Method for improving insulating property of oil-impregnated paper of transformer

A technology for transformer oil and insulation performance, applied in insulators, organic insulators, organic liquid insulators, etc., can solve the problems of high cost, inability to fundamentally improve the insulation performance of oil-impregnated paper, and complex manufacturing process of new insulation paper, and achieve cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The insulating cardboard is first dried and dehydrated in an oven at 105°C for 48 hours, and then vacuum-dried at 85°C for 48 hours before use. A titanium dioxide modifier with a particle size of 10nm was used to modify Karamay No. 25 transformer oil in an amount of 0.06% of the transformer oil to obtain a nano-material modified transformer oil (referred to as nano-oil). The pretreated insulating paperboard was immersed in pure transformer oil oil sample (abbreviation: pure oil) and nano oil sample, and treated under vacuum condition at 80°C for 48 hours to obtain pure oil paperboard and nano oil paperboard.

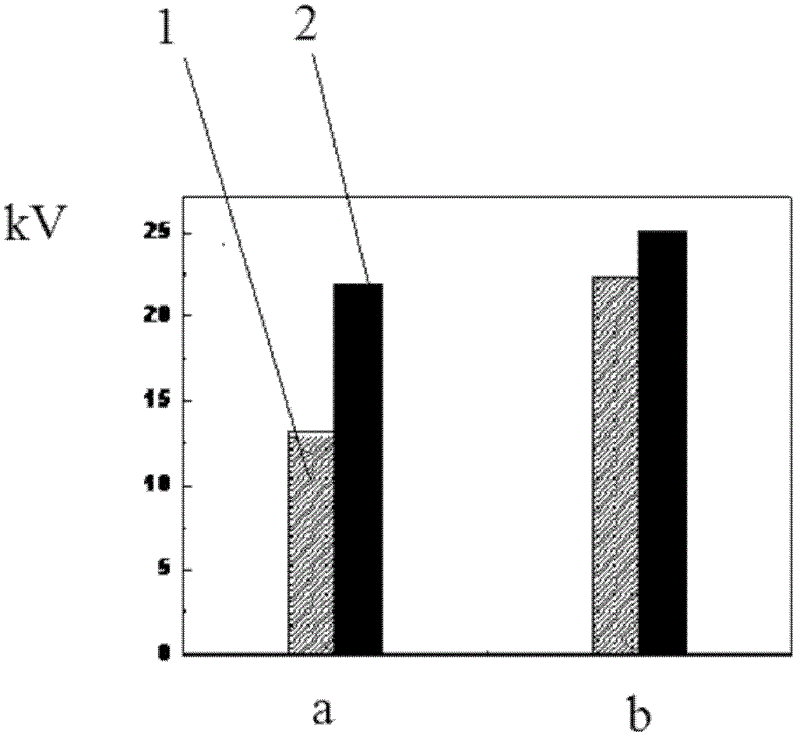

[0015] According to the ASTM D149 standard, the partial discharge inception voltage of two types of oil-impregnated paper was tested, and the results were as follows figure 1 shown. Depend on figure 1 From the results shown in a, it can be seen that after adding the titanium dioxide modifier, the partial discharge initiation voltage of the nano-oil-impregnated p...

Embodiment 2

[0017] The insulating cardboard is first dried and dehydrated in an oven at 105°C for 48 hours, and then vacuum-dried at 85°C for 48 hours before use. A titanium dioxide modifier with a particle size of 5nm was used to modify Karamay No. 25 transformer oil in an amount of 0.5% of the transformer oil to obtain a nano-material modified transformer oil (referred to as nano-oil). Immerse the pretreated shape insulating paperboard into pure transformer oil oil sample (abbreviation: pure oil) and nano oil sample, and treat it under vacuum condition at 80°C for 48 hours to prepare pure oil paperboard and nano oil paperboard.

[0018] According to ASTM D149 standard, the partial discharge inception voltage of two types of oil-impregnated paper was tested. After adding titanium dioxide modifier, the partial discharge inception voltage of nano-oil-impregnated paperboard was significantly improved compared with pure oil-impregnated paperboard. Nano-oil-impregnated paperboard The partial ...

Embodiment 3

[0020] The insulating cardboard is first dried and dehydrated in an oven at 105°C for 48 hours, and then vacuum-dried at 85°C for 48 hours before use. A zinc oxide modifier with a particle size of 2nm was used to modify Karamay No. 25 transformer oil in an amount of 0.01% of the transformer oil to obtain a nano-material modified transformer oil (referred to as nano-oil). The pretreated insulating paperboard was immersed in pure transformer oil oil sample (abbreviation: pure oil) and nano oil sample, and treated under vacuum condition at 80°C for 48 hours to obtain pure oil paperboard and nano oil paperboard.

[0021] According to ASTM D149 standard, the partial discharge inception voltage of two types of oil-impregnated paper was tested. After adding zinc oxide modifier, the partial discharge inception voltage of nano-oil-impregnated paperboard was significantly improved compared with pure oil-impregnated paperboard. The partial discharge initial voltage of the paperboard can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com