Patents

Literature

98results about How to "Suitable for industrial large-scale applications" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Homogenization heat treatment process of large-size magnesium alloy ingot

The invention relates to a homogenization heat treatment process of a large-size magnesium alloy ingot, belonging to the technical field of magnesium alloy material preparation. The process is characterized by heating a large-size magnesium alloy ingot to 320-350 DEG C at a heating rate of 10-30 DEG C / min and then heating the large-size magnesium alloy ingot to 410-430 DEG C at a heating rate of 12-27 DEG C / h, insulating the large-size magnesium alloy ingot and then cooling the large-size magnesium alloy ingot to the room temperature at a cooling speed of 2-10 DEG C / min, thus obtaining the finished product, wherein the diameter phi of the large-size magnesium alloy ingot is not less than 220mm. The process has the beneficial effects that quick heating is carried out at the early stage of homogenization to release the casting stress to prevent growth of grains in the homogenization process; later, slow heating is carried out till the homogenization temperature to ensure that all the parts are heated uniformly to prevent overburning; then cooling is carried out at a cooling speed of 2-10 DEG C / min till the room temperature is reached, thus preventing cracking due to too quick cooling and also avoiding precipitation strengthening, which is unfavourable for subsequent deformation, due to too slow cooling; dendritic segregation of the large-size magnesium alloy ingot treated by the process is basically eliminated and the components in various parts of the large-size magnesium alloy ingot are uniform; besides, the equipment used in the process is a conventional resistance furnace, is mature in process and is safe and reliable.

