Control method of multiphase motor driving topology with suspension capacitor

A suspension capacitor and motor drive technology, which is applied in motor generator control, electronic commutation motor control, motor control, etc., can solve the problems of inapplicability and less control dimensions, and achieve extended life, stable working status, and reliable torque. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

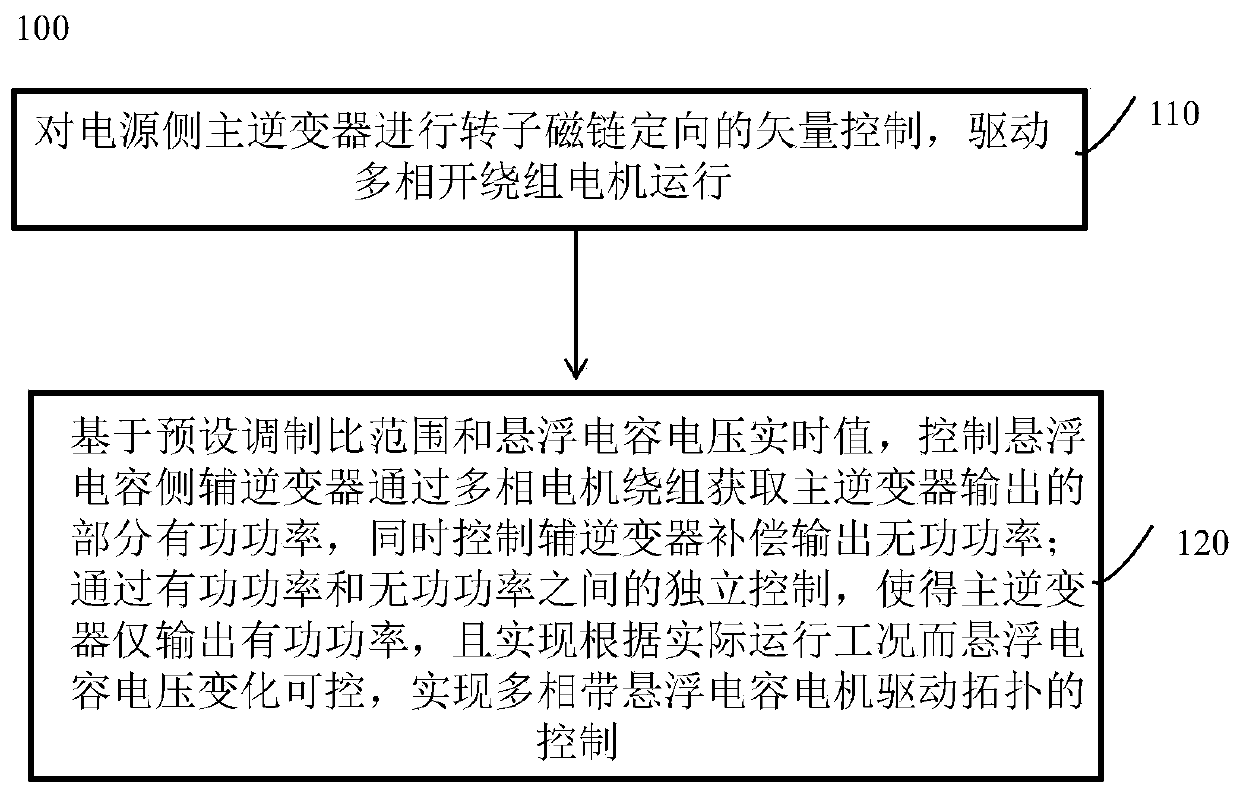

[0042] A control method 100 for a multi-phase motor drive topology with a floating capacitor, such as figure 1 shown, including:

[0043] Step 110, performing vector control of the rotor flux linkage orientation on the main inverter on the power supply side, and driving the multi-phase open-winding motor to run;

[0044] Step 120, based on the preset modulation ratio range and the real-time value of the floating capacitor voltage, control the auxiliary inverter on the floating capacitor side to obtain part of the active power output by the main inverter through the multi-phase motor winding, and at the same time control the auxiliary inverter to compensate the output reactive power power; through the independent control between active power and reactive power, the main inverter only outputs active power, and realizes the controllable change of the floating capacitor voltage according to the actual operating conditions, realizing the multi-phase motor drive topology with floati...

