Pipe feeding and discharging device suitable for pipes of different diameters and working method thereof

A technology for pipe and material determination, which is used in conveyor control devices, transportation and packaging, conveyors, etc., can solve the problems of inability to adjust pipes, single function of transportation pipe fittings, and single structure of feeding devices, and achieves a simple and easy working principle. , The effect of flexible application and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

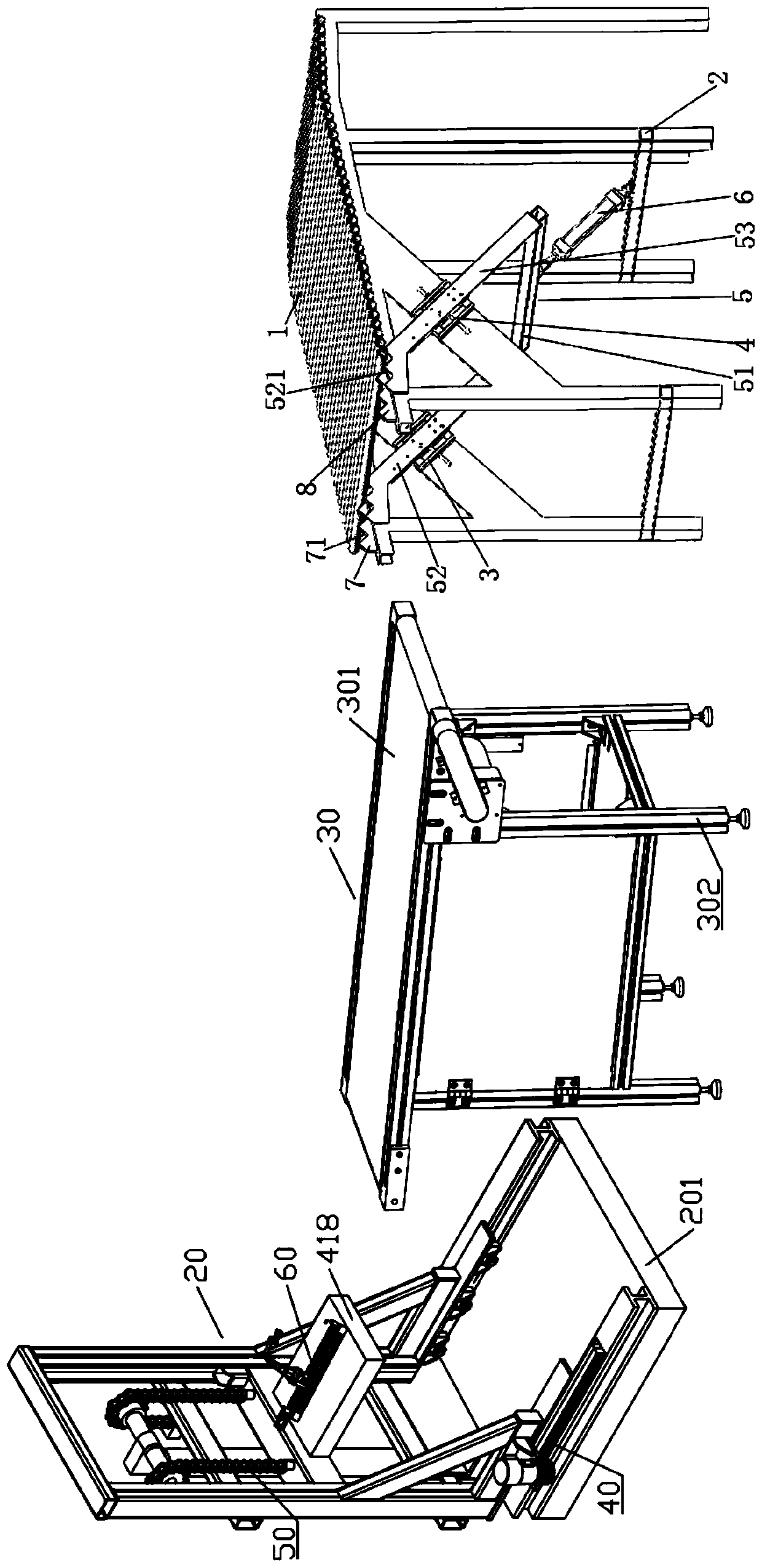