Owner:CENT SOUTH UNIV

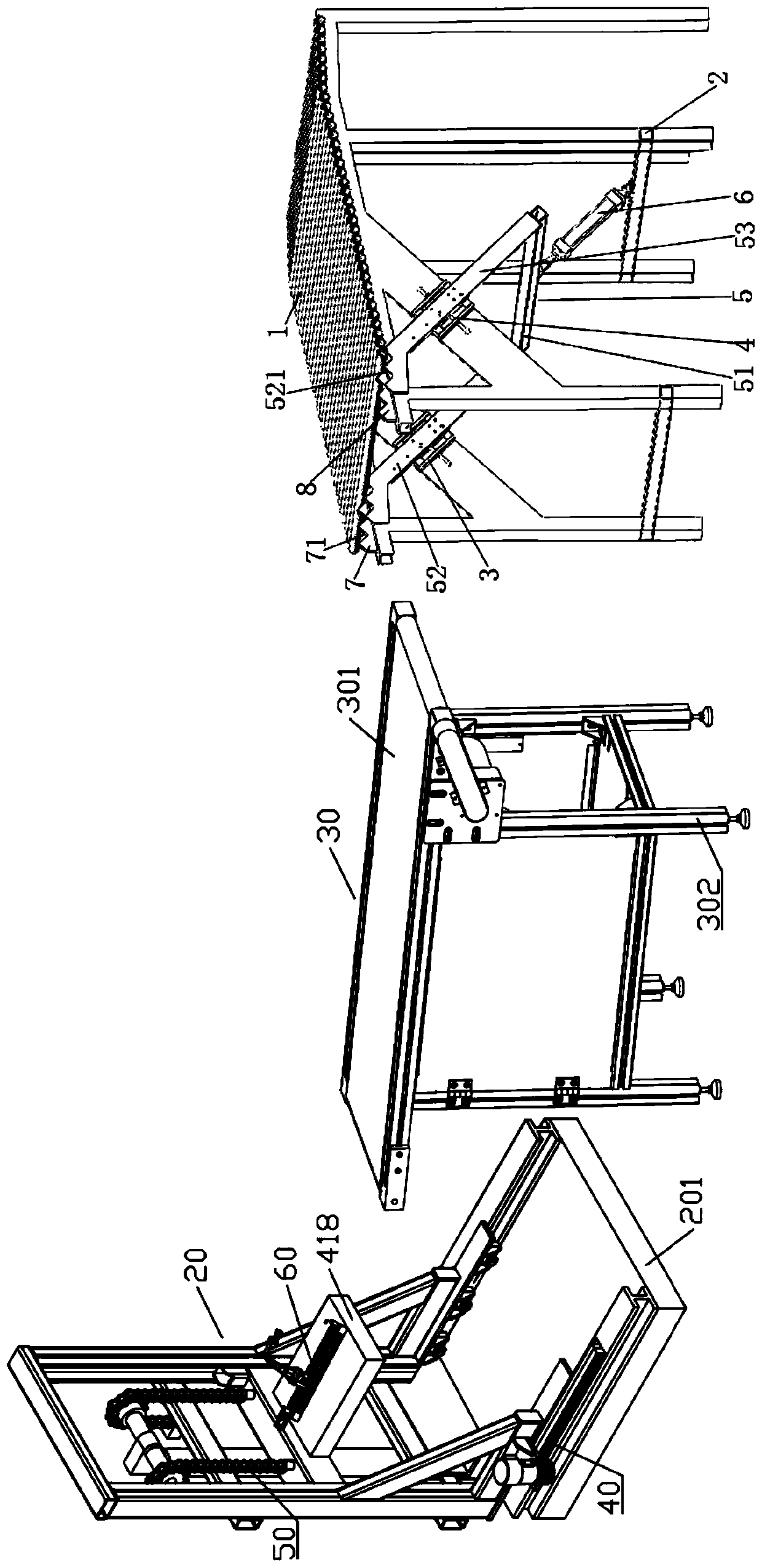

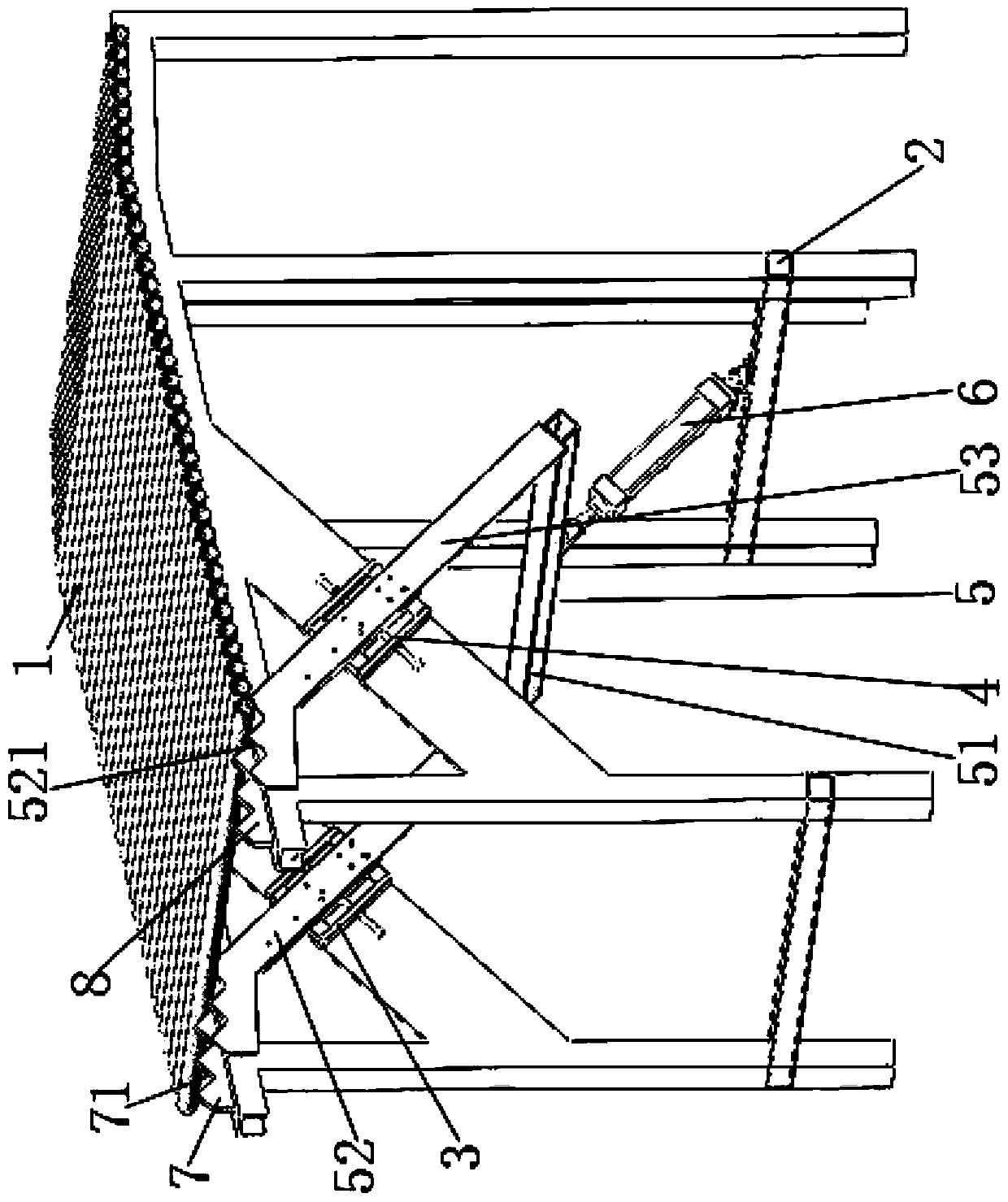

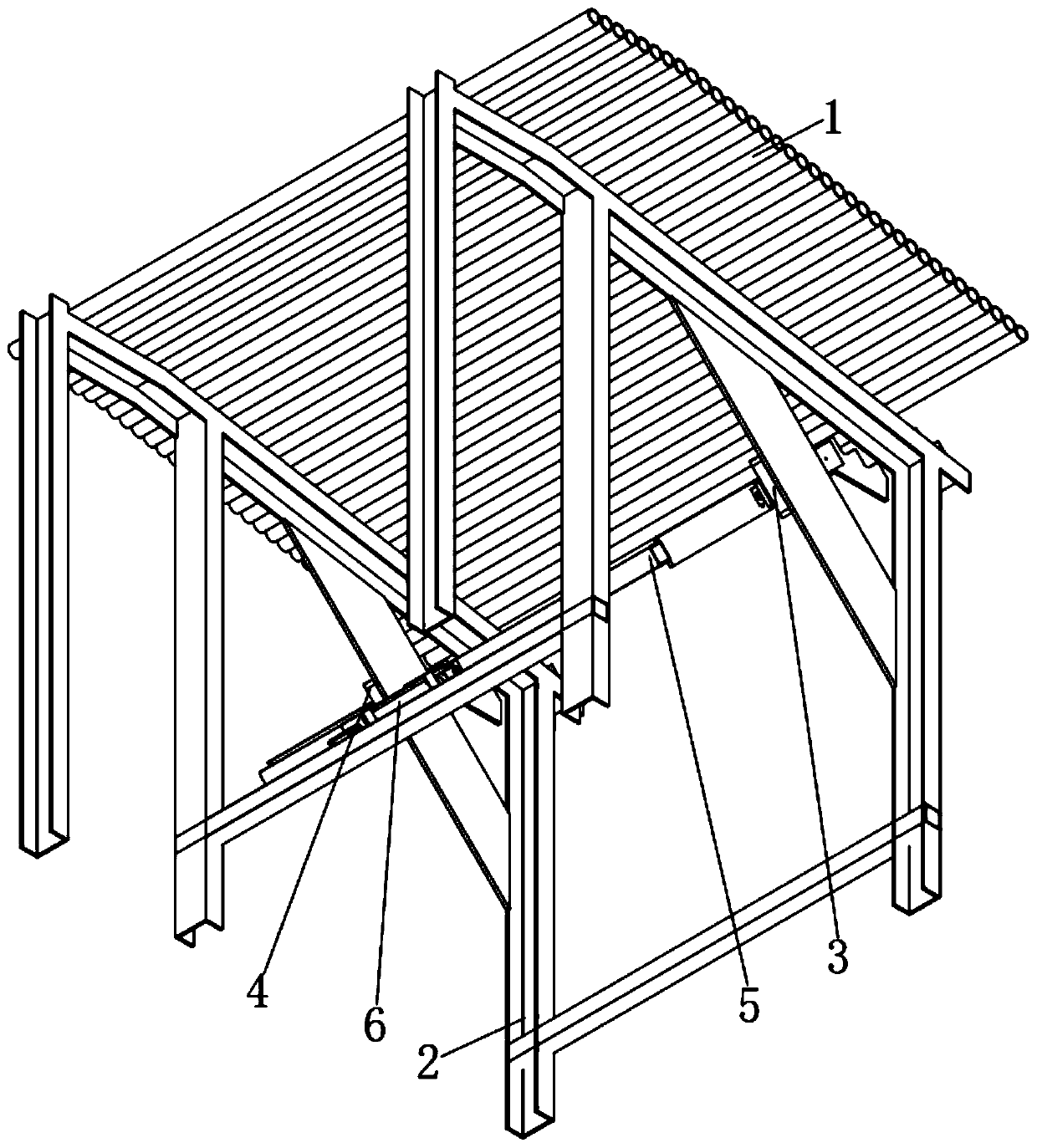

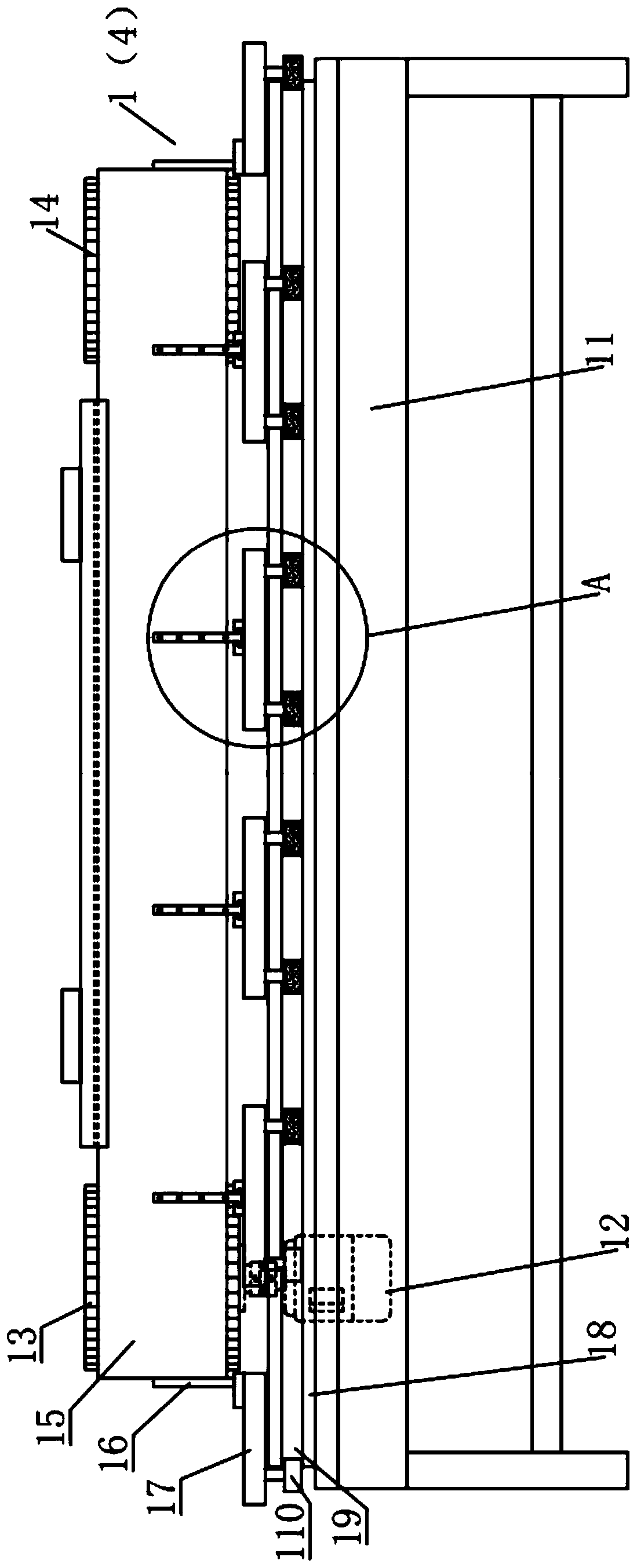

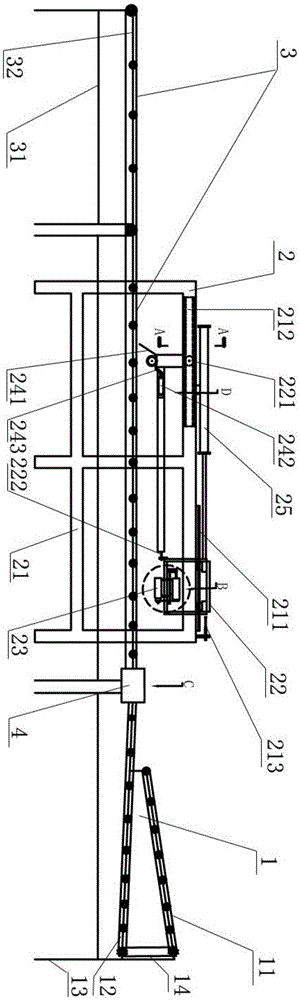

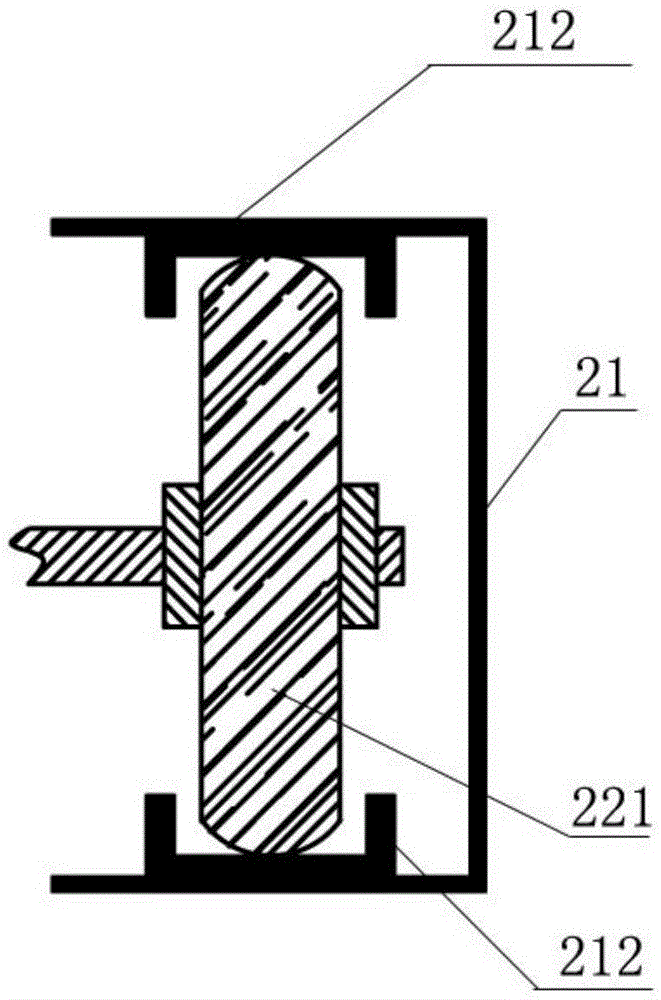

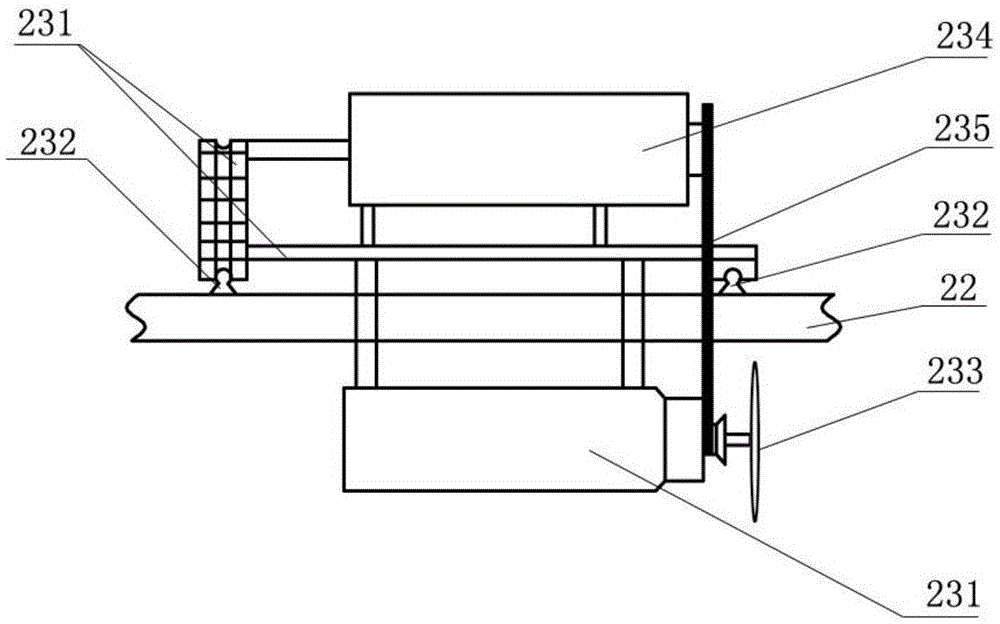

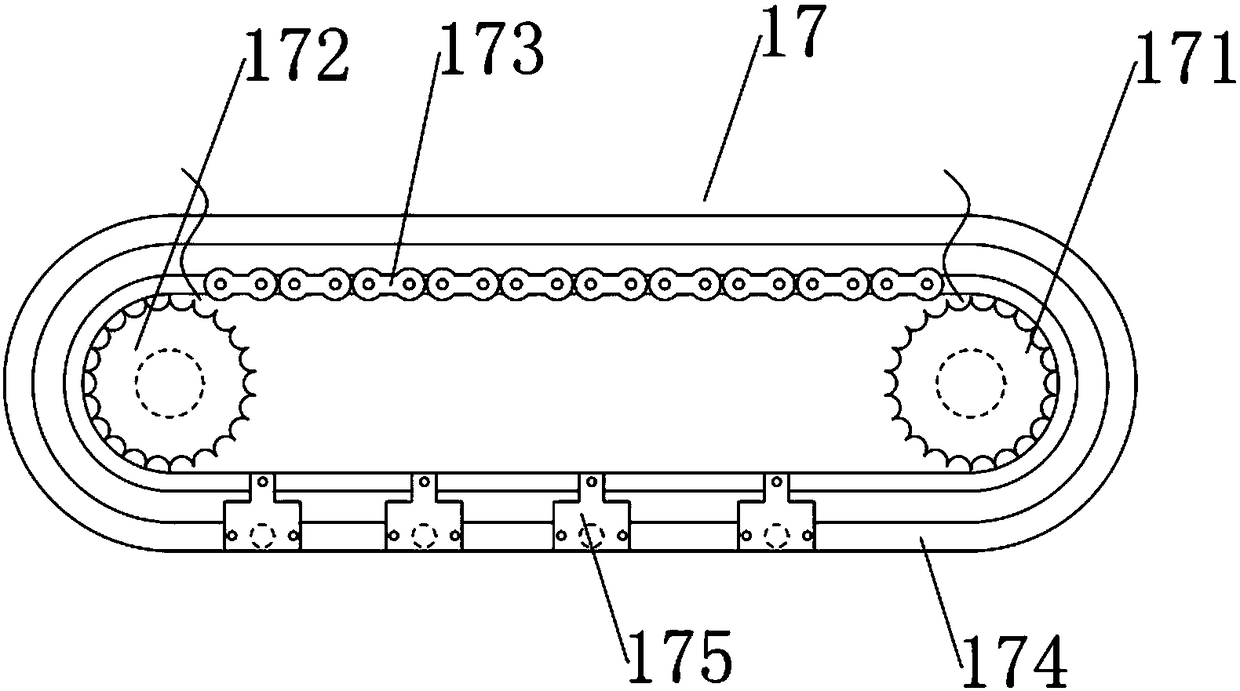

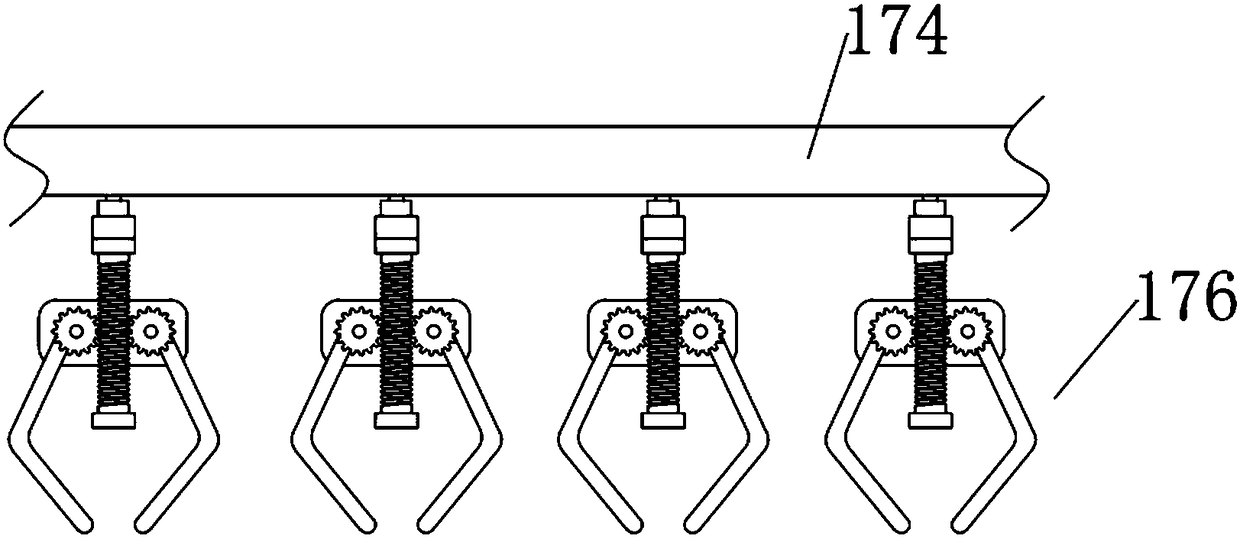

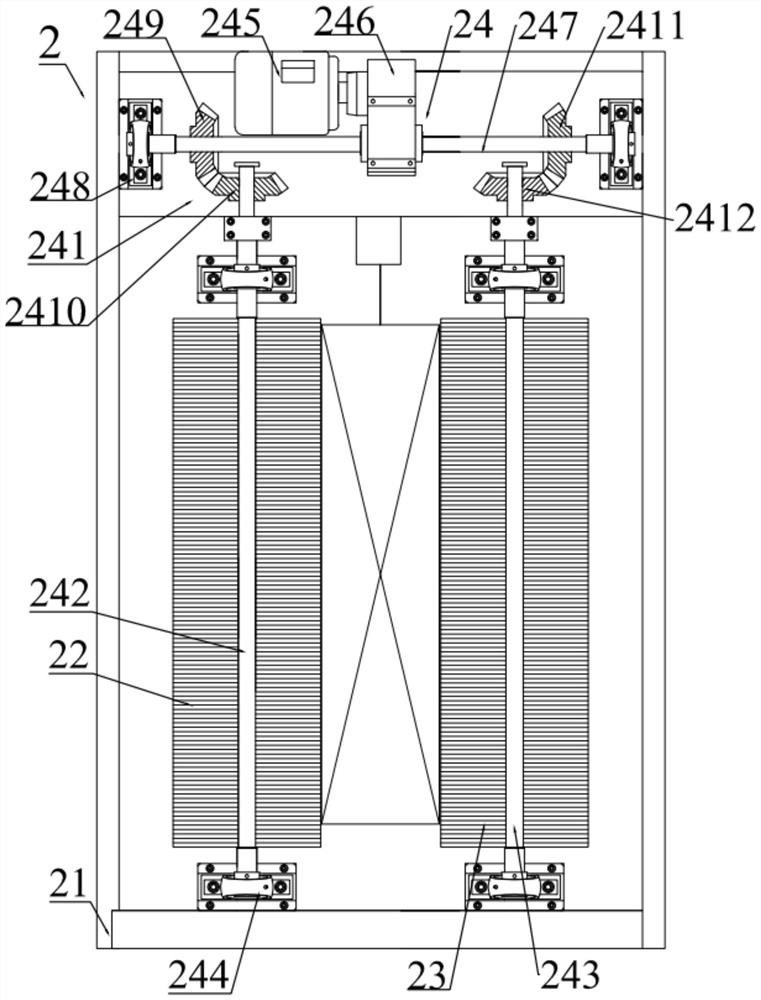

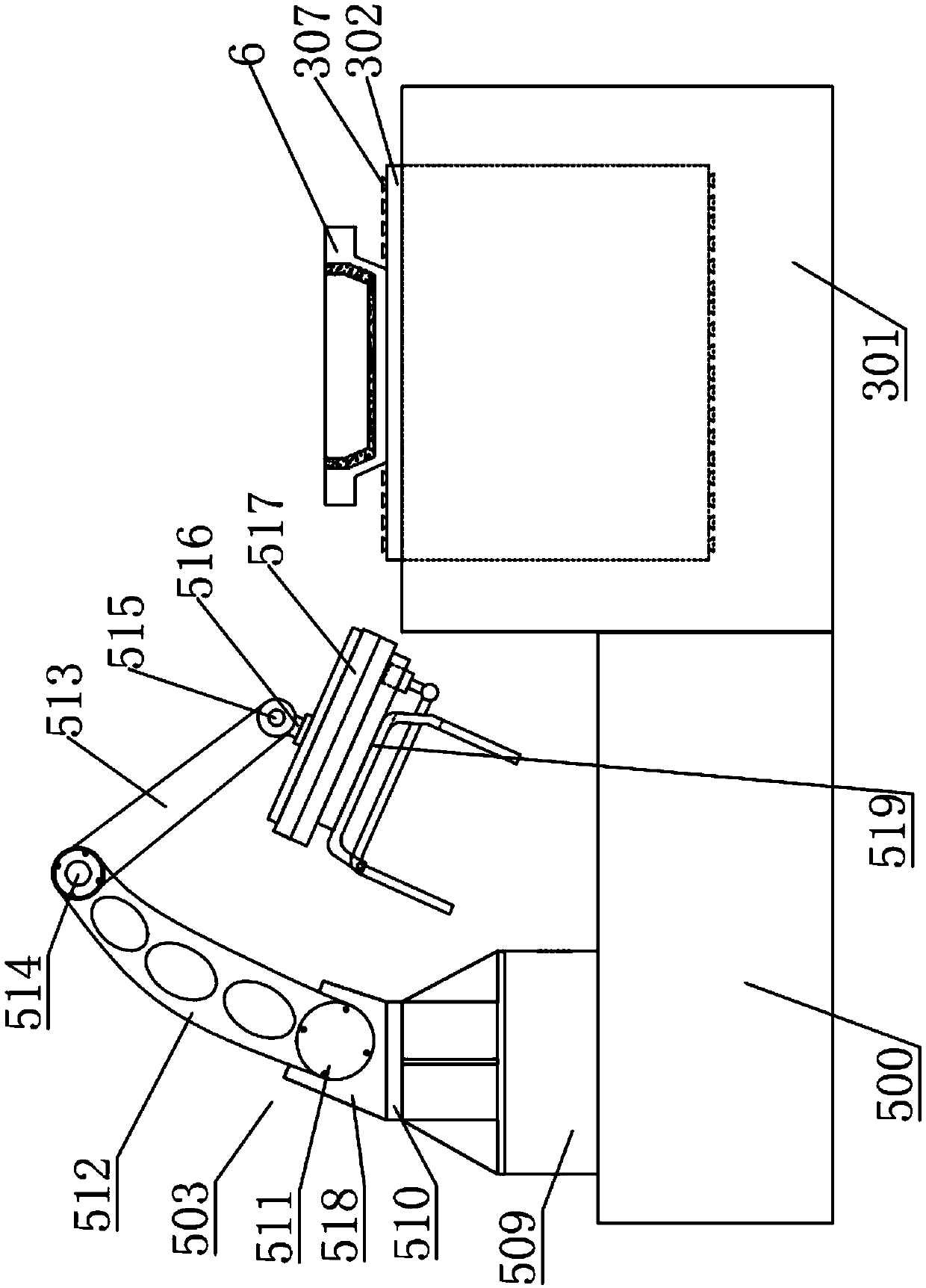

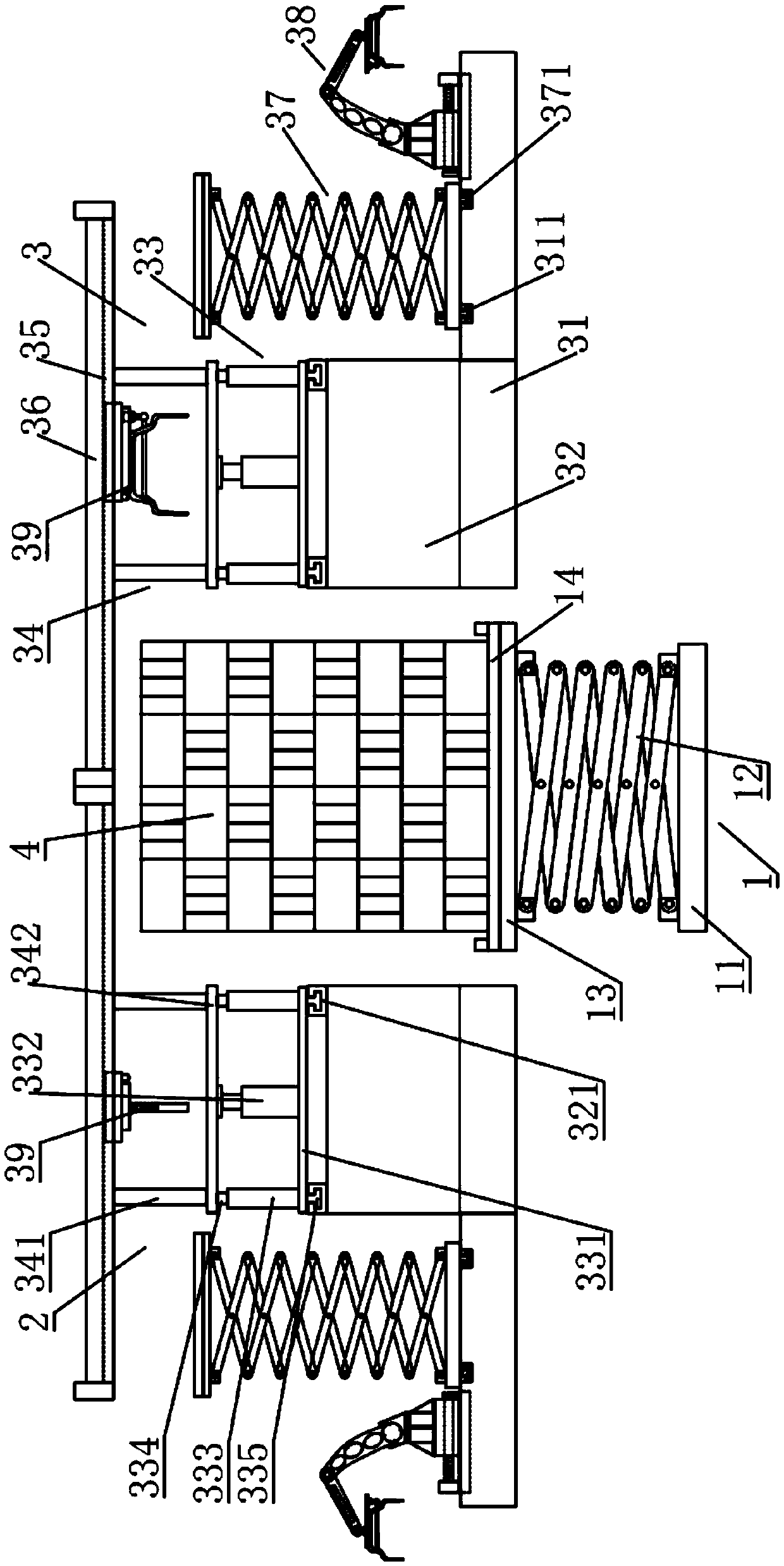

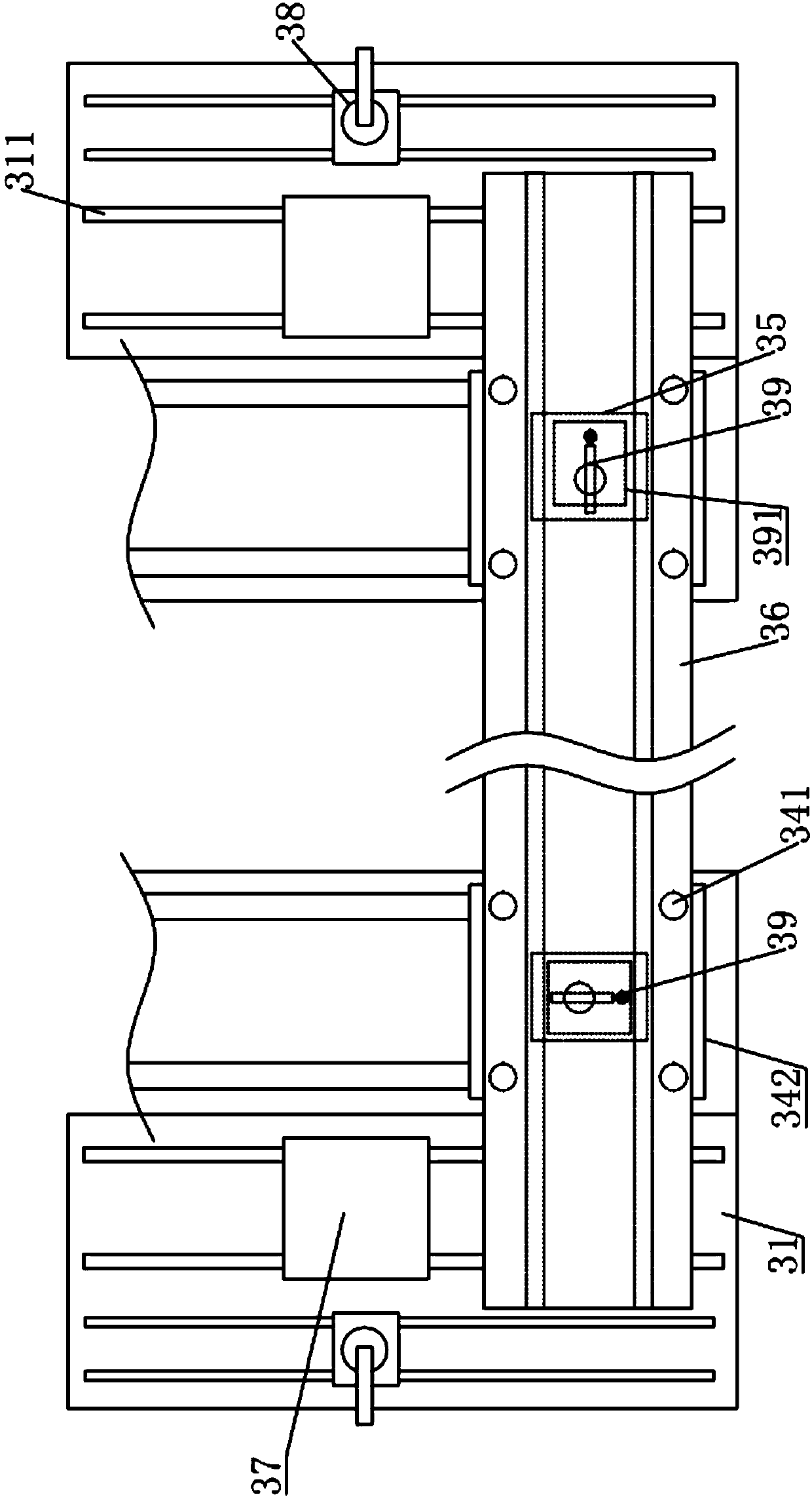

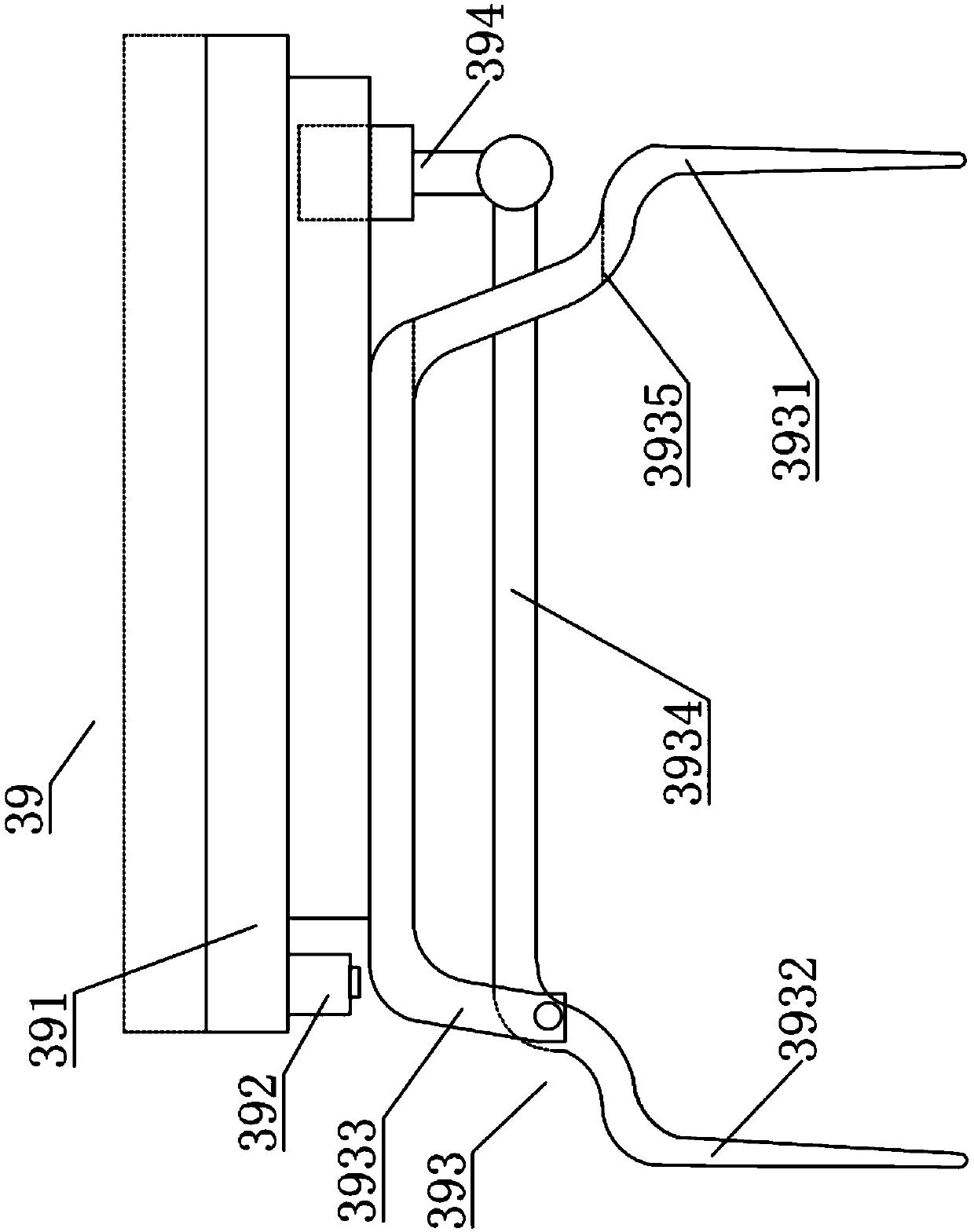

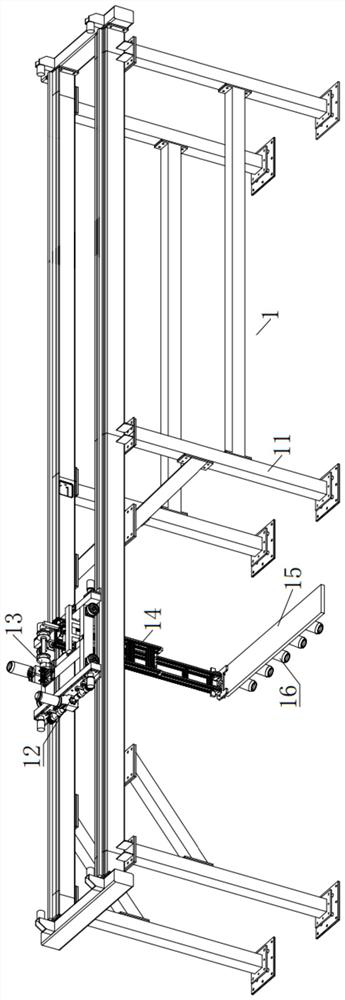

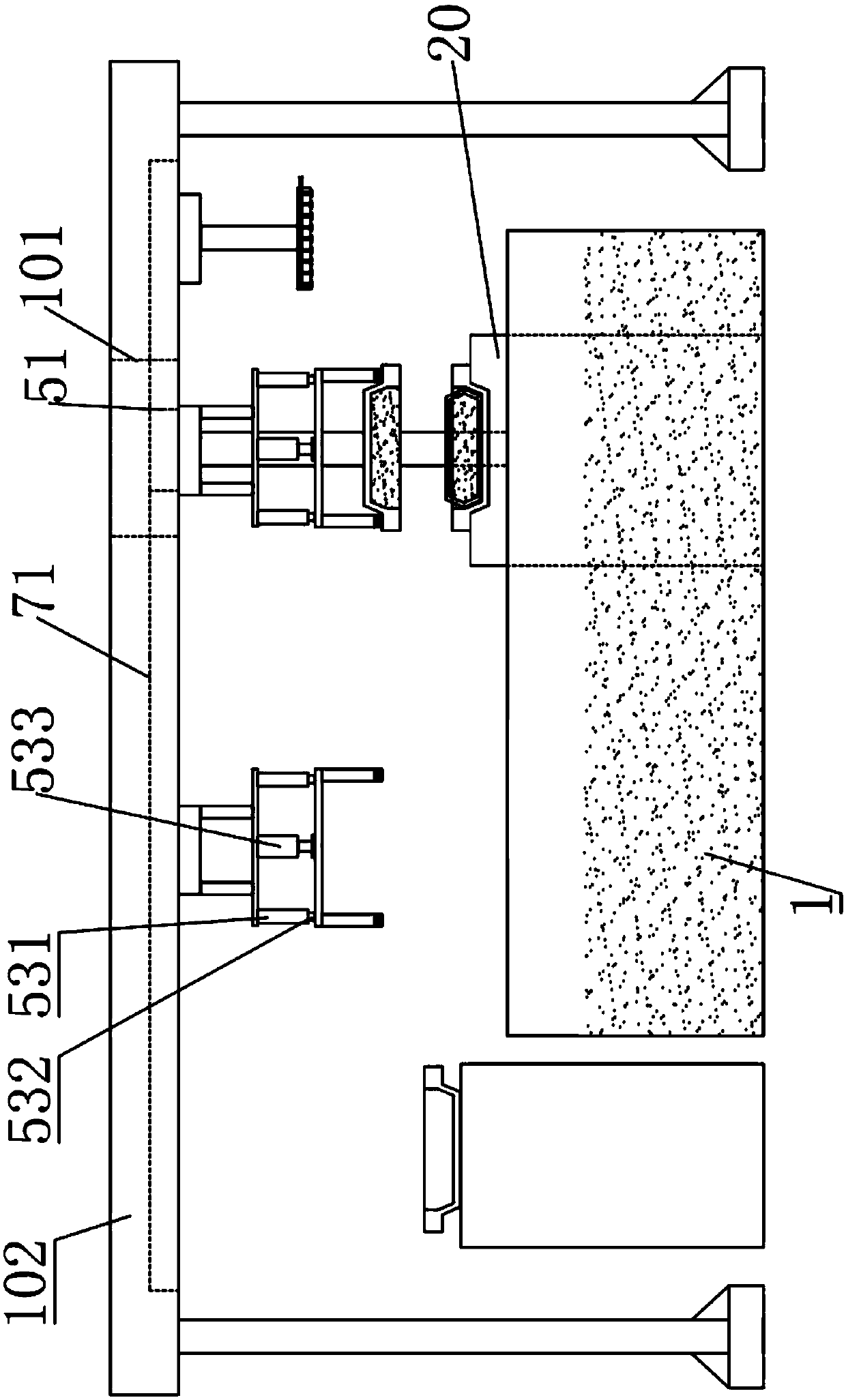

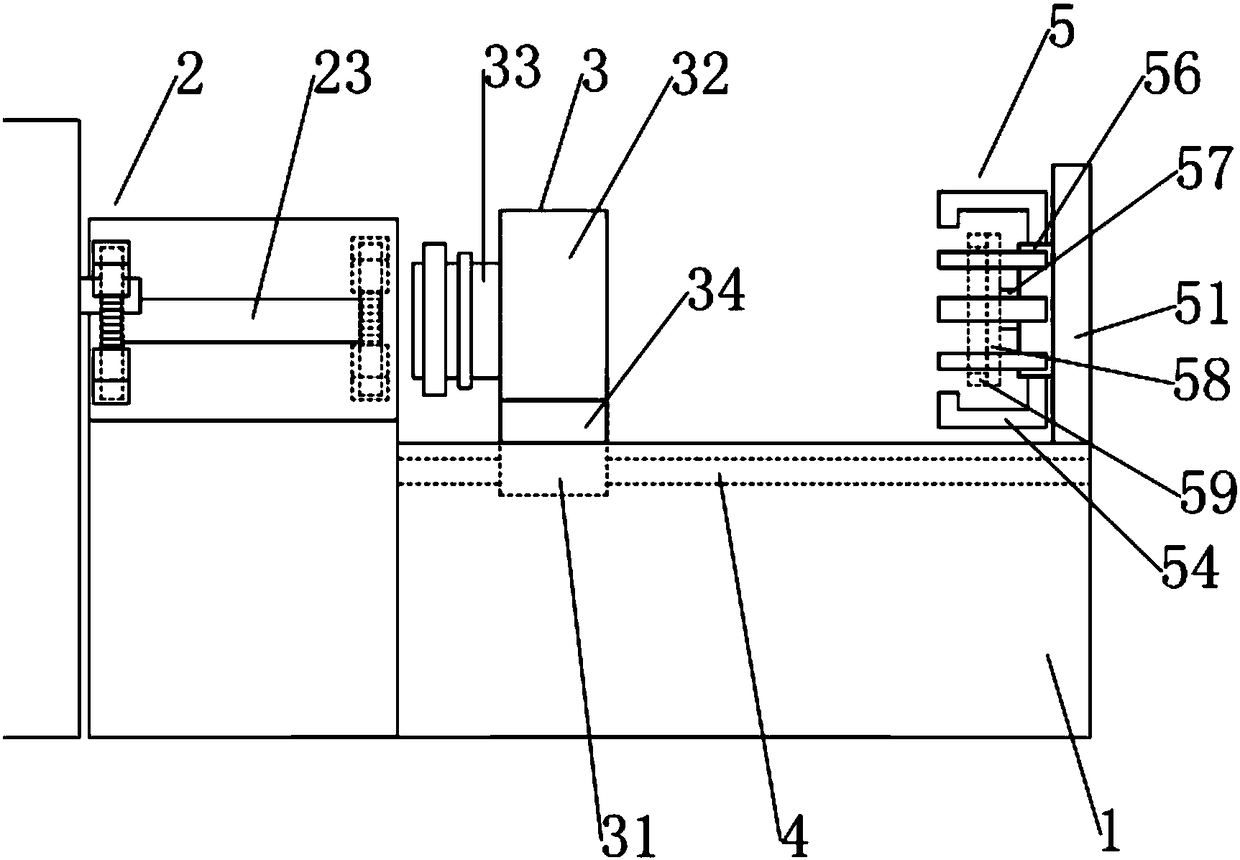

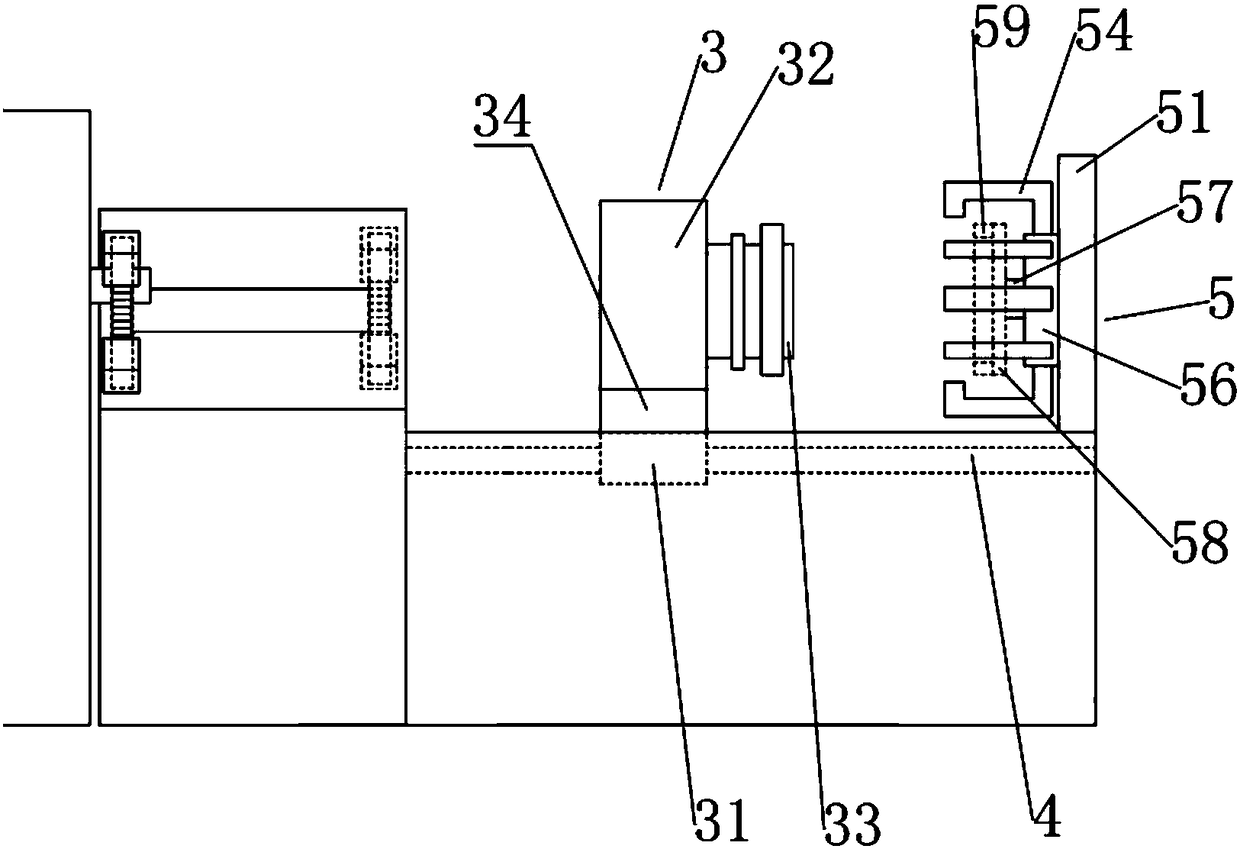

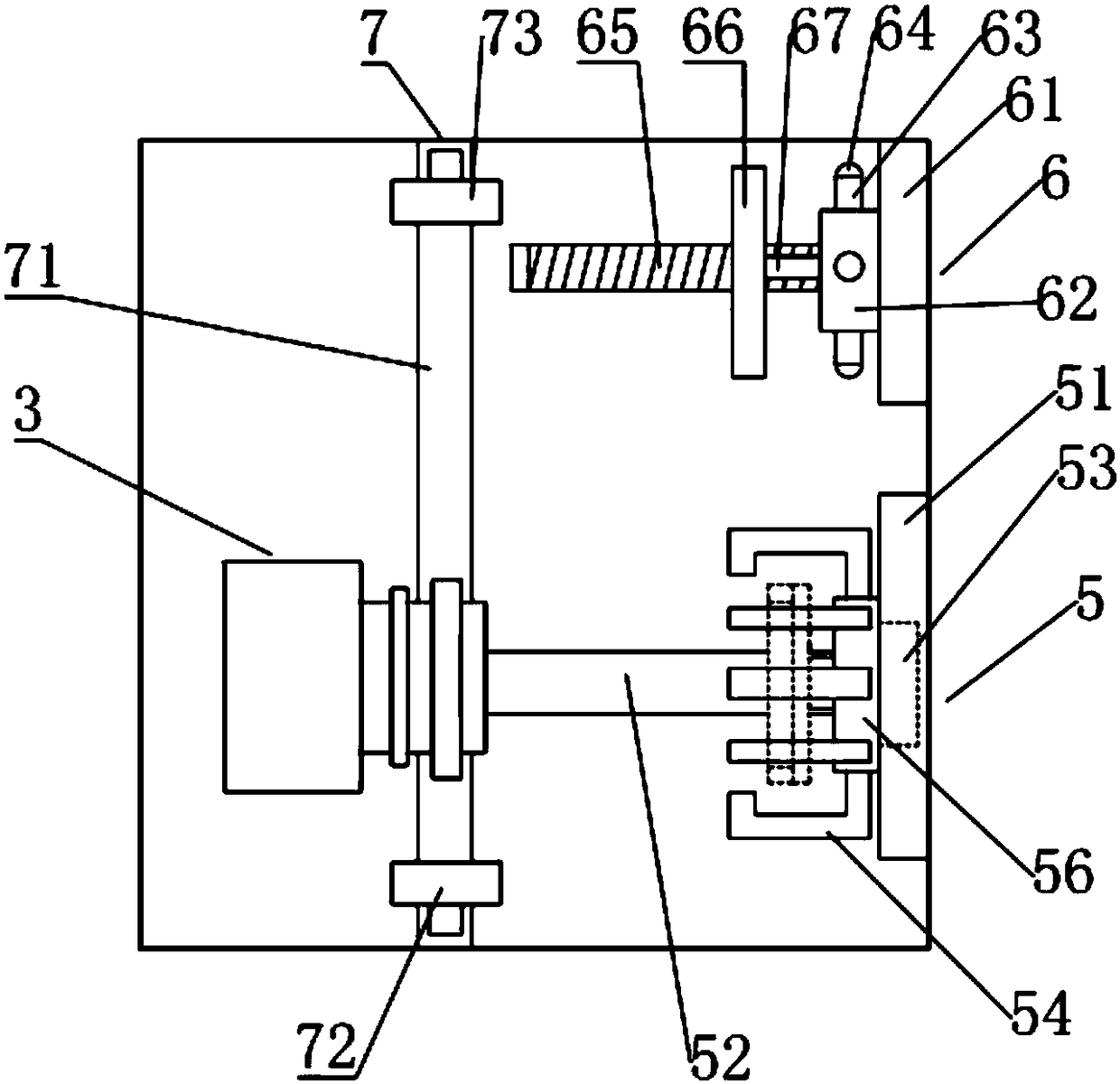

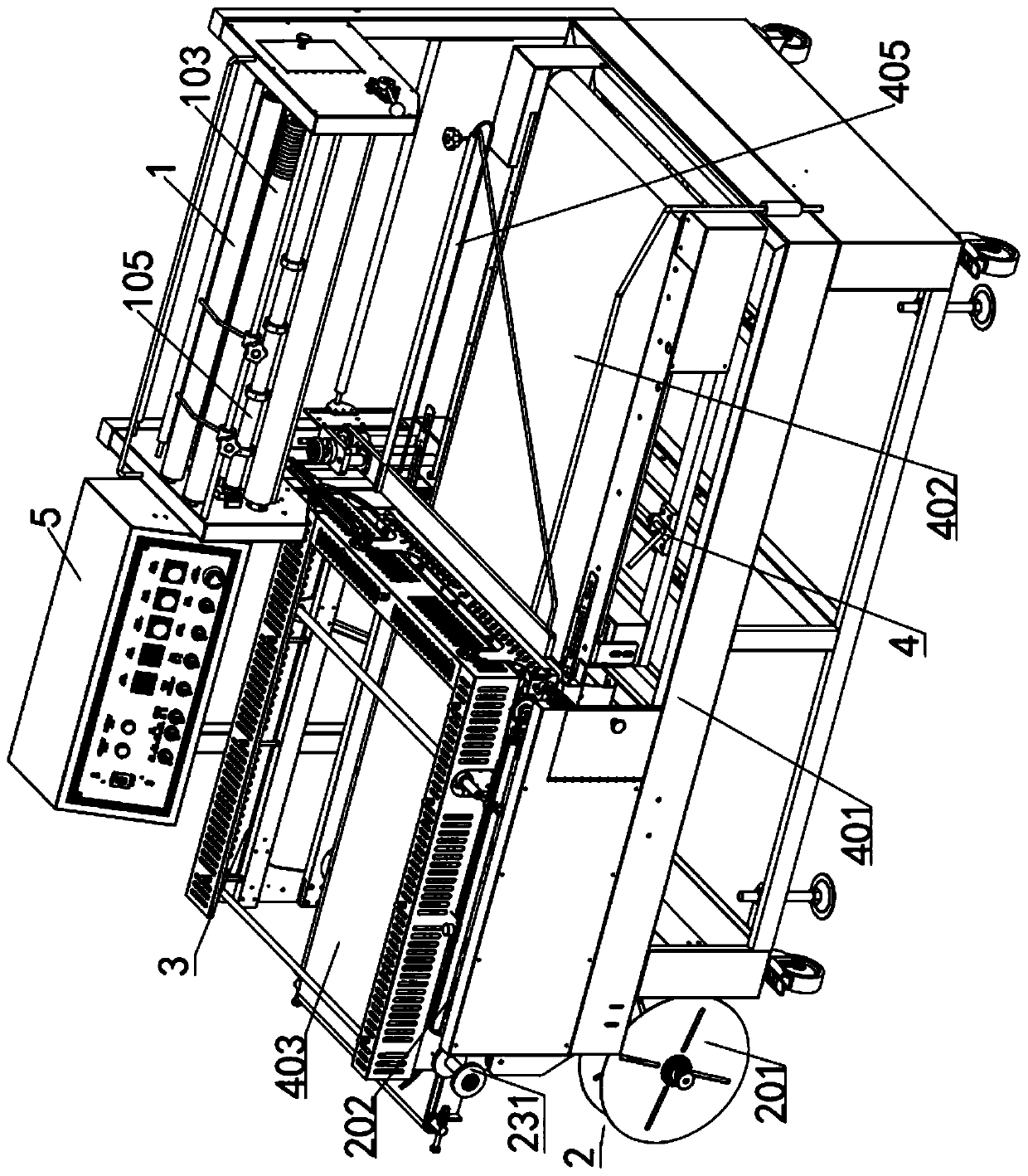

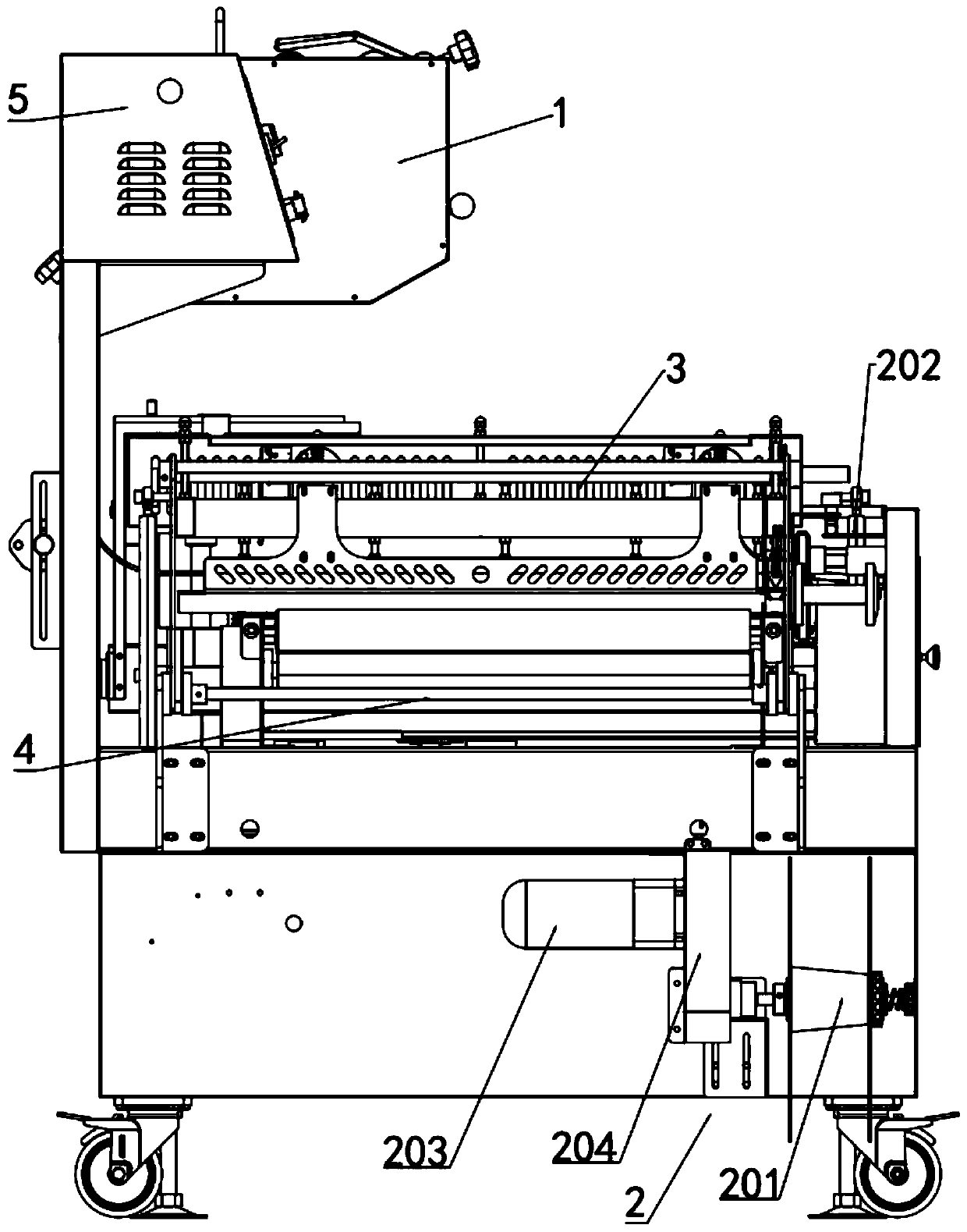

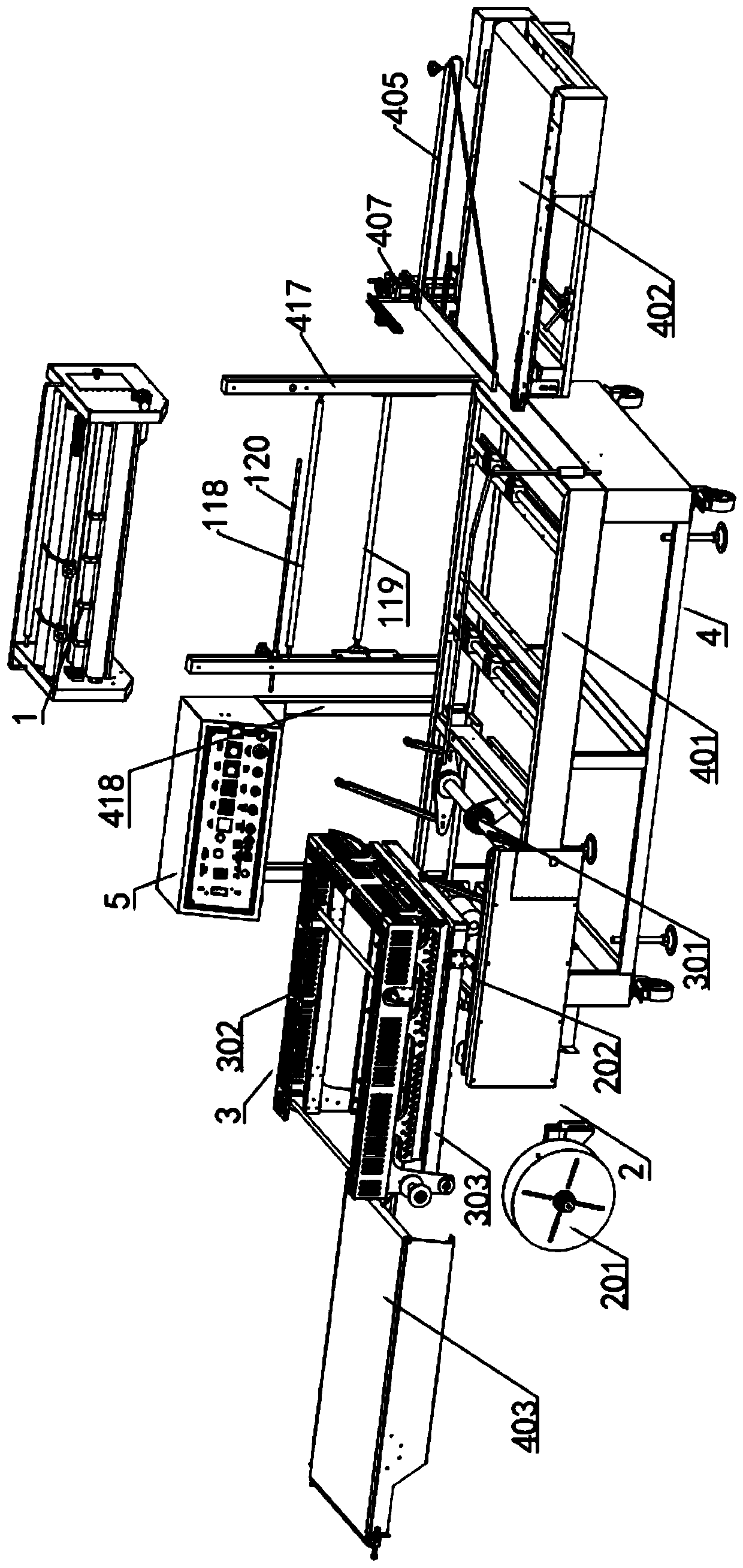

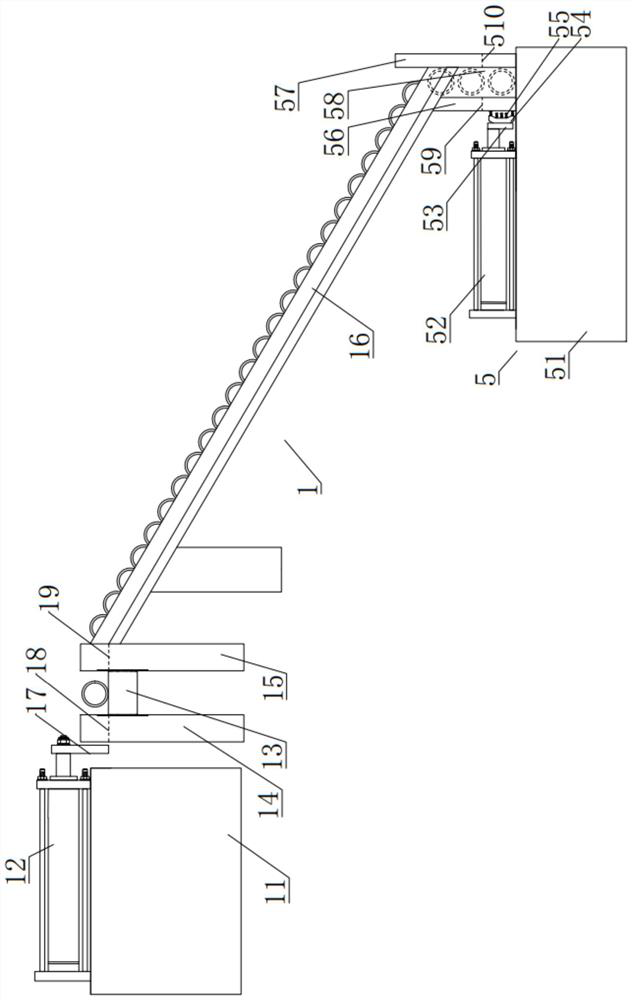

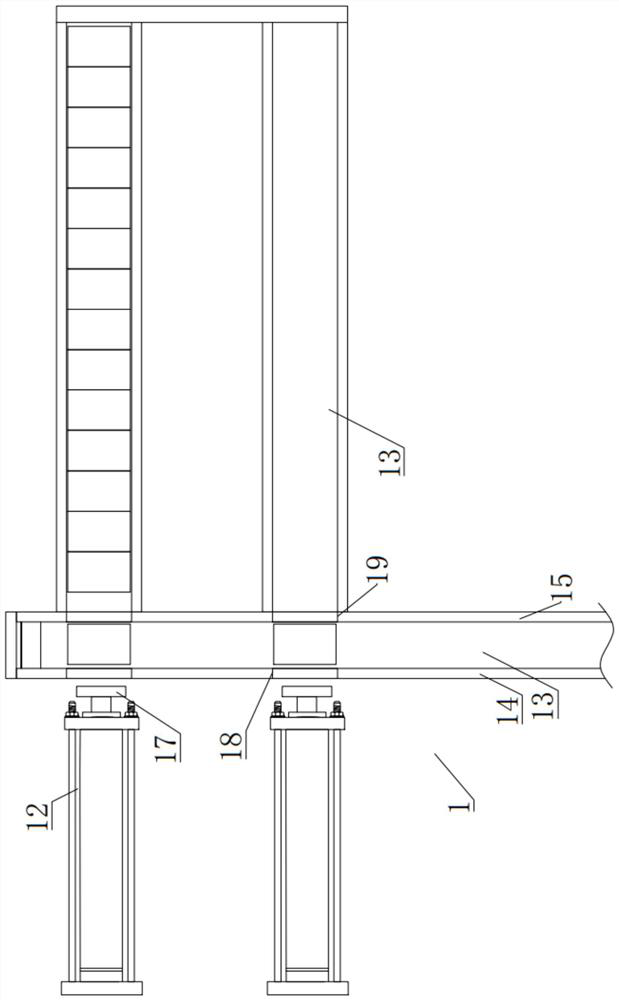

Pipe feeding and discharging device suitable for pipes of different diameters and working method thereof

PendingCN110817285ASimple working principleHigh degree of automationConveyorsControl devices for conveyorsProcess engineeringPipe

The invention discloses a pipe feeding and discharging device suitable for pipes of different diameters and a working method. The pipe feeding and discharging device includes a feeding unit, a discharging unit, a pipe transfer and conveying unit and the pipes. The pipe transfer and conveying unit is located between the feeding unit and the discharging unit, the feeding unit can place the pipes atone end of the pipe transfer and conveying unit, the pipe transfer and conveying unit can transfer the pipes, and the discharging unit can take the pipes from the end, away from the feeding unit, of the pipe transfer and conveying unit; and the feeding unit includes a machine frame, an oblique-direction