Embodiment 2

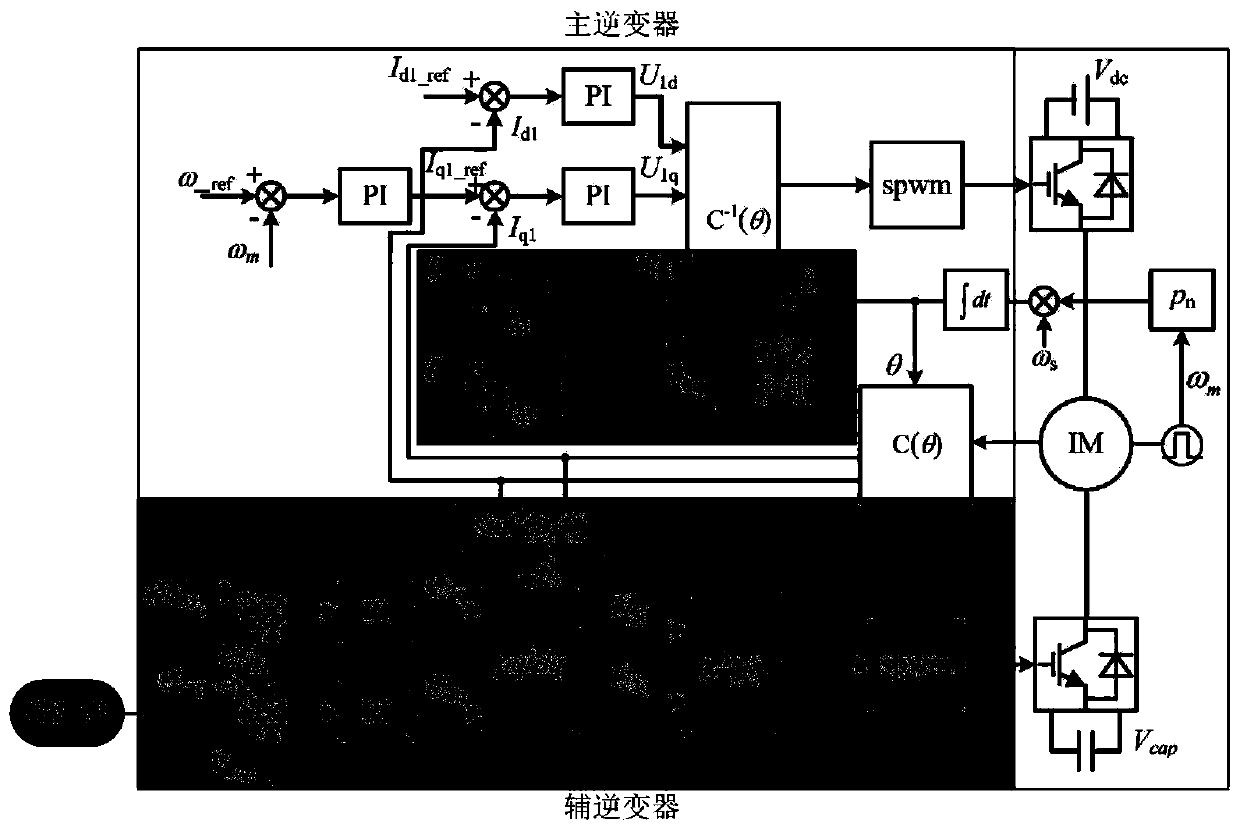

[0091] A multi-phase motor drive topology system with floating capacitors, such as Figure 9 As shown, it includes: a controller, and a main inverter on the power supply side respectively connected to the controller (the power supply voltage is V dc ), the floating capacitor side auxiliary inverter (the capacitor voltage is V cap ) and a multi-phase motor (the number of phases is n); wherein, each phase of the main inverter on the power supply side, the auxiliary inverter on the suspension capacitor side and the multi-phase motor is connected in sequence, and the controller is used to perform the above-described first embodiment A control method for any multiphase motor drive topology with a floating capacitor. In the figure, g 1 and g 2 Represents the reference ground potential of the main and auxiliary inverters.

[0092] The relevant technical solutions are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0094] A storage medium, in which instructions are stored, and when a computer reads the instructions, the computer is made to execute any one of the above-mentioned control methods for multi-phase motor drive topologies with floating capacitors.

[0095] The relevant technical solutions are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com