Straw torque measurement device

A technology for measuring torsion and straw, which is used in measuring devices, instruments, scientific instruments, etc., can solve the problems of low measurement accuracy and research efficiency, irregular size and shape, and difficult to process samples, and achieves stable, reliable and fast detection. Length controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

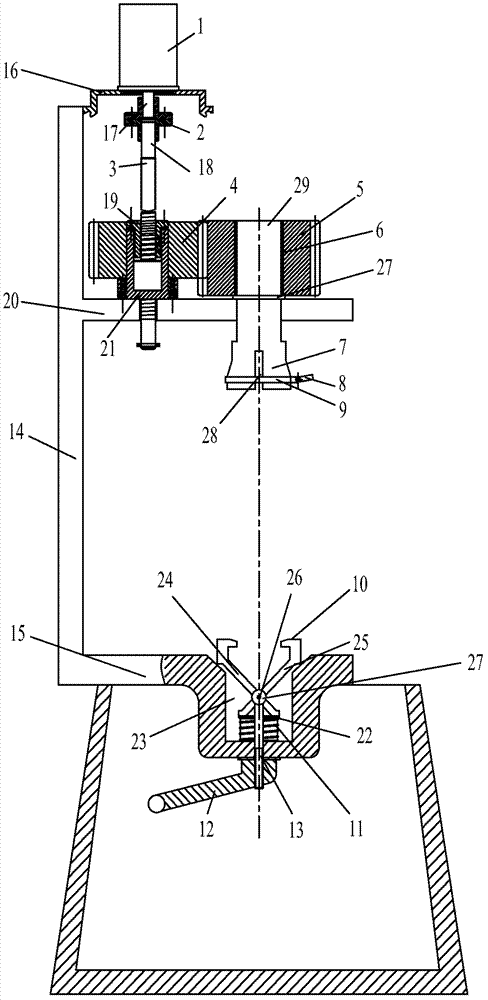

[0015] The present invention provides a straw torsion measuring device, which includes a frame 14, a lower clamping device and an upper clamping device; the frame 14 is sequentially provided with a top platform frame 16, an upper platform frame 20 and a lower platform frame 15 from top to bottom .

[0016] A universal testing machine 1 is fixed on the top platform frame 16; a screw nut device is arranged directly below the universal testing machine 1, and the screw nut device is a ball screw 3, and the ball screw 3 is composed of a screw 18 and a supporting screw nut. 19; the upper end of the screw mandrel 18 is fixedly connected to the transmission shaft 17 of the universal testing machine 1 through a coupling (ie, the rigid coupling 2), and the lower end of the screw mandrel 18 passes through the upper platform frame 20 and is exposed on the upper platform frame 20 lower end;

[0017] A transverse transmission device is provided above the upper platform frame 20, and the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com