adjustable device I, an oblique-direction adjustable device II, a V-shaped feeding push rod assembly, a feeding driving device, a V-shaped wide material fixing block I and a V-shaped wide material fixing block II. The working method of the pipe feeding and discharging device suitable for the pipes of different diameters is simple and easy to operate in working principle, high in degree of automation of the working process and less in required manpower, the production efficiency is improved,and the pipe feeding and discharging device and the working method are suitable for large-scale industrial applications.

Owner:SUZHOU CHIEN SHIUNG INST OF TECH

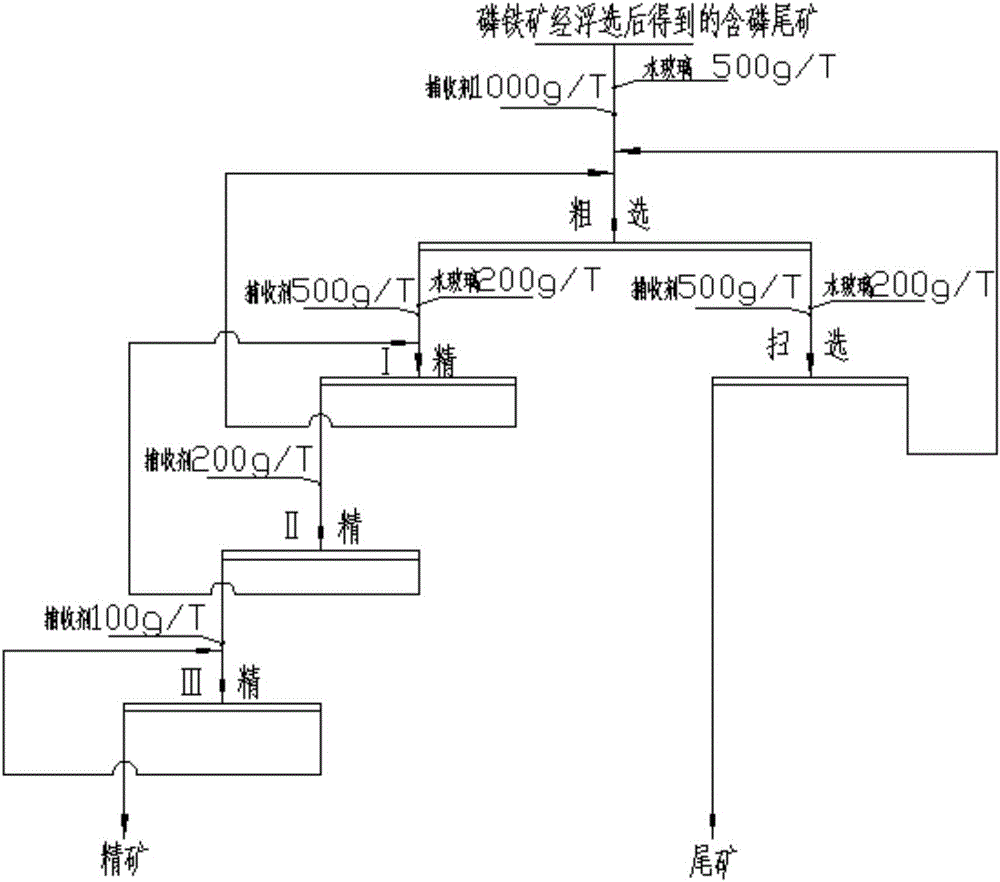

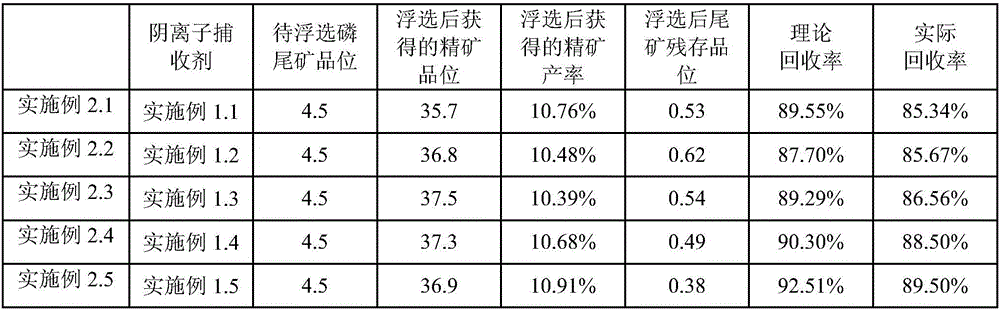

Anionic collector and preparation method thereof

The invention provides an anionic collector. The anionic collector is mainly prepared from, by weight, 25-30 parts of petroleum sodium sulfonate, 20-25 parts of drainage oil, 2-3 parts of triethanolamine, 3-4 parts of dimethyl phthalate, and 35-40 parts of water with the pH value being 10. According to the obtained anionic collector, the two low-cost waste by-products, namely petroleum sodium sulfonate and drainage oil, are used as the main raw materials, so that the cost of the anionic collector is greatly reduced, the phosphorus collection rate is increased, the grade of phosphorus remaining after phosphorus tailings are subjected to floatation through the anionic collector is lowered to an extremely low level, and phosphorus in the tailings is efficiently recovered. According to a preparation method provided by the invention, the raw materials do not need to be separated and purified, reaction products are all used as anionic collectors, no waste is produced, the reaction temperature requirement is low, waste resources are effectively utilized, huge economic benefits can be created, and the anionic collector is applicable to large-scale industrial application.