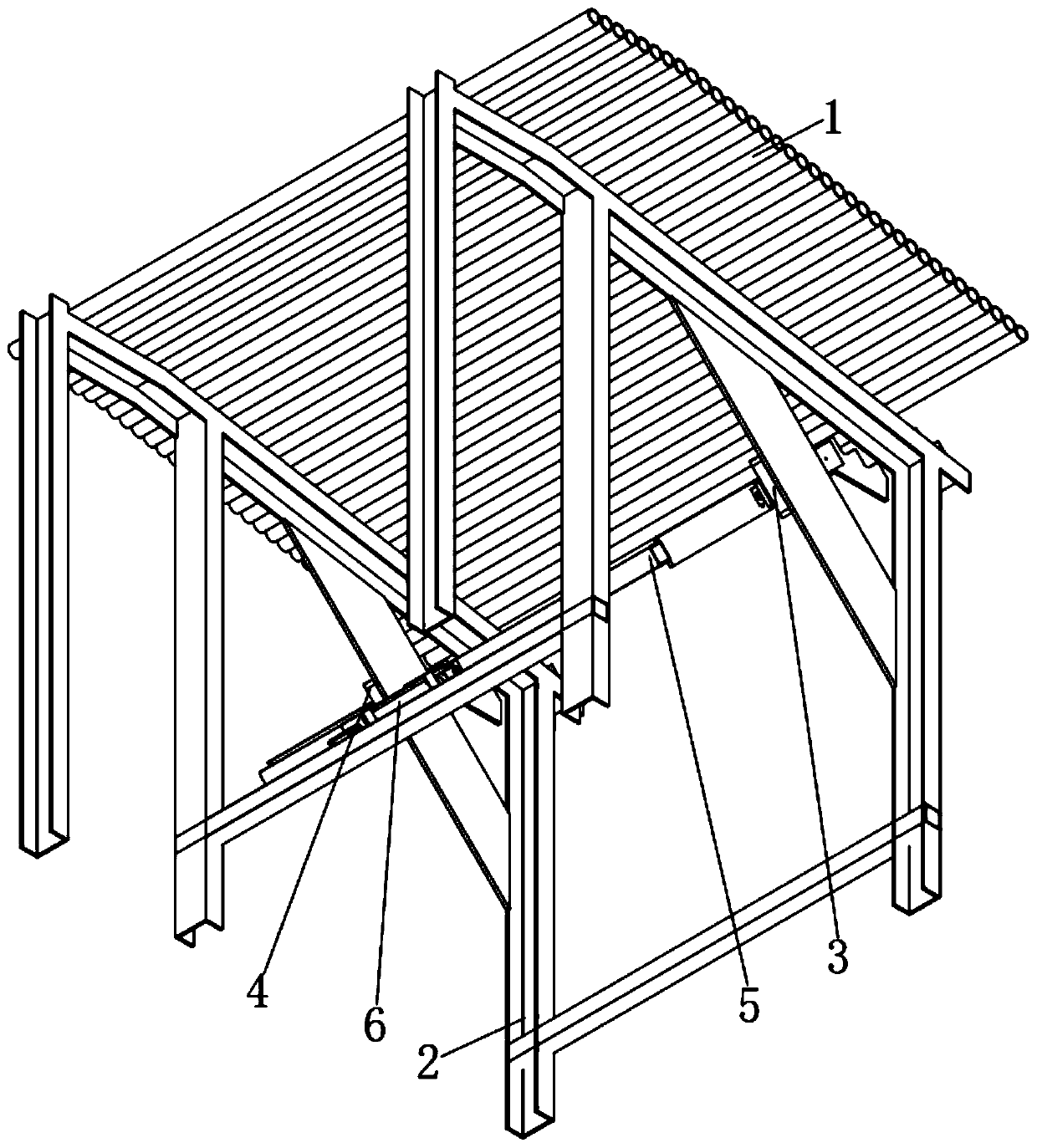

[0047] Such as figure 1 The shown pipe loading and unloading device suitable for pipes with different diameters includes a loading unit 10, a feeding unit 20, a pipe transfer unit 30 and a pipe 1, and the pipe transfer unit 30 is located between the loading unit 10 and the unloading unit. Between 20, the loading unit 10 can place the pipe 1 on one end of the pipe transfer unit 30, the pipe transfer unit 30 can transfer the pipe 1, and the unloading unit 20 can place the pipe 1 It is removed from the end of the pipe transfer unit 30 away from the loading unit 10 .

