Ultra-low speed dynamometer based on ultrasonic antifriction principle

An ultra-low speed, dynamometer technology, applied in the field of motors, can solve the problems of unstable vibration, creeping phenomenon, inaccurate loading and measurement data, etc., to achieve the effect of adjustable torque and solving creeping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

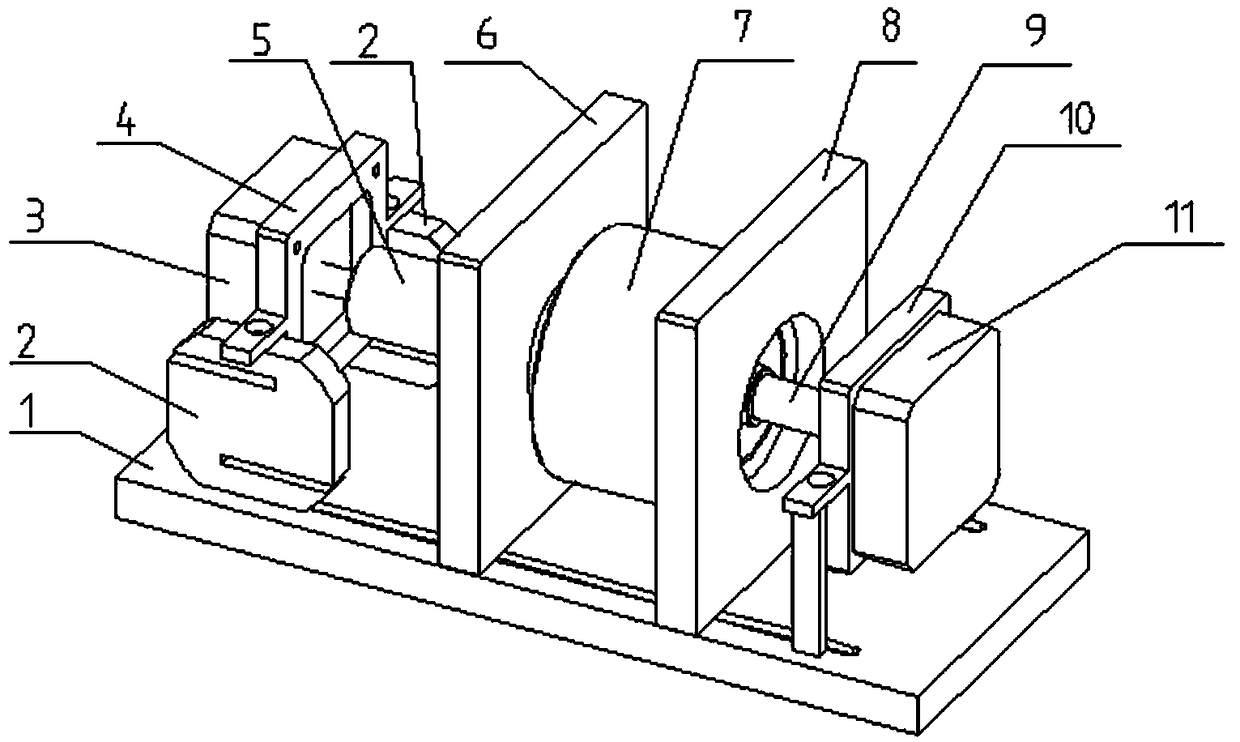

[0012] Such as figure 1 As shown, an ultra-low-speed dynamometer based on the principle of ultrasonic anti-friction includes two parts: a motor speed and torque measuring and controlling machine and a torque generator, and the torque generator is fixed on the base 1 of the motor speed and torque measuring and controlling machine; The measuring and controlling machine includes base 1, two pressure sensors 2, measuring motor 3, measuring motor fixing frame 4, coupling 5, bearing fixing frame 6, encoder 7, encoder fixing frame 8 and shaft 9, two pressure sensors 2 symmetrically fixed on both sides of the base 1, the motor fixing frame 4 is fixed above the two pressure sensors 2 by screws, the measuring motor 3 is fixed on the measuring motor fixing frame 4, and the measuring motor 3 drives the rotation of the shaft 9 through the coupling 5, The two bearings are respectively fixed inside the bearing fixing frame 6 and the encoder fixing frame 8, and are fixed on both ends of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com