Owner:HEBEI SHUNJIA MINING PROD TECH CO LTD

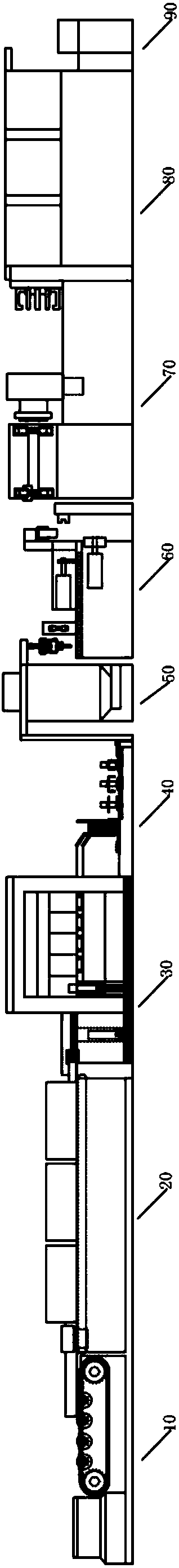

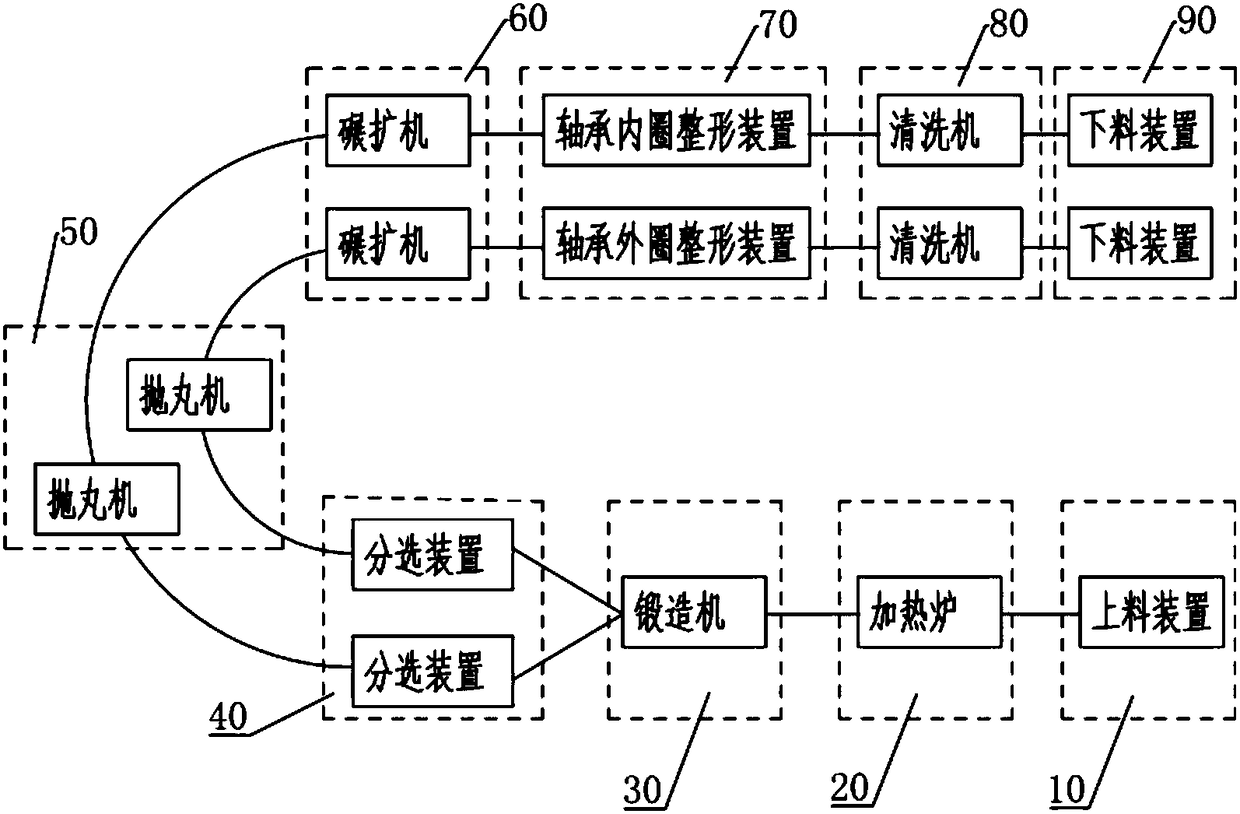

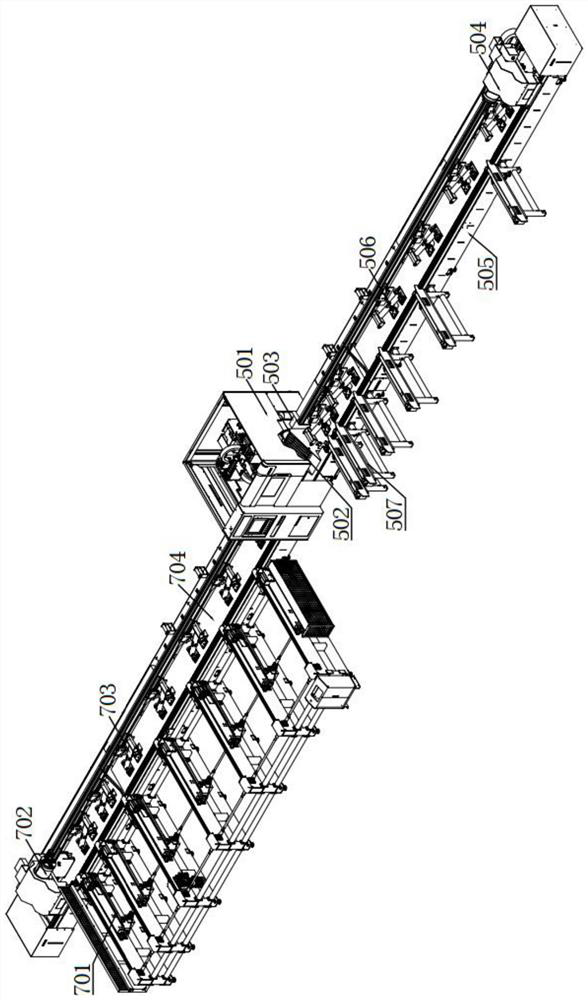

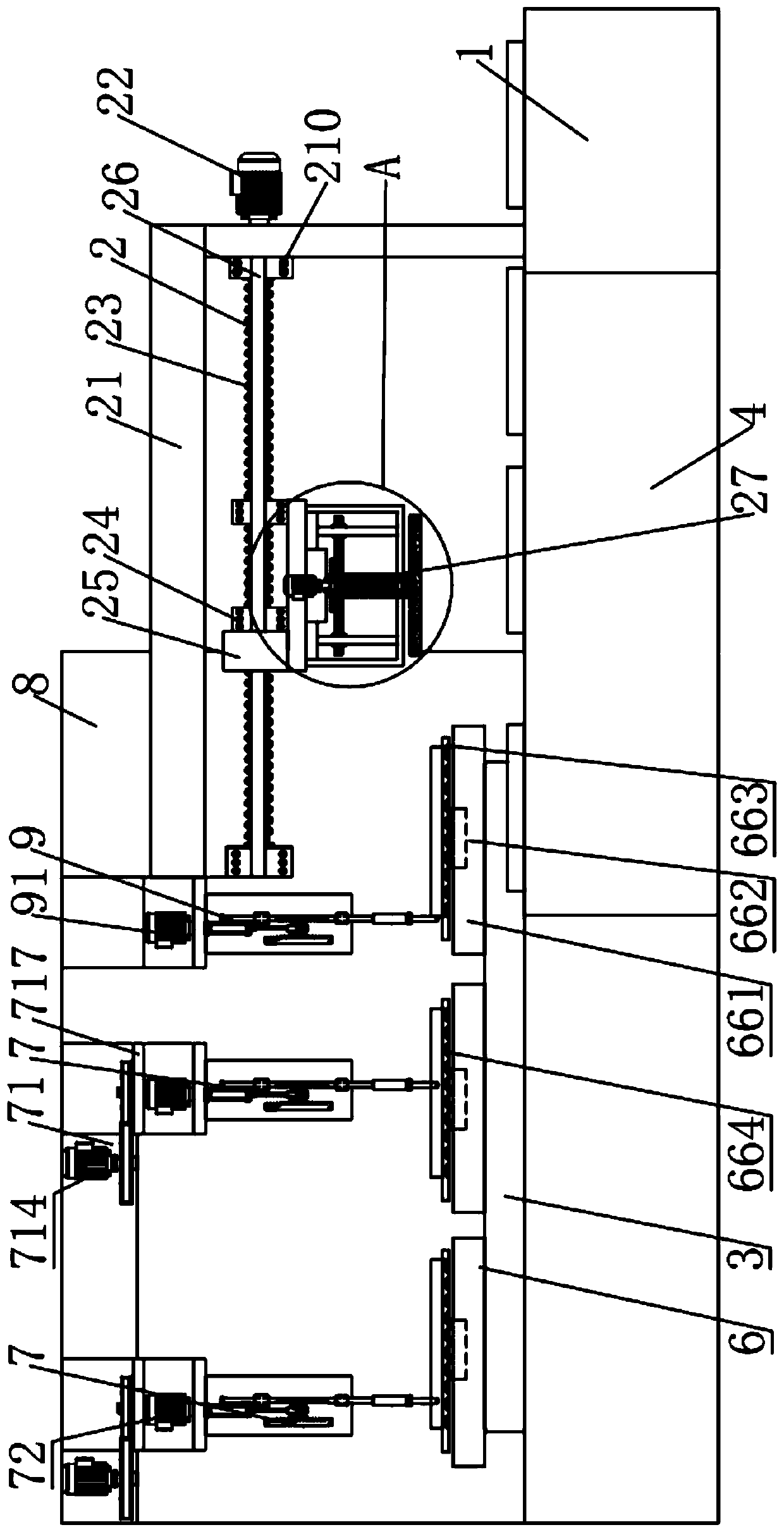

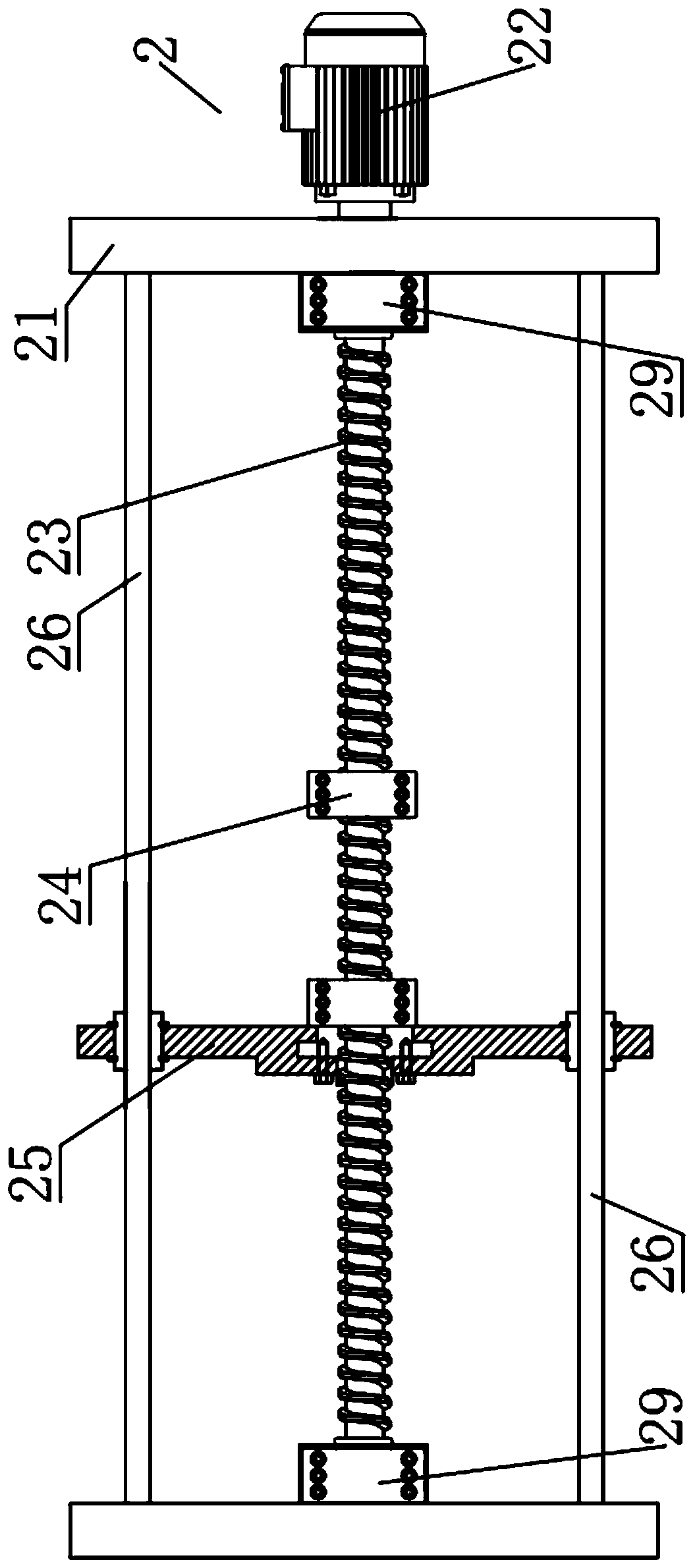

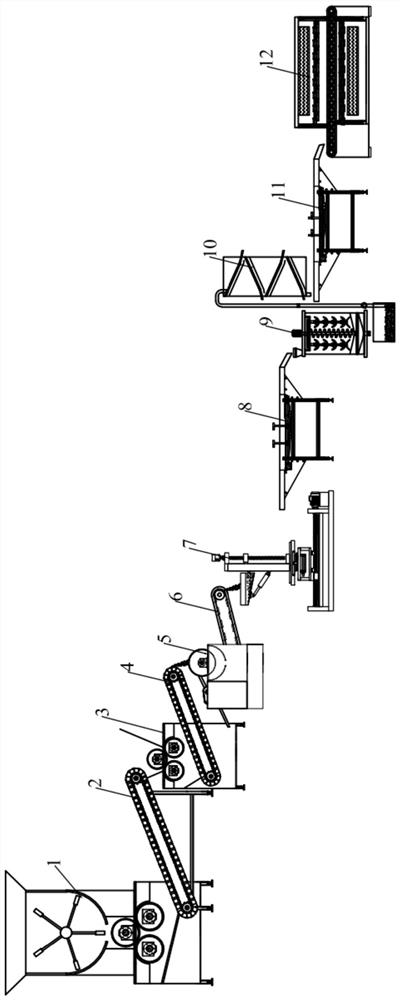

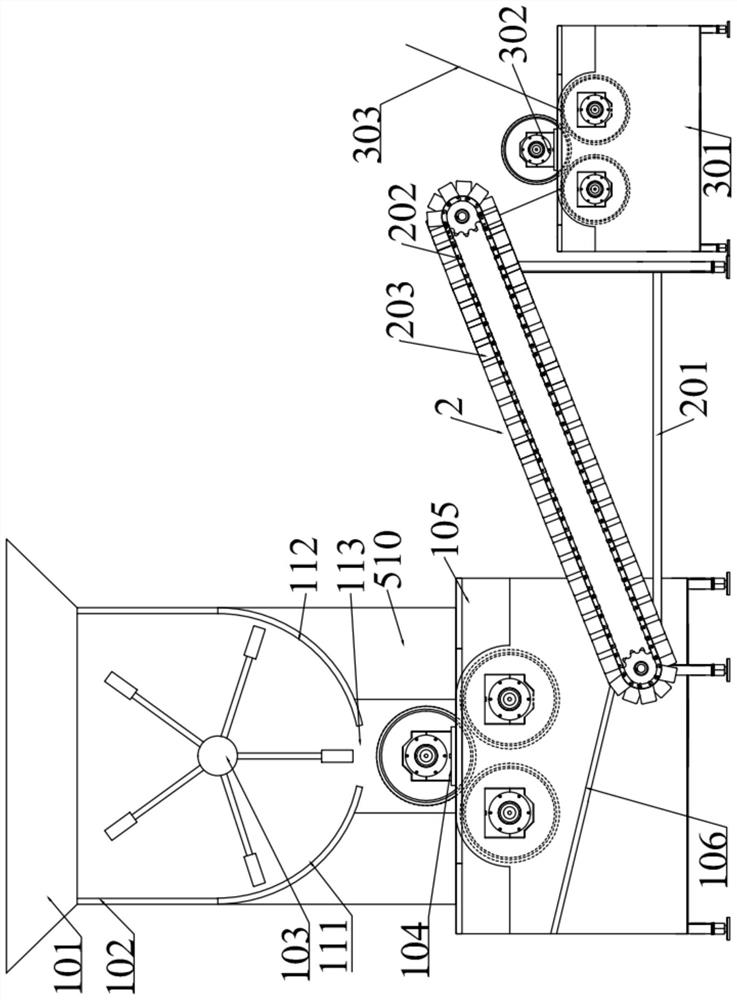

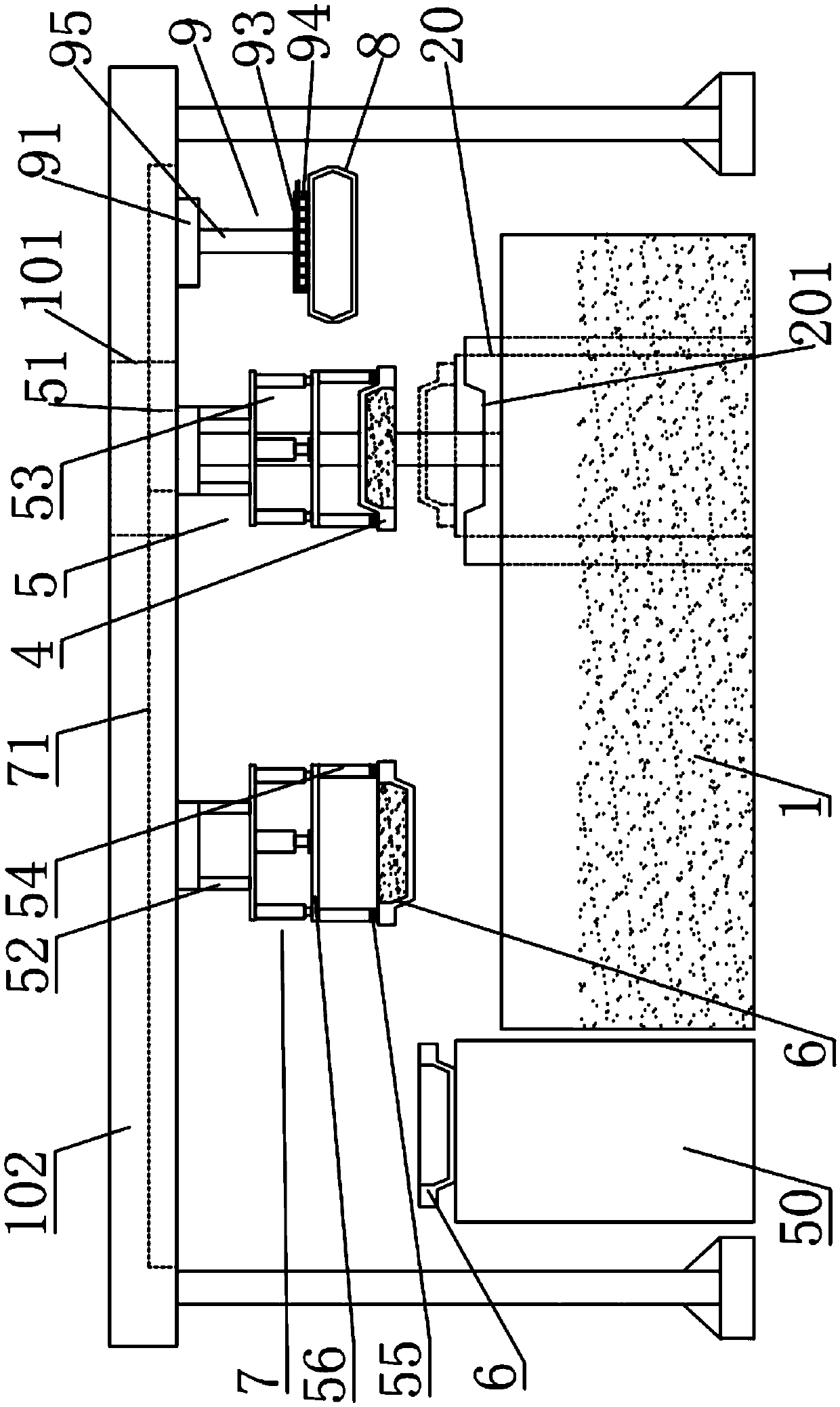

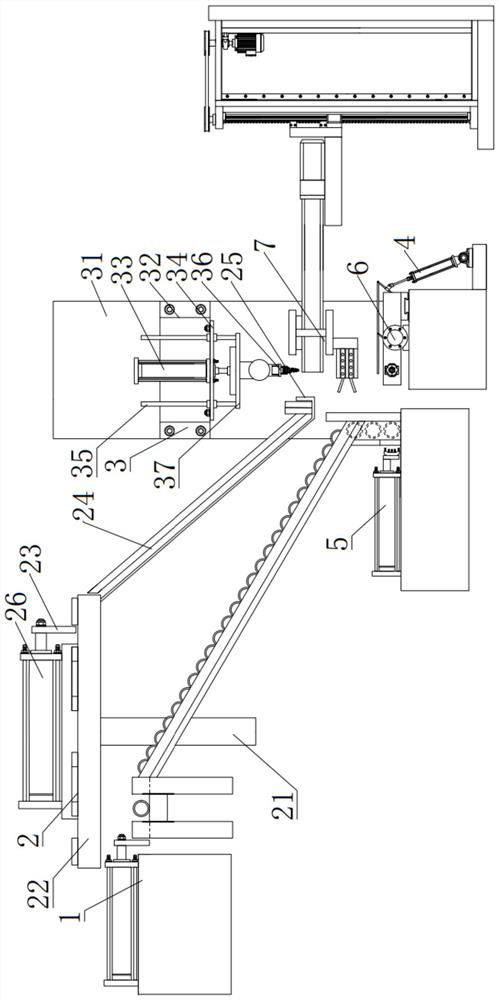

High-efficiency full-automatic bearing ring production line and production method thereof

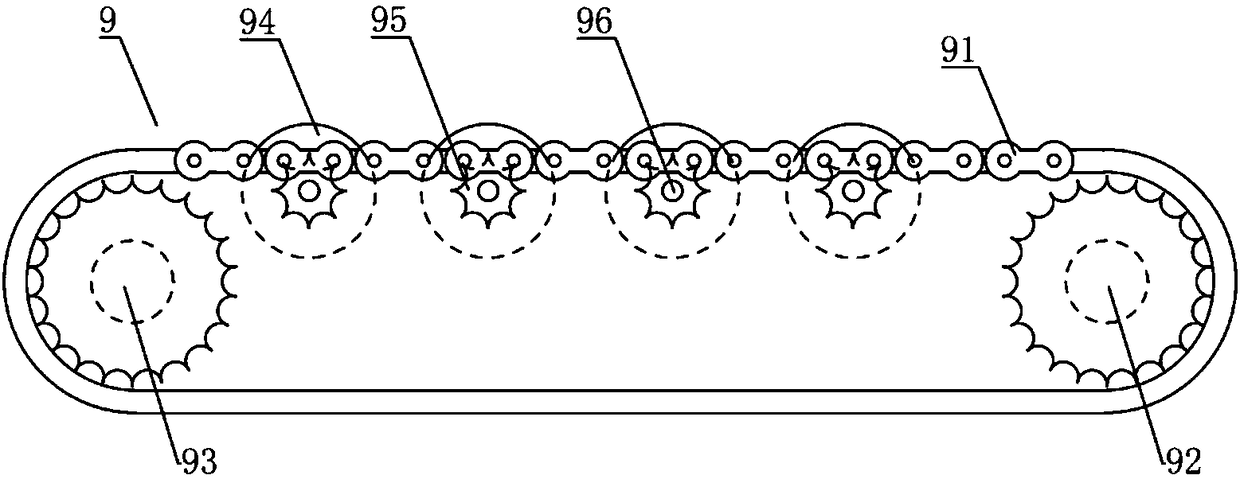

ActiveCN108326566AHigh degree of automationReasonable structural designShaftsBearing componentsProduction lineConveyor belt

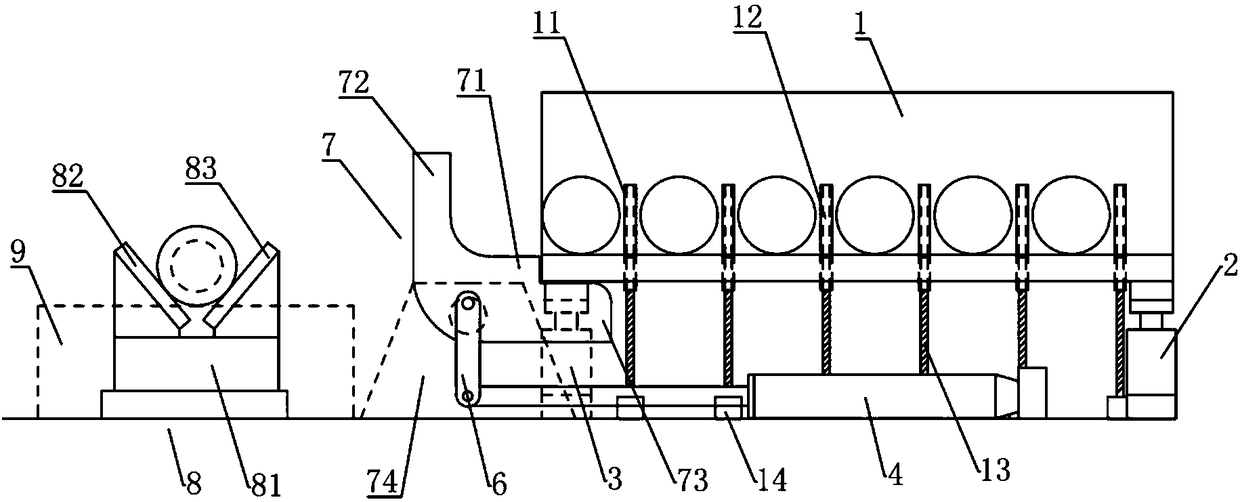

The invention discloses a high-efficiency full-automatic bearing ring production line. The high-efficiency full-automatic bearing ring production line comprises a feeding unit, a heating unit, a forging unit, a separation unit, a shot blasting unit, a rolling expanding unit, a shaping unit, a cleaning unit and a discharging unit which are arranged in sequence, wherein bearing ring materials are conveyed between the units through manipulators, and the whole process is conducted full-automatically; the bearing ring materials passing through the forging unit are machined into bearing outer ringsand bearing inner rings, and the bearing inner rings and the bearing outer rings are divided into two routes to be machined. The high-efficiency full-automatic bearing ring production line can automatically achieve machining of the bearing inner rings and the bearing outer rings. The technological process comprises feeding, heating, forging, separation, shot blasting, rolling expanding, shaping, cleaning and discharging, and the whole process is conducted full-automatically; in the bearing feeding process, heavy raw materials need to be conveyed to the position in front of the heating unit; through the feeding device, the raw materials can be stored and automatically transferred to a conveyor belt, the conveyor belt can achieve conveying of the materials, the automation degree is high in the operating process, and high-efficiency full-automatic bearing ring production line is stable and reliable in operation.

Owner:江苏保捷精锻有限公司

Preparation method for mercury-free catalyst used in synthesis of vinyl chloride from acetylene through hydrochlorination

InactiveCN110142053AIncrease profitHigh activityPhysical/chemical process catalystsPreparation by halogen halide additionHydrogenCopper chloride

The invention relates to a preparation method for a catalyst, specifically to a preparation method for a mercury-free catalyst used in the synthesis of vinyl chloride from acetylene through hydrochlorination. The catalyst of the invention comprises a carrier and three active components. The three active components are composed of a component A, a component B and a component C, wherein the component A is chloroauric acid; the component B is ruthenium chloride; the component C is copper chloride; a weight ratio of the elemental gold in the component A to the carrier is 0.01 to 0.2%; a weight ratio of element ruthenium in the component B to the carrier is 0.01 to 0.2%; and a weight ratio of copper chloride in the component C to the carrier is 0.5 to 5%. The active components are loaded on thecarrier by using an equivalent-volume impregnation process; and then drying is carried out to obtain the three-element mercury-free catalyst. The catalyst of the invention has high activity, good selectivity, low price and long service life when applied to the hydrochlorination reaction of acetylene; the catalyst can be conveniently applied to conventional industrial fixed-bed acetylene hydrochlorination reactors, and can conveniently replace existing mercury chloride catalysts without additional auxiliary procedures and steps.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

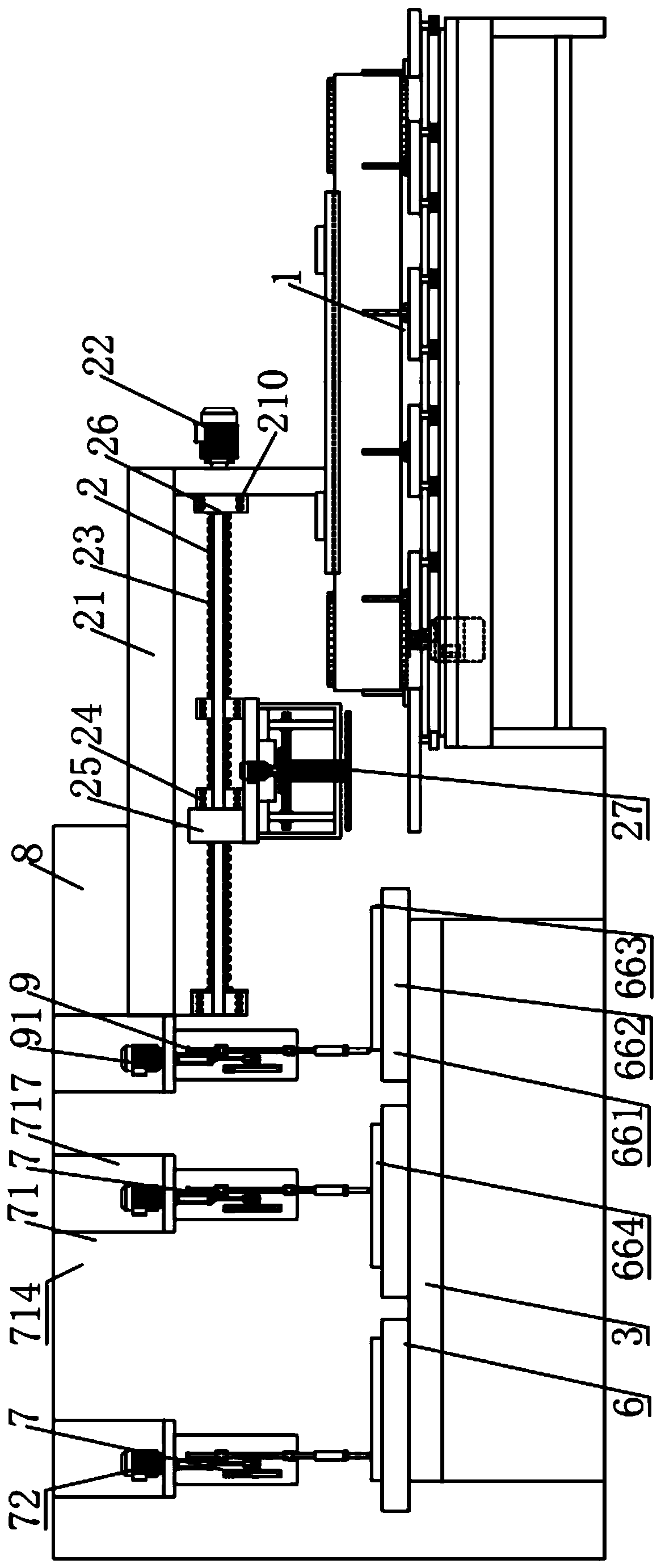

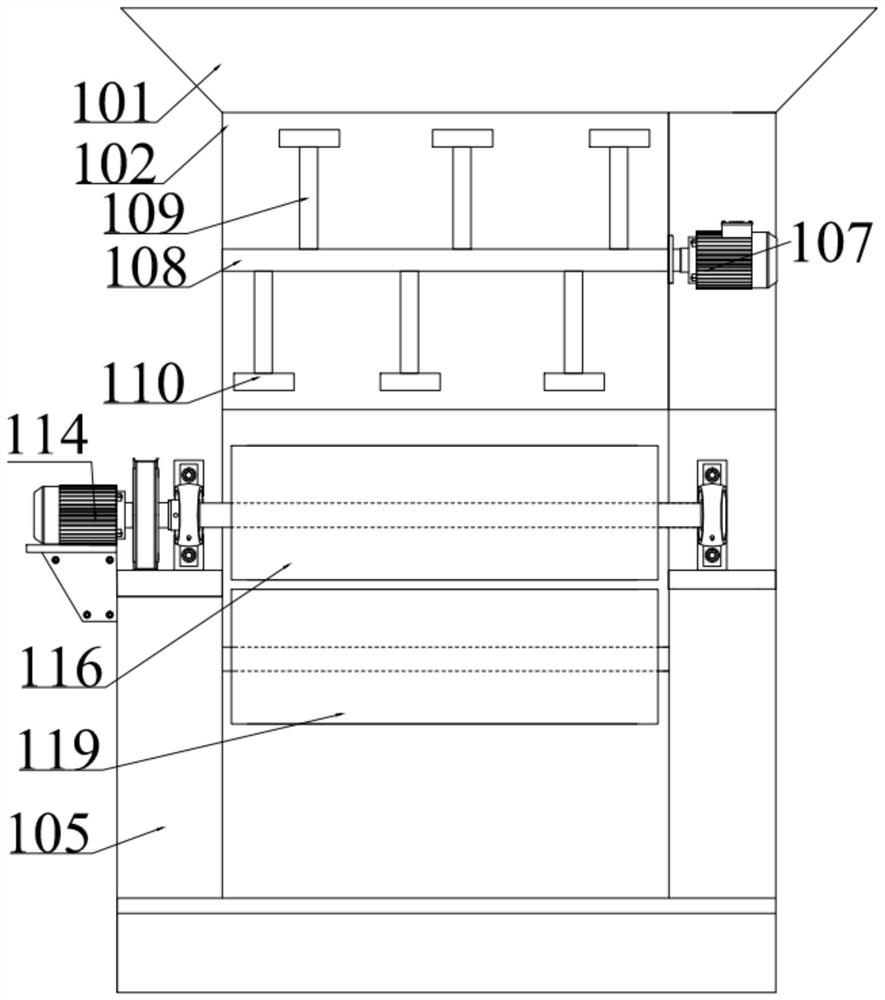

Bearing ring production line with automatic feeding device and work method of bearing ring production line

ActiveCN108480919AHigh degree of automationSave human effortBearing componentsOther manufacturing equipments/toolsProduction lineHydraulic cylinder

The invention discloses a bearing ring production line with an automatic feeding device. The bearing ring production line comprises a feeding unit, a heating unit, a forging unit, a sorting unit, a shot blasting unit, a grinding and chambering unit, a shaping unit, a cleaning unit and a discharging unit, all of which are sequentially arranged. The automatic feeding device comprises a bearing ringraw material tank, a first electric cylinder, a second electric cylinder, a first hydraulic cylinder, a second hydraulic cylinder, a drive rod, a bearing raw material transferring table, a bearing rawmaterial bearing table and a bearing raw material feeding conveying table. The bearing ring production line can automatically achieve bearing inner ring and outer ring machining, the technology processes of the bearing ring production line include feeding, heating, forging, sorting, shot blasting, grinding and chambering, shaping, cleaning and discharging, and the whole process is automatically conducted. In the bearing feeding process, heavy raw materials need to be conveyed to the position in front of the heating unit, the feeding device is adopted, raw material storage can be achieved, theraw materials are automatically transferred to a conveying belt, the conveying belt can convey the materials, the automation degree of the work process is high, and running is stable and reliable.

Owner:江苏保捷精锻有限公司

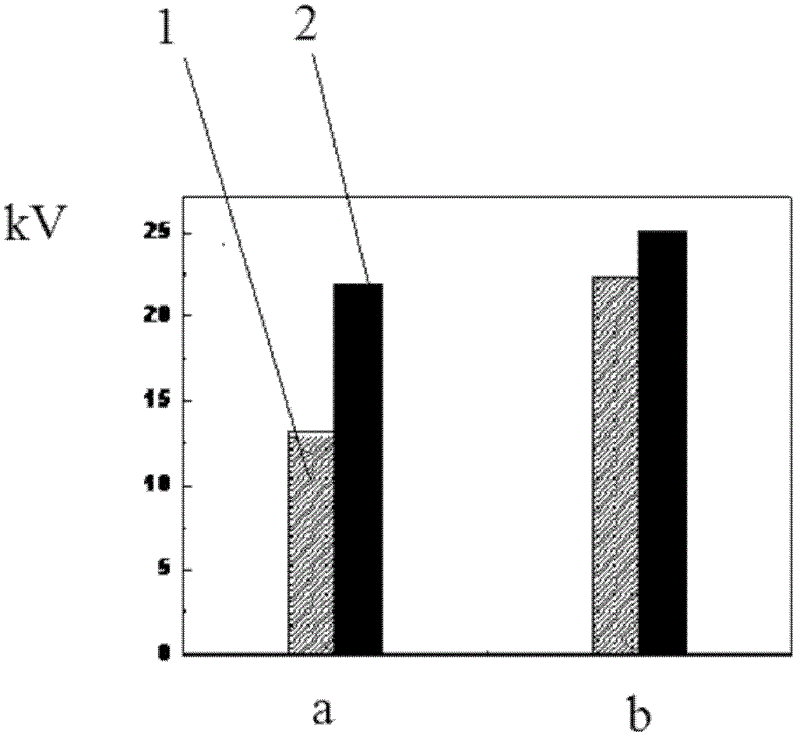

Method for improving insulating property of oil-impregnated paper of transformer

InactiveCN102623113ALow costSuitable for industrial large-scale applicationsLiquid organic insulatorsCardboardPulp and paper industry

The invention discloses a method for improving the insulating property of oil-impregnated paper of a transformer, which belongs to the technical field of oil / paper insulation for electrical equipment. According to the method, a modifier is added into an oil-impregnated paper insulation system for the electrical equipment, the insulating property of an oil-impregnated paper board is enhanced by the dissipating and transporting effects of the modifier on charges in the oil-impregnated paper and the enhancement of the insulating property has important significance for improving the safety operating ratio of the large-scale electrical equipment and reducing the insulating fault rate.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

