Motor rotor and self-starting synchronous motor

A motor rotor and permanent magnet technology, applied in synchronous machines, magnetic circuit rotating parts, electromechanical devices, etc., can solve the problems of poor motor starting ability and lack of spiral structure, reduce braking torque and solve technical difficulties , reduce the effect of harmonics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

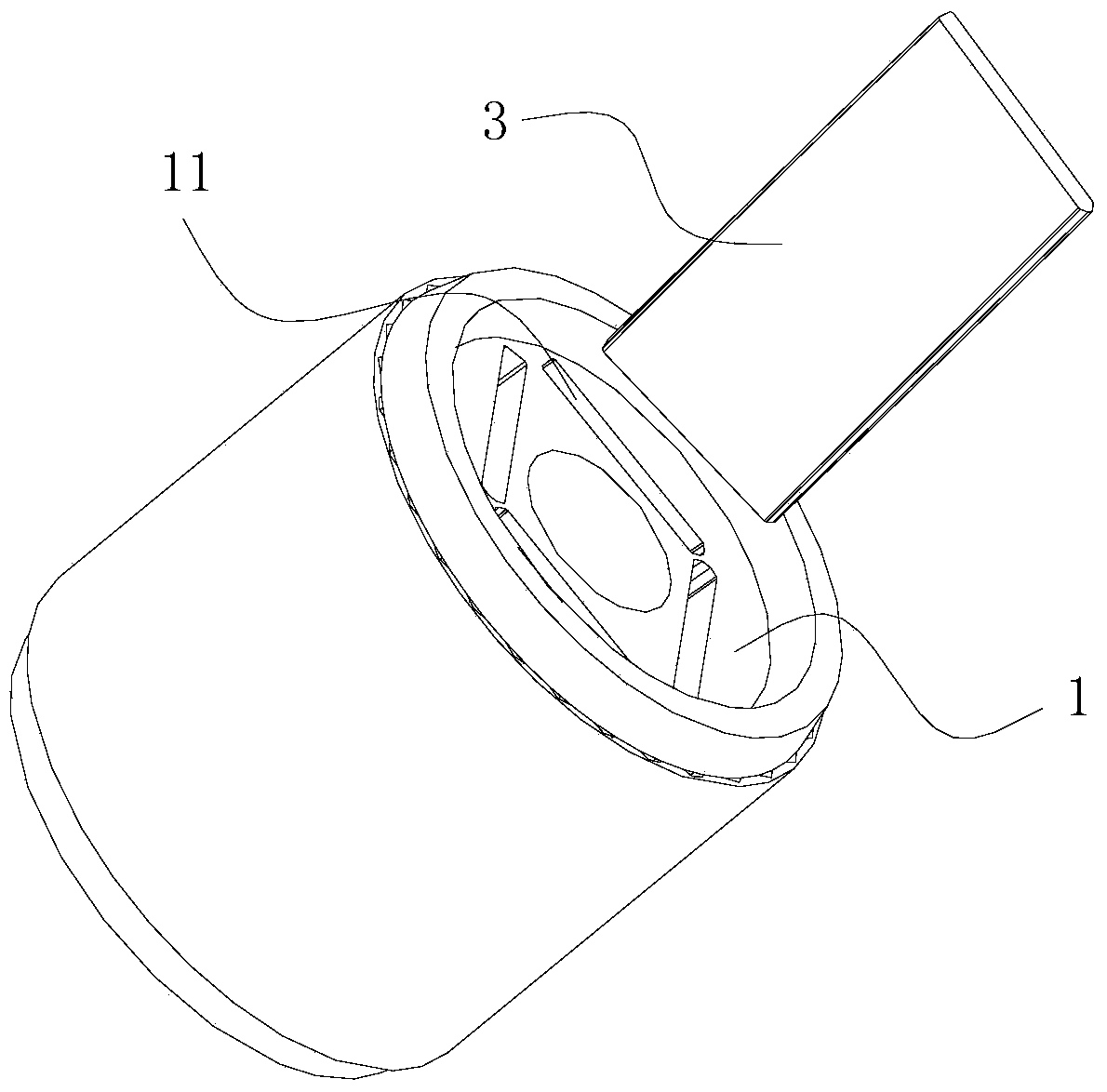

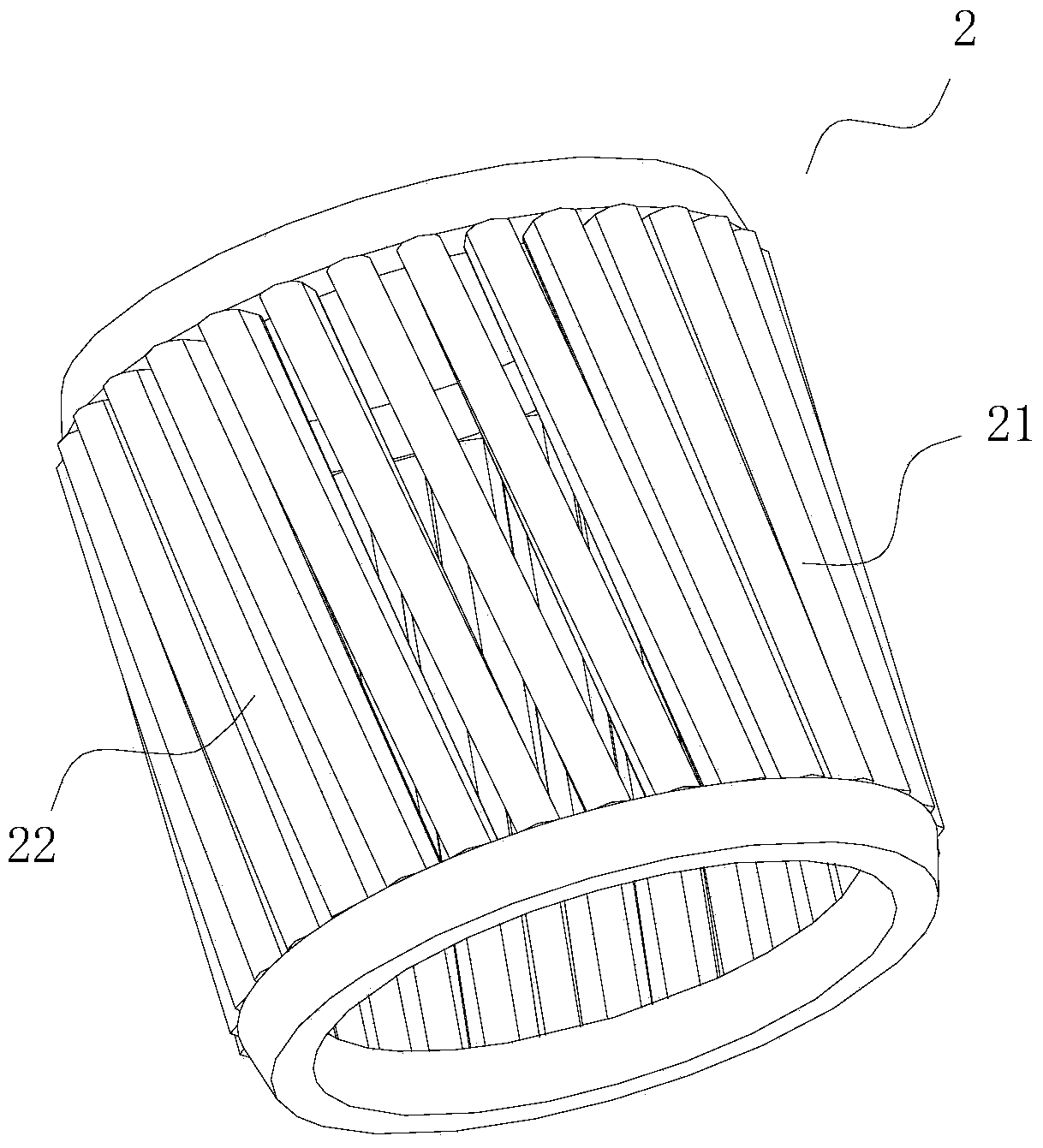

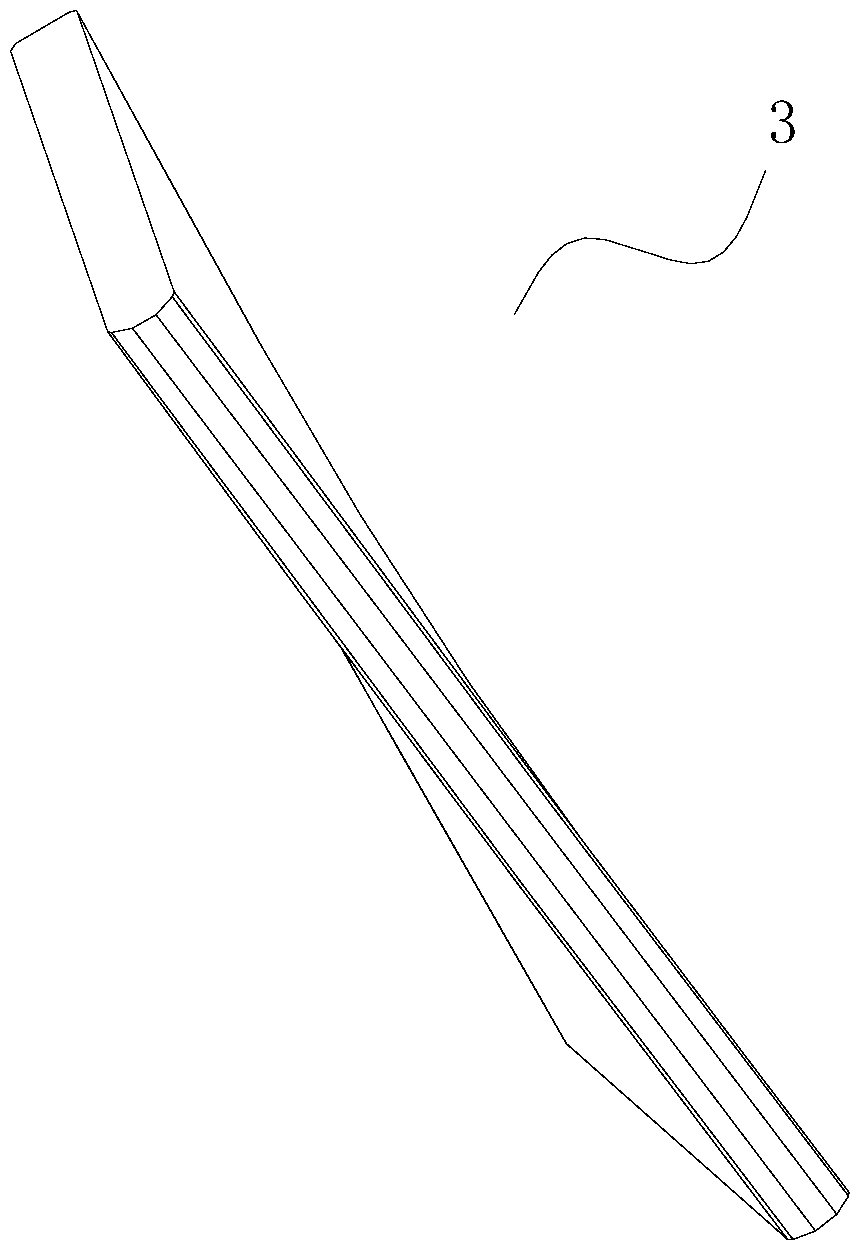

[0027] The preferred embodiment discloses a motor rotor. Such as Figure 1 to Figure 4 As shown, the motor rotor includes an iron core 1, a squirrel cage 2, and a permanent magnet 3. Among them, the permanent magnet 3 has a plate-shaped structure, and at least a part of the area on the permanent magnet 3 is bent toward the vertical direction of the plane to which the permanent magnet 3 belongs. The side wall column 21 of the squirrel cage 2 is inclined with respect to the bottom surface, and a chute 22 is formed between the side wall column 21; the inclination angle of the side wall column 21 matches the bending angle of the permanent magnet 3. The iron core 1 is provided with a slot 11 which is inclined with respect to the bottom surface; the inclination angle of the slot 11 is adapted to the bending angle of the permanent magnet 3.

[0028] After installation, the iron core 1, the squirrel cage 2 and the permanent magnet 3 are all spirally stretched from the bottom surface of...

Embodiment 2

[0031] The preferred embodiment discloses a self-starting synchronous motor including a stator, and the motor is provided with a rotor as described in the first preferred embodiment. The side wall columns of the squirrel cage are inclined with respect to the bottom surface, and a slanted slot is formed between the side wall columns, and the span of the slanted slot is a stator tooth width, which increases the starting ability of the motor and reduces the influence of harmonics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com