Power output control circuit and multi-layer power supply system

A power supply output and control circuit technology, applied in control/regulation systems, output power conversion devices, DC power input conversion to DC power output, etc., can solve problems such as long start-up time, unclear start-up sequence, and large start-up current , to achieve the effect of improving the starting ability, clear and reliable starting sequence, and stabilizing the output voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

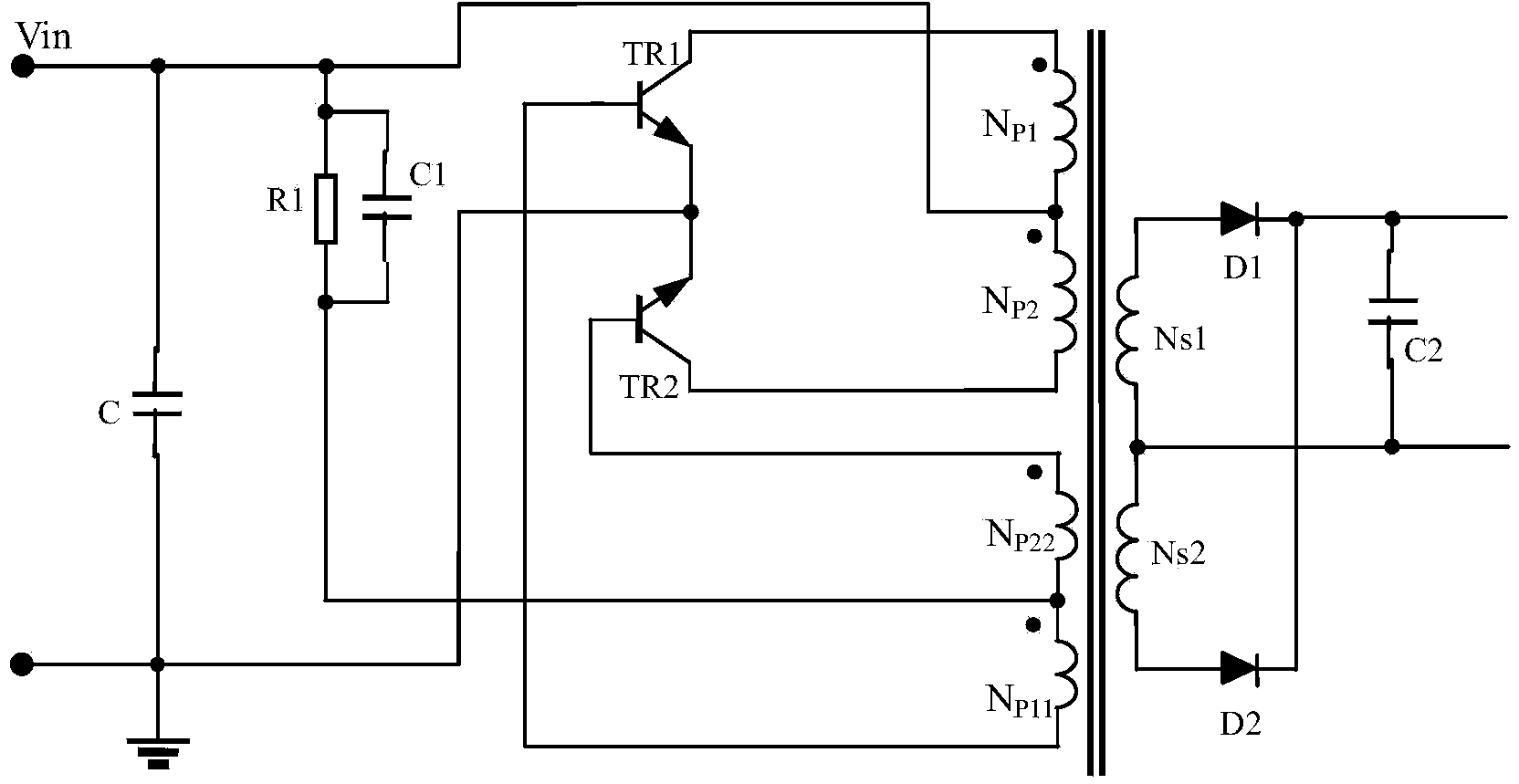

[0048] Such as Figure 5 As shown, the power supply output control circuit B of the present invention is arranged between the output terminal of the power supply circuit A and the load, and it is composed of a switch tube and a detection control circuit with a preset voltage value, and the switch tube is connected in series at the output of the power supply circuit A Between the terminal and the load, the detection control circuit detects the output voltage of the power supply circuit A, and controls the switching tube to turn off when the output voltage is lower than the preset voltage value, and controls the switching tube to turn off when the output voltage is above the preset voltage value conduction. Wherein, the load may be a current load or a resistance load, and a large capacitance may be connected in parallel.