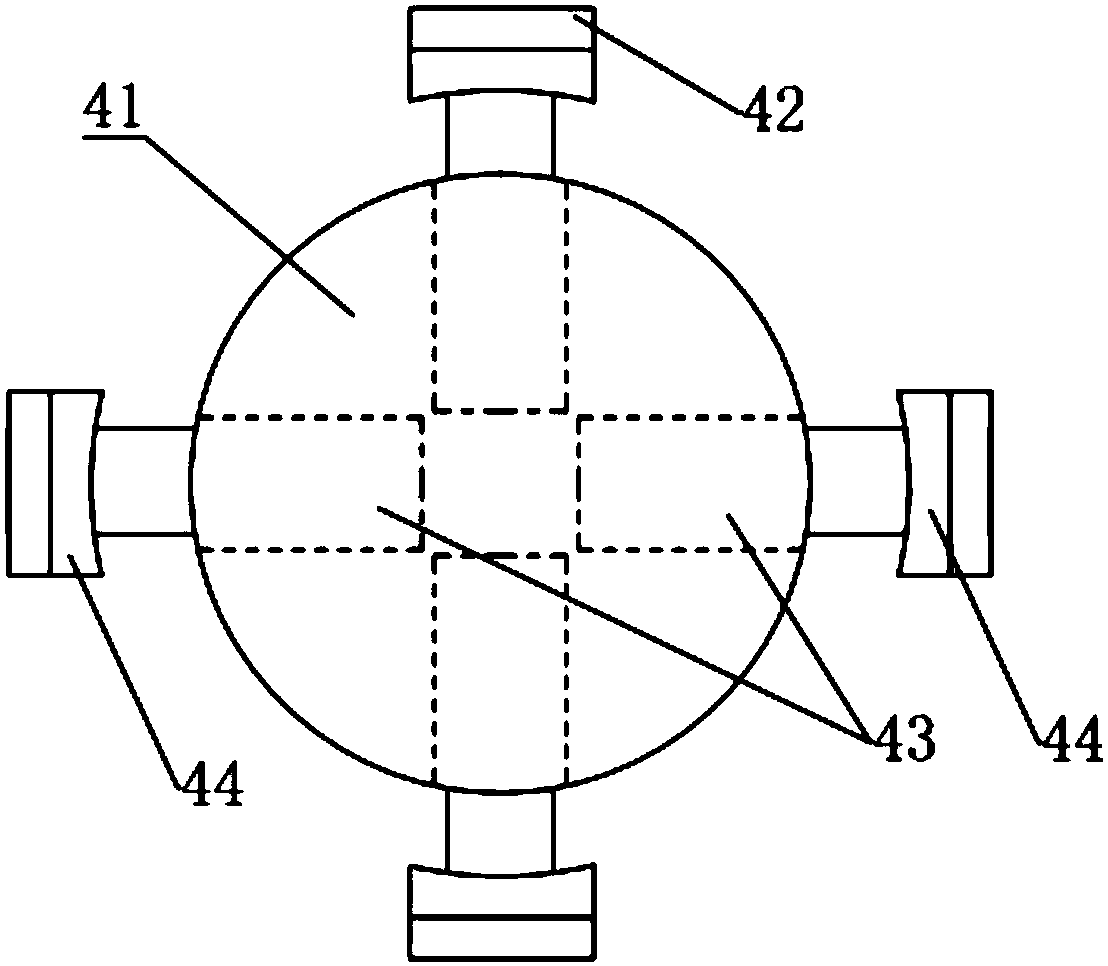

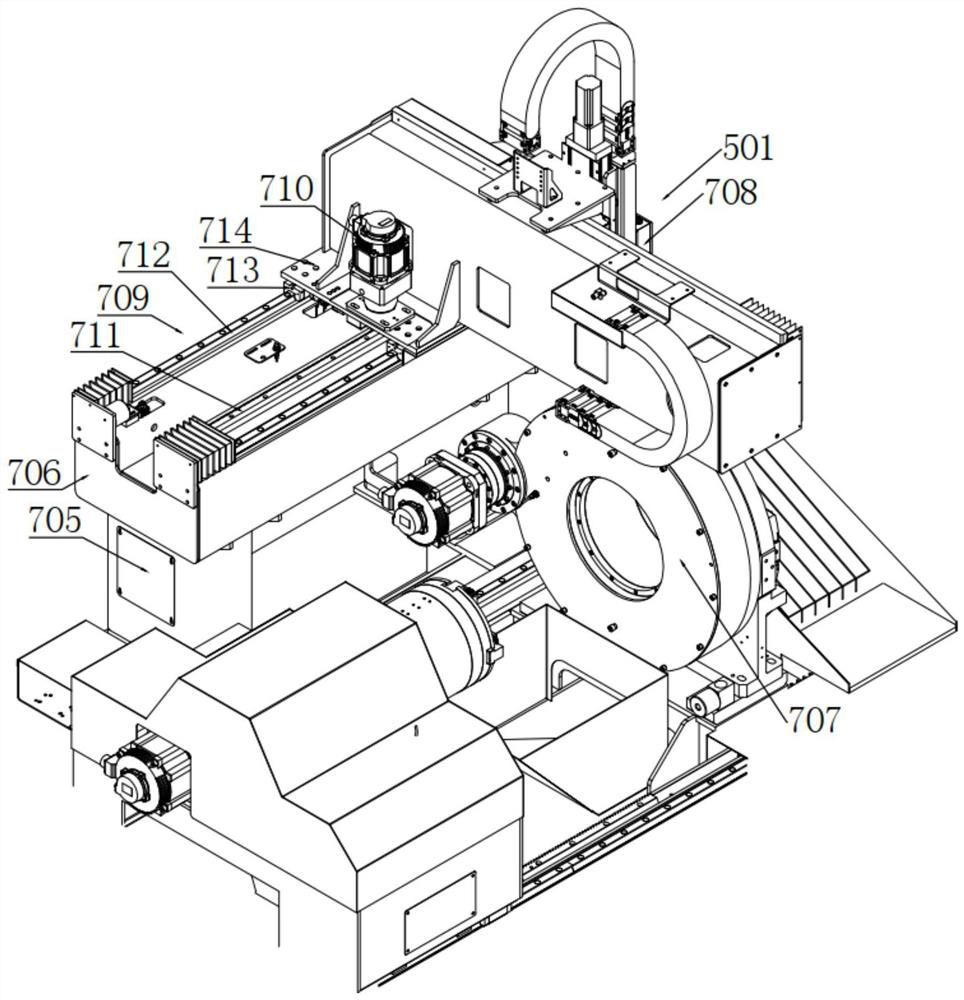

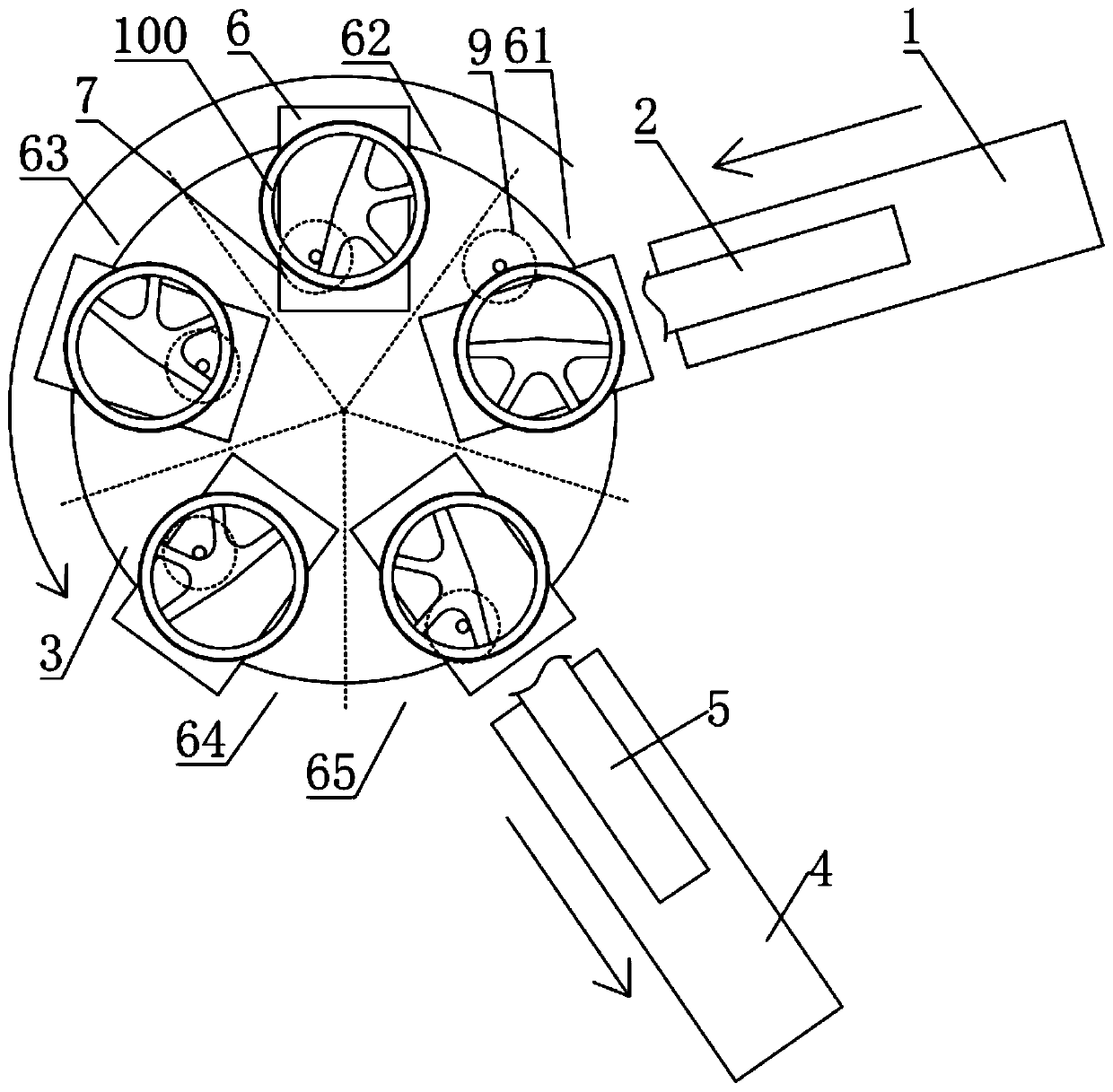

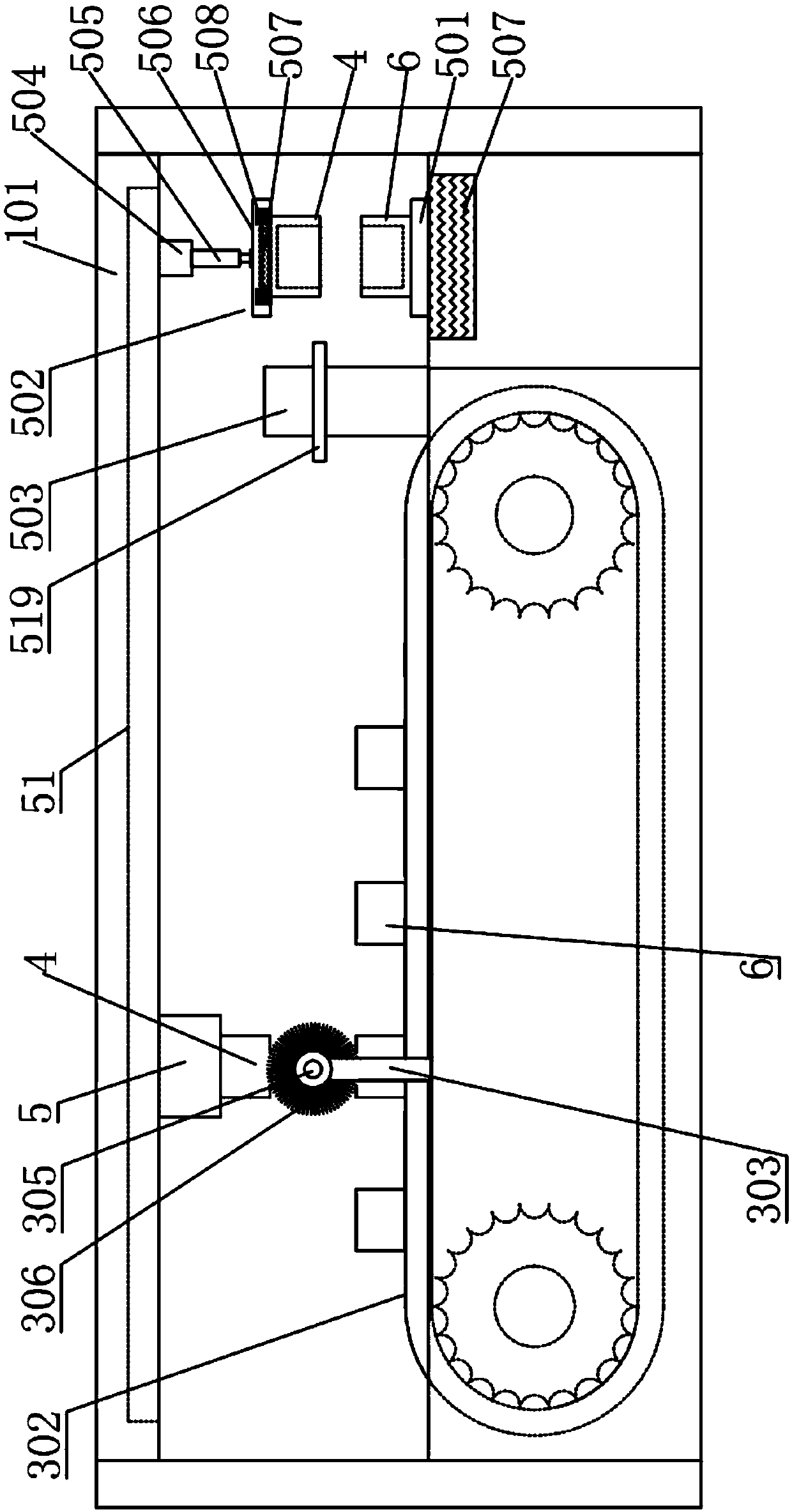

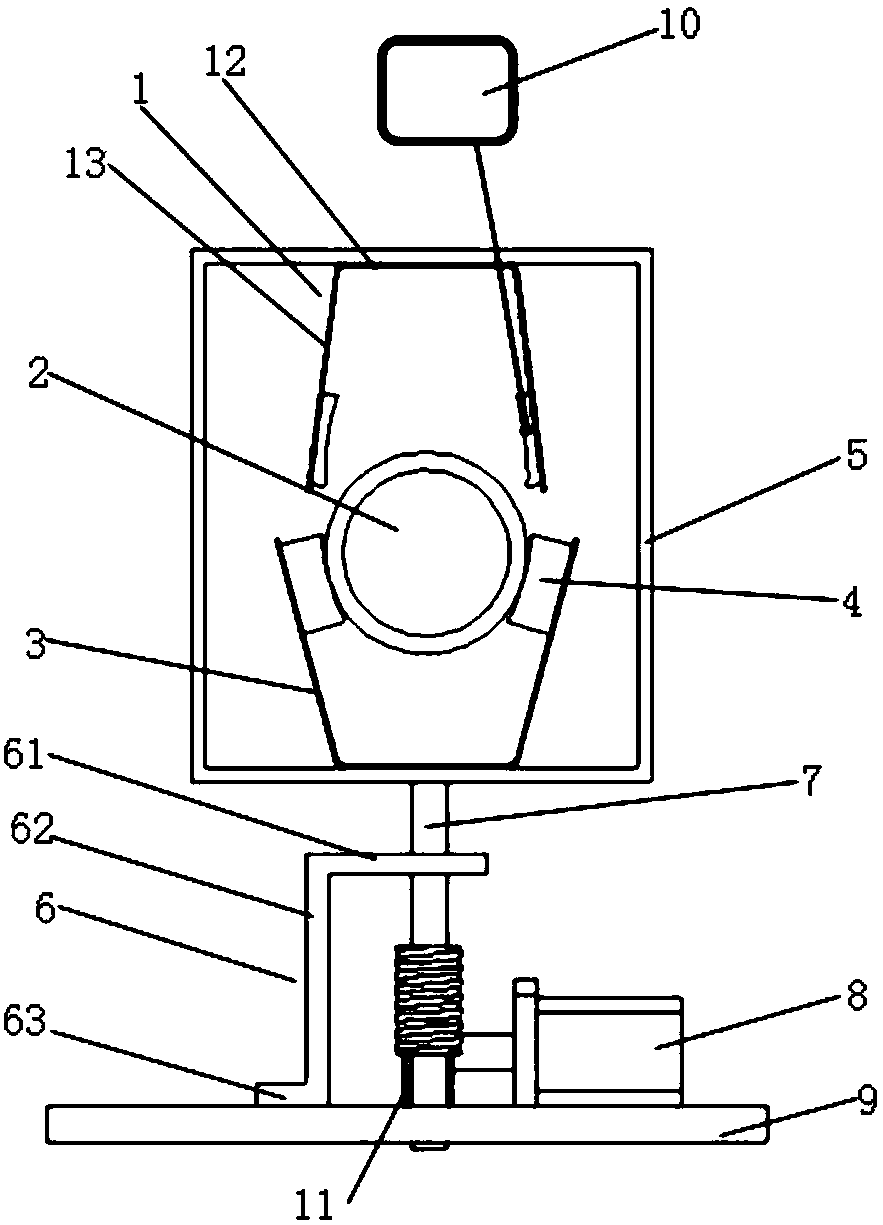

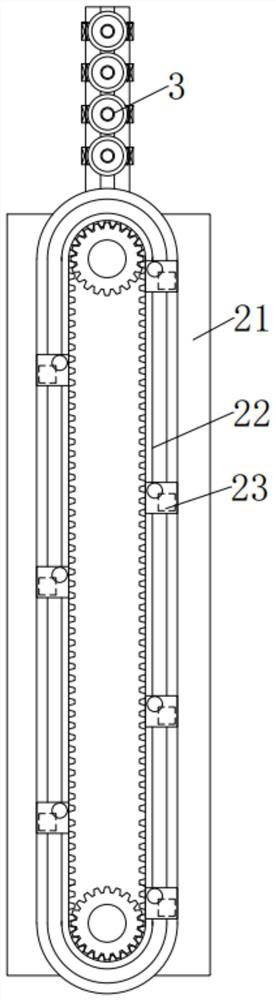

Multi-level circulation full-automatic welding device and work method thereof

InactiveCN111571068AReasonable structural designEasy to produceWelding/cutting auxillary devicesAuxillary welding devicesGear wheelElectric machinery

The invention discloses a multi-level circulation full-automatic welding device and a work method. A to-be-welded piece feeding conveying belt, a to-be-welded piece feeding assembly, a rotation workbench, a welding piece discharging conveying belt, a to-be-welded piece discharging assembly, a to-be-welded piece welding rotation table, a to-be-welded piece inner ring welding assembly, a machine table and a to-be-welded piece outer ring welding assembly are included. Each of the to-be-welded piece feeding conveying belt and the welding piece discharging conveying belt comprises a transmission work machine table, a conveying drive motor, a first conveying gear, a second conveying gear, a first conveying gear belt, a conveying guiding rod and a raw material containing trolley. According to themulti-level circulation full-automatic welding device, the multi-level circulation full-automatic welding device is high in automation degree and work efficiency and flexible in application. According to the work method of the multi-level circulation full-automatic welding device, the work principle is simple and feasible, the automation degree is high in the work process, needed manpower is little, the production efficiency is improved, and the multi-level circulation full-automatic welding device and the work method are suitable for industry large-scale application.

Owner:元祥精密机电新沂有限公司

Three-component mercury-free catalyst for hydrochlorination of acetylene and preparation method of catalyst

ActiveCN107983375AHigh reactivityGood choicePhysical/chemical process catalystsPreparation by halogen halide additionCeriumHigh activity

The invention discloses a mercury-free catalyst for hydrochlorination of acetylene and a preparation method of the catalyst. The catalyst contains carrier activated carbon and an active component which is a mixture of three components, wherein the component A is chloroauric acid, the component B is copper chloride, the component C is one of sodium chloride, potassium chloride, rubidium chloride, cesium chloride, magnesium chloride, calcium chloride, cerium chloride and barium chloride, the weight percentage of a gold element in the component A and the carrier is 0.01%-0.1%, the weight percentage of copper chloride in the component B and the carrier is 0.5%-20%, and the weight percentage of the component C and the carrier is 1%-30%. The active component is supported on the carrier through equivalent-volume impregnation, and the novel mercury-free catalyst is obtained with a drying means. The catalyst has very high activity, selectivity and better stability in the reaction for preparingvinyl chloride through hydrochlorination of acetylene.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

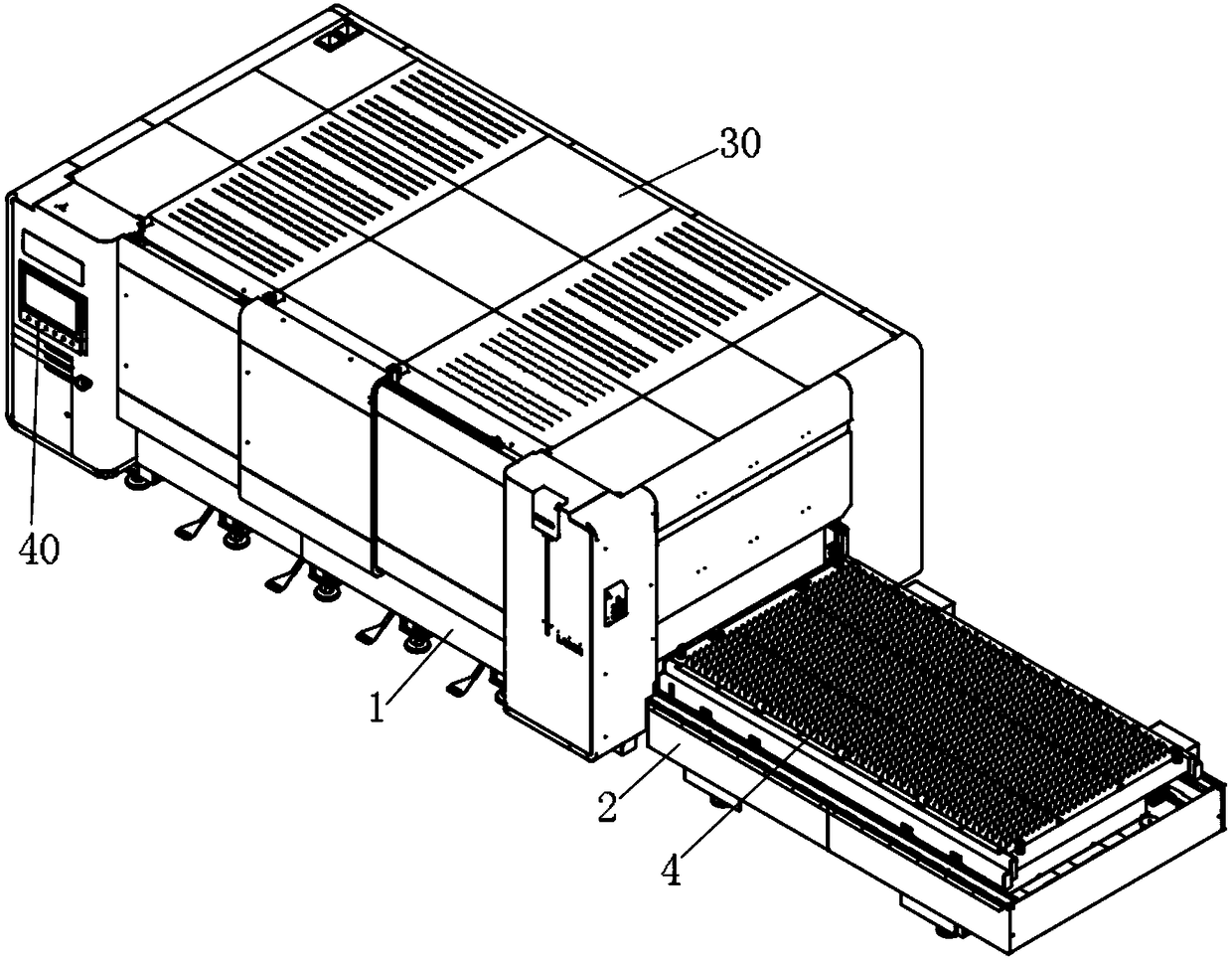

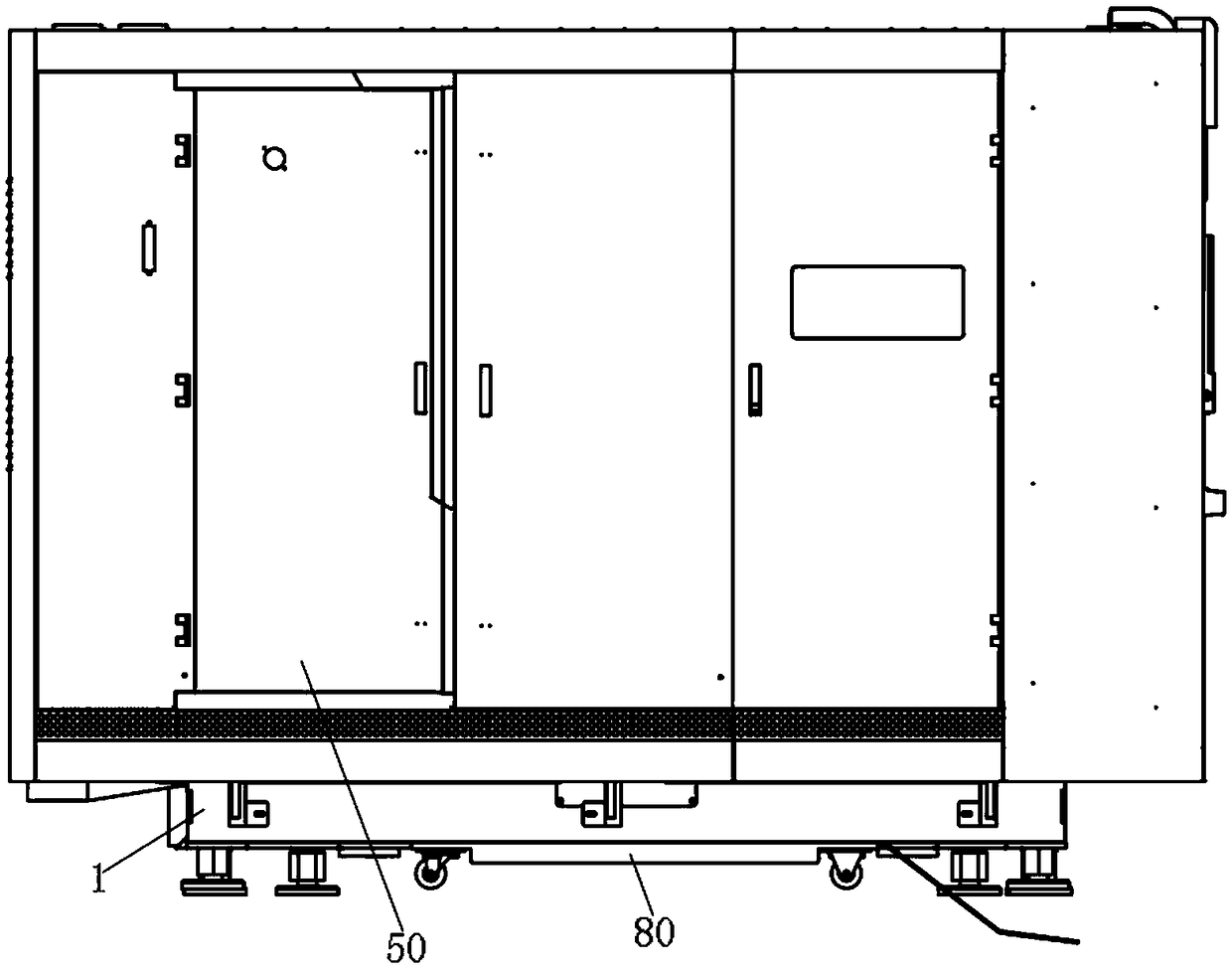

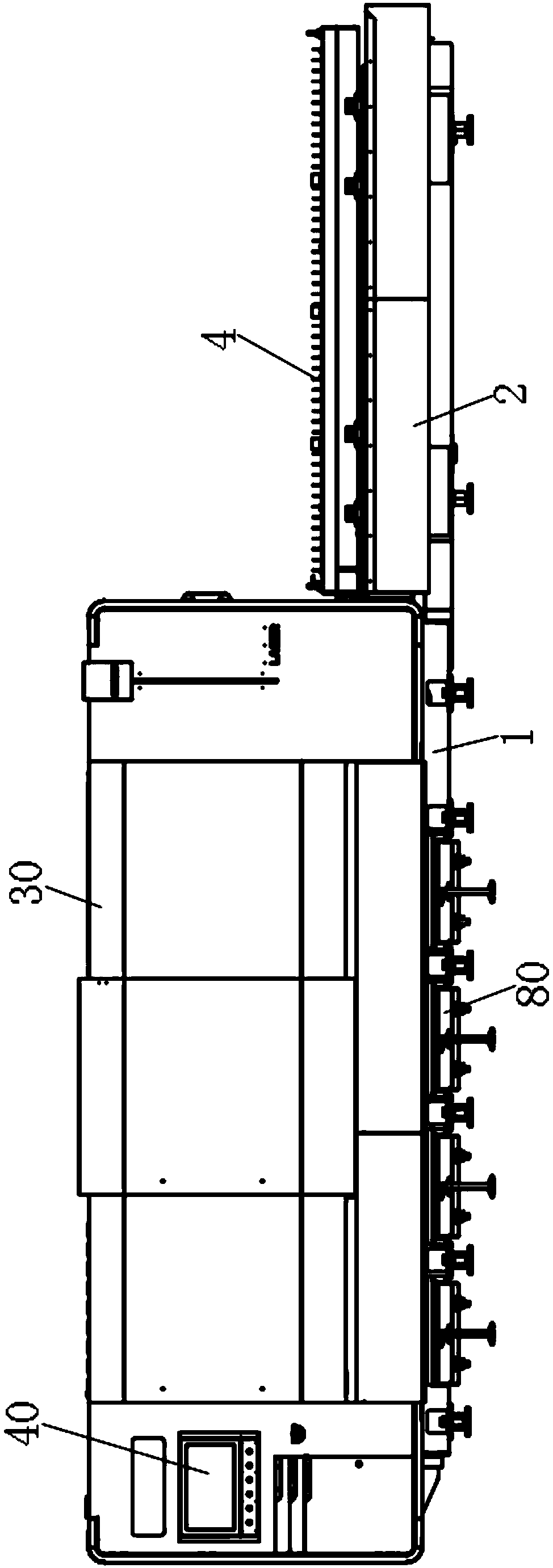

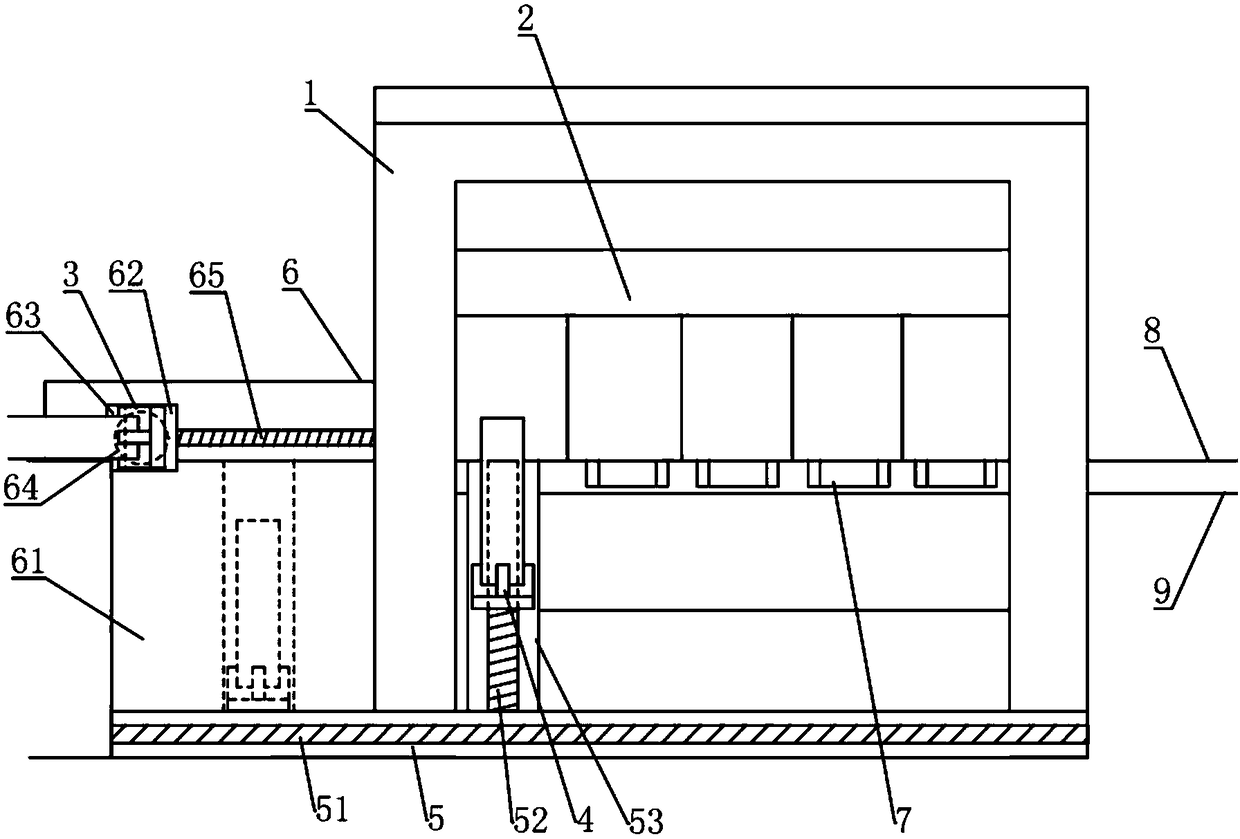

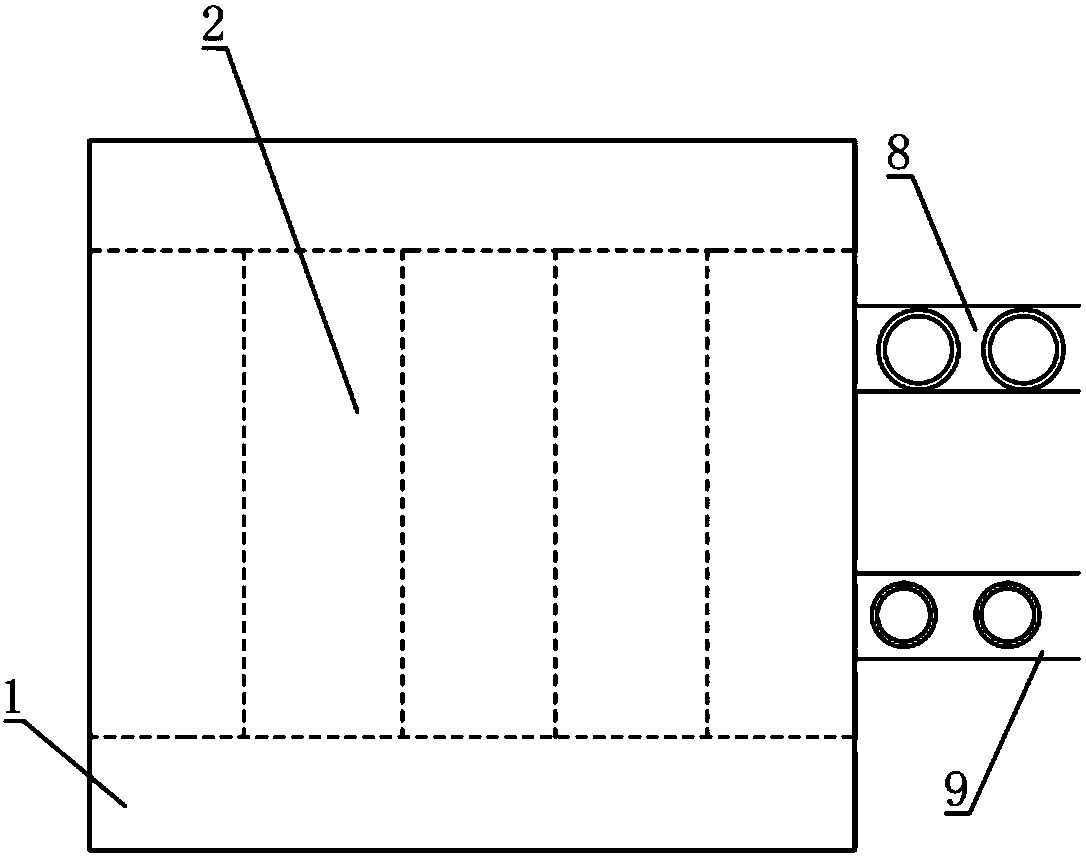

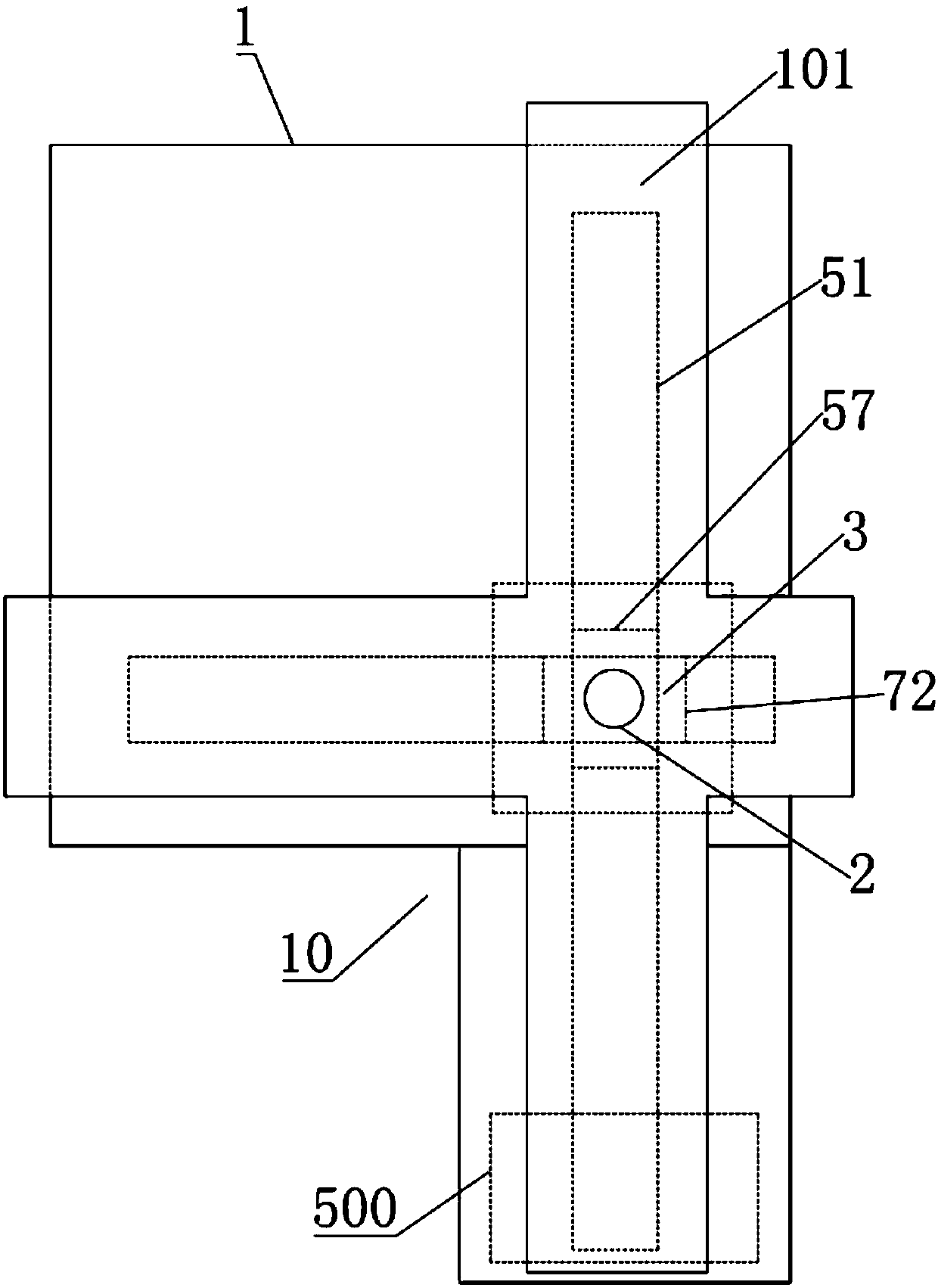

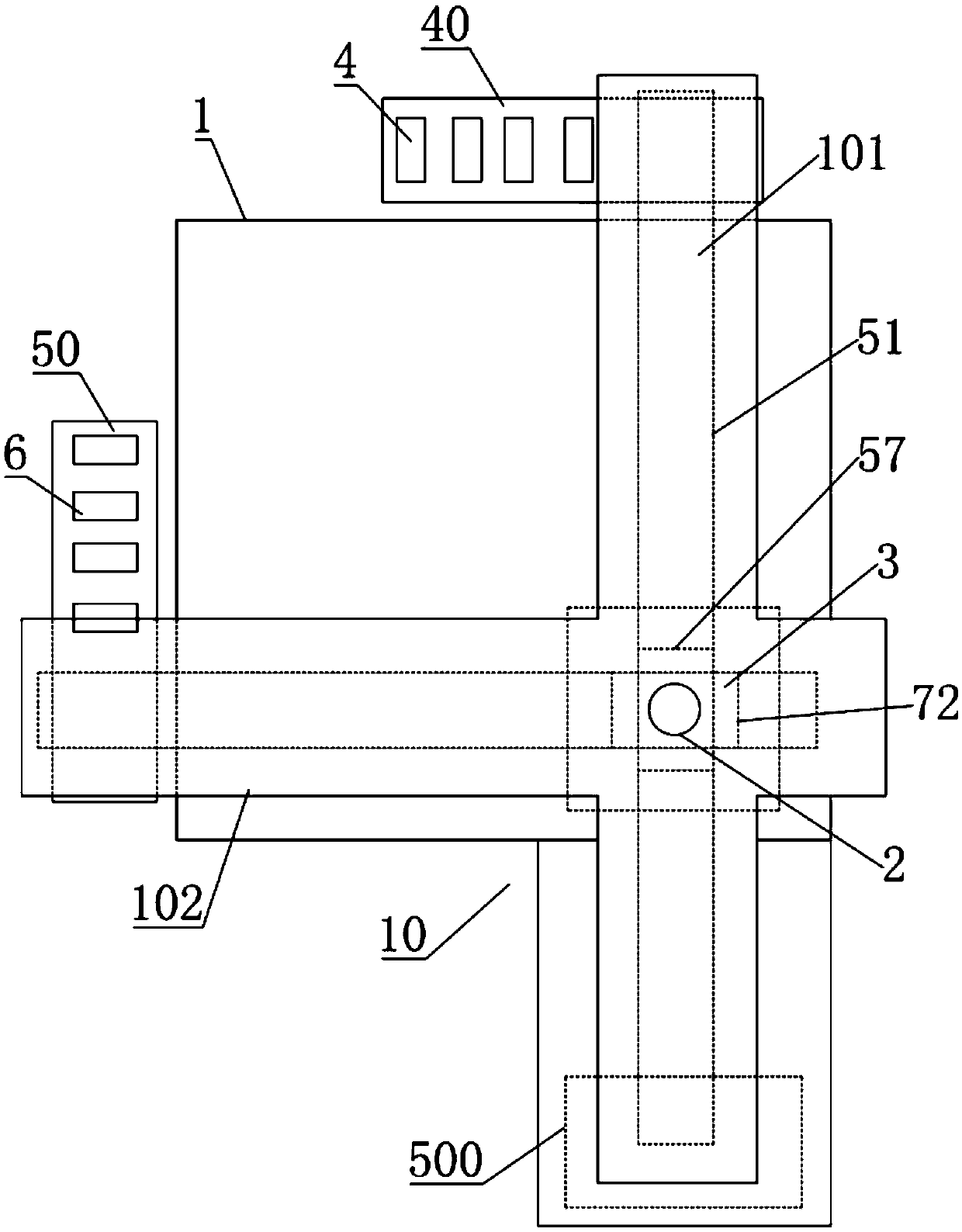

Laser cutting machine with efficient and intelligent lifting exchanging table and working method thereof

PendingCN108817708AHigh degree of automationSave human effortLaser beam welding apparatusControl systemWorking set

The invention discloses a laser cutting machine with an efficient and intelligent lifting exchanging table, and belongs to the technical field of special machining. The laser cutting machine comprisesa main bed body, a lifting table, a lower cutting box, an upper cutting box, a protective cover, an operation station, an electric control cabinet, a moving beam, a laser cutting head, a set of falling trolleys and a dust removal system. The main bed body is provided with a front deceleration sensor, a front stop sensor, a rear stop sensor, a rear deceleration sensor, an upper in-place sensor, anintermediate sensor, a lower in-place sensor, a transmission assembly, a driving assembly and a first guiding rail. According to the laser cutting machine, signal data of all the sensors need to be extracted firstly and received by a control system, the current position states of two material platforms are judged through the data, and then subsequent actions of the two material platforms are controlled, so that the material platforms reach the required working positions quickly and automatically; and in this way, the two material platforms can achieve one-key exchanging at any position, automatic material exchanging is achieved, and the working efficiency is improved.

