Numerical control constant torque vertical bolt wrench

A fixed torque and bolt technology, applied in the field of wrenches, can solve the problems of inconvenient operation, difficulty in controlling torque, and too small torque, etc., and achieve the effect of convenient on-site operation and easy control of torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

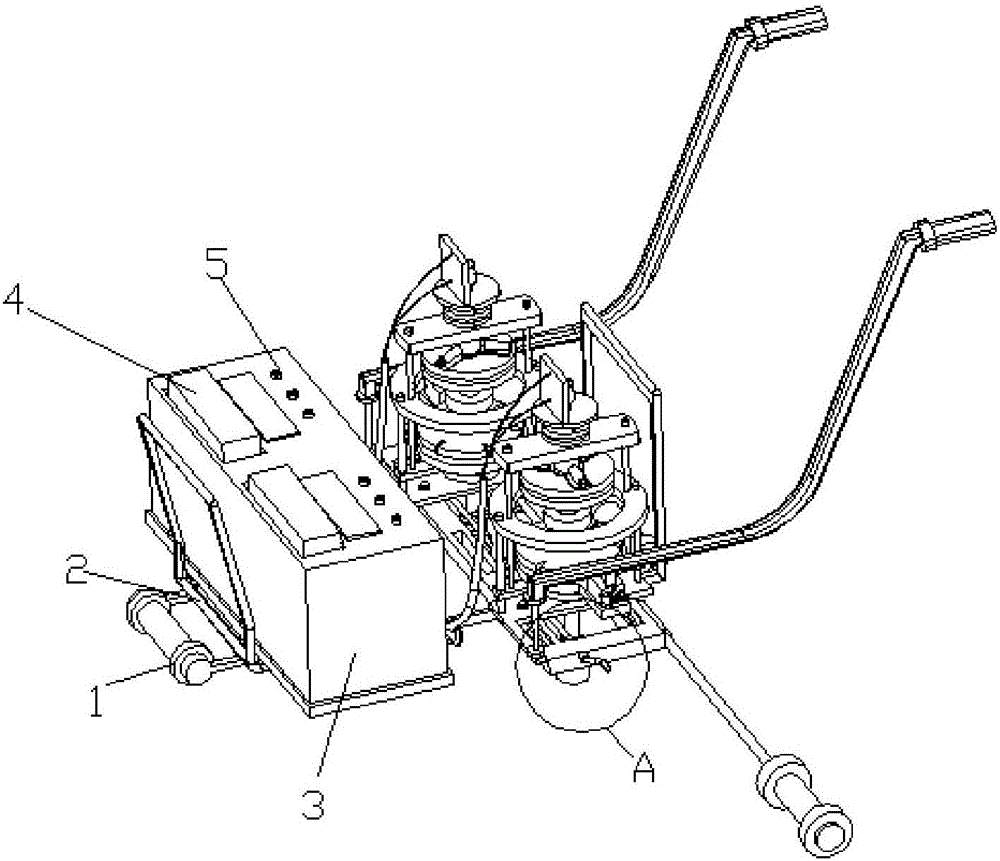

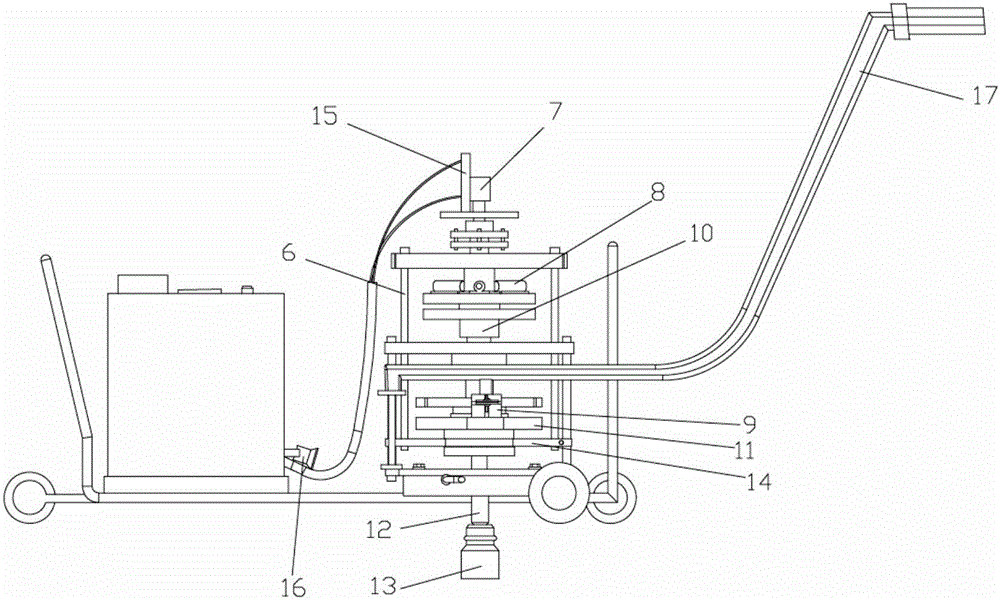

[0021] Such as figure 1 and figure 2 As shown, a kind of numerical control fixed torque vertical bolt wrench of the present invention comprises traveling wheel 1, traveling frame 2, power supply device, drive frame 14 and wrench main body; Said traveling wheel 1 is installed on described traveling frame 2 The two ends of the two ends; the power supply device and the driving frame 14 are installed on the walking frame 2 respectively; the wrench main body is two, respectively installed on the movable driving frame 14; The wrench main body includes a support frame 6, a motor 7, a clutch 8, a torque switch 9, a driver 10, a torque