Double-station feeding double-point automatic welding system and working method thereof

An automatic welding, double-station technology, applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of unstable welding quality, unstable forming quality, and high work intensity of workers, and achieve the degree of automation High, simple working principle, less manpower effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

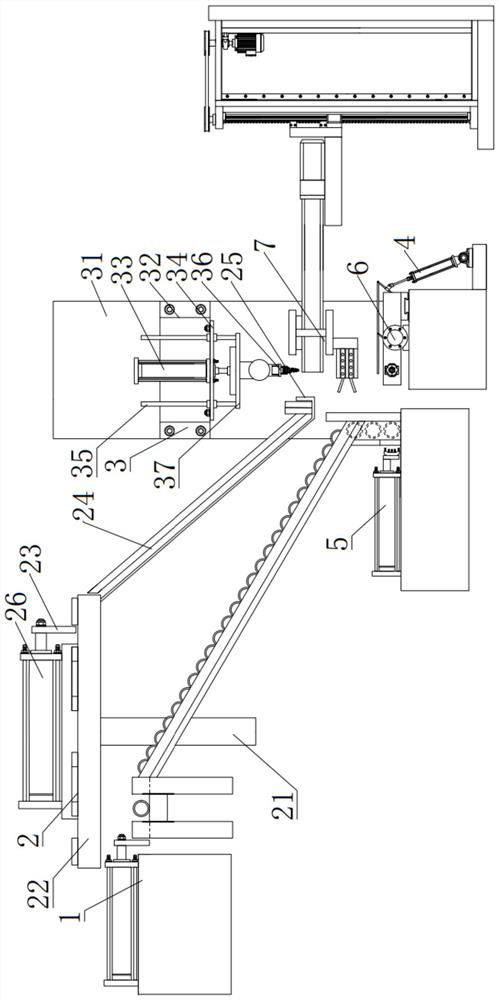

[0048] like figure 1 The shown dual-station automatic welding system for double-station feeding includes a double-station pipe fitting feeding unit 1, a rod feeding unit 2, a welding unit 3, a rod welding pushing unit 4, a pipe pushing unit 5, Welding support unit 6 and rod clamping unit 7, pipe fittings are provided on the double-station pipe feeding unit 1, rods are provided on the rod feeding unit 2, and the double-station pipe feeding unit The lower end of 1 is connected with the pipe pushing unit 5, the rod clamping unit 7 can clamp the rod on the rod feeding unit 2, and the welding unit 3 can carry out the rod and rod on the welding support unit 6. For the welding of pipe fittings, the rod welding pushing unit 4 can push the welding parts on the welding support unit 6. The pipe fittings are round pipes, and the cross-sectional shape of the rods is isosceles trapezoidal.

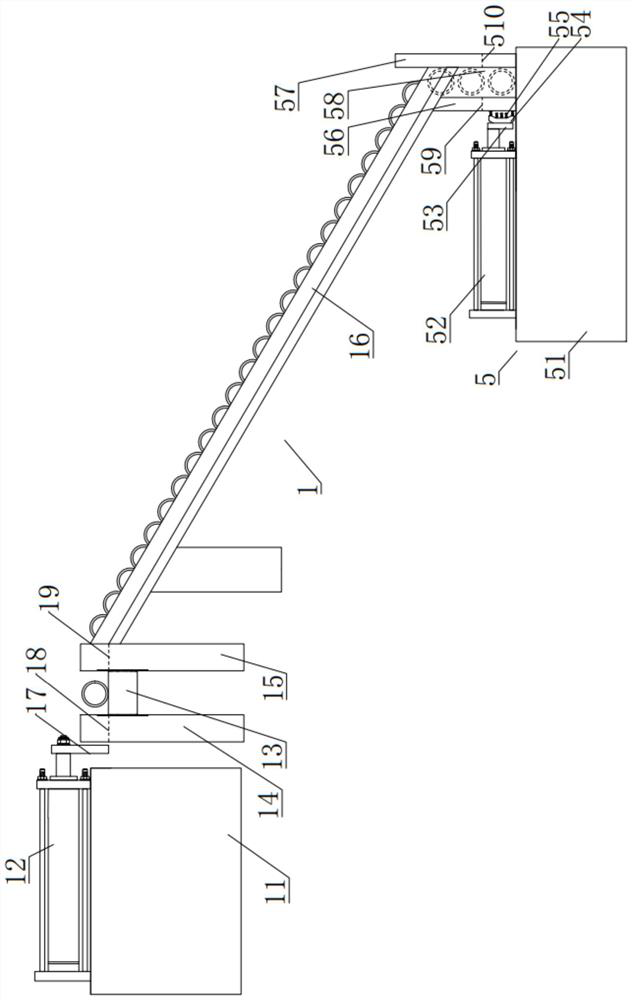

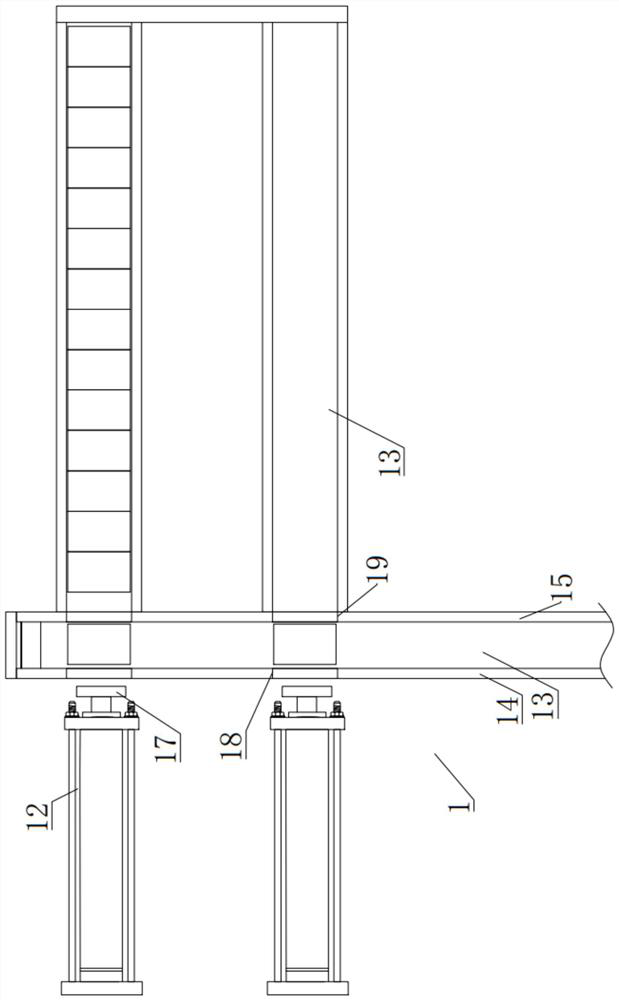

[0049] like figure 2 , 3 The shown double-station pipe fitting feeding unit 1 includes a feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com