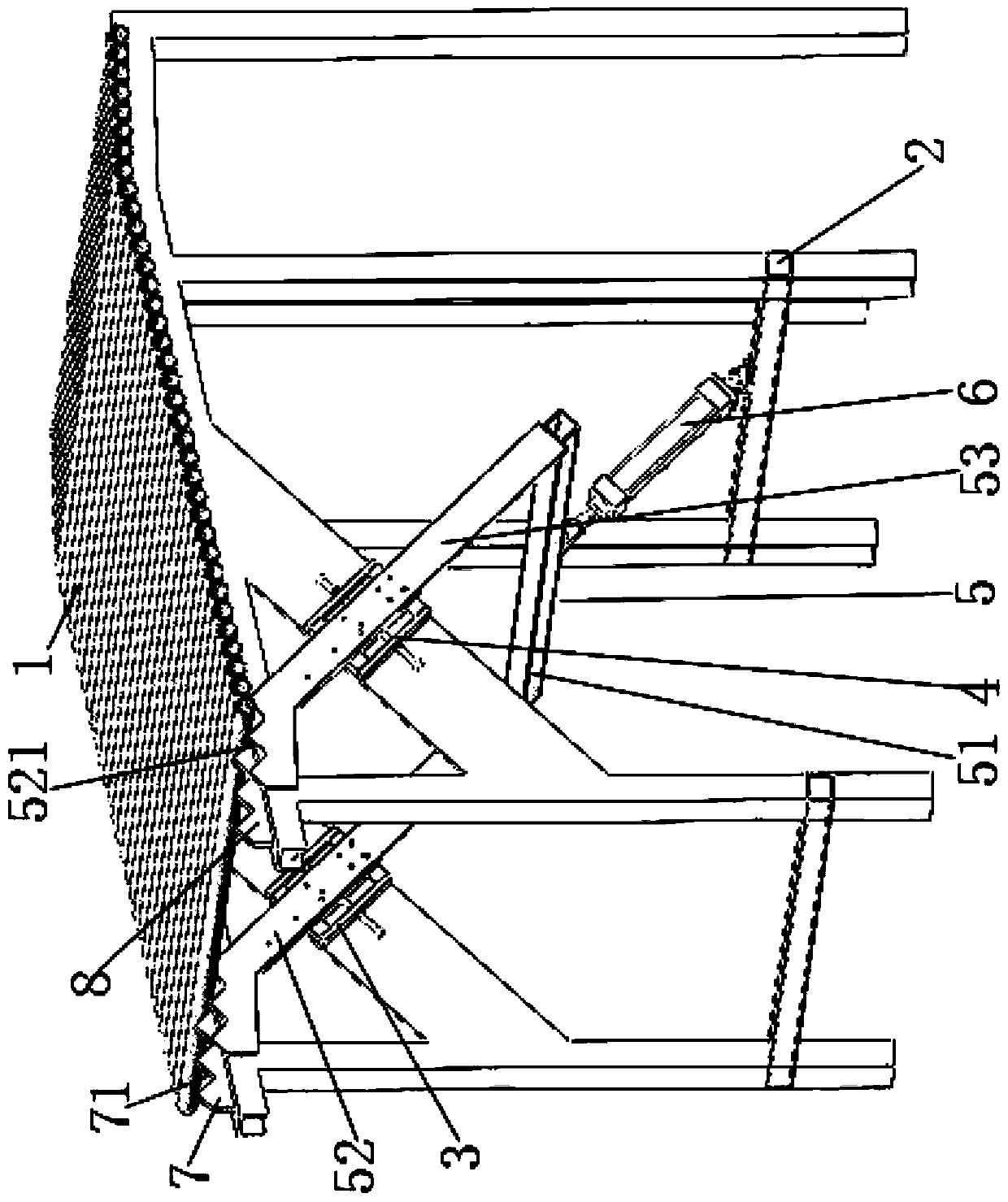

[0048] Among them, such as figure 2 , 3 The feeding unit 10 shown in and 6 includes a pipe material 1, a frame 2, a tilting adjustable device one 3, a tilting adjustable device two 4, a V-shaped feeding push rod assembly 5, a feeding driving device 6, a V-shaped wide fixed Material block one 7 and V-shaped wide fixed material block two 8, said V-shaped wide fixed material block one 7 and V-shaped wide fixed mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com