Device of throwing inoculant automatically and working method thereof

An inoculant, automatic technology, applied in the directions of chemical instruments and methods, packaging, transportation and packaging, can solve the problems of reducing the utilization rate of the inoculant, increasing the production cost, waste of the inoculant, etc. Work efficiency, improve the effect of precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

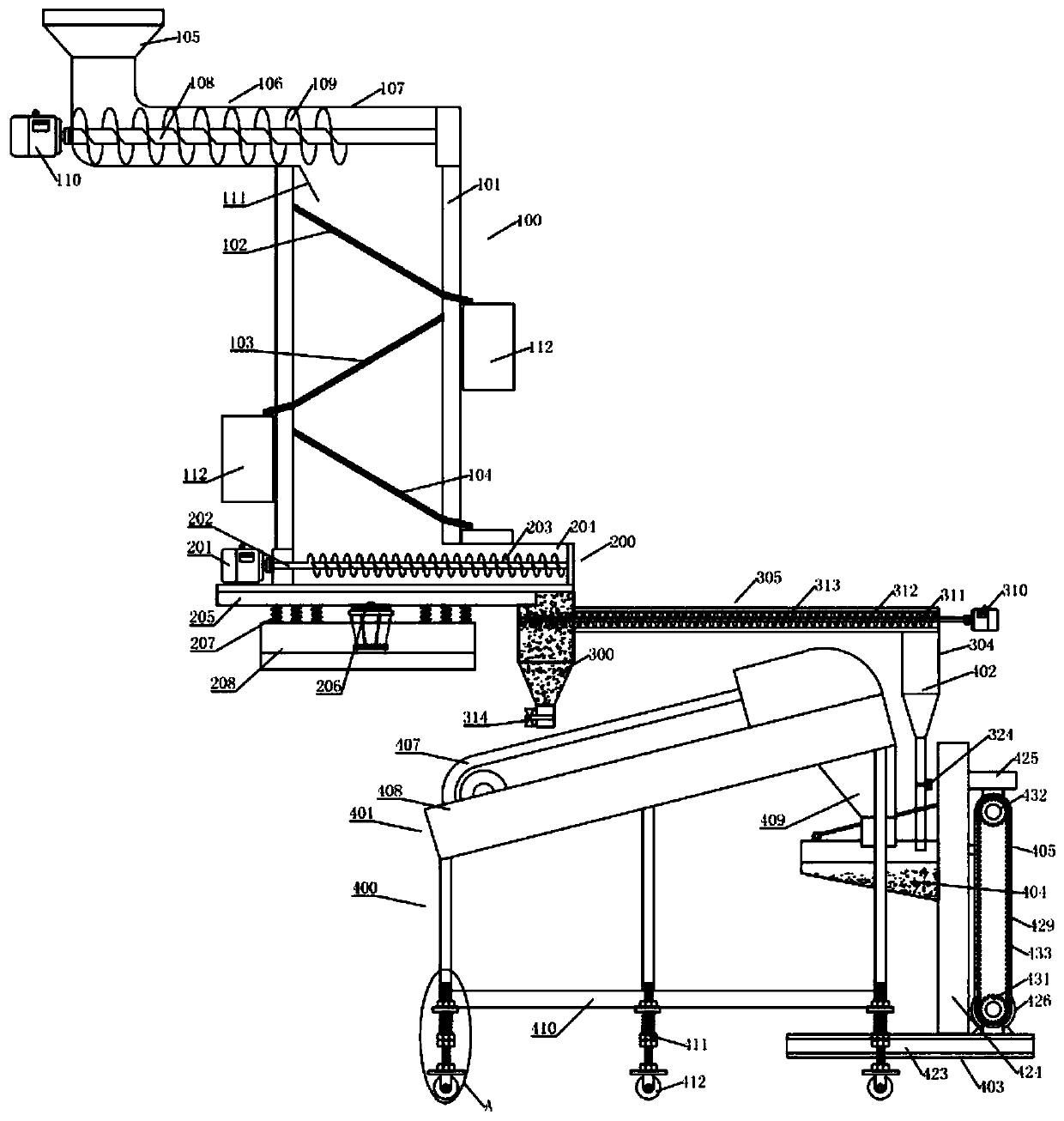

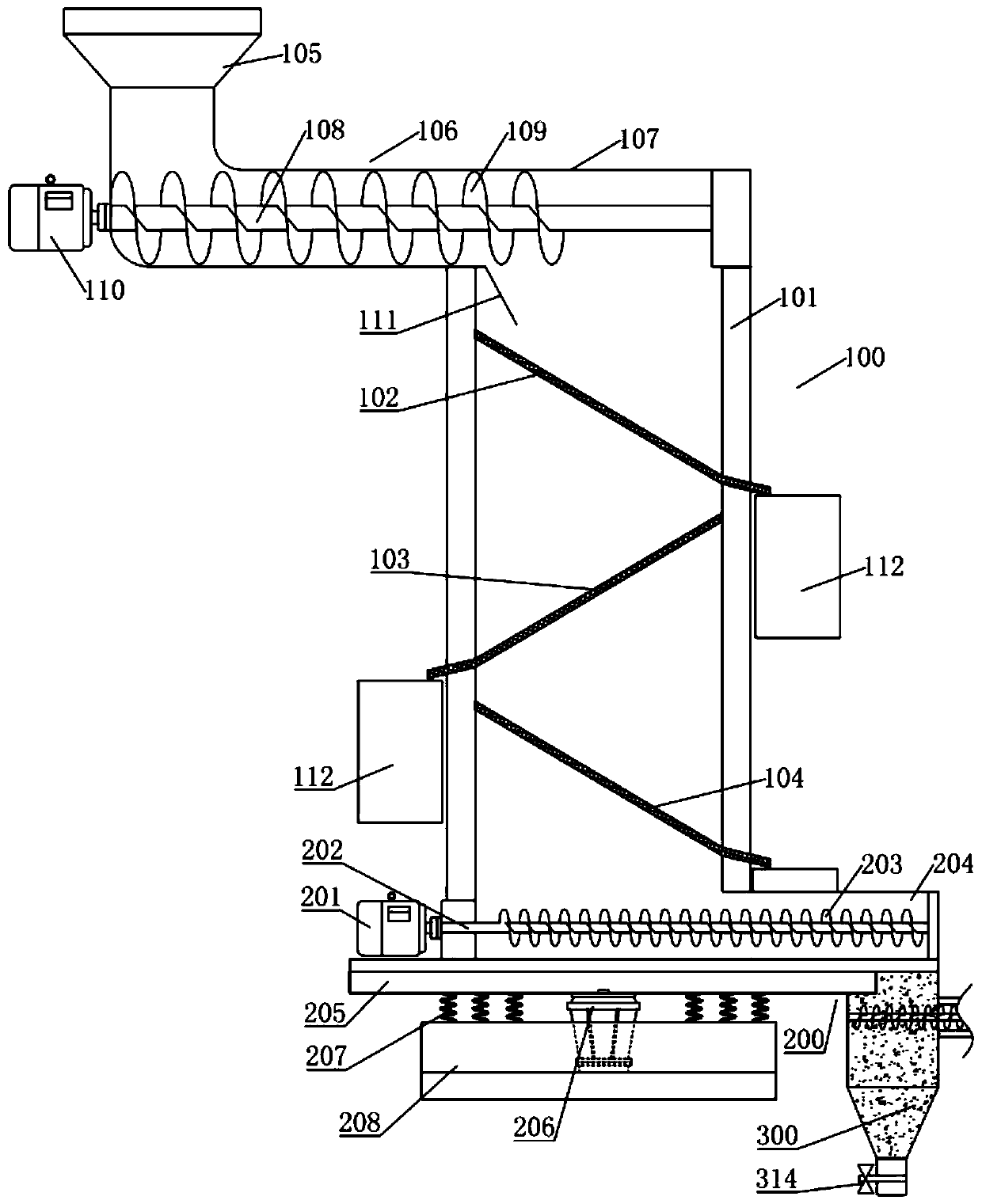

