Single-tube combustor device of ground combustion gas turbine

A technology of gas turbines and combustion chambers, applied in the direction of combustion chambers, continuous combustion chambers, combustion methods, etc., can solve the problems of additional pressure loss in turning, asymmetric flow, large cooling area of flame tubes, etc., and achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

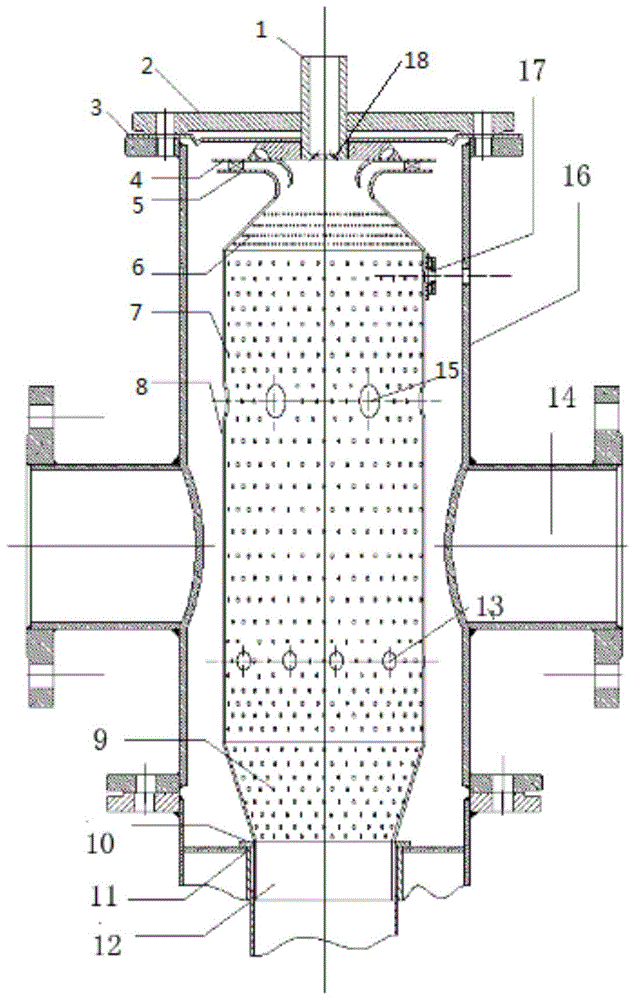

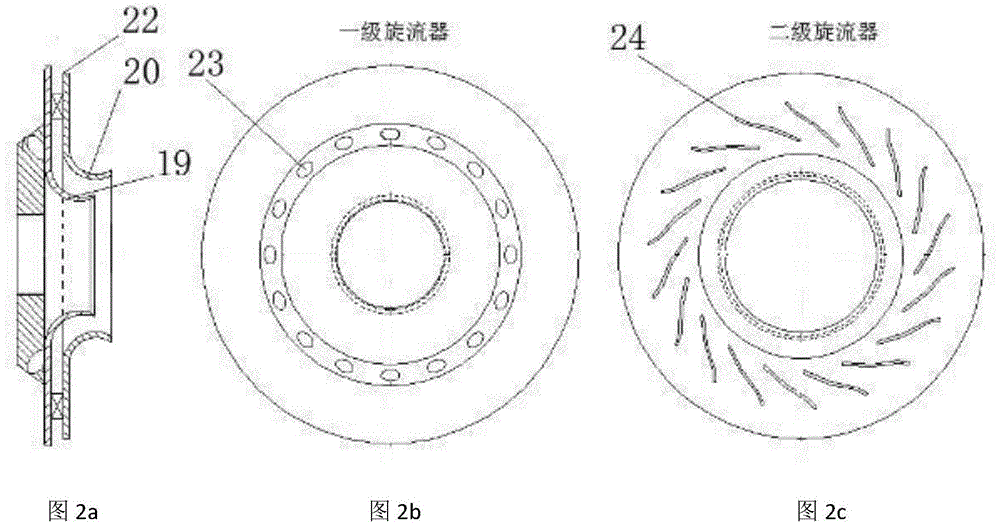

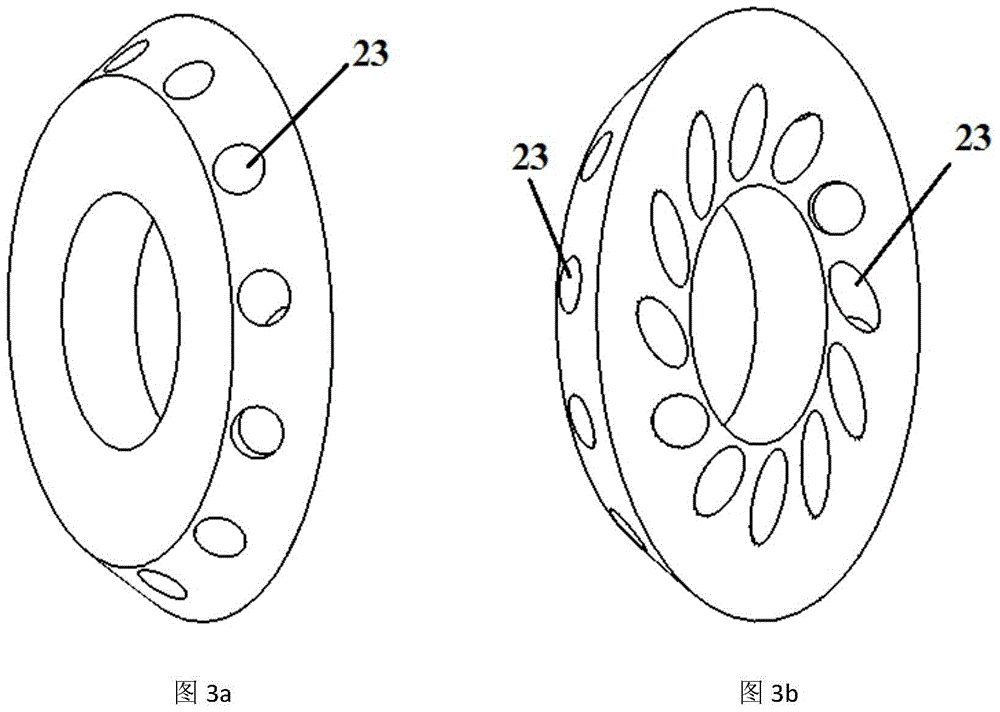

[0017] The single tube combustion chamber of the ground gas turbine designed by the present invention is composed of a natural gas burner 18, a first-stage obliquely cut hole swirler 4, a second-stage radial swirler 5, a casing 16 and a flame tube, and the flame tube is composed of a flame tube head 6. It is composed of the middle part 8 of the flame tube and the tail part 9 of the flame tube. After the high-pressure gas from the centrifugal compressor enters the single-tube combustion chamber through the symmetrical air inlet 14 on both sides, it is divided into five parts and enters the flame tube of the combustion chamber. The radial swirler 5, the main combustion hole 15 on the flame tube, the mixing hole 13 and the full-coverage film cooling small hole 7 on the wall surface of the flame tube. The combustion chamber end cover 2 is connected to the gas turbine case 16 by bolts; the natural gas inlet pipe 1 at the head is threaded to facilitate connection with the natural ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com