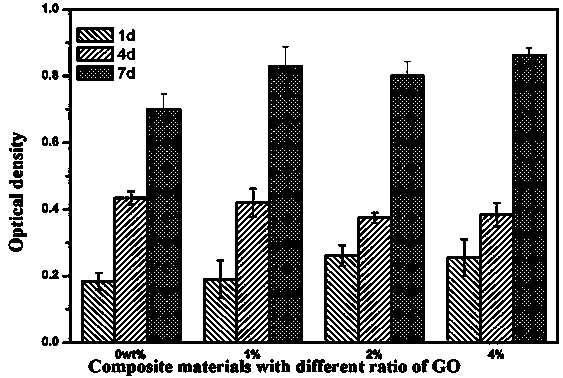

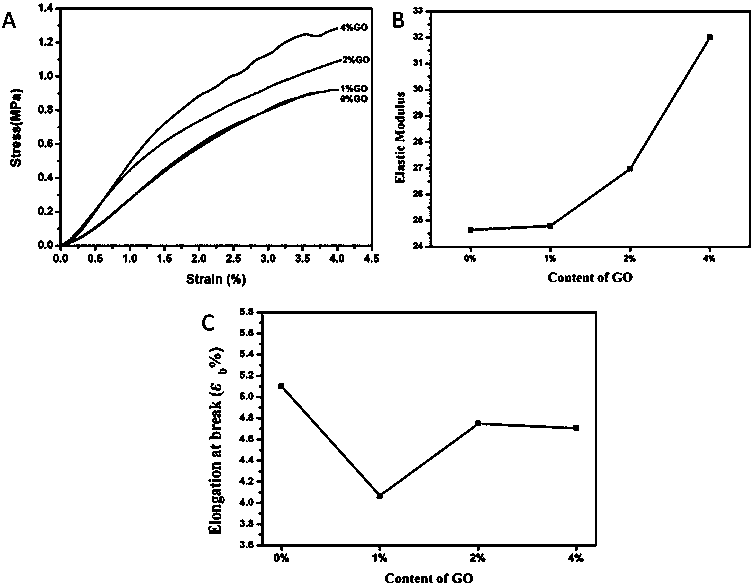

Image

Examples

Example Embodiment

[0036] Example 1

[0037] (1) Weigh 0.4 g of freeze-dried bovine tendon collagen and dissolve it in 99.6 mL of malonic acid with a volume concentration of 0.3% to obtain a collagen solution with a mass concentration of 0.4%, and continue stirring for 4 hours;

[0038] (2) Gradually add 0.08 g of nano-hydroxyapatite powder to the obtained collagen solution, magnetically stir for 8 hours, freeze-dry for 48 hours, and cross-link in 1000 mL of cross-linking solution;

[0039] (3) The composite membrane obtained after cross-linking is repeatedly washed with deionized water, and then freeze-dried again to obtain a nano-hydroxyapatite / collagen composite membrane with a GO content of 0 wt%.

Example Embodiment

[0040] Example 2

[0041] (1) Add 0.005 g of graphene oxide powder to water and ultrasonically disperse it for 2 hours to obtain a 2 mg / mL graphene oxide dispersion;

[0042] (2) Weigh 0.4 g of freeze-dried bovine tendon collagen and dissolve it in 99.6 mL of malonic acid with a volume concentration of 0.3% to obtain a collagen solution with a mass concentration of 0.4%;

[0043] (3) Mix the obtained graphene oxide dispersion with the collagen solution and stir for 4 hours to obtain a uniform graphene oxide-collagen mixture;

[0044] (4) Gradually add 0.095 g of nano-hydroxyapatite powder to the obtained graphene oxide-collagen mixture, magnetically stir for 8 h, freeze-dry for 48 h, and cross-link in 1000 mL of cross-linking solution;

[0045] (5) The composite film obtained after cross-linking is repeatedly washed with deionized water, and then freeze-dried again to obtain a graphene oxide / nano-hydroxyapatite / collagen composite film with a GO content of 1 wt%.

Example Embodiment

[0046] Example 3

[0047] (1) Add 0.01 g of graphene oxide powder to water and ultrasonically disperse it for 2 hours to obtain a 2 mg / mL graphene oxide dispersion;

[0048] (2) Weigh 0.4 g of freeze-dried bovine tendon collagen and dissolve it in 99.6 mL of malonic acid with a volume concentration of 0.3% to obtain a collagen solution with a mass concentration of 0.4%;

[0049] (3) Mix the obtained graphene oxide dispersion with the collagen solution and stir for 4 hours to obtain a uniform graphene oxide-collagen mixture;

[0050] (4) Gradually add 0.09 g of nano-hydroxyapatite powder to the obtained graphene oxide-collagen mixture, magnetically stir for 8 hours, freeze-dry for 48 hours, and cross-link in 1000 mL of cross-linking solution;

[0051] (5) The composite film obtained after cross-linking is repeatedly washed with deionized water, and then freeze-dried again to obtain a graphene oxide / nano-hydroxyapatite / collagen composite film with a GO content of 2 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com