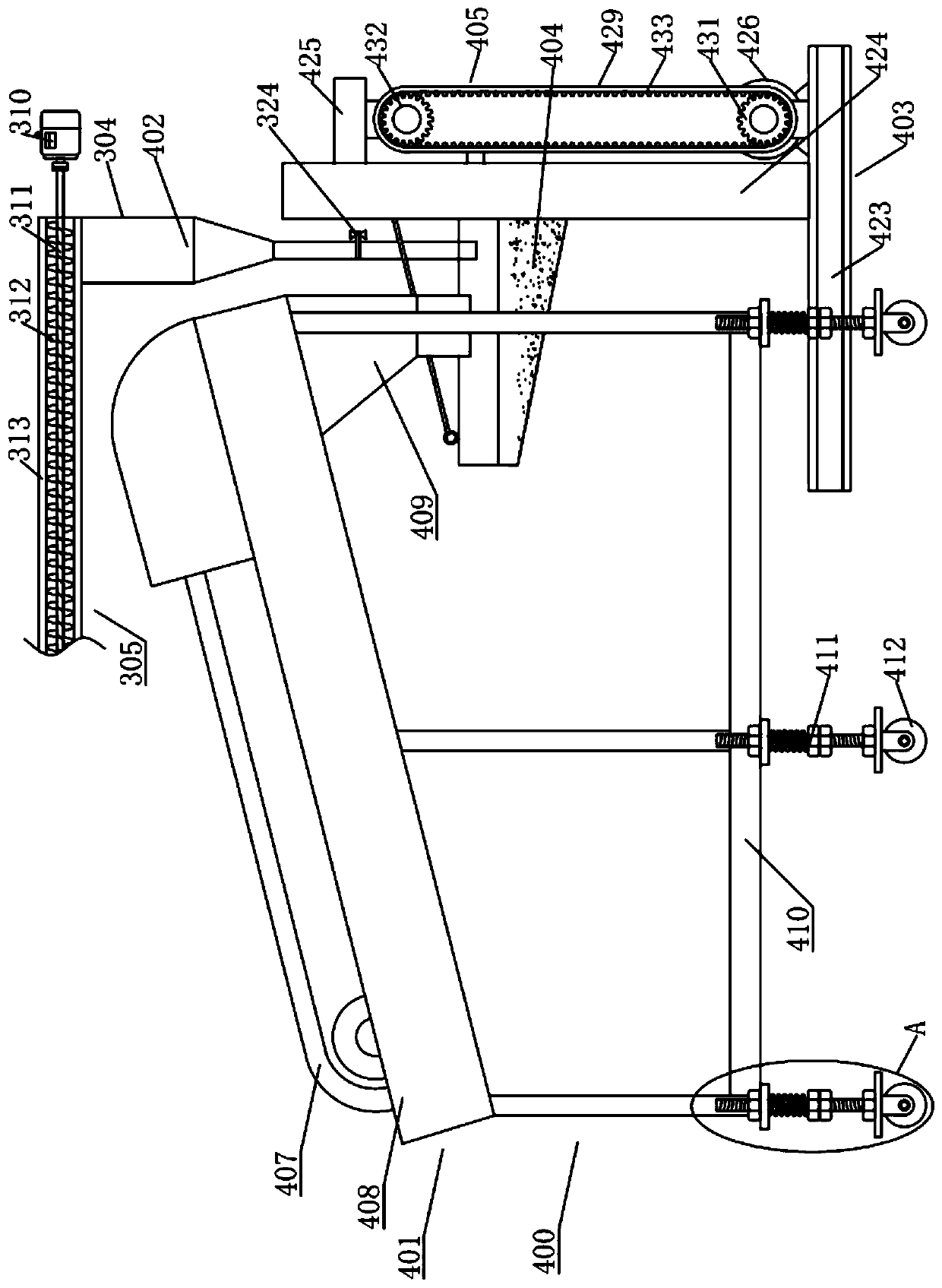

[0046] Such as figure 1 , 2 The device for automatically screening and transporting cast iron inoculants includes an inoculant screening assembly 100, an inoculant delivery assembly 200, an inoculant stirring assembly 300, and an inoculant feeding assembly 400. The inoculant screening assembly 100, inoculant delivery assembly The component 200, the inoculant stirring component 300 and the inoculant feeding component 400 are arranged in sequence according to the production process of the inoculant; wherein, the inoculant screening component 100 includes a screening housing 101, a first screen 102, a second screen 103, The third screen 104, the inoculant general inlet 105 and the material guide assembly 106, the first screen 102, the second screen 103 and the third screen 104 are arranged in the screening housing in order from top to bottom 101, and the first screen 102, the second screen 103 and the third screen 104 are arranged in a turn-back shape, the guide assembly 106 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com