Owner:苏州松谷智能装备股份有限公司

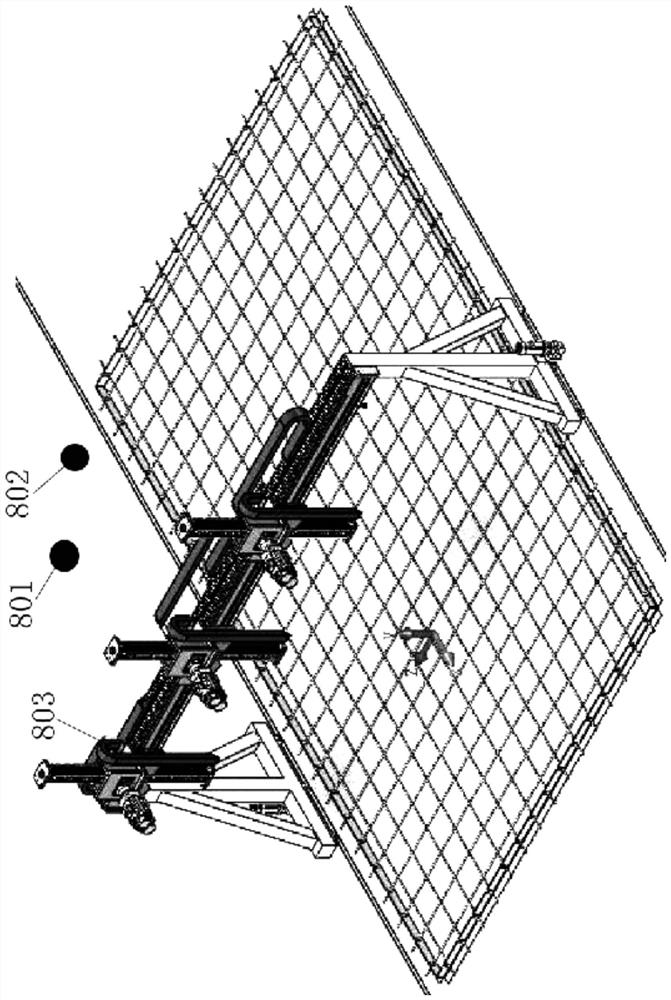

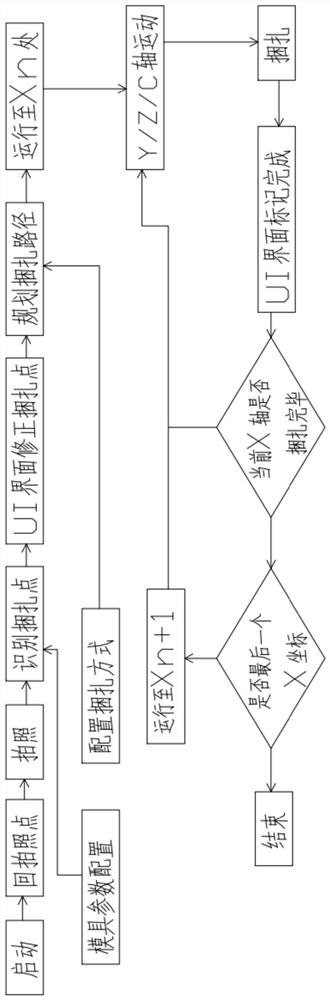

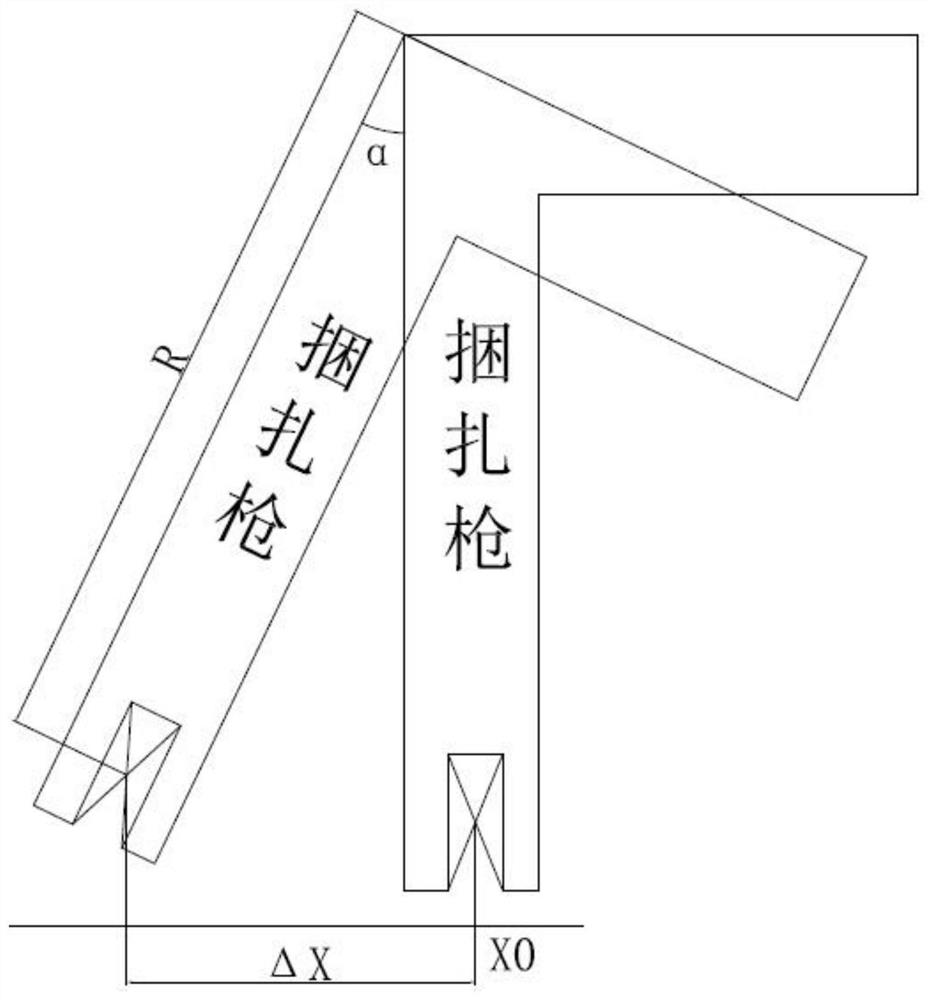

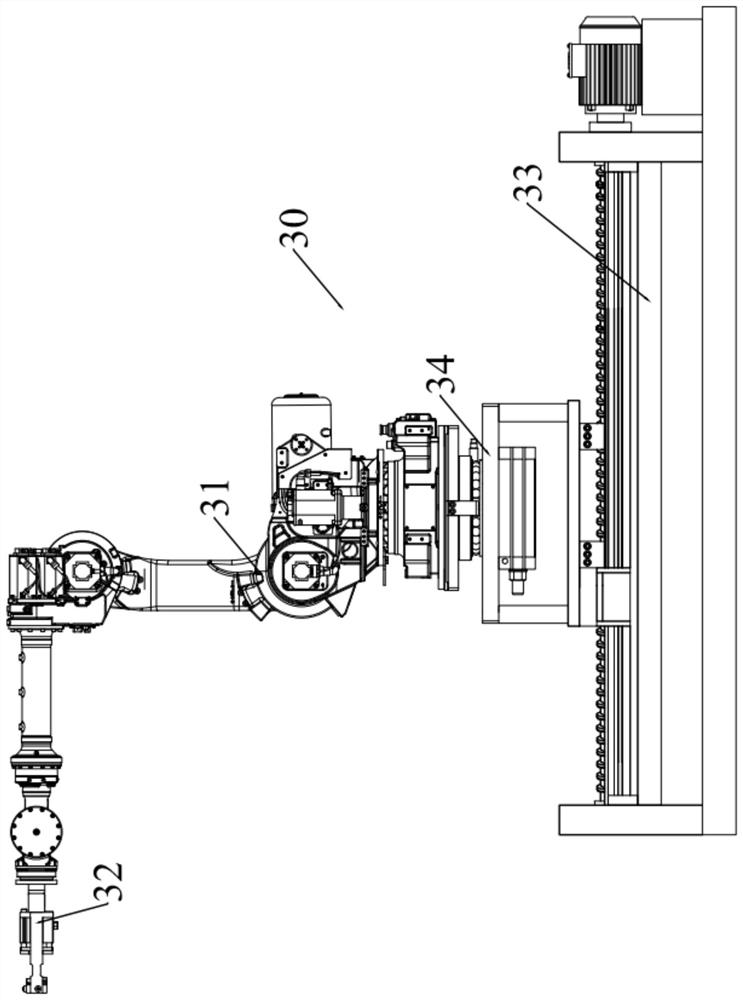

Multi-axis robot dot-matrix reinforcing steel bar bundling system and working method thereof

ActiveCN113264212ASimple working principleHigh degree of automationPackaging automatic controlBundling machine detailsKinematic controllerControl system

The invention discloses a multi-axis robot dot-matrix reinforcing steel bar bundling system and a working method thereof. The system comprises a visual identification camera, a visual positioning camera, a multi-axis bundling robot and a control system, wherein the visual identification camera acquires global data of reinforcing steel bar meshes needing to be bundled, and cross intersection data of transverse and longitudinal reinforcing steel bar meshes are formed; the visual positioning camera acquires position information of all cross intersections on the transverse and longitudinal reinforcing steel bar meshes in a vertical direction; and the multi-axis bundling robot conducts reinforcing steel bar bundling according to a planned bundling path. According to the multi-axis bundling robot dot-matrix reinforcing steel bar bundling system, three-dimensional coordinates of a target bundling point and a rotation angle of a bundling gun are calculated by means of a motion control algorithm and then sent to a motion controller in sequence, and the bundling gun is moved to a position above the bundling point for bundling. The working method is simple and easy to implement, the automation degree of a working process is high, the needed manpower is less, the production efficiency is improved, and the method is suitable for industrial large-scale application.

Owner:济客筑科技太仓有限公司

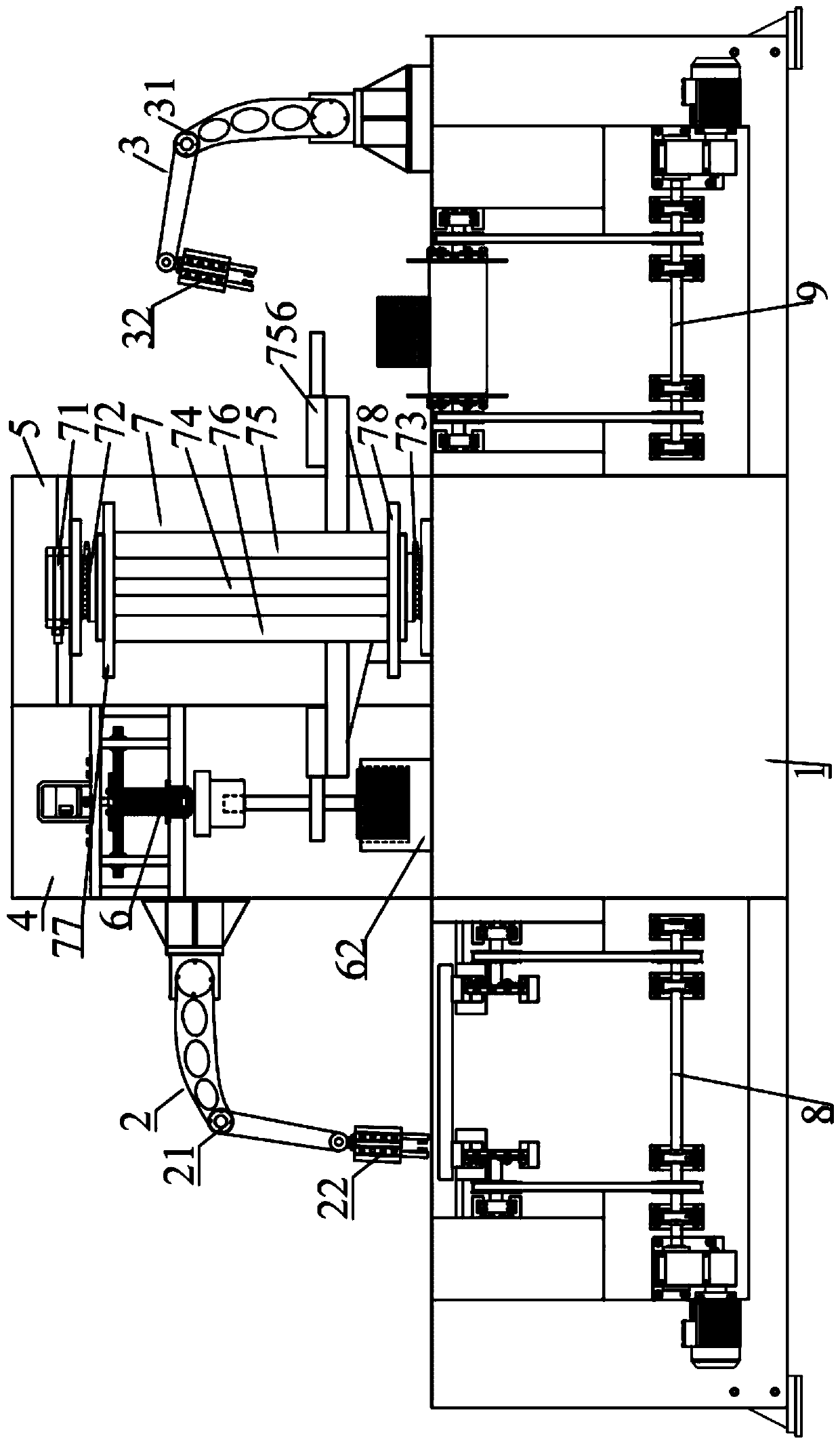

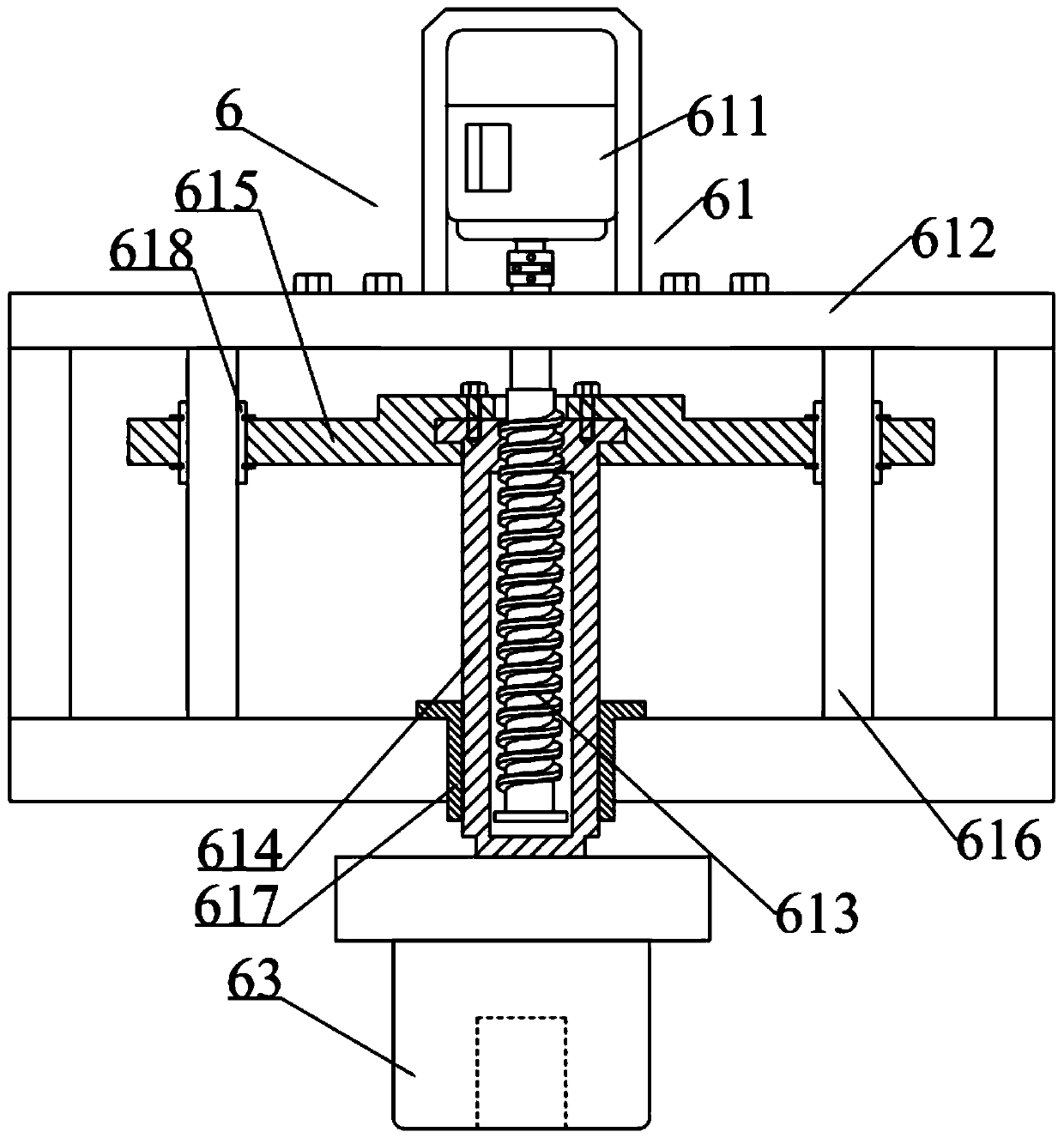

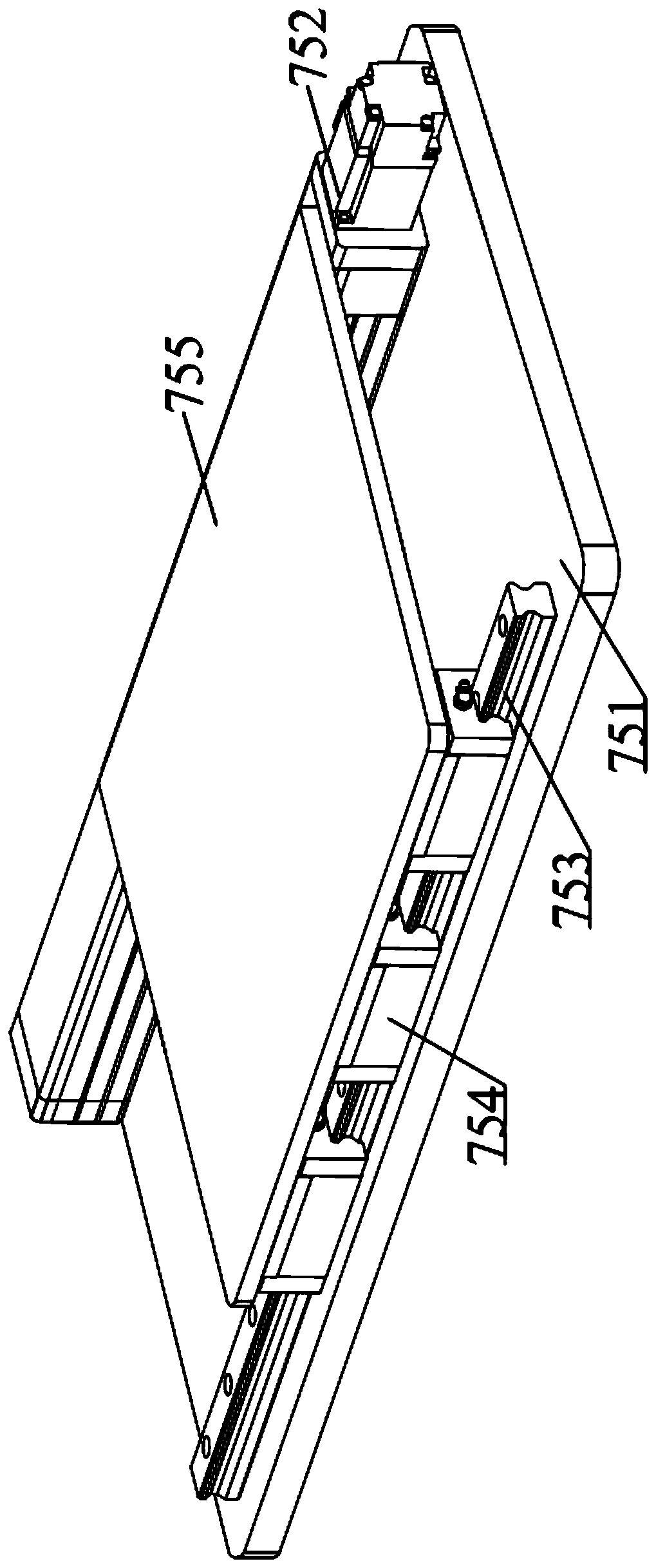

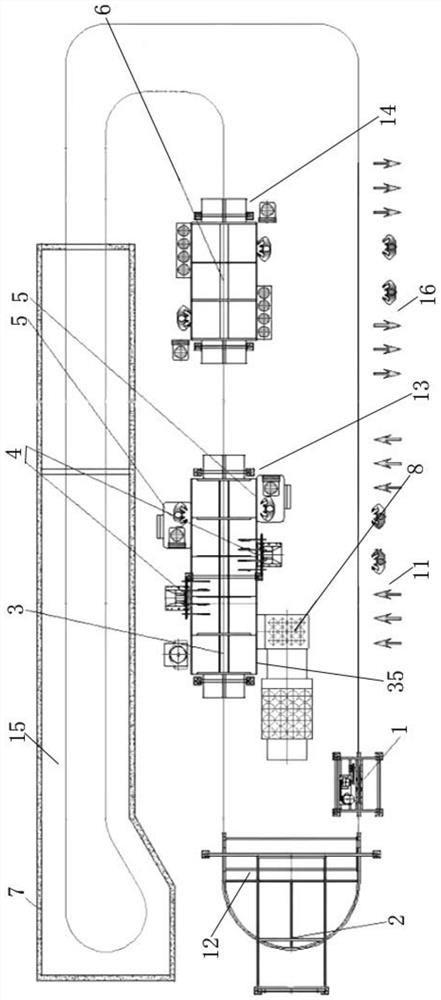

Full-automatic rotor shaft core press-in production line and working method thereof

ActiveCN111136444ASimple working principleHigh degree of automationMetal working apparatusAutomatic controlEngineering

The invention discloses a full-automatic rotor shaft core press-in production line and a working method thereof, and belong to the technical field of manufacturing equipment such as lifting transportation equipment and material handling equipment using automatic control, computer information management and other technical equipment. The full-automatic rotor shaft core press-in production line comprises a production line platform, a rotor shaft clamping manipulator, a rotor clamping manipulator, a press-in workbench, a rotating workbench, a rotor shaft core press-in assembly, a rotor rotating assembly, a rotor shaft conveying assembly and a rotor conveying assembly. The rotor shaft clamping manipulator can clamp rotor shafts on the rotor shaft conveying assembly to the rotor shaft core press-in assembly, and the rotor clamping manipulator can clamp rotors on the rotor conveying assembly to the rotor rotating assembly. The full-automatic rotor shaft core press-in production line is simple structure and reasonable in design, and is easy for production. According to the working method, the working principles are simple and easy to operate, the degree of automation in the working process is high, less manpower is required, the production efficiency is improved, and the working method is suitable for large-scale industrial application.

