Application of industrial textile

A fabric and industrial technology, applied in the field of printers, can solve the problems of the printing medium and the mesh belt not being tightly bonded, the size of the conveyor belt cannot be accurately controlled, and the running stability is poor, so as to achieve tight bonding and good running stability , to reduce the effect of reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

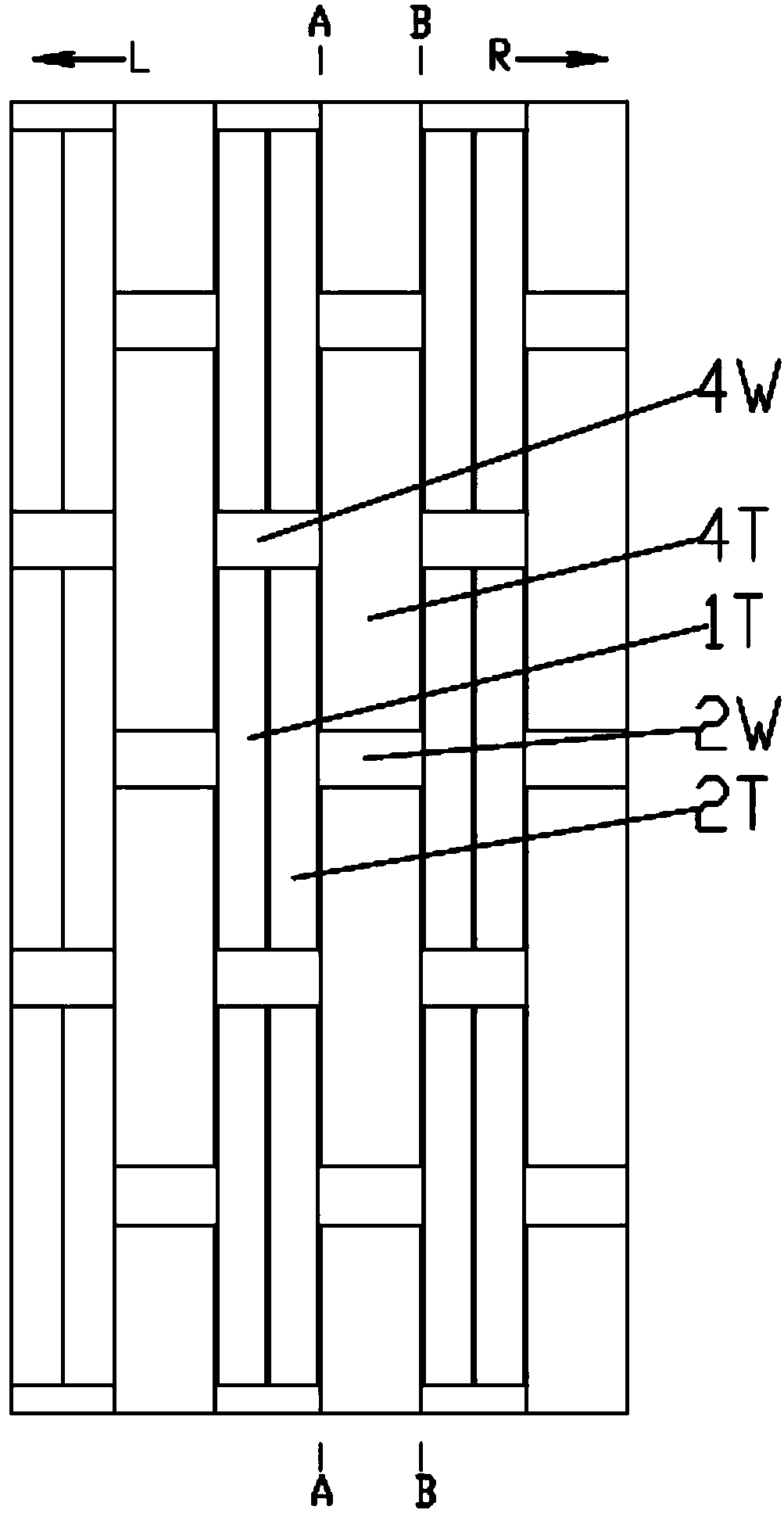

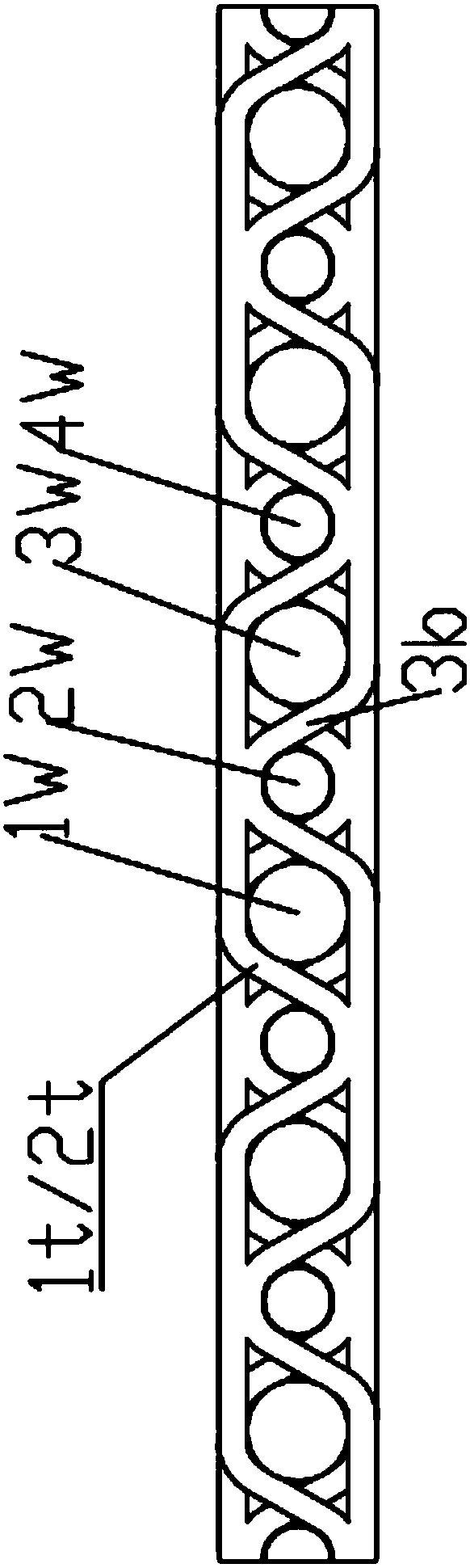

[0047] The double-layer structure is: one unit of the upper warp is 1 wide warp, and the other unit is 2 narrow warps; one unit of the lower warp is 2 narrow warps, and the other unit is 1 wide warp; the upper unit is 1 wide warp and The two narrow meridians in the lower layer are vertically stacked, and the width of the wide meridian is 0.6--1.5 times the sum of the widths of the two narrow meridians; The width of the warp is 0.6--1.5 times of the sum of the widths of the two narrow warps.

