Laser cutting machine with efficient and intelligent lifting exchanging table and working method thereof

A laser cutting machine and exchange table technology, applied in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problem that the dust removal effect of the bottom cutting of the machine tool cannot be consistent, which is not conducive to the development of higher performance and higher dynamics, and cannot be Judging all positions of the material platform, etc., to achieve the effect of high degree of automation, reasonable design and less manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

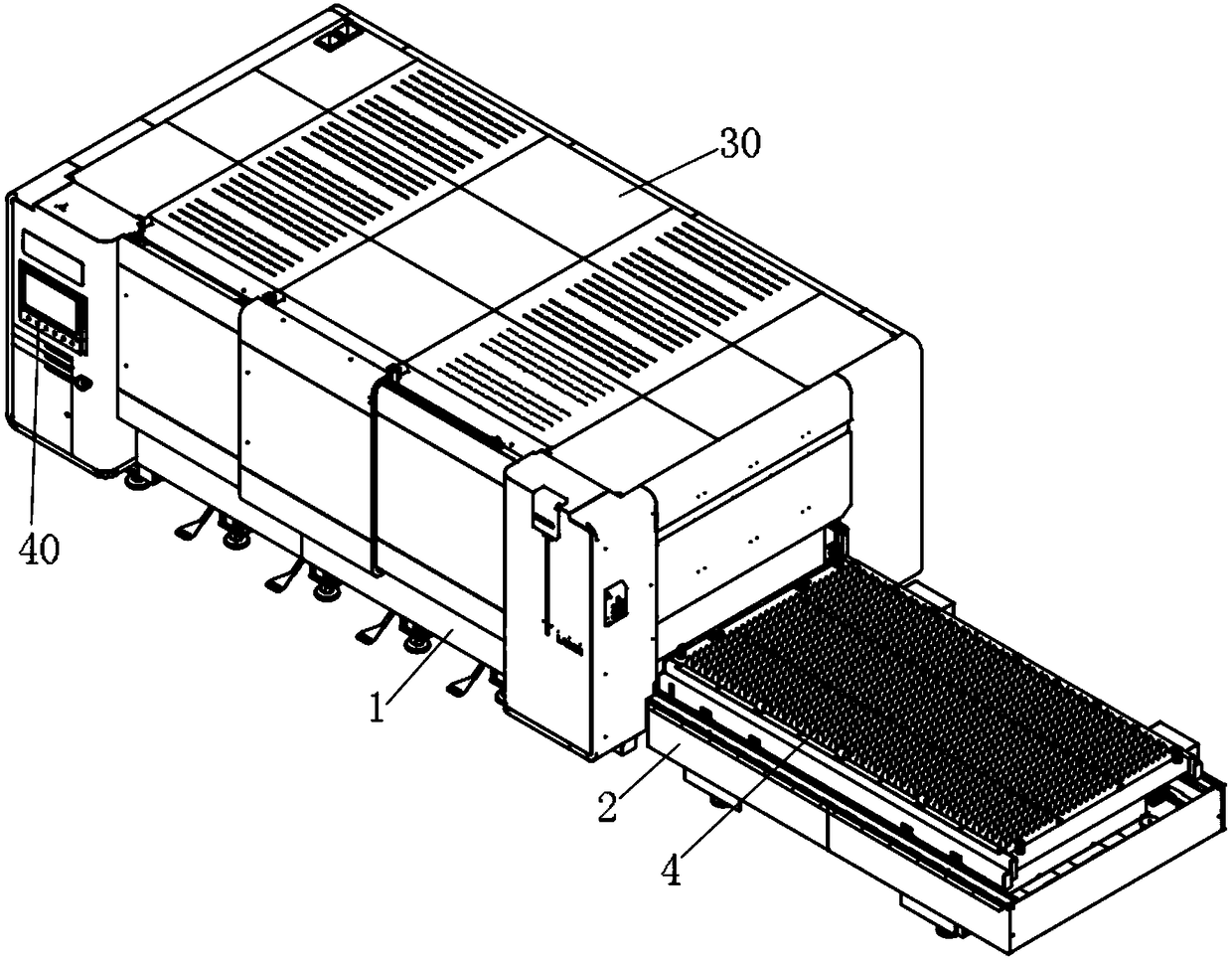

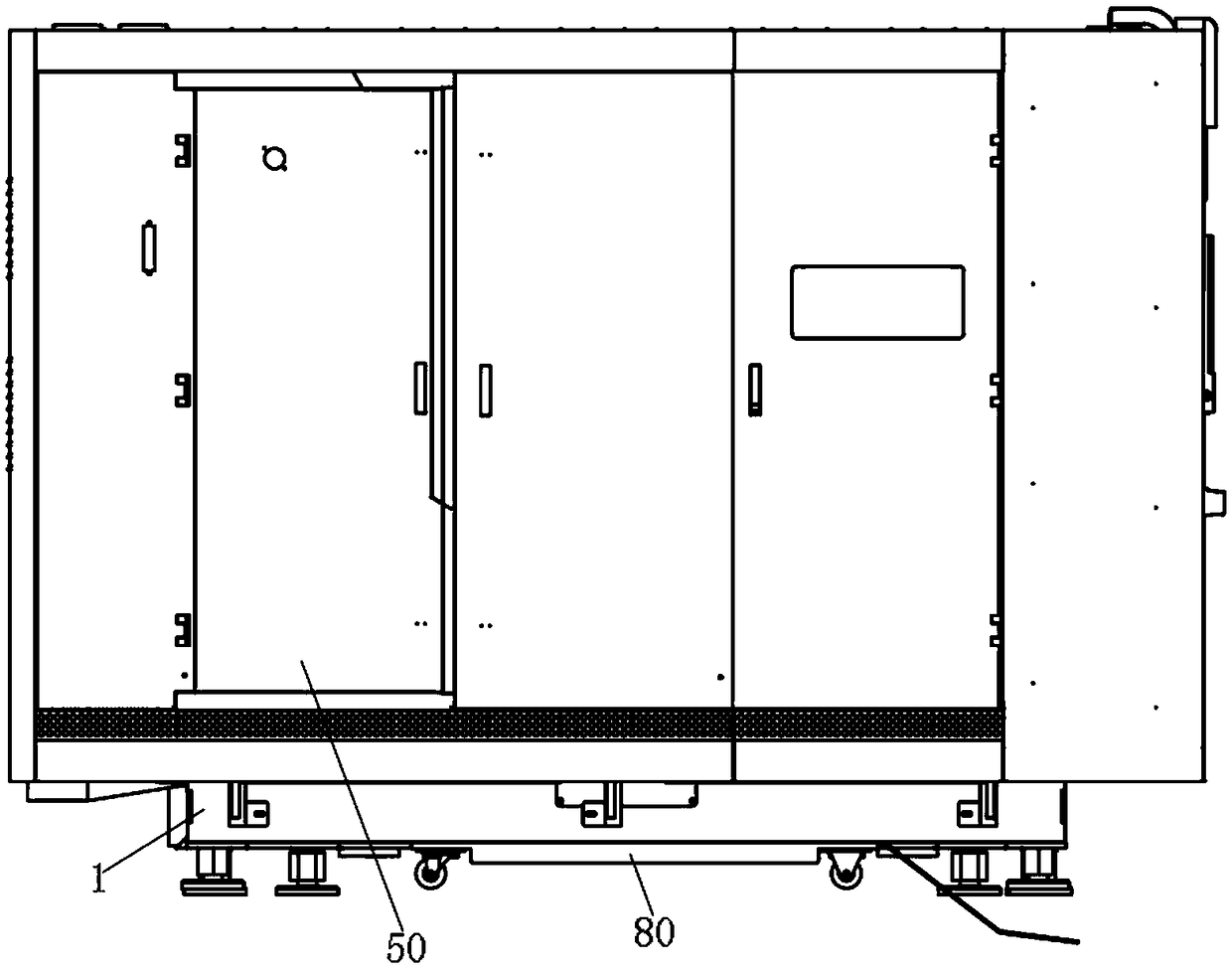

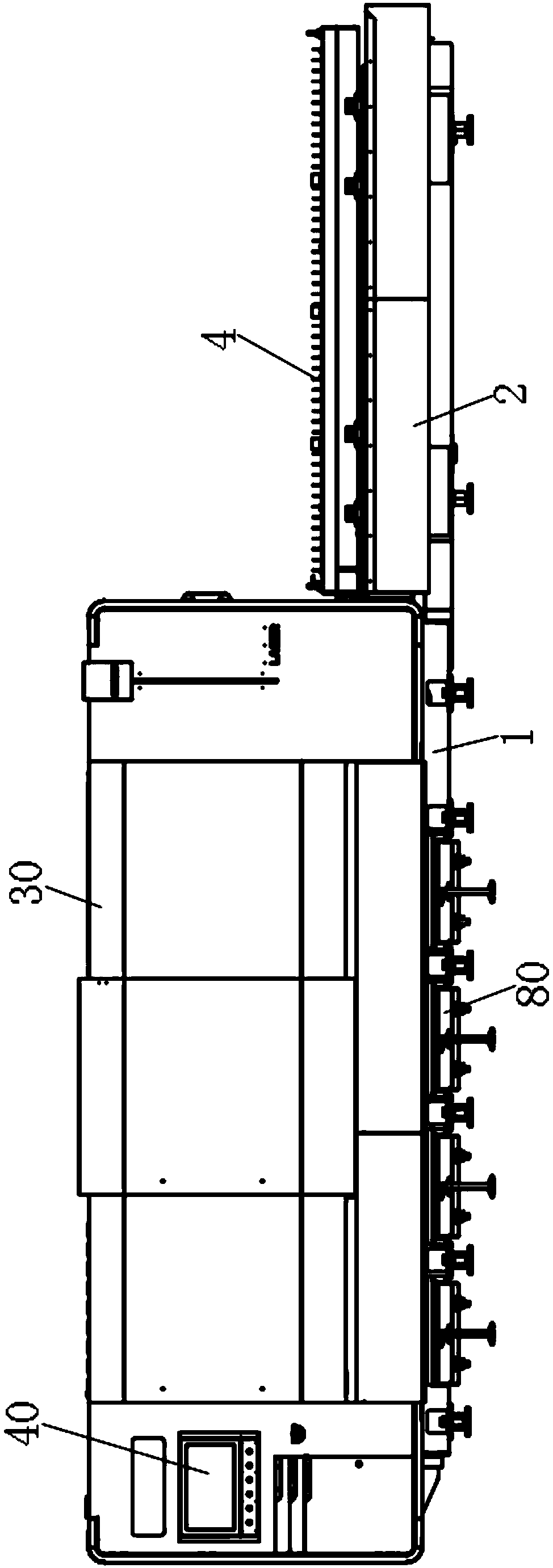

[0068] like Figure 1-6 And the laser cutting machine shown in 18-20 with high-efficiency intelligent lifting exchange table, including main bed 1, lifting table 2, lower cutting box 3, upper cutting box 4, protective cover 30, operation station 40, electric control Cabinet 50, moving beam 60, laser cutting head 70, a group of blanking trolleys 80 and a dust removal system 90, the protective cover 30 is arranged on the main bed 1, and the lift table 2 is arranged at one end of the main bed 1, The lower cutting box 3 and the upper cutting box 4 can be arranged on the main bed 1 or the lifting platform 2, the operation station 40 and the electric control cabinet 50 are all arranged on the main bed 1, and the moving beam 60 Erected on the edges of both sides of the main bed 1, and the moving beam 60 can move along the main bed 1, the laser cutting head 70 is set on the moving beam 60, and the blanking trolley 80 is set under the main bed 1 , the dust removal system 90 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com