Anionic collector and preparation method thereof

An anion collector and raw material technology, applied in solid separation, flotation, etc., can solve the problems of many impurities, waste of resources and environment, and reduce the collection effect, achieve huge economic benefits, use waste resources, and improve phosphorus collection rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This example relates to the anion collector of the present invention and its preparation.

[0024] The preparation method is as follows: Add the raw materials according to the established order, first stir the waste oil and heat up to 35-38°C, then add sodium petroleum sulfonate, continue to stir and heat up to 55-58°C, then add triethanolamine and phthalic acid di Methyl ester, keep stirring, control the temperature not to exceed 60°C, after the raw materials are fully fused into a uniform solution, add water with a temperature of 40±1°C and a pH value of 10, heat while stirring, control the temperature at 65°C-80 Carry out saponification reaction at ℃ for 20-30 minutes, wait until the material is translucent, then add surfactant fatty alcohol polyoxyethylene ether sodium sulfate (AES) or α-sulfo fatty acid methyl ester sodium salt (MES), and then After stirring for another 10 minutes until uniform, adjust the pH to 7.5±0.1 and lower to room temperature to obtain an an...

Embodiment 2

[0028] This example relates to the performance evaluation of the anion collector of the present invention.

[0029] The anion collector of Example 1 is used to carry out flotation to the phosphorus-containing tailings obtained after iron flotation of phosphorite ore, and the flotation operation steps are as follows:

[0030] (1) Take the slurry from the phosphorite tailings after flotation in a mining site, divide it into several parts after wet mixing, and test its phosphorus grade;

[0031] (2) Using a 1.5L flotation machine in the laboratory, the roughing and sweeping impeller speeds are adjusted to 2000 rpm, and the selected impeller speeds are adjusted to 1500 rpm;

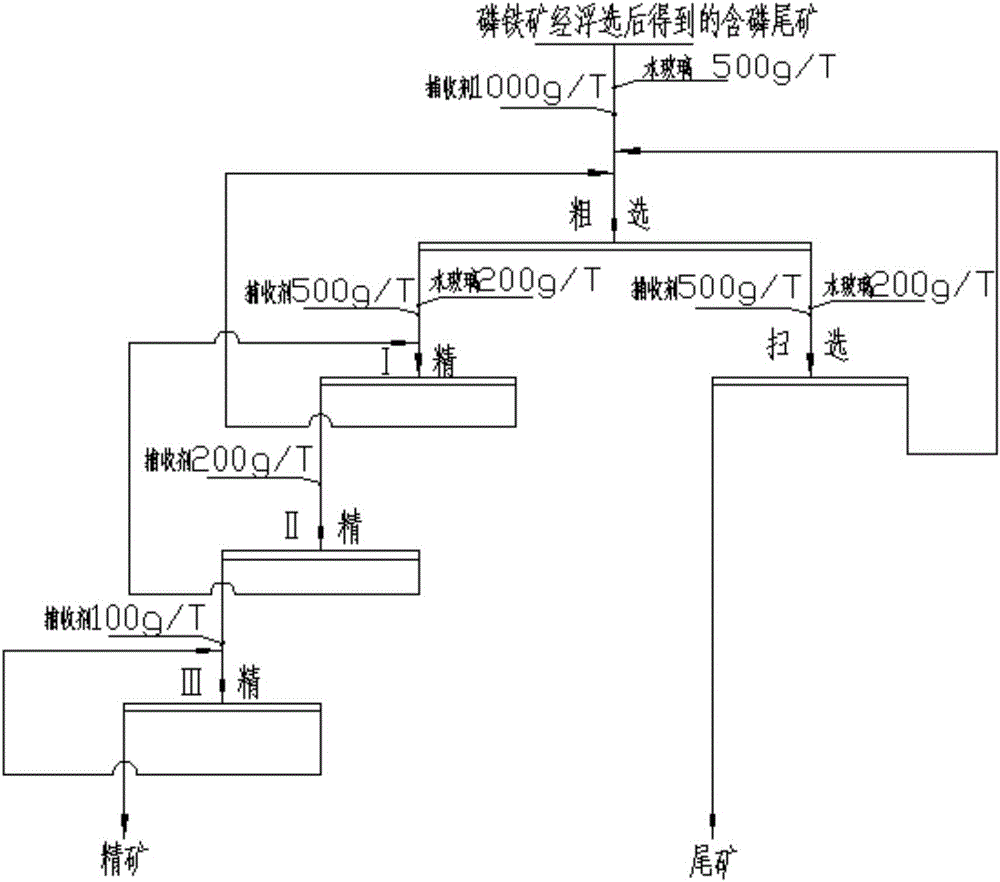

[0032] (3) According to figure 1 The shown test procedure and sequential dosing form a closed-circuit test procedure; the roughing and sweeping flotation time is 3 minutes, the refining 1 flotation time is 2 minutes, and the refining 2 and refining 3 flotation time are both 1.5 minutes;

[0033](4) Collecto...

Embodiment 3

[0038] This embodiment relates to the performance comparison between the anion collector described in the present invention and the existing anion collector.

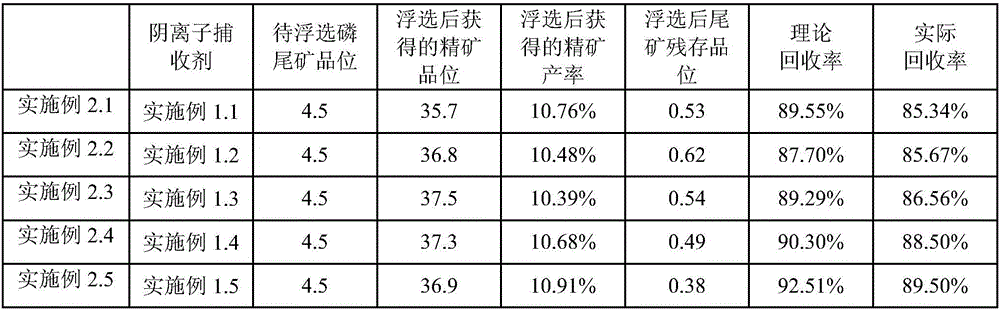

[0039] The anion collector of the present invention and the existing anion collector are used in the same flotation experiment, and the phosphorus-containing tailings obtained after iron flotation are carried out to flotation, and the flotation process is the same as Embodiment two, flotation result is:

[0040]

[0041] As can be seen from the results in the table above, the anion collector of the present invention is used to carry out flotation of phosphorus-containing tailings obtained after iron flotation of ferrophosphite ore, which can improve the phosphorus collection rate, improve the concentrate grade obtained, and make After the phosphorus tailings are floated by the anion collector of the present invention, the residual phosphorus grade is reduced to extremely low, and the phosphorus in the tailings...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com