Vertical-ring high-gradient magnetic separator

A high-gradient magnetic separator and vertical ring technology, applied in the direction of high-gradient magnetic separator, etc., can solve the problems such as the improvement of the separation magnetic field and the adverse effect of stability, the gas is not easily discharged, and the heat dissipation effect, etc., and is conducive to oil circulation. And the effect of gas discharge, improved heat dissipation effect, improved stability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below with reference to the accompanying drawings and examples.

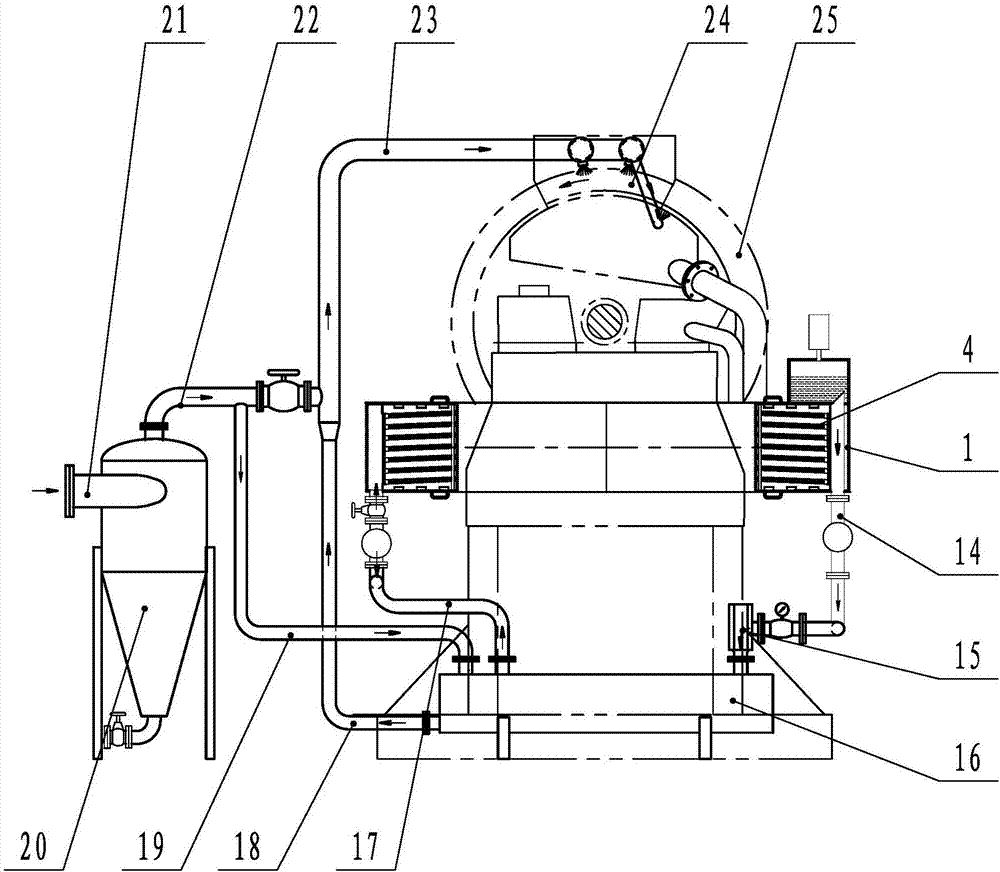

[0031] Such as figure 1 As shown, the vertical ring high gradient magnetic separator of the present invention includes a cooling system and an ore flushing system.