sensor 11, a transmission shaft 12 and a working sleeve 13; the support frame 6 is movably mounted on the drive frame 14, the motor 7 and the clutch 8 are mounted on the upper end of the support frame 6; the torque switch 9 and the driver 10 are mounted on the support frame 6; the torque sensor 11 is mounted on the support The lower end of the frame 6...

Embodiment 2

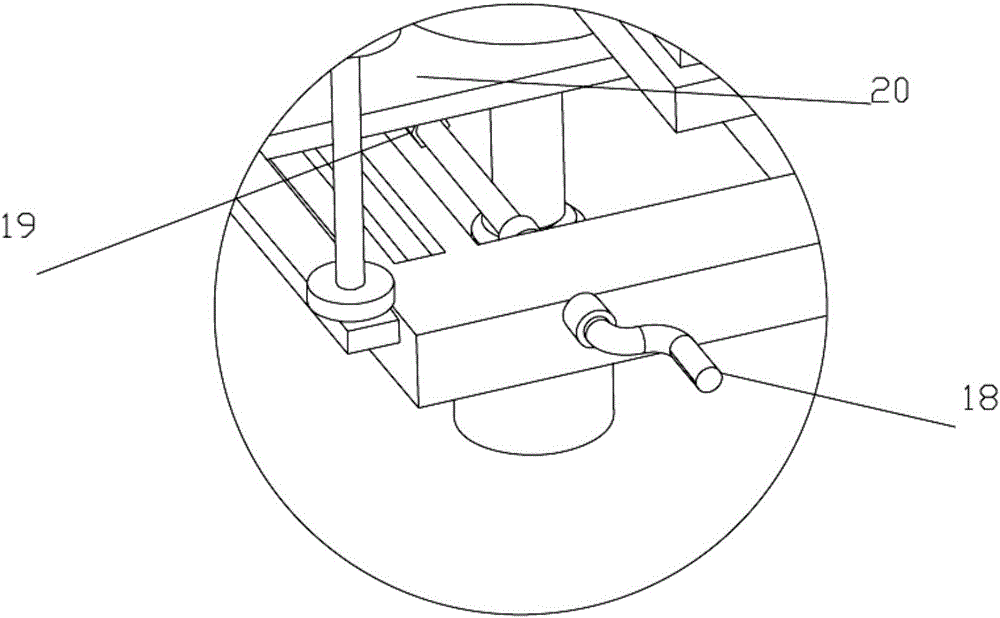

[0029] Embodiment two is basically the same as embodiment one, the difference is: as figure 2 As shown, the numerically controlled fixed-torque stand bolt wrench also includes a lighting lamp 16, which is installed on one side of the electric control instrument box 3, which is convenient for operation at night. The numerical control fixed torque vertical bolt wrench also includes an operating rod 17, and the operating rod 17 is fixed on one side of the driving frame 14 with bolts, which is convenient for workers to work. The driving frame 14 is provided with a cavity 20 through which the transmission shaft 12 passes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com