Bearing ring production line with efficient shot blasting device and working method thereof

A technology of shot blasting device and bearing ring, which is applied in the field of bearing manufacturing, can solve the problems of difficulty in guaranteeing the consistency of blank quality, high work intensity of workers, and low production efficiency, and achieve high shot blasting efficiency, high degree of automation, and improved production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

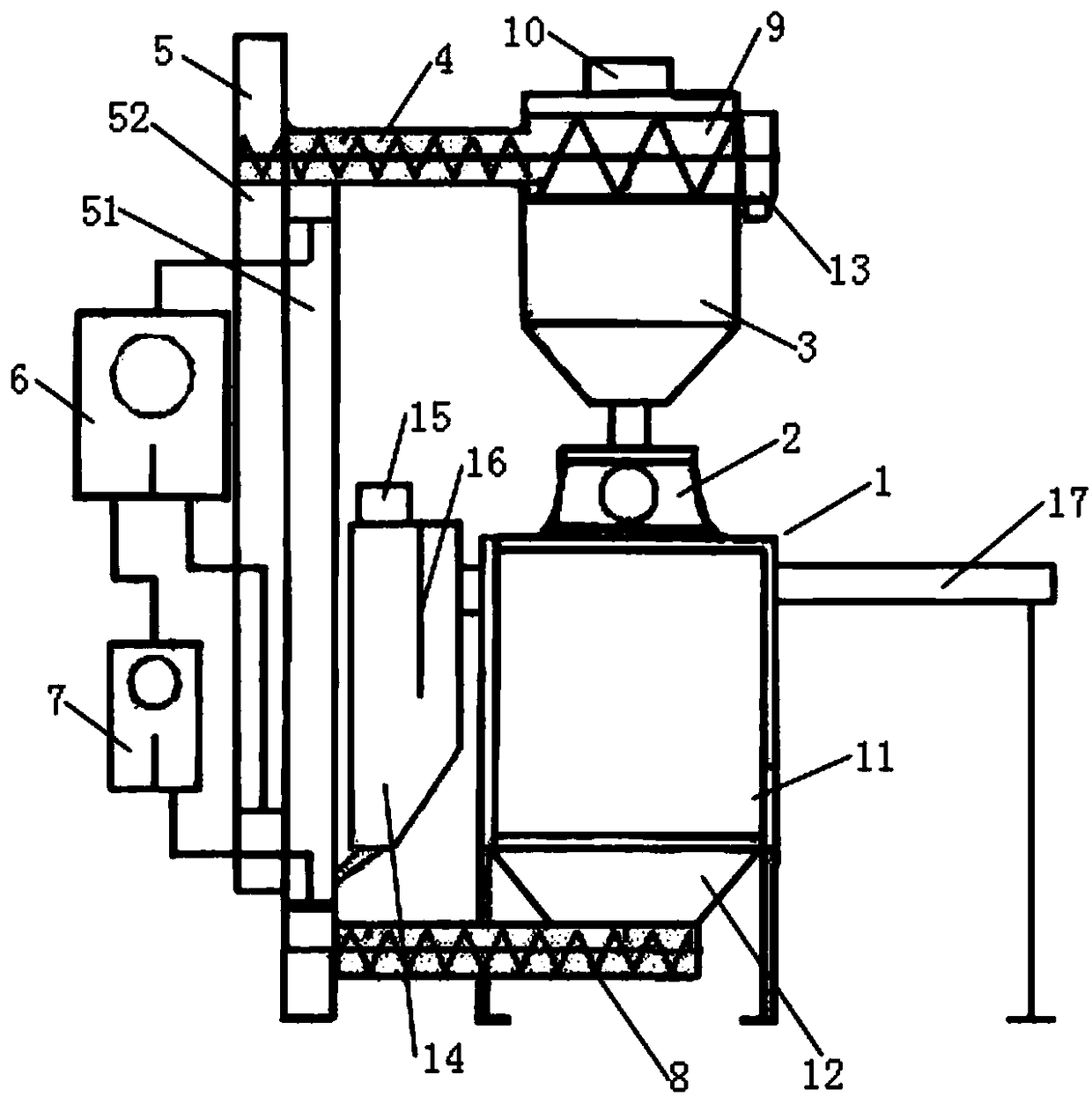

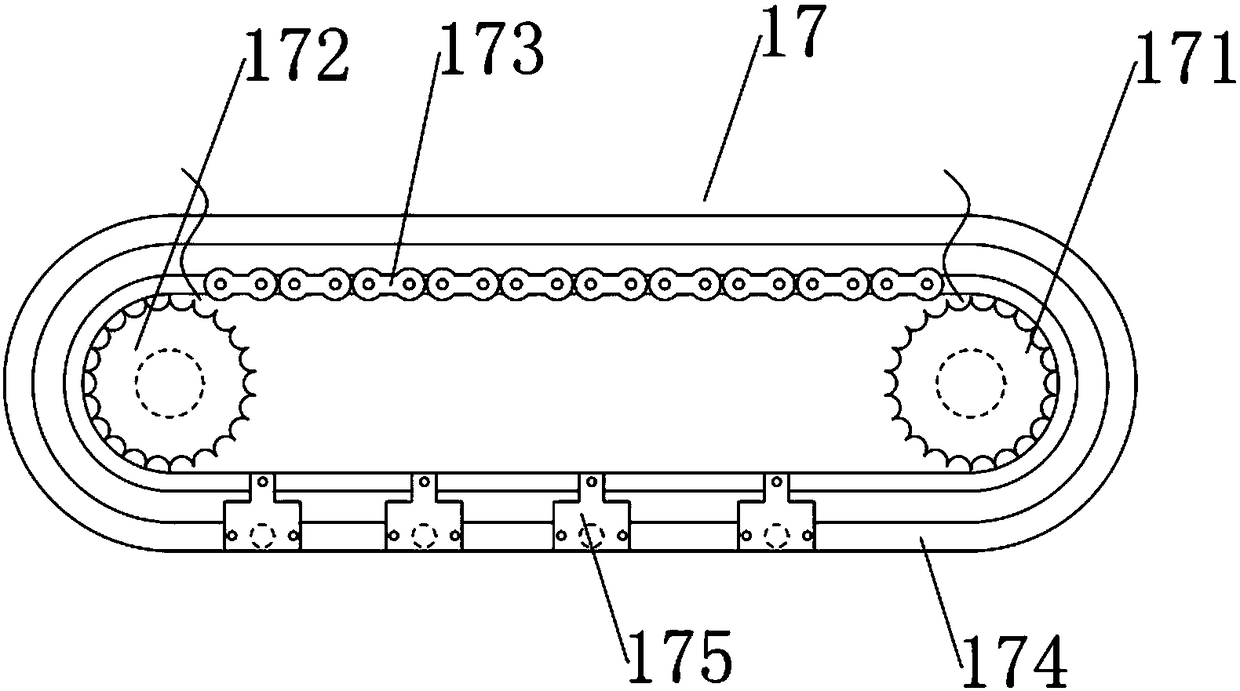

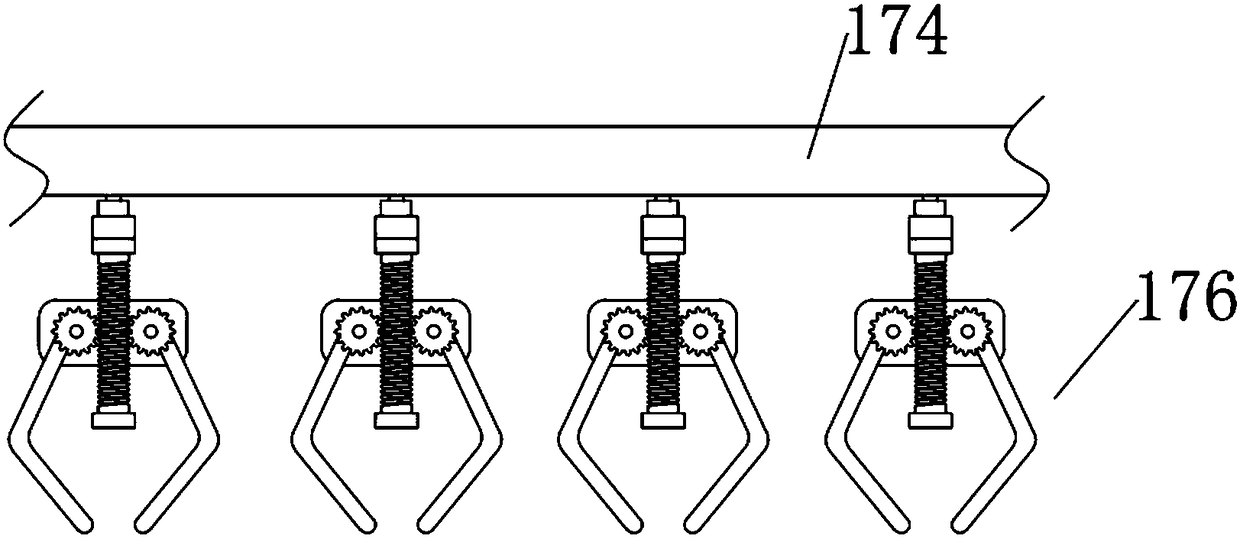

[0055] like figure 1 , 5 The bearing ring production line with high-efficiency shot blasting device shown in and 6 includes a feeding unit 10, a heating unit 20, a forging unit 30, a sorting unit 40, a shot blasting unit 50, a rolling unit 60, and a shaping unit 70 arranged in sequence , cleaning unit 80 and unloading unit 90; wherein, shot blasting unit 50 includes shot blasting chamber 1, shot blasting device 2, curtain-type winnowing box 3, first screw conveyor 4, compound bucket elevator 5, main magnetic Separator 6, secondary magnetic separation separator 7, second screw conveyor 8, drum screen 9, expansion chamber 14 and slide rail assembly 17, one end of which slide rail assembly 17 is located in the shot blasting chamber 1, and the shot blasting device 2 is located on the top of the shot blasting chamber 1, and the upper part of the shot blasting device 2 is connected with the curtain winnowing box 3. 9 connections, and stretch out the curtain type winnowing box 3 ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com