Bearing race production line with full-automatic forging structure and working method thereof

A fully automatic technology for bearing rings, applied in the field of bearing manufacturing, can solve problems such as difficult to guarantee the quality consistency of blanks, high work intensity of workers, poor quality of blanks, etc., and achieve the effects of high degree of automation, reduced labor intensity, and less manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

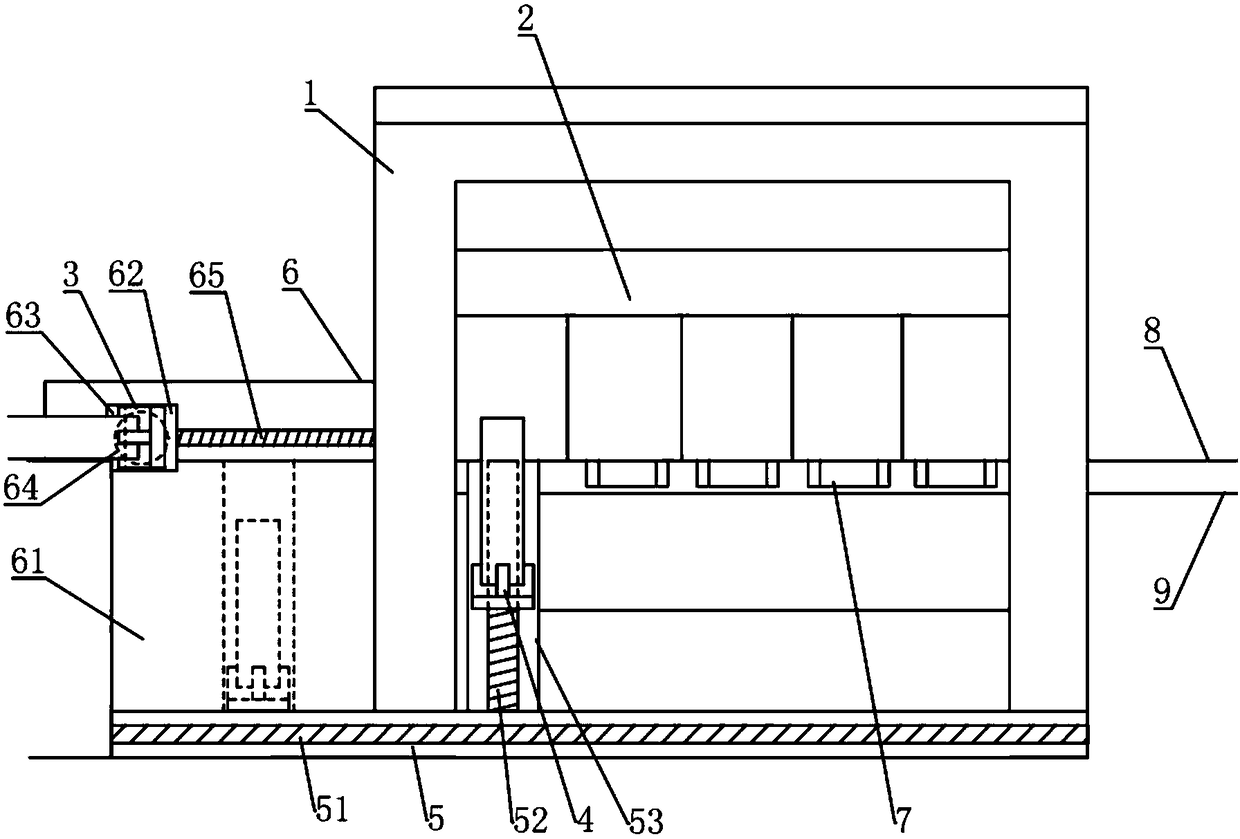

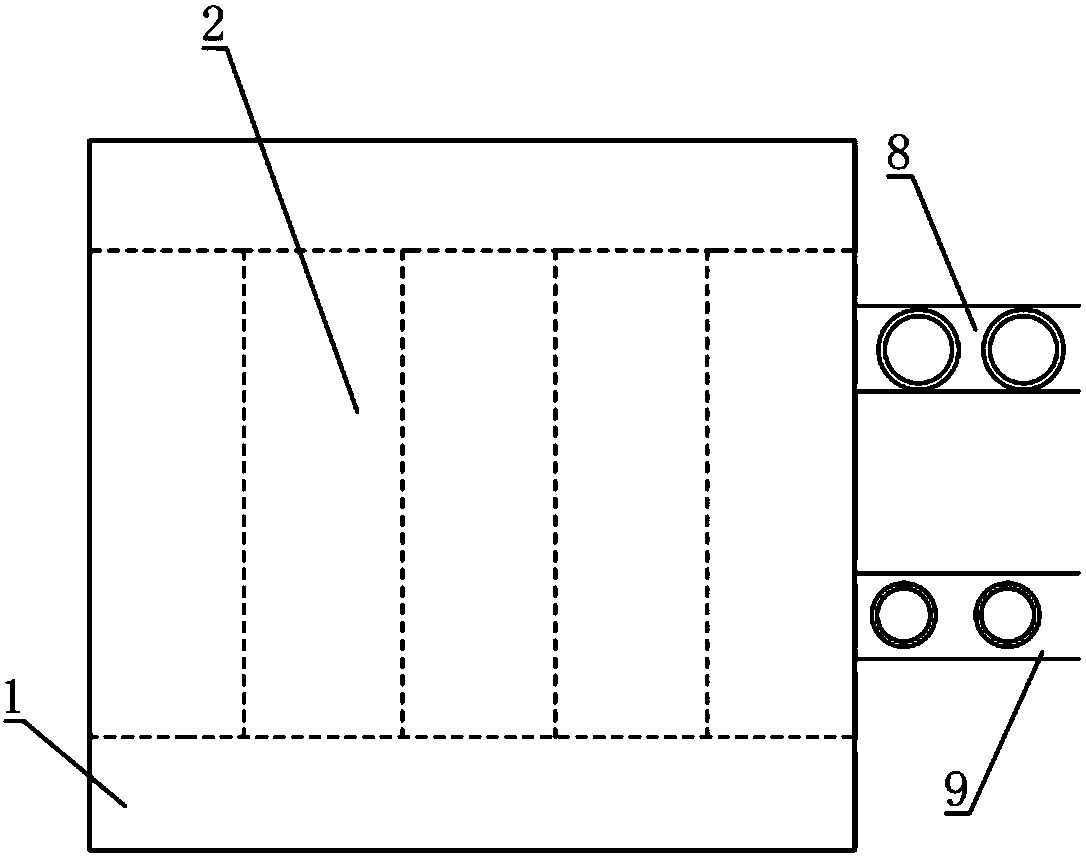

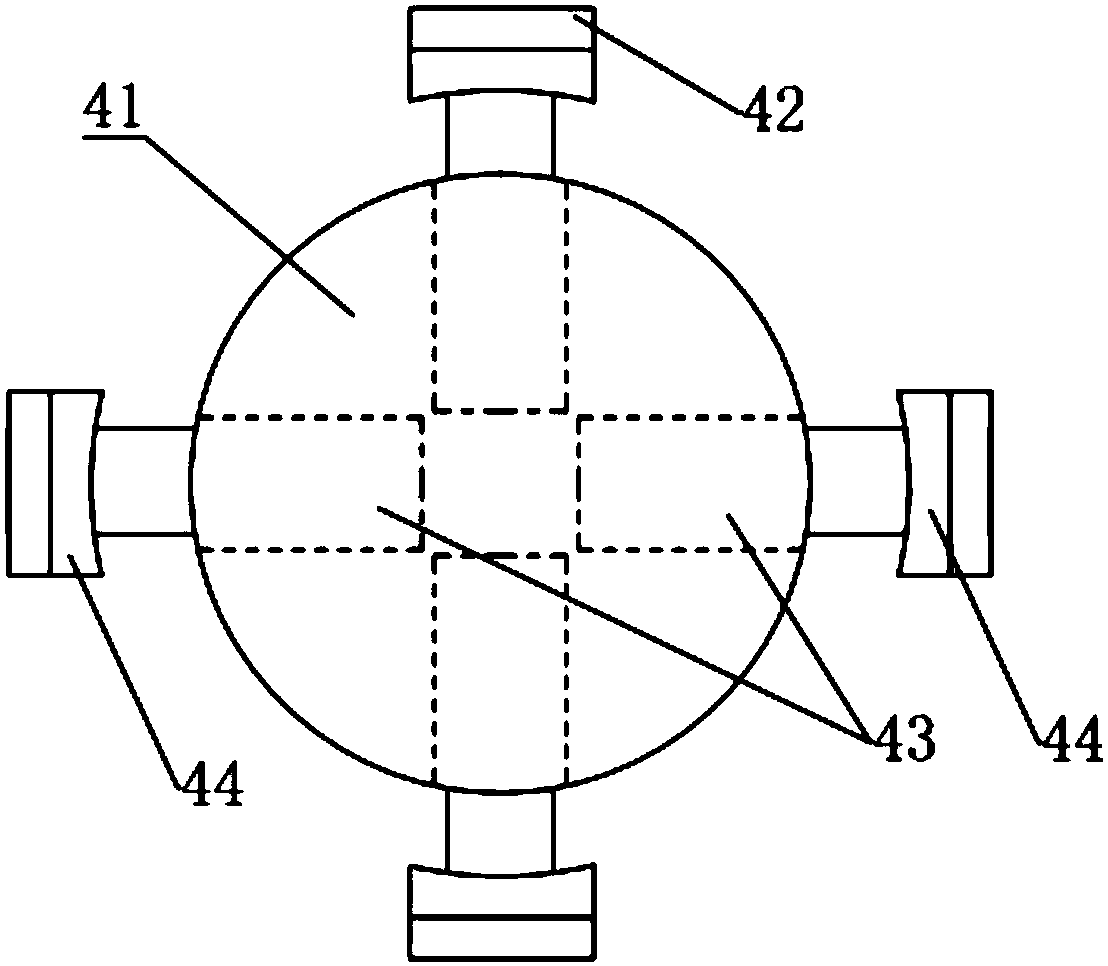

[0051] like figure 1 , 2 The bearing ring production line with fully automatic forging structure shown in , 5, 6 and 7 includes a feeding unit 10, a heating unit 20, a forging unit 30, a sorting unit 40, a shot blasting unit 50, and a rolling unit 60. , a shaping unit 70, a cleaning unit 80 and a blanking unit 90; wherein, the forging unit 30 includes a high-speed upsetting machine 1, a die 2, a first bearing ring blank grabbing robot 3, a second bearing ring blank grabbing robot 4, bearings The ring blank transfer device 5, the feeding device 6, the third bearing ring grabbing manipulator 7, the bearing outer ring transfer belt 8 and the bearing inner ring conveyor belt 9, the mold 2 is set in the high-speed upsetting machine 1, and the feeding device 6 is set in the The feed port of the high-speed upsetting machine 1, the bearing ring blank transfer device 5 is arranged at the lower part of the high-speed upsetting machine 1, the first bearing ring blank grabbing manipulato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com