Owner:苏州磐驰自动化设备有限公司

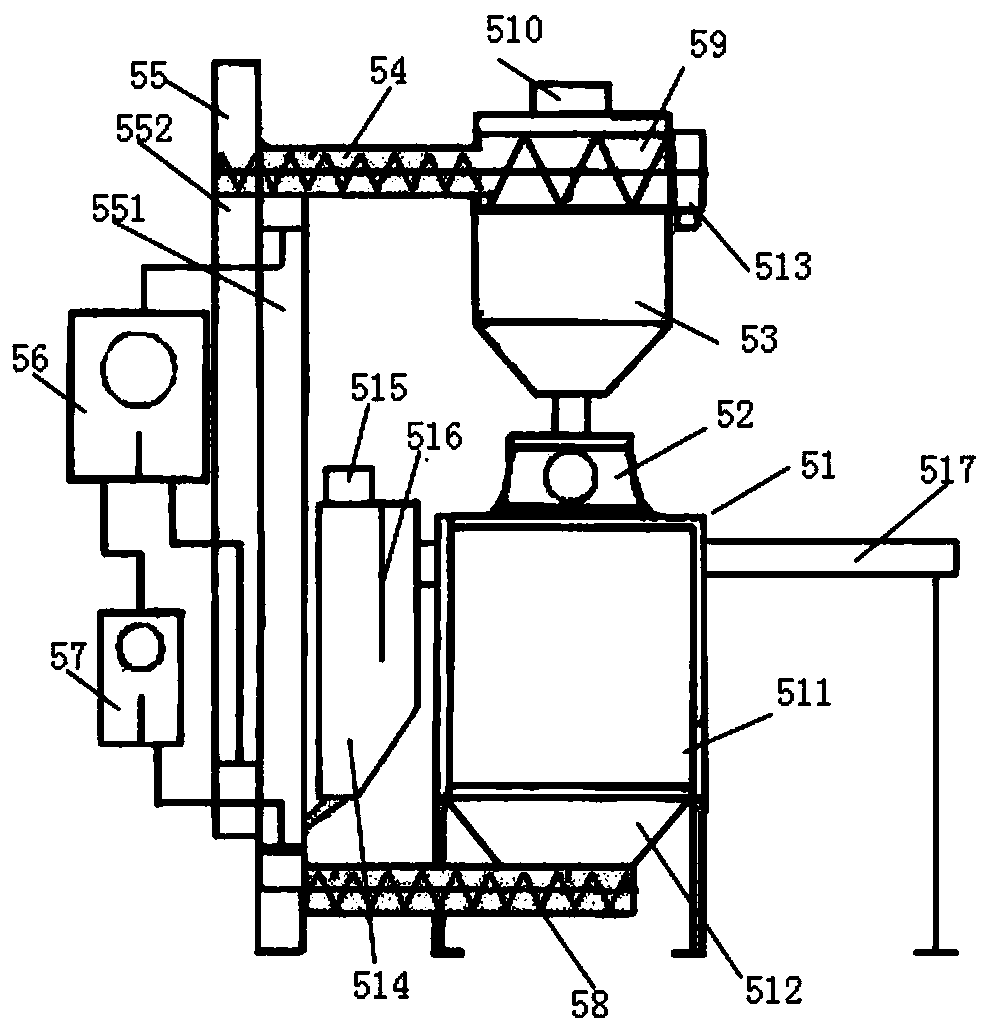

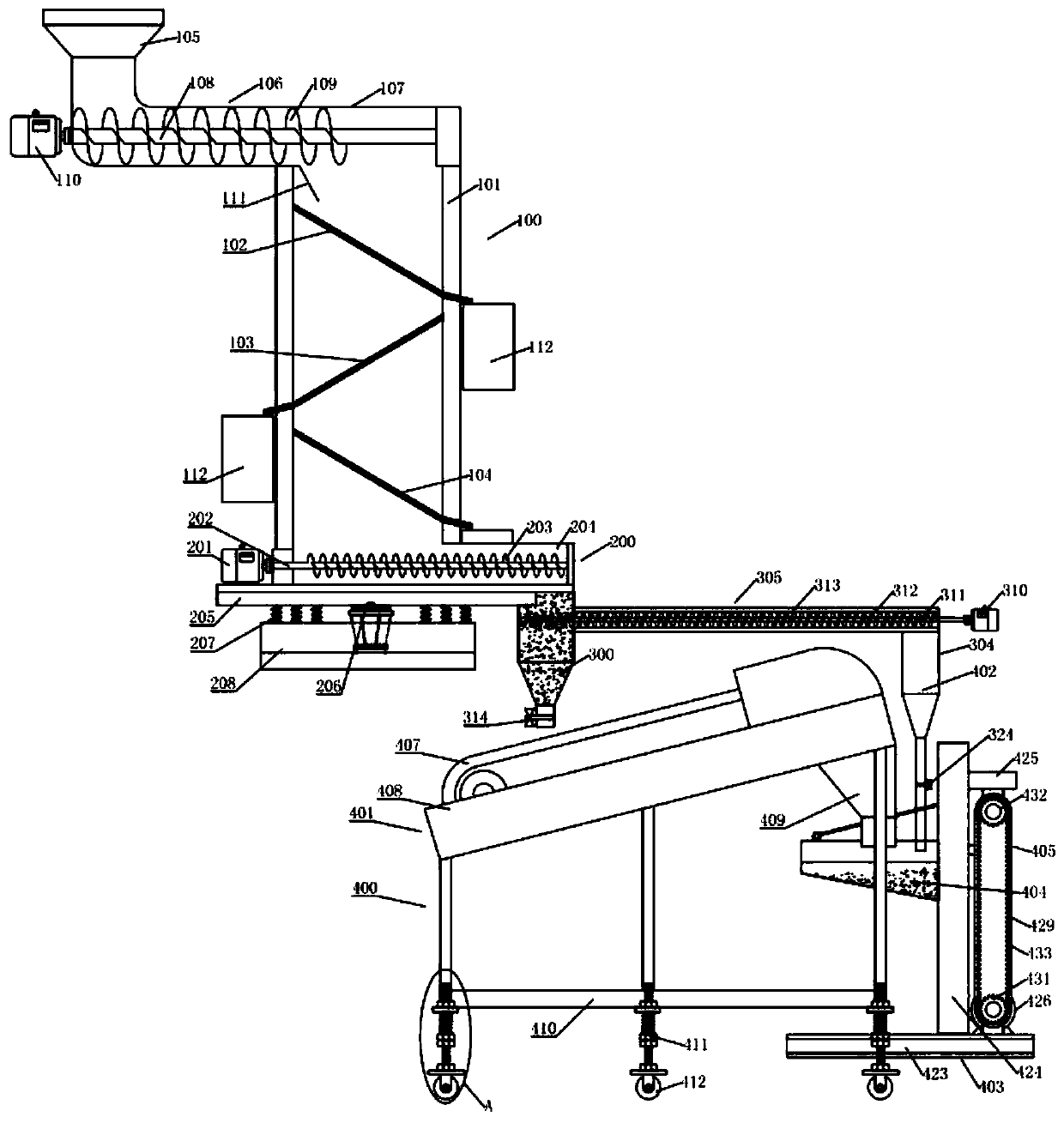

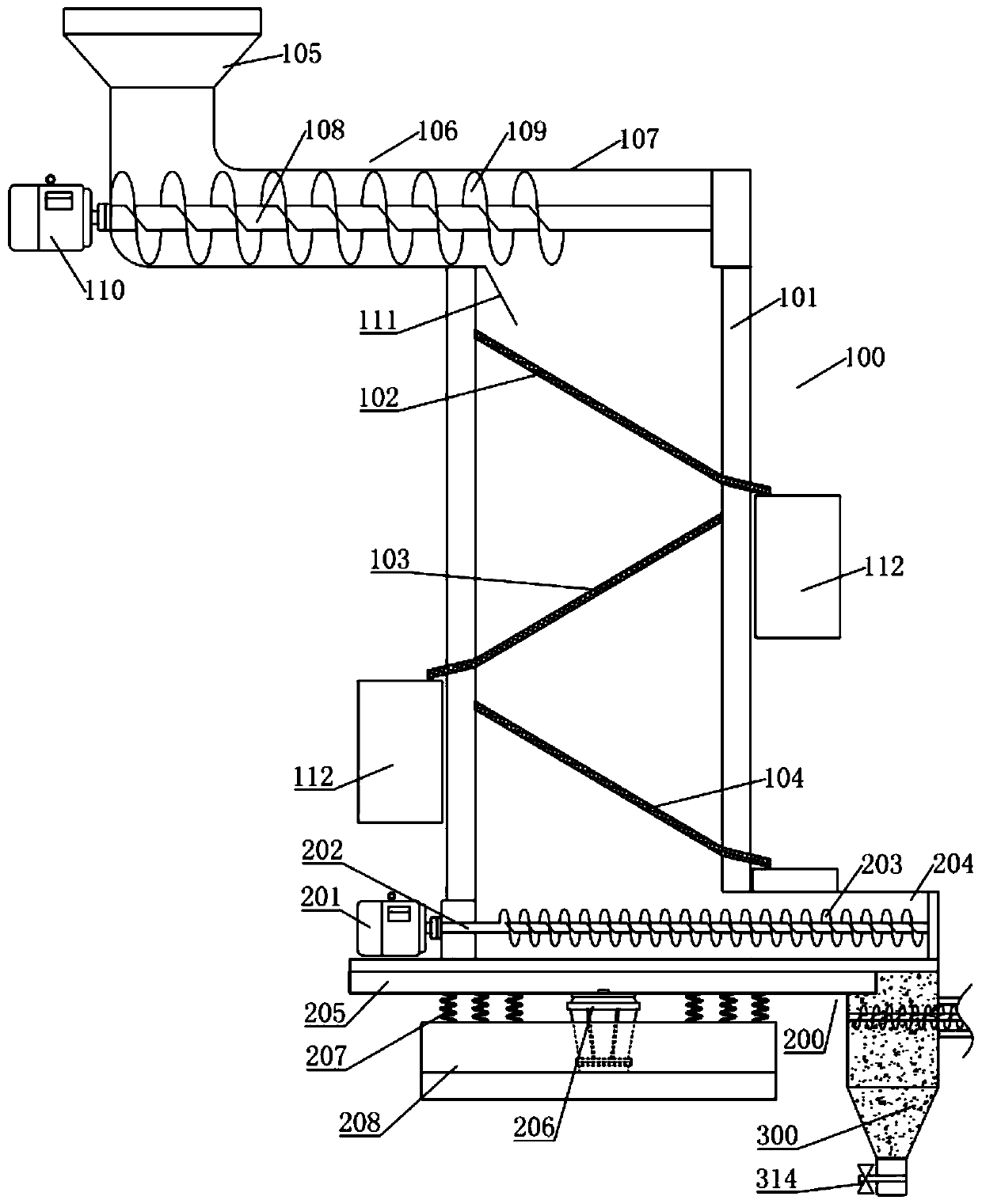

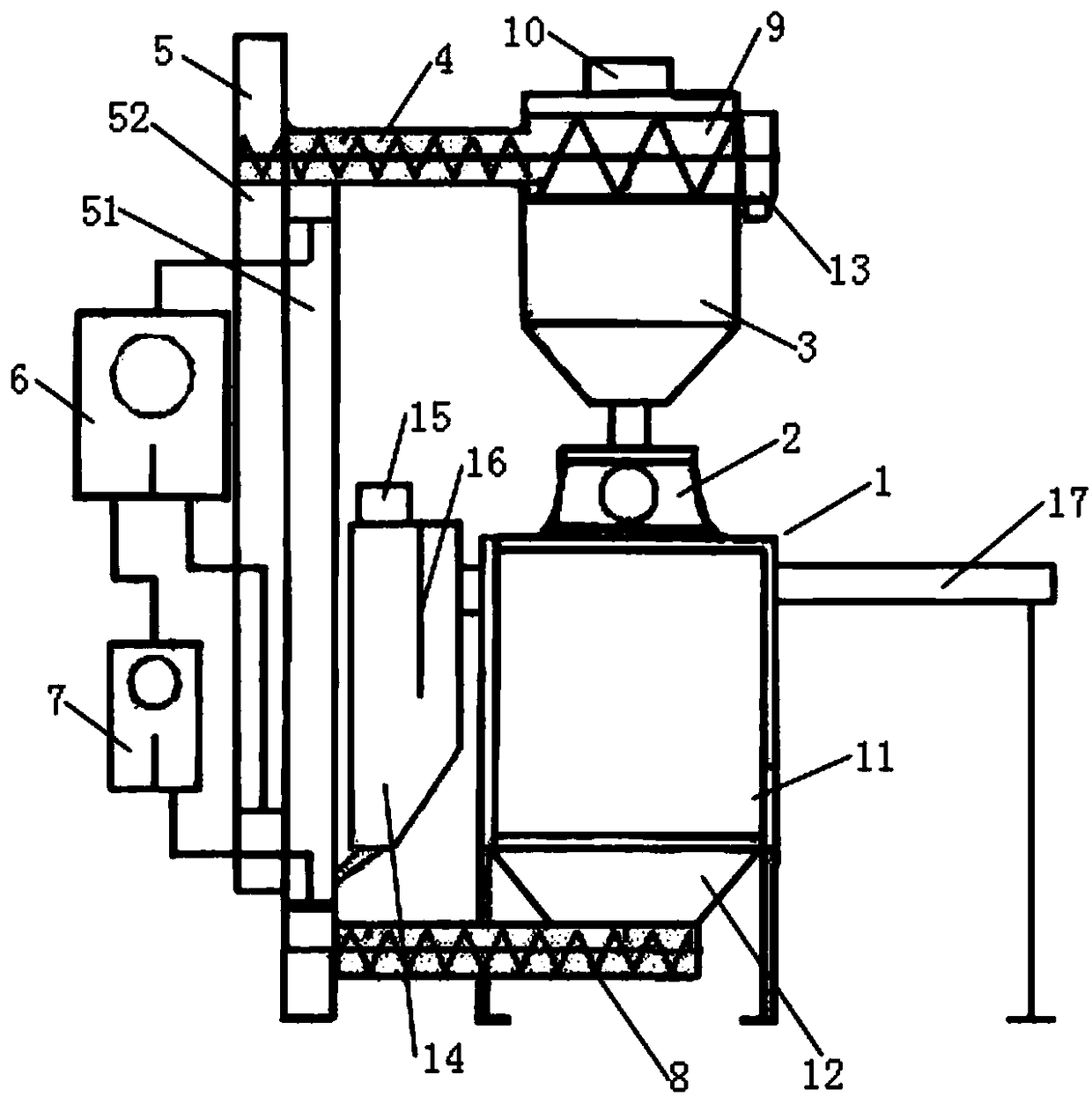

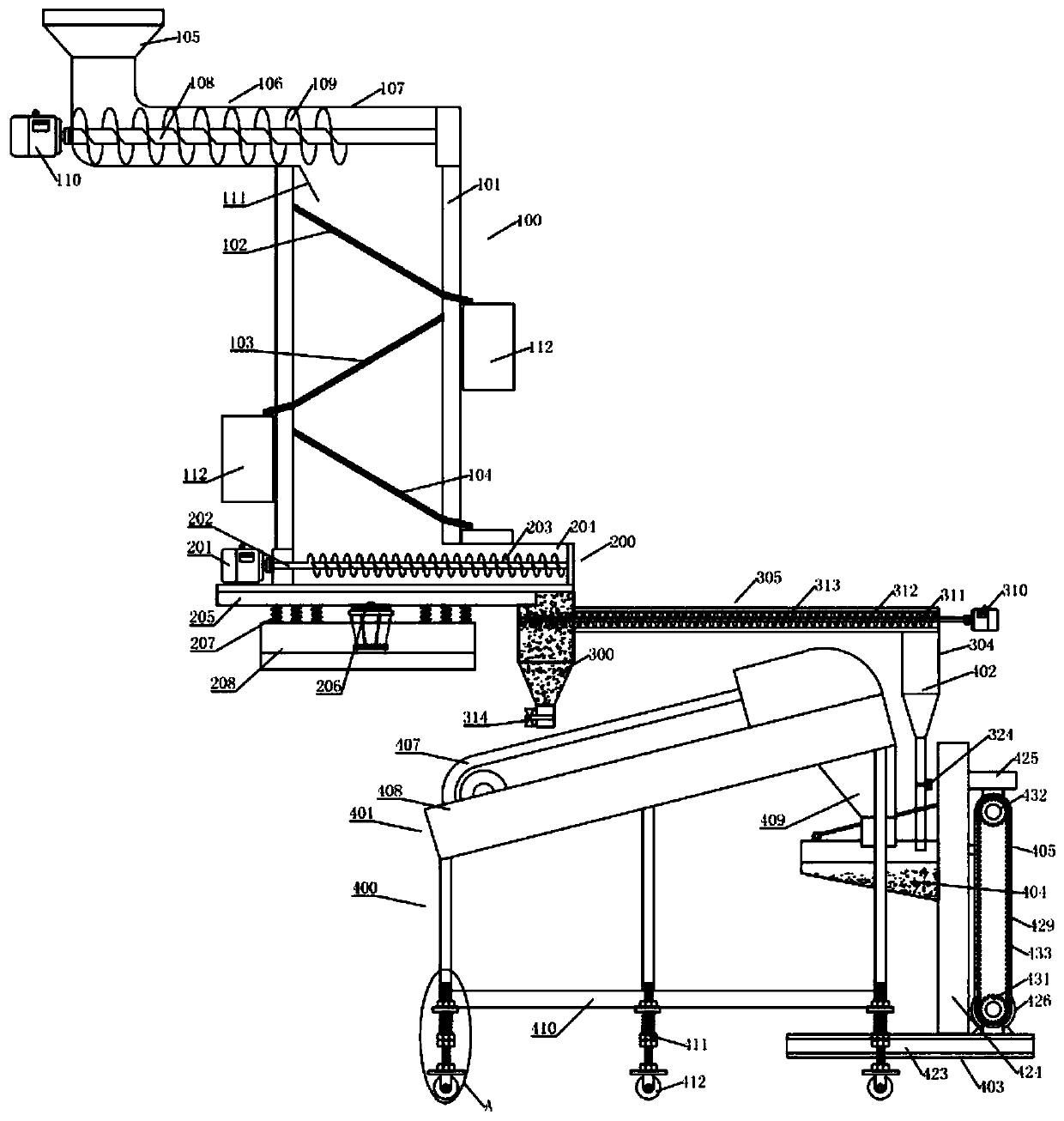

Device for automatically conducting cast iron inoculant screening and transporting and working method thereof

InactiveCN110328136ASimple structureReasonable designSievingRotary stirring mixersEngineeringCast iron

The invention discloses a device for automatically conducting cast iron inoculant screening and transporting and a working method thereof. The device comprises an inoculant screening assembly, an inoculant conveying assembly, an inoculant stirring assembly and an inoculant feeding assembly; the inoculant screening assembly comprises a screening shell, a first screening mesh, a second screening mesh, a third screening mesh, an inoculant main feeding port and a material guiding assembly, and the inoculant main feeding port is arranged on the material guiding assembly; the inoculant conveying assembly is arranged at the lower end of the screening shell; and the inoculant stirring assembly can put an inoculant into the inoculant feeding assembly. According to the working method of the device for automatically conducting cast iron inoculant screening and transporting, the working principle is simple and feasible, the automation degree of the working process is high, needed manpower is less,the production efficiency is improved, the method is suitable for industrial large-scale application, the inoculant meeting the size requirements can be screened out through the multiples stages of screening meshes, and then the production and use requirements are met.

Owner:徐州市金鑫科技有限公司

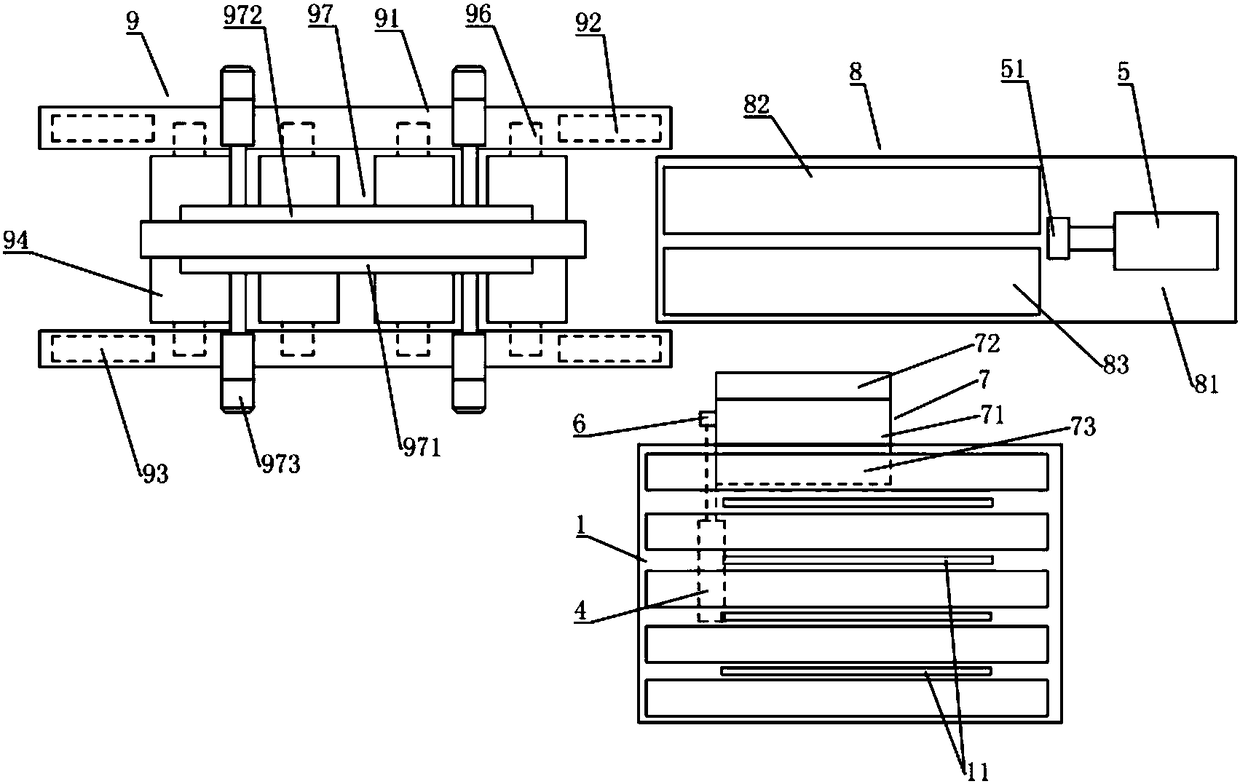

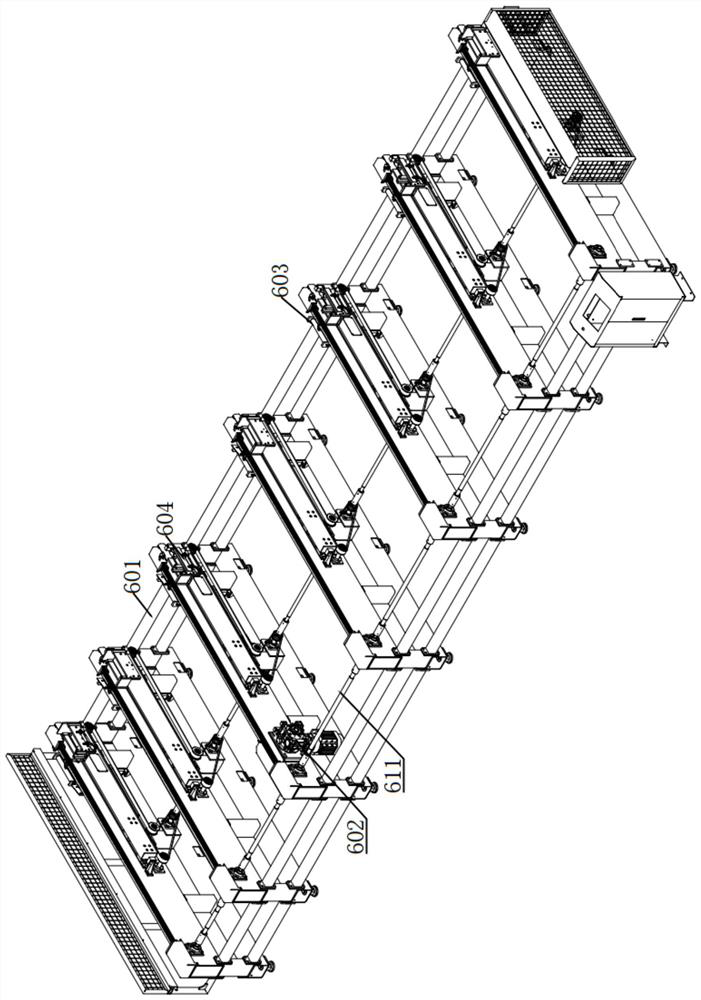

Bearing race production line with full-automatic forging structure and working method thereof

PendingCN108326567AHigh degree of automationSave human effortShaftsBearing componentsProduction lineEngineering

The invention discloses a bearing race production line with a full-automatic forging structure. The bearing race production line with the full-automatic forging structure comprises a feeding unit, a heating unit, a forging unit, a sorting unit, a shot blasting unit, a grinding and expanding unit, a shaping unit, a washing unit and a discharging unit in sequence, wherein the forging unit comprisesa high-speed upsetting forging machine, a die, a first bearing race blank grabbing manipulator, a second bearing race blank grabbing manipulator, a bearing race blank transferring device, a feeding device, a third bearing race grabbing manipulator, a bearing outer ring conveying belt and a bearing inner ring conveying belt; and the die is arranged inside the high-speed upsetting forging machine. The bearing race production line with the full-automatic forging structure can automatically achieve transferring and feeding of bearing race blanks, the bearing race blanks can be machined into bearing outer ring materials and bearing inner ring materials on the die automatically through the high-speed upsetting forging machine, the degree of automation is high, transferring of raw materials amongworking stations is conducted through the manipulators, and safety and reliability are achieved.

Owner:江苏保捷精锻有限公司

Simple and efficient conveying and cutting device

ActiveCN105751279ASimple structureEasy to produceMetal sawing devicesMetal working apparatusEngineeringMechanical engineering

The invention discloses a simple and efficient conveying and cutting device.The simple and efficient conveying and cutting device comprises a conveying mechanism, a cutting mechanism, a transporting mechanism and a servo motor, wherein the conveying mechanism is arranged on one side of the cutting mechanism, the transporting mechanism is connected with the conveying mechanism, penetrates through the cutting mechanism and extends to the other side of the cutting mechanism, and the servo motor is arranged at the connecting portion of the conveying mechanism and the transporting mechanism.The simple and efficient conveying and cutting device is simple in structure, reasonable in design and easy to produce; synchronous working of two mechanisms can be controlled through one servo motor, so that working efficiency is high, manufacturing cost is reduced, and the simple and efficient conveying and cutting device is suitable for large-scale industrial application.

Owner:MEICHENG NEW MATERIAL TECH JIANGSU CO LTD

Bearing ring production line with efficient shot blasting device and working method thereof

PendingCN108436486AHigh degree of automationReasonable structural designBearing componentsOther manufacturing equipments/toolsProduction lineEngineering

The invention discloses a bearing ring production line with an efficient shot blasting device. The bearing ring production line with the efficient shot blasting device comprises a loading unit, a heating unit, a forging unit, a sorting unit, a shot blasting unit, a rolling expansion unit, a shaping unit, a cleaning unit and an unloading unit arranged in sequence, wherein the shot blasting unit comprises a shot blasting chamber, a shot blasting machine, a curtain winnowing box, a first spiral conveyor, a double bucket elevator, a main magnetic separation machine, a secondary magnetic separationmachine, a second spiral conveyor, a roller screen, an expansion chamber and a slide rail module; one end of the slide rail module is arranged in the shot blasting chamber; the shot blasting machineis arranged at the top of the shot blasting chamber for shot blasting of materials; the expansion chamber communicates with the internal of the shot blasting chamber; and the lower end of the expansion chamber is connected with the double bucket elevator. Through continuous rotation of the slide rail module, bearing ring materials are fed from an inlet of the shot blasting chamber; the bearing ring materials after shot blasting are transferred out from an outlet; and the adopted shot blasting machine can efficiently blast shots and recycle the shots.

Owner:江苏保捷精锻有限公司

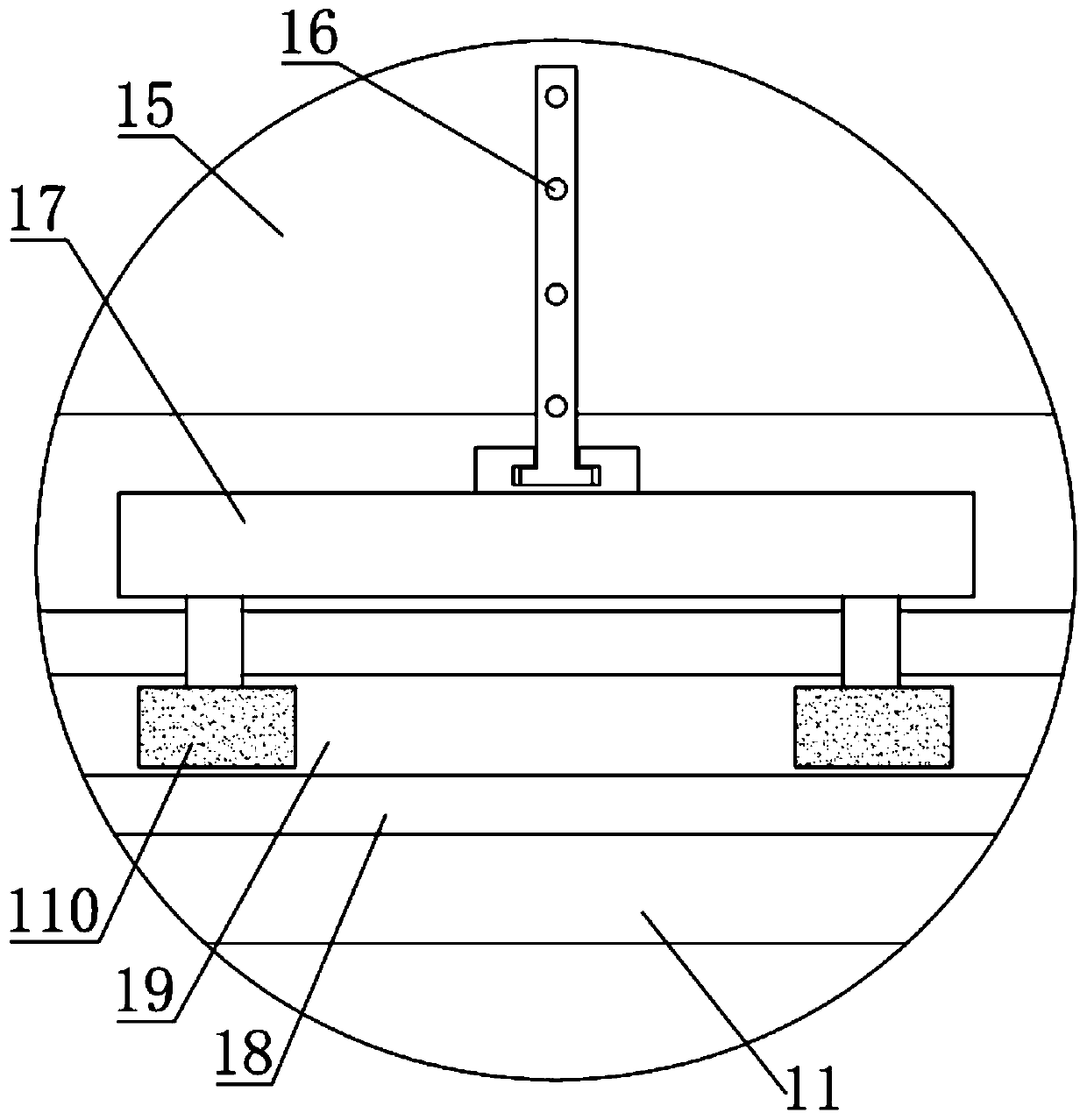

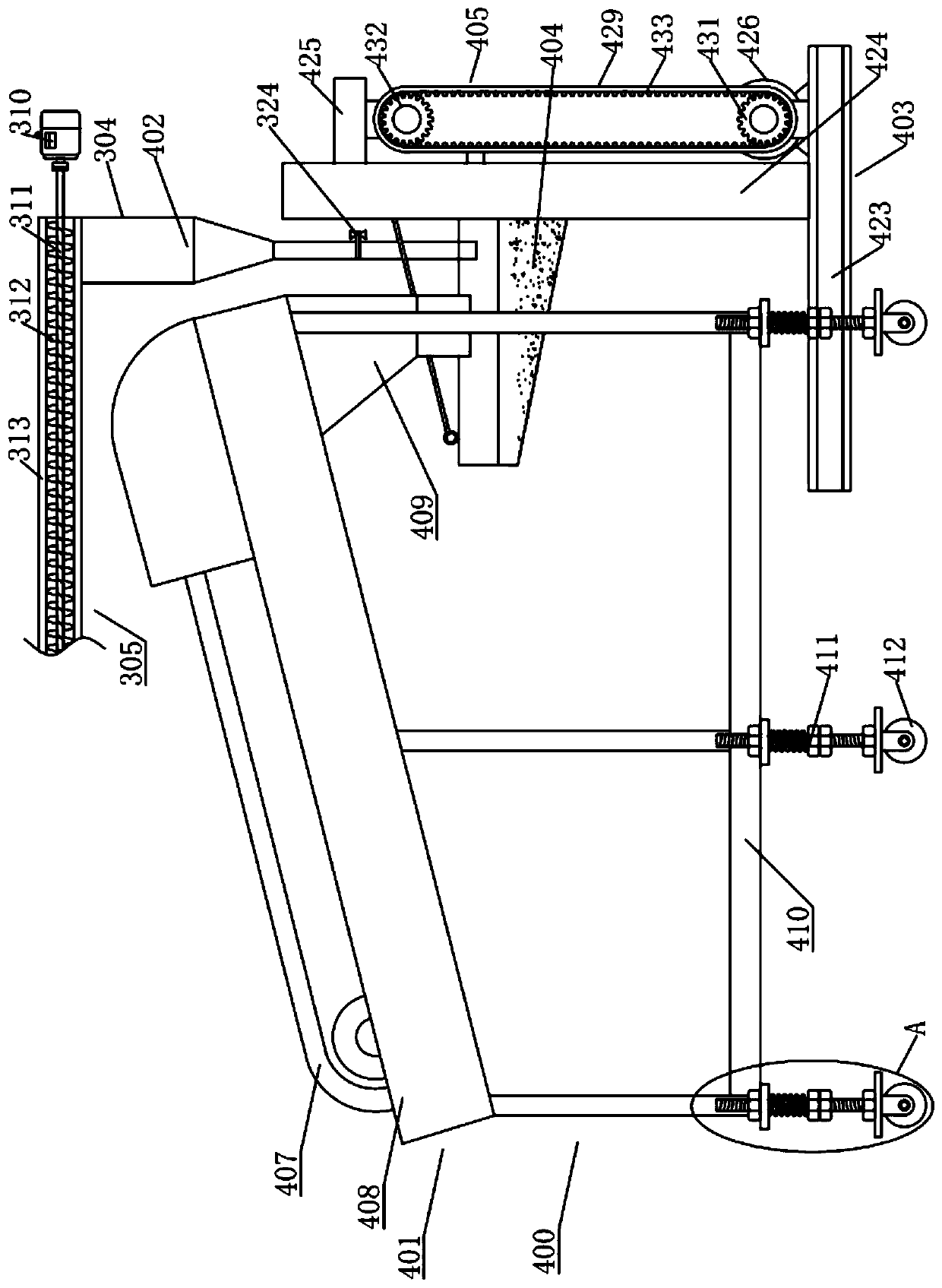

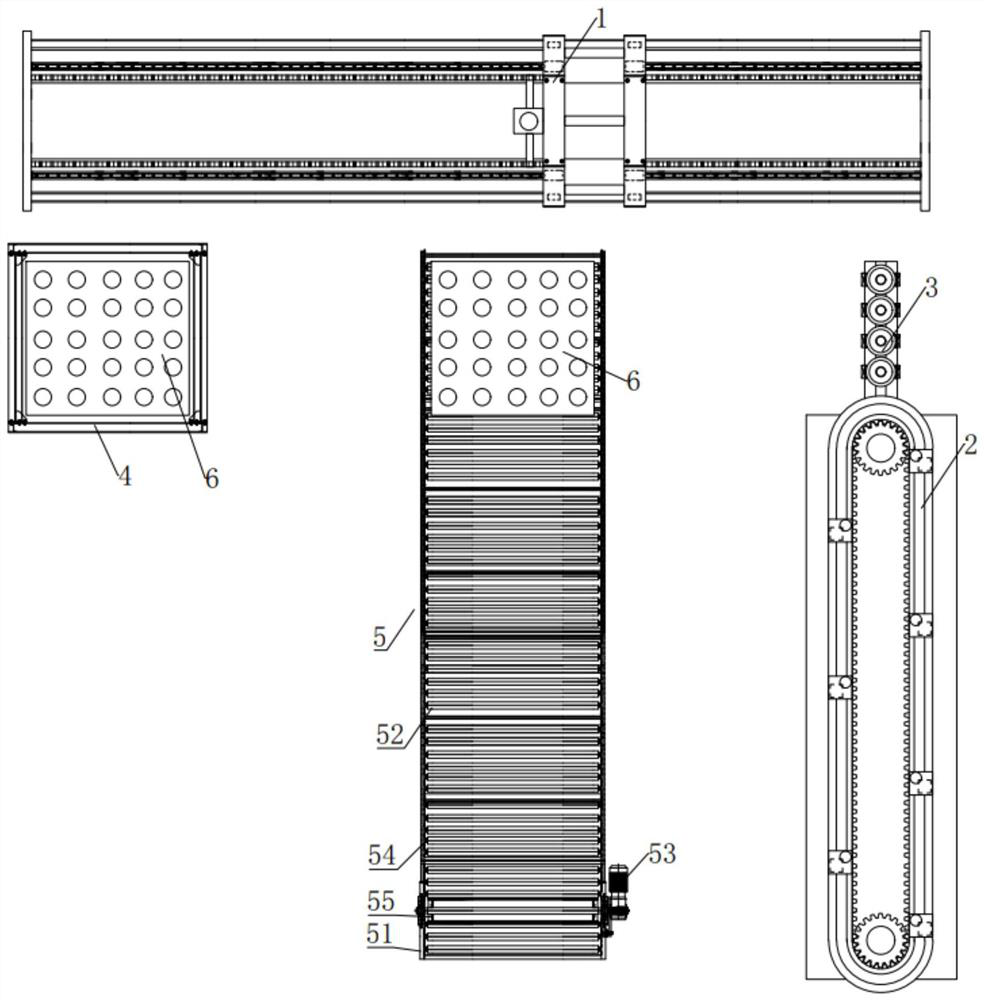

Laser pipe cutting machine feeding device suitable for various pipes and working method of laser pipe cutting machine feeding device

PendingCN112658510AGuaranteed coincidencePrevent rollingConveyorsWelding/cutting auxillary devicesIndustrial engineeringSupport plane

The invention discloses a laser pipe cutting machine feeding device suitable for various pipes and a working method. The laser pipe cutting machine feeding device comprises a pipe feeding support frame, a pipe conveying unit, a group of pipe lifting units and a pipe feeding unit, wherein the pipe lifting units are located on one side, close to a laser pipe cutting machine, of the pipe feeding support frame, the pipe conveying unit can convey pipes to the position of the pipe lifting units, and the pipe lifting units can transfer the pipes on the pipe conveying unit to the pipe feeding unit. The feeding device of the structure can feed various pipes, and the laser pipe cutting machine provided with the feeding device of the structure is high in automation degree, high in working efficiency and flexible in application. The working method of the laser pipe cutting machine feeding device suitable for various pipes is simple and easy to implement, high in automation degree of the working process, small in needed manpower, improved in production efficiency and suitable for industrial large-scale application.

