Multi-connecting-rod robot head and neck control mechanism

A control mechanism, multi-link technology, applied in the field of robotics, can solve the problems of difficult processing and manufacturing, many non-standard parts, complex and cumbersome structure of the head and neck mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

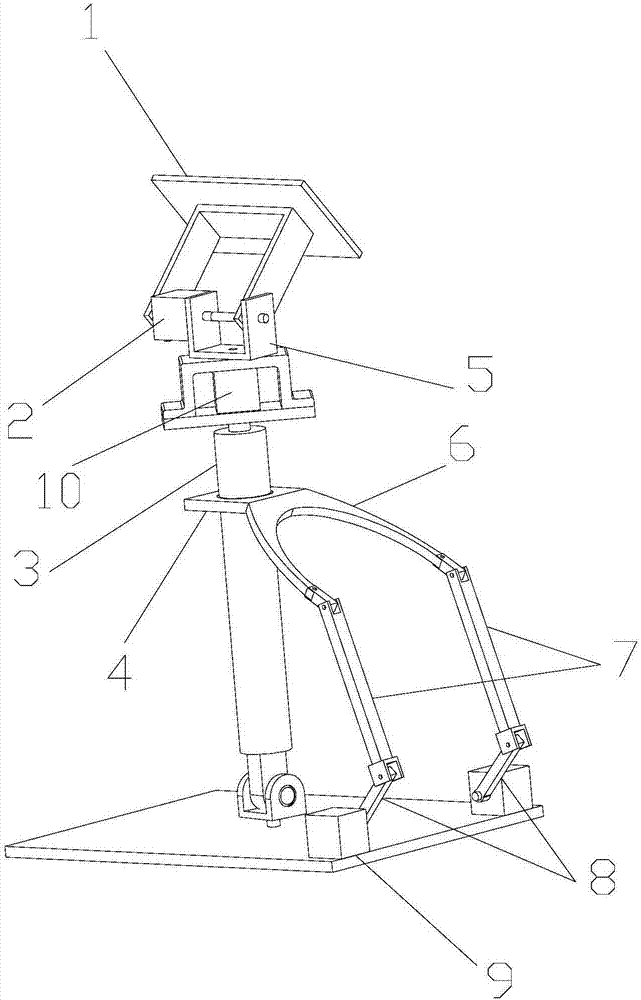

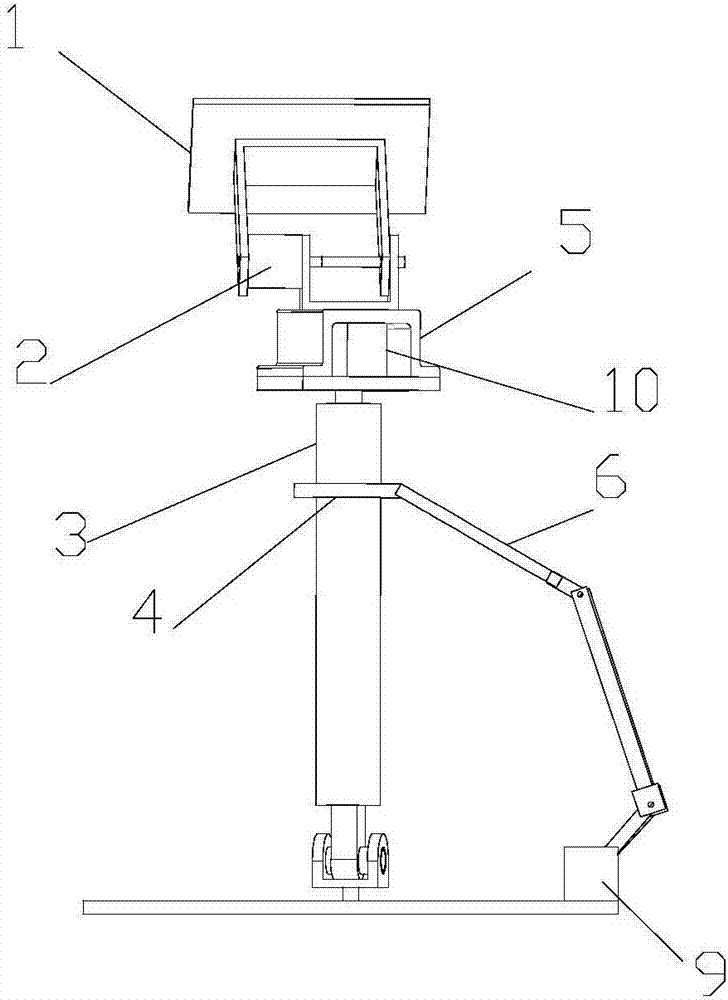

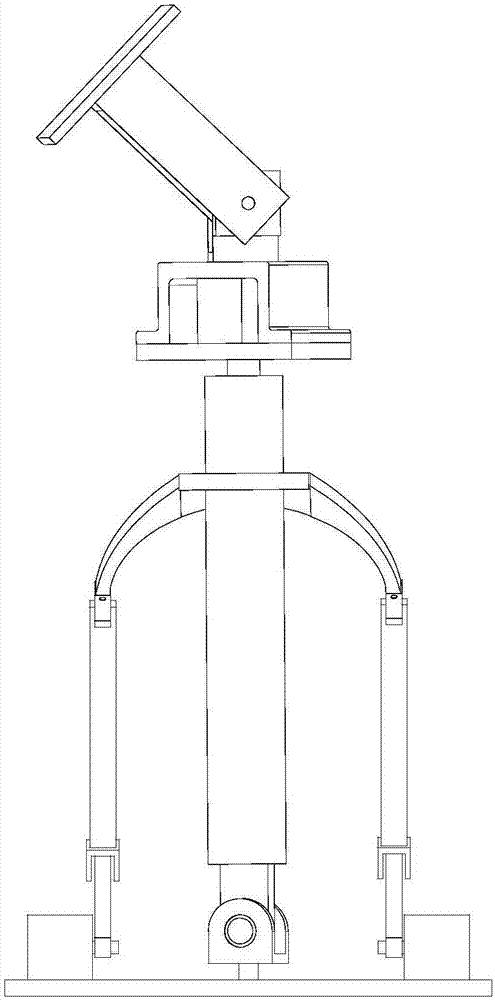

[0018] figure 1 It is an axonometric drawing of the present invention. As shown in the figure, the multi-link robot head and neck control mechanism in this embodiment includes a base for fixing with the torso of the robot, a head support plate 1 for fixing the head of the robot, and a head support plate 1 located on the head support plate 1. The neck between the base and the neck control mechanism for controlling the movement of the neck, the lower end of the neck is hinged to the base through a universal hinge; the neck control mechanism includes at least two The multi-link 7 mechanism connected to the neck and at least two motors 19 that control the action of the multi-link 7 mechanism one by one; the multi-link robot head and neck control mechanism of the present embodiment, two groups of multi-link 7 mechanisms and the neck Two groups of crank 8 rocker mechanisms are formed between the pillars 3, and the cranks 8 of the two crank 8 rocker mechanisms are respectively drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com