[0049] Figure 7 The power supply output control circuit B of Embodiment 1 of the present invention is shown, the switch tube is a PNP transistor Q1, the de...

no. 1 example approach

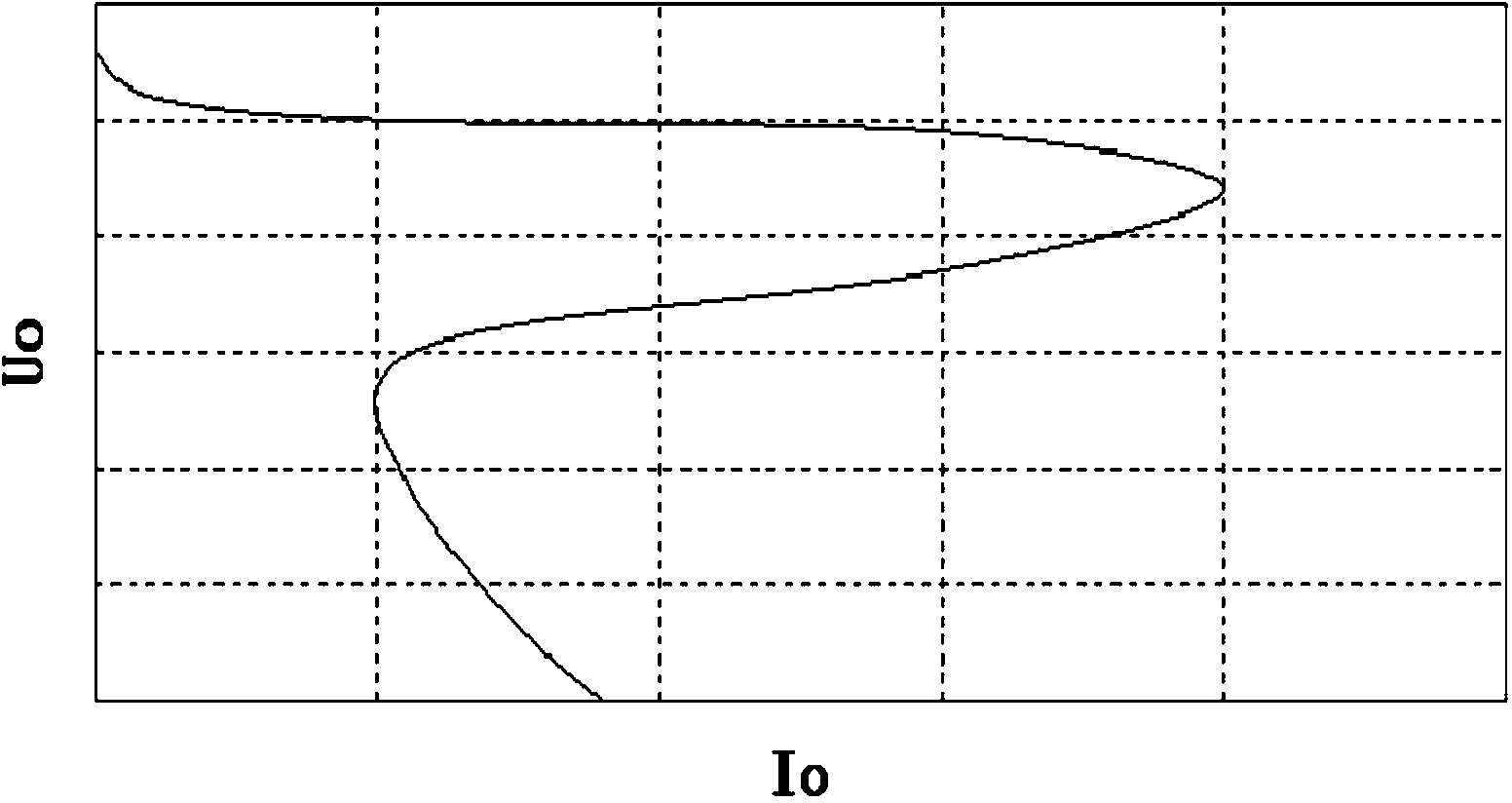

[0055]When adopting the existing scheme, the power supply circuit is directly connected to the load circuit, and the power supply output control circuit is not connected in the middle. Since the voltage cannot rise rapidly when the output load has capacitance, in order to show the difference in start-up sequence between the first embodiment of the present invention and the existing solution, a common DC power supply with a start-up time of about 8 mS is used here to supply power to the power circuit. The start-up waveform of the existing power control scheme is as follows Figure 8 shown. The start-up waveform when using the power control scheme of the first embodiment of the present invention is as follows Figure 9 shown. Waveform 1 in the figure is the power supply voltage variation waveform, and waveform 2 is the load voltage variation waveform. It can be seen from the start-up waveform diagram that in the existing scheme, as the output voltage of the power supply is es...

no. 1 example

[0057] In order to illustrate the starting capability of the power supply under the scheme of the first embodiment of the present invention, the input voltage of the power supply is stepped up, and the output voltage waveform of the power supply is tested to illustrate the difference between the first embodiment of the present invention and the existing scheme. The test waveform of the existing scheme is as follows Figure 10 , the test waveform of the first embodiment of the present invention is as follows Figure 11 . Waveform 1 in the figure is the waveform of the voltage change of the power supply, and waveform 2 is the waveform of the load voltage change of the measured power supply. Figure 10 In the process of establishing the load voltage of the medium power supply, it shows a rapid rise first, then a slow rise, and then a rapid rise after approaching the output voltage of the power supply. The change in the voltage rise rate indicates that the output current capabil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Relative permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com