Owner:苏州松谷智能装备股份有限公司

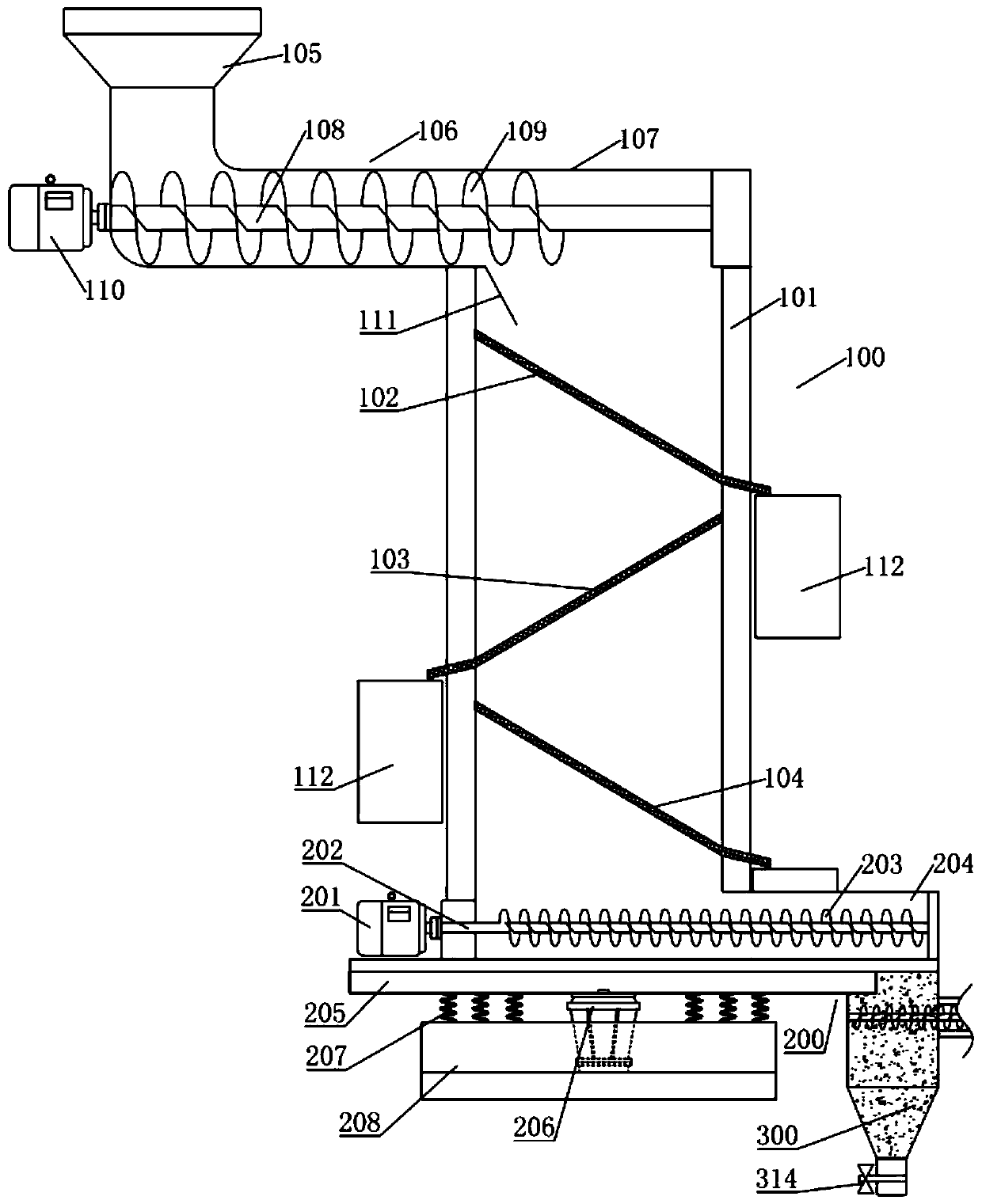

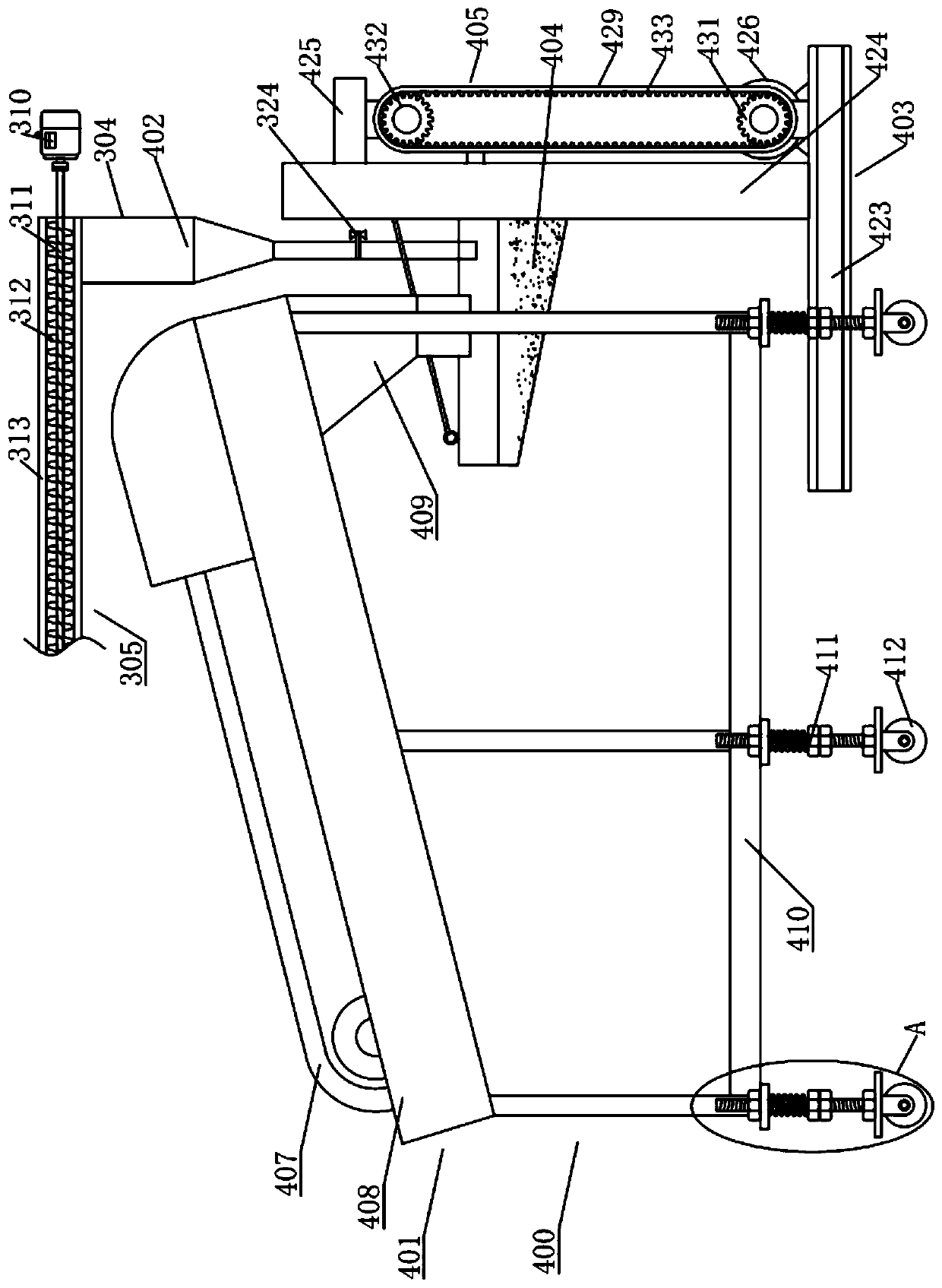

Device of throwing inoculant automatically and working method thereof

InactiveCN110358886AReasonable structural designEasy to produceSievingGas current separationBiochemical engineeringConveyor belt

The invention discloses a device of throwing an inoculant automatically and a working method thereof. The device of throwing the inoculant automatically comprises an inoculant screening assembly, an inoculant conveying assembly, an inoculant stirring assembly and an inoculant putting assembly, wherein the inoculant putting assembly comprises a large dosage putting conveyor belt, a small dosage putting assembly, a first supporting rack, a receiving hopper, a receiving hopper lifting driving assembly and a receiving hopper overturning driving assembly. The receiving hopper overturning driving assembly is arranged on the receiving hopper, and the emptying amount of the small dosage putting assembly is smaller than that of the large dosage putting conveyor belt. The device of throwing the inoculant automatically disclosed by the invention can add the inoculant by two ways flexibly according to the adding amount of the inoculant. When the inoculant is added in a large dosage, the work efficiency can be improved. In the later period or the working process of inoculant addition, the inoculant can be finely adjusted through the small dosage adding assembly.

Owner:徐州市金鑫科技有限公司

Multi-angle overturning automatic grinding equipment for ship steering wheel

InactiveCN111531431AReasonable structural designEasy to produceEdge grinding machinesRevolution surface grinding machinesGrindingAutonomation

Multi-angle overturning automatic grinding equipment for a ship steering wheel comprises a steering wheel feeding conveying belt, a steering wheel feeding assembly, a rotation workbench, a steering wheel discharging conveying belt, a steering wheel discharging assembly, a steering wheel grinding rotation table, a steering wheel inner ring grinding assembly, a machine table and a steering wheel outer ring grinding assembly. The multi-angle overturning automatic grinding equipment for the ship steering wheel is reasonable in structure design and easy to produce. The automatic grinding equipmentis high in automation degree, high in work efficiency and flexible in application. A work method of the automatic grinding equipment is simple and feasible in work principle, the automation degree inthe work process is high, needed manpower is little, the production efficiency is improved, and the multi-angle overturning automatic grinding equipment is suitable for industrial large-scale application.

Owner:徐州尚航船舶配件有限公司

Electrostatic spraying device for cabinet cold-rolled steel plate and working method thereof

InactiveCN112742616ASimple working principleHigh degree of automationLiquid spraying plantsPretreated surfacesSteel platesEngineering

The invention discloses an electrostatic spraying device for a cabinet cold-rolled steel plate and a working method. The electrostatic spraying device comprises a steel plate conveying unit, a steel plate cleaning unit, a four-station automatic spraying unit, an automatic reciprocating spraying unit, a first manual checking and supplementary spraying unit, a second double-station manual supplementary spraying unit, a heat preservation oven unit and a dust removal unit. According to the electrostatic spraying device for the cabinet cold-rolled steel plate, through continuous spraying, an electrostatic field is formed between a spraying gun and a workpiece, an air ionization area is formed by the electric field force borne by coating particles and the electrostatic field, corona discharge is generated, and the coating particles move towards the surface of the workpiece with the polarity and are deposited on the surface of the workpiece to form a uniform coating film. According to the working method of the electrostatic spraying device for the cabinet cold-rolled steel plate, the working principle is simple and easy to implement, the automation degree in the working process is high, less manpower is required, the production efficiency is improved, and the working method is suitable for industrial large-scale application.

Owner:太仓欢鑫金属制品有限公司

Hot-pressing shaping machine for paper-pulp molding and working method thereof

InactiveCN109594428ASimple working principleHigh degree of automationTextiles and paperShell moldingComputer module

The invention discloses a hot-pressing shaping machine for paper-pulp molding and belongs to the field of key technologies of cleaning production. The hot-pressing shaping machine comprises a hot-pressing shaping machine platform, a lower mold seat, a hot-pressing component, a transferring manipulator and a forming machine for paper-pulp molding, wherein the hot-pressing component comprises a first sliding block, a third cylinder and an adsorbing plate; the hot-pressing shaping machine platform is internally provided with an electric heating module which is positioned under the lower mold seat; the first sliding block is arranged on a sliding rail of the forming machine for paper-pulp molding; the third cylinder is connected with the first sliding block; the adsorbing plate is arranged atthe extending end of the third cylinder and is internally provided with an electric heating module and a second electromagnet; and the adsorbing plate is opposite to the lower mold seat in the upsideand downside. The hot-pressing shaping machine disclosed by the invention has the beneficial effects of reasonable structure design, high working efficiency and flexibility in application. A working method of the hot-pressing shaping machine for paper-pulp molding has the beneficial effects of high automation degree in the working process, increased production efficiency and suitability for industrial large-scale application.

Owner:徐州利华环保科技有限公司

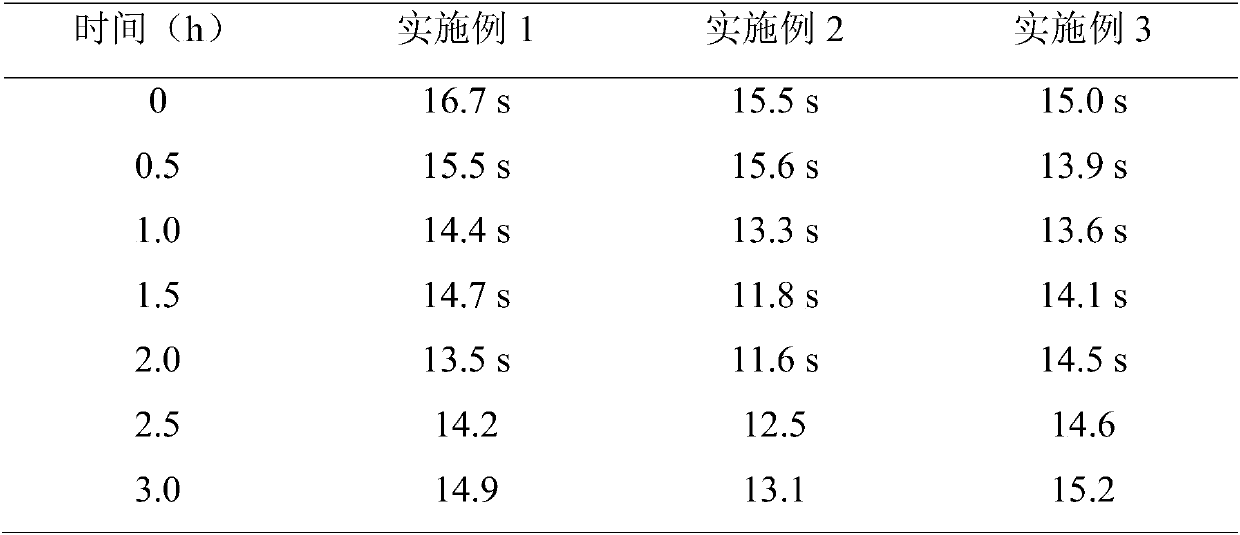

Seed sludge preparing method and sludge processing method

PendingCN109626600APromote enrichmentGood acid resistanceWater treatment parameter controlSludge treatment by de-watering/drying/thickeningWater contentBiology

The invention provides a seed sludge preparing method. Seed sludge is obtained by directly conducting aeration treatment on sludge with rich acidophilic florae on the surface, and the relative abundance of the acidophilic florae on the surface of the seed sludge is 25-35%. The invention further provides a method for processing and dewatering sludge through the seed sludge. The processed sludge hasthe water content lower than 65%. The seed sludge has the good acid resistance and high active recovery rate. When the seed sludge is inoculated to a new sludge environment, the reaction can rapidlyhappen, extra-cellular polymeric substances (EPS) in the sludge system and polysaccharides in cell walls are rapidly consumed, the content and viscosity of sludge organic matter are reduced, the better sludge dewatering effect is achieved, and the sludge settling performance is improved.

Owner:光大水务(深圳)有限公司 +2

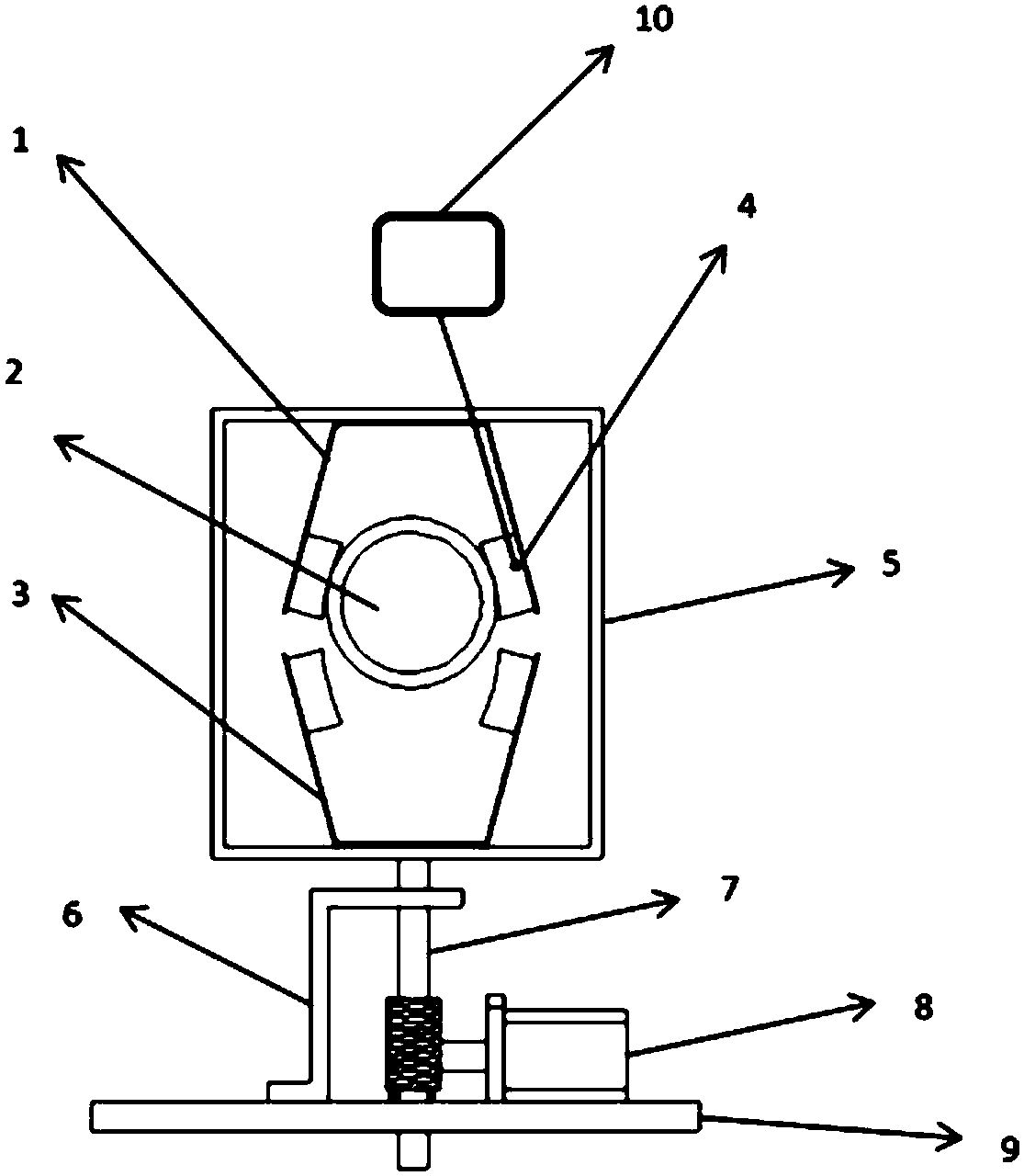

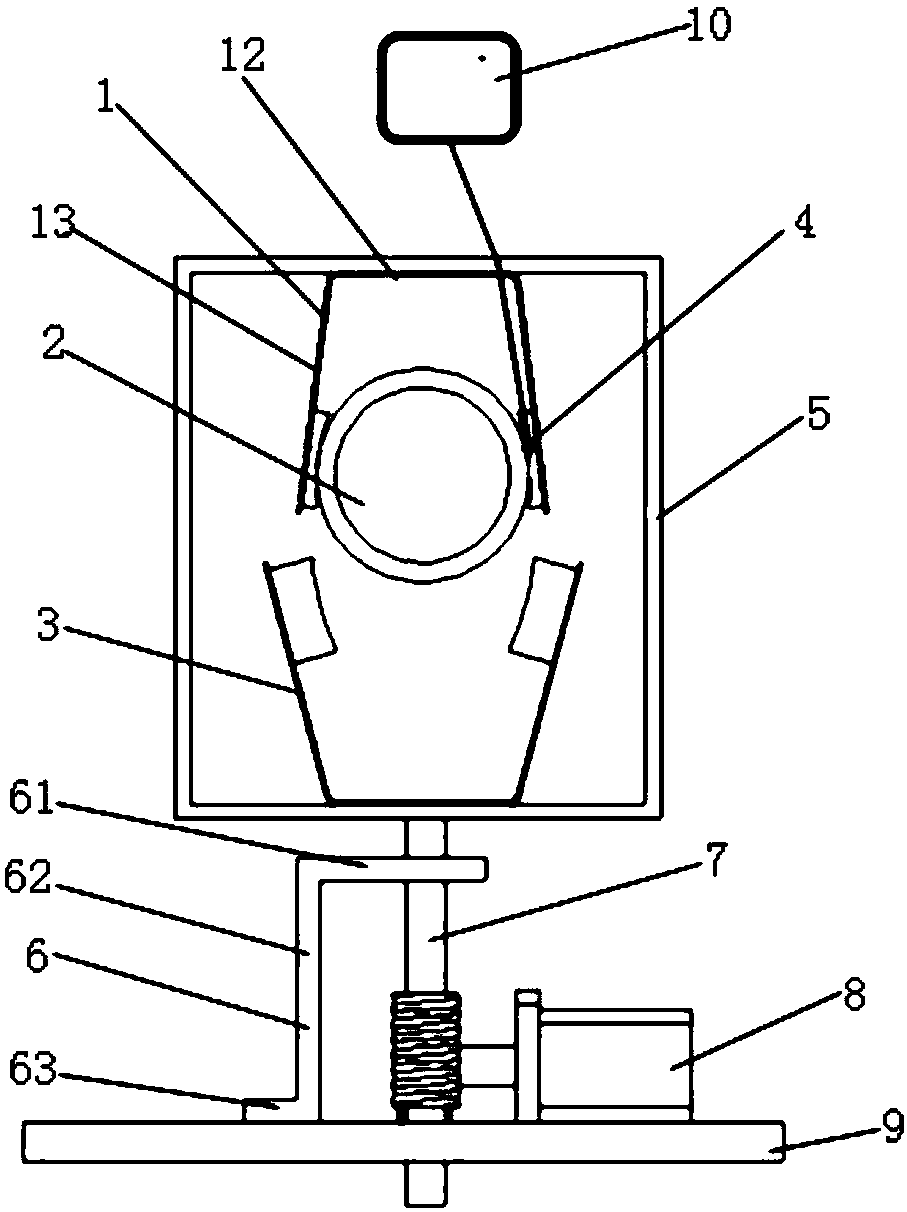

Conductive sliding ring brush holder system capable of automatic switching and working method thereof

The invention discloses a conductive sliding ring brush holder system capable of automatic switching, comprising an electric brush, a conductive ring, a backup electric brush, a wear thimble, a movable frame, a screw rod fixing frame, a screw rod, a motor, a support plate, an upper computer and a gear. The electric brush is connected with the backup electric brush. The wear thimble is disposed atend portions, away from the conductive ring, of the electric brush and the backup electric brush. The electric brush is connected with the upper end surface of the movable frame. The backup electric brush is connected with the lower end surface of the movable frame. The lower end portion of the screw rod fixing frame is fixed on the support plate. The upper end surface of the screw rod is fixed onthe outer wall of the movable frame, and the lower end portion of the screw rod passes through the screw rod fixing frame and the support plate in sequence. The gear meshes with the screw rod. The motor is connected with the gear. The upper computer is connected with the wear thimble through a signal line. The working method of the conductive sliding ring brush holder system capable of automaticswitching according to the invention is simple and easy, the conductive sliding ring does not need to be removed for maintenance, the time is greatly saved, and the work efficiency is improved.

Owner:浙江恩碧技创新科技有限公司

Preparation method of high-purity optical coating material silicon dioxide

InactiveCN112791825AReasonable process structure designEasy to produceSilicaMagnetic separationMagnetic separatorMagnetic separation

The invention discloses a preparation method of a high-purity optical coating material silicon dioxide. The preparation method comprises the following steps of coarse crushing, conveying, fine crushing, conveying, first-stage magnetic separation, second-stage magnetic separation, conveying belt conveying, transferring, conveying, cleaning, third-stage magnetic separation, conveying and drying. According to the preparation method of the high-purity optical coating material silicon dioxide, a quartz raw material is fed into a high-precision intelligent magnetic separator after being subjected to first-stage crushing and second-stage fine crushing, the quartz raw material passes through the magnetic separator for three times, metal-containing particles in waste quartz particles are adsorbed and discharged through a strong magnetic field in the magnetic separator, high-purity water is used for cleaning, floating objects are removed, after cleaning, the quartz particles are fed into a drying box, and high-purity silicon dioxide can be obtained through reasonable procedure setting. The production process is high in automation degree, high in working efficiency and flexible in application; and the working method and the working principle of the production process are simple and easy to implement, less manpower is needed, the production efficiency is improved, and the production process is suitable for industrial large-scale application.

Owner:江苏微纳光膜科技有限公司

Transfer manipulator for material handling and working method of transfer manipulator

InactiveCN109625926ASimple working principleHigh degree of automation of work processConveyor partsAdvanced manufacturingManipulator

The invention discloses a transfer manipulator for material handling, and belonging to the field of advanced manufacturing and automation. The transfer manipulator for material handling comprises a first material supporting assembly, a first material handling manipulator assembly, a second material handling manipulator assembly and materials. The first material handling manipulator assembly and the second material handling manipulator assembly are symmetrically arranged on both sides of the first material supporting assembly. The first material handling manipulator assembly and the second material handling manipulator assembly comprise bases, supporting platforms, first lifting drive assemblies, first supporting frames, first linear modules, first supporting plates, first material transferassemblies, first material transfer manipulators and first material handling manipulators. According to the transfer manipulator for material handling, the structure is simple and reasonable, production is easy, the degree of automation is high, manual labor is reduced, the working efficiency is improved, the material storage is large, and application is flexible. The working method is simple andeasy to operate, the degree of automation of the working process is high, the manpower required is less, the production efficiency is improved, and the working method is suitable for large-scale industrial application.

Owner:徐州欧普莱斯工业机械有限公司

Spindle stacking gantry automatic production line and working method thereof

PendingCN113772430AReasonable structural designEasy to produceConveyorsStacking articlesManufacturing engineeringAutonomation

The invention discloses a spindle stacking gantry automatic production line and a working method. The spindle stacking gantry automatic production line comprises a gantry grabbing unit, a spindle feeding and conveying unit, a spindle stacking and arranging unit, a partition plate stock bin and a spindle stacking and discharging unit, and spindles grabbed by the spindle feeding and conveying unit are transferred to the spindle stacking and arranging unit; and the spindles are arranged in a row on the spindle stacking and arranging unit, a set of partition plates are arranged in the partition plate stock bin from top to bottom, and the gantry grabbing unit can transfer the partition plates in the partition plate stock bin to the spindle stacking and discharging unit. The gantry grabbing unit can grab the spindles on the spindle stacking and arranging unit to a station of the spindle stacking and discharging unit. According to the spindle stacking gantry automatic production line, the structural design is reasonable, production is easy, multi-station linkage is adopted, the consistency of working actions is guaranteed, interference and collision existing in multi-machine operation are avoided, the safe waiting time of multi-machine work is omitted due to continuous actions, the working efficiency is high, and application is flexible.

Owner:常州市立达塑胶电器制造有限公司

Continuous pulp shaping machine and working method thereof

InactiveCN109629344ASimple working principleHigh degree of automationTextiles and paperShell moldingElectric machinery

The invention discloses a continuous pulp shaping machine, and belongs to the key technical field of cleaning production. The continuous pulp shaping machine comprises a hot pressing shaping machine table, a lower mold base, a hot pressing assembly, a transfer manipulator and a pulp molding forming machine; the hot pressing assembly comprises a first sliding block, a third air cylinder and an adsorption plate, the pulp molding forming machine comprises a pulp pool, a first driving motor, a rotating track, a set of upper pulp suction molds, a set of upper pulp suction mold driving assemblies, aset of lower pulp suction molds, a set of lower pulp suction mold driving assemblies, a forming mold, a forming mold driving assembly, a gantry, an extrusion forming table, an upper pulp suction moldfeeding assembly and a lower pulp suction mold feeding assembly. The continuous pulp shaping machine is reasonable in structural design, high in working efficiency and flexible to apply. A working method of the continuous pulp shaping machine has the advantages that the degree of automation in the working process is high, the production efficiency is improved, and the working method is suitable for industrial large-scale application.

Owner:徐州利华环保科技有限公司

Bearing race production line with bearing outer ring machining device and working method thereof

PendingCN108331843AReasonable structural designHigh degree of automationRevolution surface grinding machinesShaftsProduction lineEngineering

The invention discloses a bearing race production line with a bearing outer ring machining device. The bearing race production line with the bearing outer ring machining device comprises a feeding unit, a heating unit, a forging unit, a sorting unit, a shot blasting unit, a grinding and expanding unit, a shaping unit, a washing unit and a discharging unit in sequence, wherein the shaping unit comprises a bearing inner ring machining device and the bearing outer ring machining device; and the bearing outer ring machining device comprises a machine table, a feeding manipulator, a bearing outer ring transferring assembly, a first screw rod, a bearing outer ring shaping assembly, a bearing outer ring polishing assembly and a bearing outer ring clamping assembly. The bearing race production line with the bearing outer ring machining device transfers bearing outer rings to the bearing outer ring shaping assembly for outer wall shaping of the bearing outer rings through cooperative work of the feeding manipulator and the bearing outer ring transferring assembly, outer walls of the bearing outer rings are clamped and fixed through the bearing outer ring clamping assembly, the inner walls of the bearing outer rings are polished through the bearing outer ring polishing assembly, and the degree of automation is high.

Owner:江苏保捷精锻有限公司

Automatic high-efficiency L-type packaging machine

InactiveCN110481883AAvoid affecting work orderHigh degree of automationWrappers shrinkageWrapping material feeding apparatusIn degreeAdvanced manufacturing

The invention provides an automatic high-efficiency L-type packaging machine, and belongs to the technical field of advanced manufacture and automation. The packaging machine comprises a set film assembly device, an automatic defective material recycling device, upper and lower cutter devices and an automatic conveyor device; the set film assembly device, the automatic conveyor device, the upper and lower cutter devices and the automatic defective material recycling device are arranged according to the production procedures in sequence. According to the packaging machine, films can be conveyedthrough the arranged set film assembly device stably and continuously, so that subsequent products are packaged; residual film defective materials cut off by sealing cutters can be recycled through the arranged defective material recycling device; films can be cut into the required size according to the settings through arranged upper and lower sealing cutters, so that the products are packaged completely; the products can be conveyed to the sealing cutters through arrangement of front and rear conveyor belts stably, and the overall working principle of the machine is simple and practicable;the working process is high in degree of automation, and the required labors are less; and the production efficiency is improved, and the packaging machine is suitable industrial large-scale application.

Owner:江苏群昌智能科技有限公司

Double-station feeding double-point automatic welding system and working method thereof

PendingCN114406530ASimple working principleHigh degree of automationWelding/cutting auxillary devicesAuxillary welding devicesPipe fittingIndustrial engineering

The invention discloses a double-station feeding double-point automatic welding system and a working method.The double-station feeding double-point automatic welding system comprises a double-station pipe fitting feeding unit, a rod piece feeding unit, a welding unit, a rod piece welding and pushing unit, a pipe fitting pushing unit, a welding supporting unit and a rod piece clamping unit; a rod piece is arranged on the rod piece feeding unit, the rod piece clamping unit can clamp the rod piece on the rod piece feeding unit, the welding unit can weld the rod piece and a pipe piece on the welding supporting unit, and the rod piece welding pushing unit can push a welding piece on the welding supporting unit. The double-station feeding double-point automatic welding system is high in automation degree, stable in welding quality, short in welding time and reasonable in welding method; by reasonably arranging and positioning all units of the whole system, the welding precision is greatly improved, then the production efficiency is greatly improved, the labor cost is reduced, and the labor intensity of workers in the production process can also be reduced.

Owner:江田机器人系统工程江苏有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com