Conductive sliding ring brush holder system capable of automatic switching and working method thereof

A conductive slip ring and automatic switching technology, applied in the direction of circuits, current collectors, electrical components, etc., to achieve the effect of simple working principle, less manpower, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

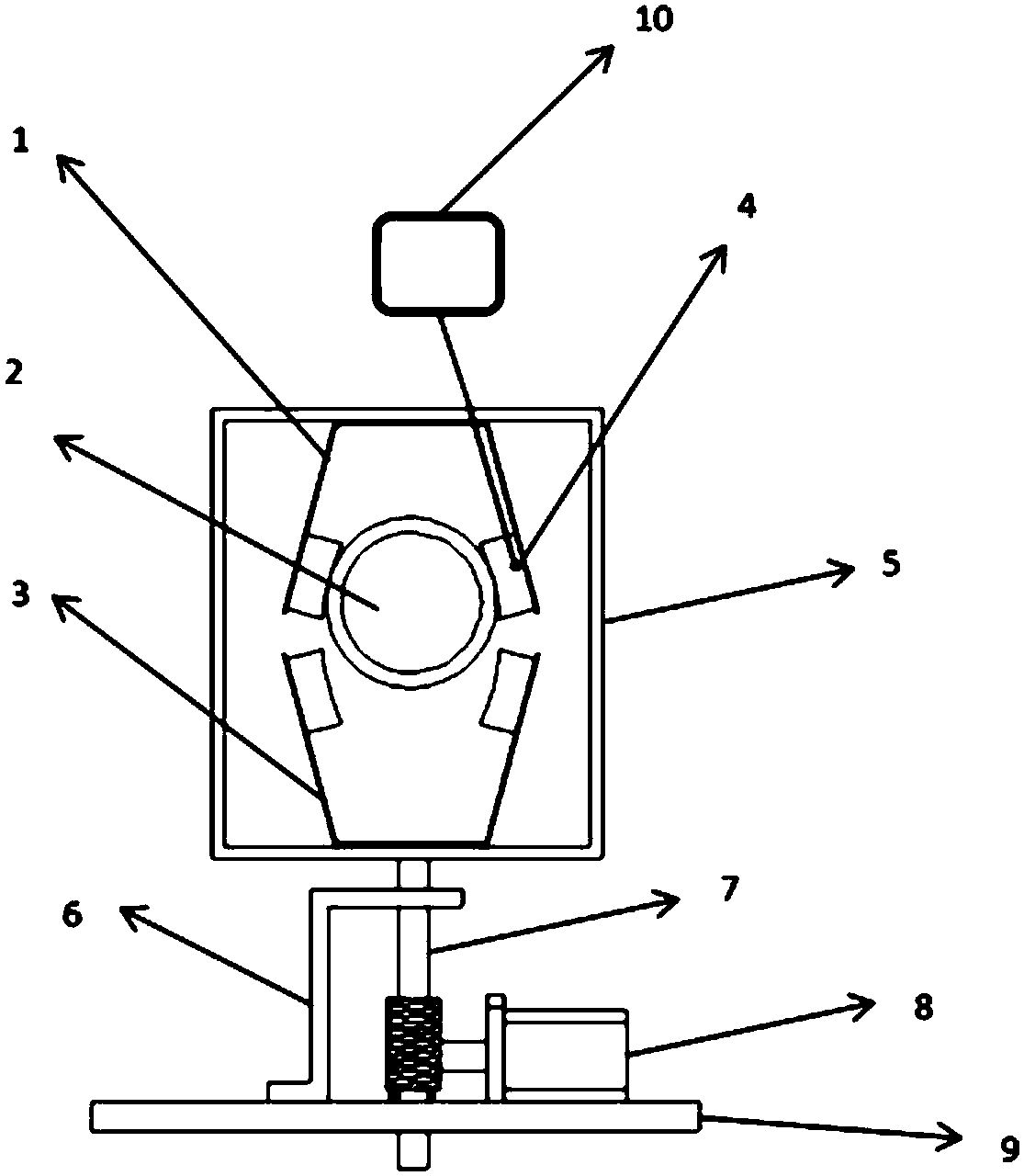

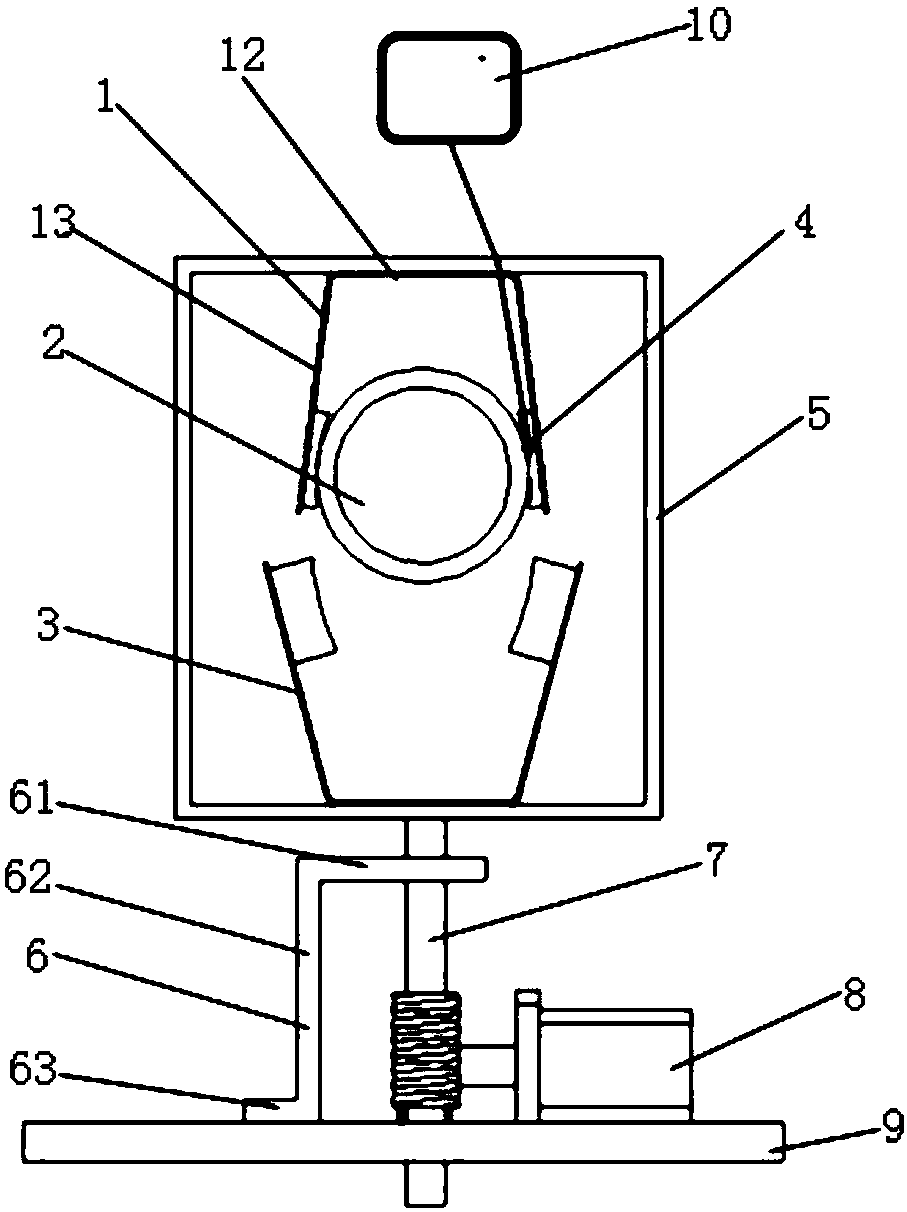

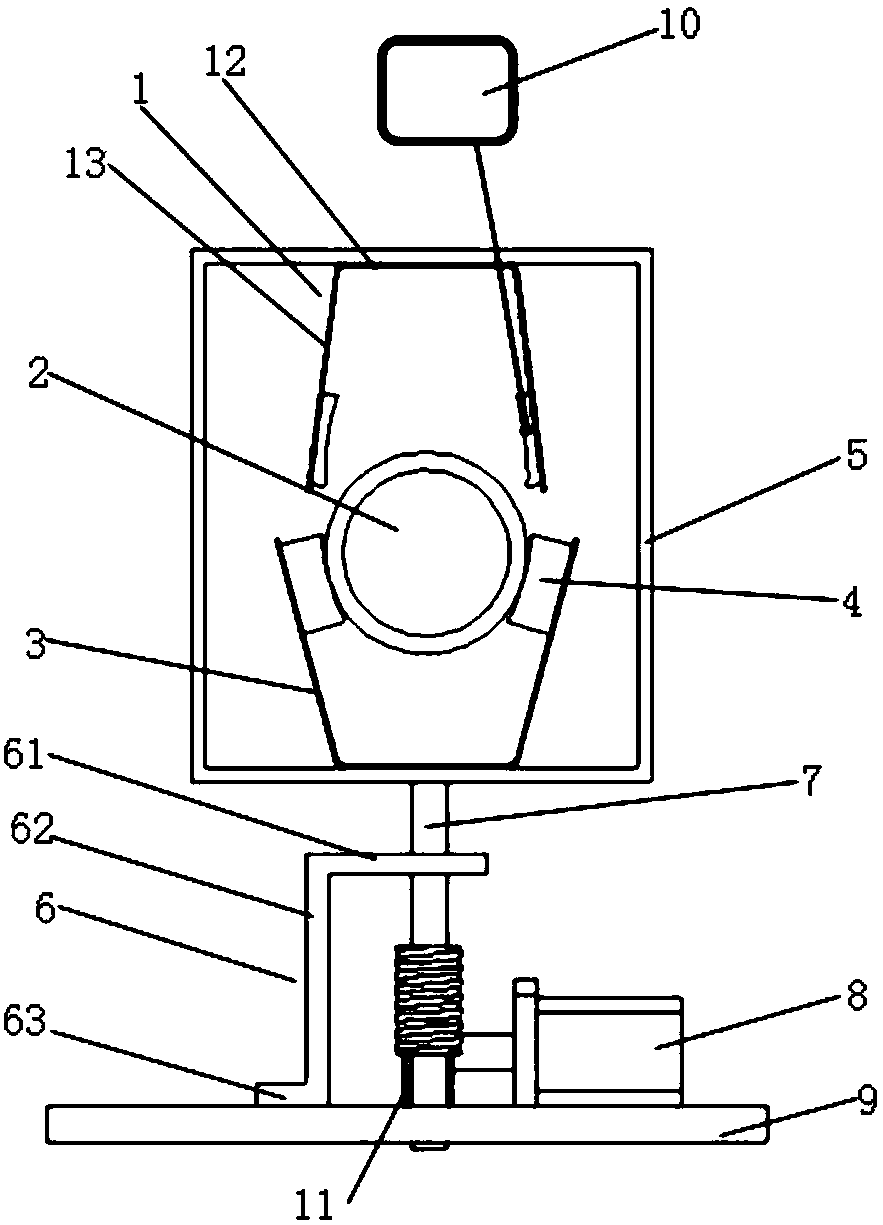

[0035] Such as Figure 1-4 The automatic switchable conductive slip ring brush holder system shown includes brush 1, conductive ring 2, spare brush 3, worn thimble 4, movable frame 5, screw rod fixing frame 6, screw rod 7, motor 8, The support plate 9, the host computer 10 and the gear 11, the brush 1 is connected to the backup brush 3, the wear thimble 4 is arranged at the end of the brush 1 and the backup brush 3 away from the conductive ring 2, the The electric brush 1 is connected with the upper end surface of the movable frame 5, the spare brush 3 is connected with the lower end surface of the movable frame 5, the lower end of the screw rod holder 6 is fixed on the support plate 9, and the screw rod 7 The upper end surface of the upper end is fixed on the outer wall of the movable frame 5, and the lower end of the screw rod 7 passes through the screw rod holder 6 and the support plate 9 in turn, the gear 11 is meshed with the screw rod 7, and the motor 8 is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com