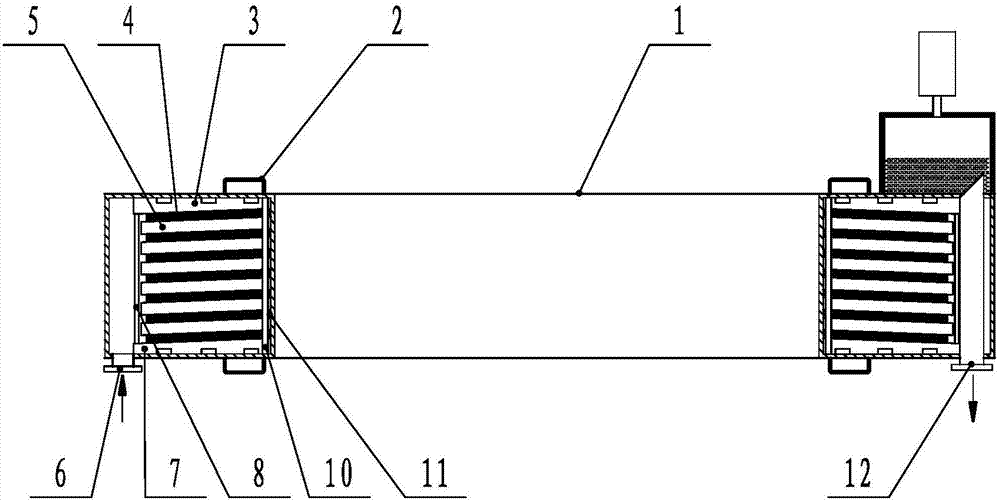

[0032] Such as figure 1 As shown, wherein, the cooling system includes: an excitation coil, an oil pump 15 and a cooler, and the cooler adopts an oil-water heat exchanger 16, and the excitation coil, the oil pump 15, and the oil-water heat exchanger 16 are connected in series through an oil inlet pipe 17 and an oil outlet pipe 14 Form a closed forced oil circulation loop.

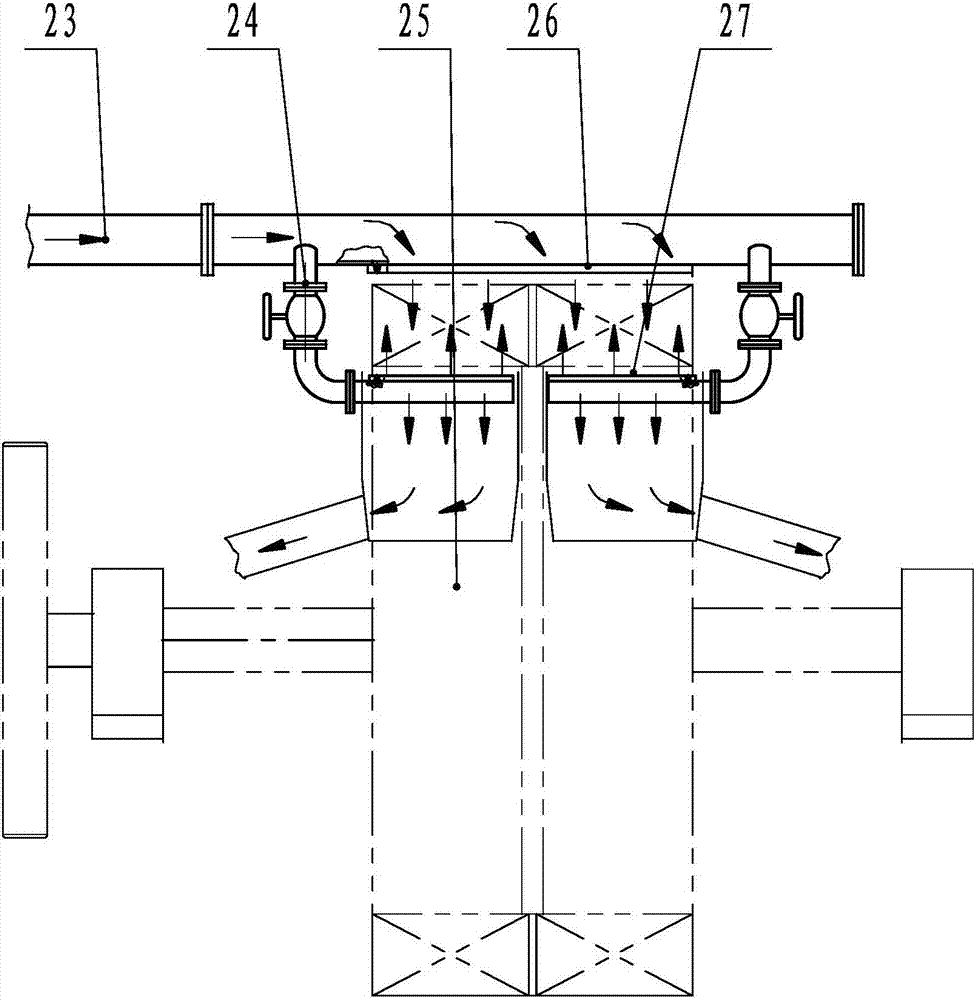

[0033] Such as figure 1 and figure 2 Commonly shown, wherein, the ore flushing system includes: ore flushing water pipe, the ore flushing water pipe is divided into a flushing ore water pipe 23 and a recoil ore water pipe 24 at its water outlet, and the flushing ore water pipe 23 is located at the end of the vertical r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com