Electrostatic spraying device for cabinet cold-rolled steel plate and working method thereof

A technology of cold-rolled steel plate and electrostatic spraying, which is applied to liquid spraying equipment, electrostatic spraying devices, cleaning methods using tools, etc., can solve problems such as unreasonable work involvement, low work efficiency, waste of manpower, etc., and achieve simple and easy working principle line, high work efficiency, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

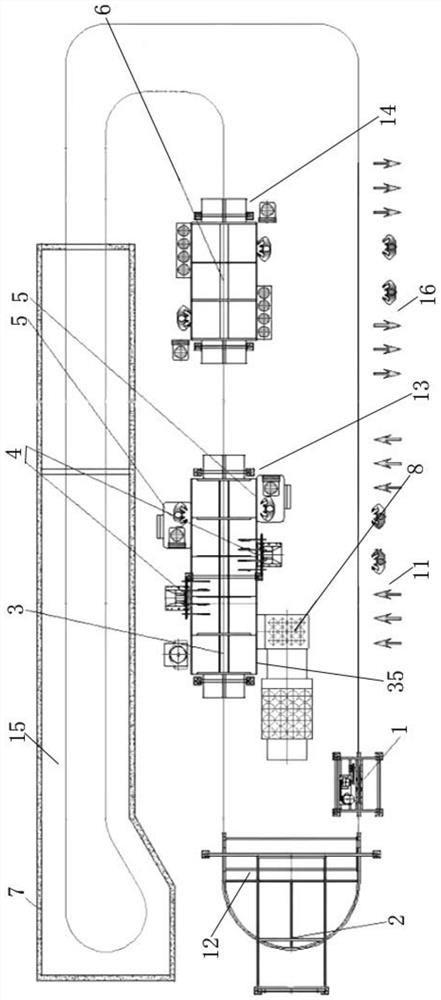

[0047] Such as figure 1 The electrostatic spraying equipment for the cold-rolled steel plate shown in the cabinet includes a steel plate conveying unit 1, a steel plate cleaning unit 2, a four-station automatic spraying unit 3, an automatic reciprocating spraying unit 4, a manual inspection and supplementary spraying unit 1, and a double-station manual Supplementary spraying unit 2 6, heat preservation oven unit 7 and dust removal unit 8, the steel plate conveying unit 1 is circularly conveyed, and the steel plate conveying unit 1 is U-shaped, and the steel plate conveying unit 1 is divided into a feeding station 11, a cleaner Position 12, spraying station one 13, spraying station two 14, drying station 15 and blanking station 16, the loading station 11, cleaning station 12, spraying station one 13, spraying station two 14. The drying station 15 and the unloading station 16 are arranged sequentially along the spraying process of the steel plate. The loading station 11 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com