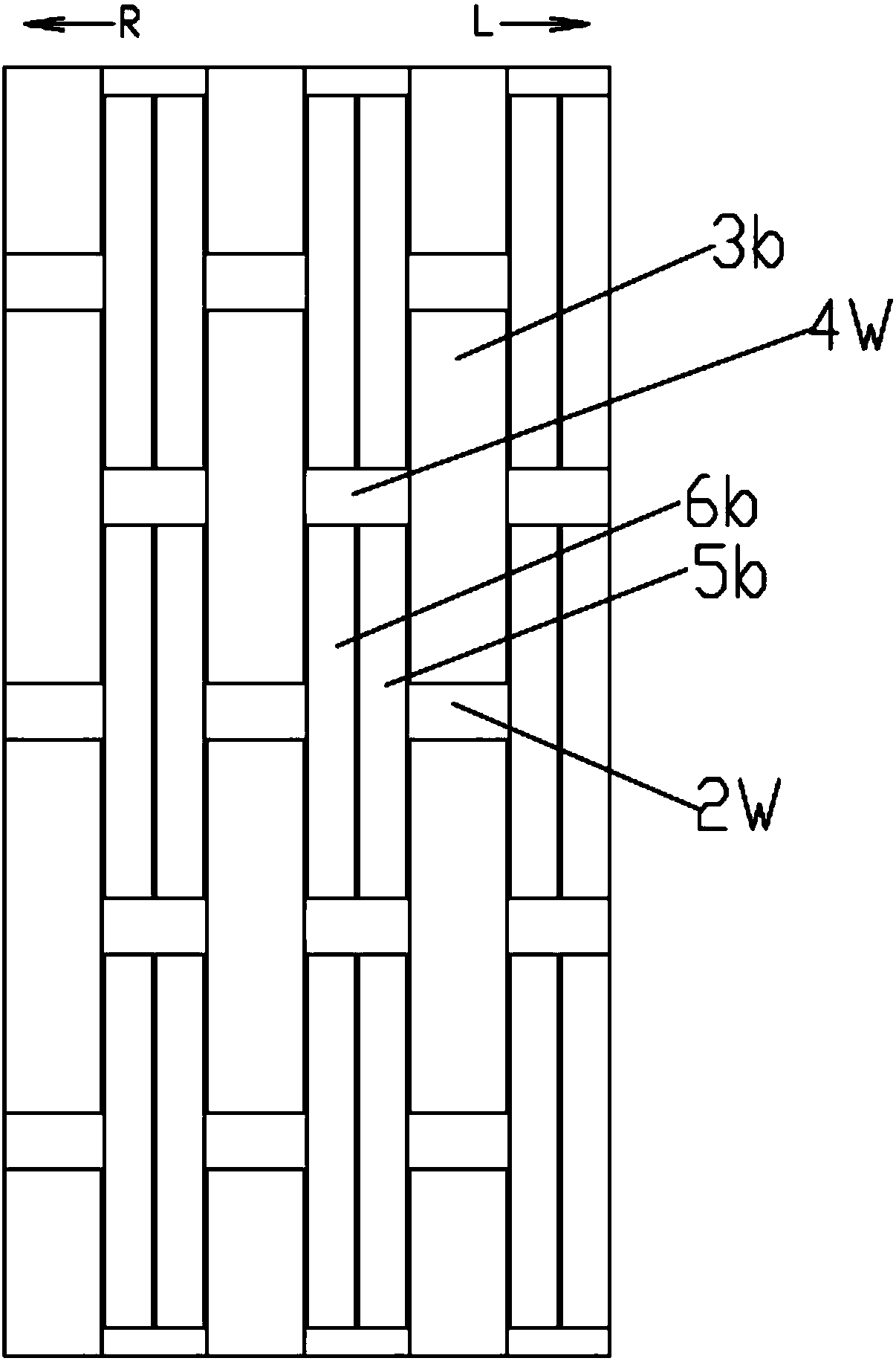

[0048] That is, one unit in the upper layer is a rectangular section wide meridian 4t, and the other unit is two parallel rectangular section narrow meridians 1t and 2t; the lower floor unit is two parallel rectangular section narrow meridians 5b and 6b, and the other unit is The unit is one rectangular section wide meridian 3b. The warps of the 4 units are interwoven according to the texture diagram in Table 1 to form a dry web fabric, and are alternately arranged on the entire dry web....

Embodiment 2

[0059] The double-layer structure is: 1 unit on the upper layer is 2 parallel narrow warps, and the other unit is also 2 parallel narrow warps; 1 unit on the lower layer is 2 parallel narrow warps, and the other unit is 2 parallel narrow warps Meridians: The two narrow meridians of the upper unit are vertically stacked with the two narrow meridians of the lower unit respectively.

[0060] That is, one unit in the upper layer is two parallel rectangular cross-section narrow warps 11t and 12t, and the other unit is also two parallel rectangular cross-section narrow warp lines 13t and 14t; one lower unit is two parallel rectangular cross-section narrow warp lines 15b and 16b, the other unit is two parallel narrow meridians 17b and 18b of rectangular section. The 4 warp units are interwoven according to the texture diagram in Table 2 to form a dry web fabric, and are alternately arranged on the entire dry web. The color of described net is through black.

[0061] Figure 8 and ...

Embodiment 3

[0071] Embodiment 3 of the present invention is that 1 unit of the upper layer is 1 wide meridian of rectangular section, and the other unit is 2 parallel narrow meridians of rectangular section; 1 unit of the lower floor is 2 parallel narrow meridians of rectangular section, and the other unit is 1 The width meridian of the root rectangular section. One wide warp of the upper layer and one wide warp of the lower layer are vertically superimposed, and the width of the upper and lower wide warp is basically the same. The 2 narrow warps of the upper layer and the 2 narrow warps of the lower layer are vertically stacked, and the sum of the widths of the 2 narrow warps of the upper layer is basically the same as the sum of the widths of the 2 narrow warps of the lower layer. The color of the net is black.

PUM

| Property | Measurement | Unit |

|---|---|---|

| gas permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com